You're using an outdated browser. Please upgrade to a modern browser for the best experience.

Please note this is a comparison between Version 3 by Dean Liu and Version 2 by Dean Liu.

FRPs (fiber-reinforced polymers) have gained increasing popularity in the last few years due to their durability, high corrosion resistance, light weight and high strength. Life cycle assessment is considered one of the most important methods to investigate the environmental impacts of the FRP.

- life cycle assessment (LCA)

- fiber-reinforced polymer (FRP)

- internal reinforcement

1. Life Cycle Assessment of FRP Used in Beams

Modern structural elements should achieve a reduction in environmental impact accompanied by improvements in functional performance. In the past few years, fiber-reinforced polymers have shown favorable characteristics in terms of durability [1], and they have proved to be promising materials that can be used in various applications of civil engineering as a replacement for traditional materials, such as steel. The dominant materials in construction are concrete and steel, which are the most used materials in the world after drinking water [2]; however, the usage of these materials causes extra amounts of CO2 emissions into the environment, the drastic depletion of resources and climate change due to global warming. Several scholars have used different strategies to minimize the environmental load caused by traditional materials to enhance the environmental performance of structural members.

An LCA study was conducted by the authors of [3] for different concrete beams to investigate the environmental impact of adopting BFRP bars as reinforcements instead of steel bars. The resulting values point to the fact that using BFRP bars as reinforcement instead of steel bars in concrete beams achieved significantly better performances across all eighteen environmental indicators evaluated in the study. Climate change emissions (CC), ozone depletion (OD), human toxicity (HT) and freshwater eutrophication (FE) were reduced by 38%, 40%, 78% and 85%, respectively, which makes BFRP a green solution for concrete compared to traditional steel. The authors of [4] performed an LCA study for three beams with the same span and under the same load in a marine environment. CFRP/GFRP-bar-reinforced seawater and sea sand concrete (SWSSC) beams were compared to steel-bar-reinforced common concrete (SRC) beams. It was found that the CFRP-SWSSC beams achieved a better environmental performance than the SRC beam in categories such as climate change (CC), terrestrial acidification (TA), human toxicity (HT) and particular matter formation (FPMF), with reductions of 29%, 37%, 1% and 40%, respectively. GFRP-SWSSC beams performed better than SRC beams in categories such as climate change (CC), terrestrial acidification (TA), ozone depletion (SOD), freshwater eco-toxicity (FRET), human toxicity (HT) and particulate matter formation (FPMF), with reduction rates of approximately 26%, 16%, 1%, 5%, 2% and 21%, respectively. An analytical study was conducted by the authors of [5] to evaluate the environmental impacts of CFRP, BFRP and GFRP rebars, and they compared them to conventional steel rebars in reinforced concrete beams. The LCA results concluded that GFRP, CFRP and BFRP-reinforced beams experienced fewer CO2 emissions of 43%, 39% and 40% and less energy consumption by 47%, 32% and 50%, respectively, compared to steel-reinforced beams. A different study by the authors of [6] investigated the sustainability of BFRP and steel reinforcement in beams through LCA. The results of this indicate that BFRP-reinforced beams scored improvements in all eighteen environmental impact categories compared to steel-reinforced beams, accomplishing a 7% and 21% reduction in global warming (GWP) and human carcinogenic toxicity (HCT). The environmental efficiency of basalt fiber reinforcement was studied in different ratios by the authors of [7] and was compared to the broadly used steel fibers in T-beams with the help of LCA. The presented results for mixtures containing 1.5% and 0.5% fiber reinforcement at the midpoint and endpoint level show that basalt fibers have a better environmental performance than steel fibers. The 1.5% steel fibers exhibited an increase in environmental load compared to all other options. When the 0.5% steel-fiber-reinforced mixture was used, categories such as ozone layer depletion (OLD), aquatic ecotoxicity (AE), land occupation (LO) and terrestrial ecotoxicity (TE) favored the steel fibers over the basalt fibers. A comparative LCA study was made by the authors of [8] for strengthening reinforced concrete beams by using CFRP laminates instead of demolishing and rebuilding. It was reported from the study that the strengthening technique consumes less energy and reduces CO2 emissions compared to the demolishing and rebuilding process. Furthermore, the authors of [9] conducted an environmental assessment through LCA for CFRP strips used as a strengthening reinforcement compared to the demolition and rebuilding of RC beams. The results of the study were in favor of the CFRP strip strengthening technique over the demolition and the reconstruction of the beams, where a reduction in the environmental impact was reported in the studied categories, which were global warming (GWP), human toxicity (HTPC) and ozone depletion potential (ODP). An environmental assessment through LCA by the authors of [10] was used to evaluate the energy consumption of concrete beams strengthened with a different solution of CFRP or BFRP sheets. The study shows that the CFRP solution consumes more energy than the BFRP strengthening solution due to the high embodied energy for the CFRP. The authors of [11] performed an LCA study to determine whether the reuse of an existing structural element shear strengthened with unidirectional glass or carbon fiber fabric can lead to a lower environmental impact compared to the case of demolishing and rebuilding the structural element. The authors reported an approximate 76% and 68% reduction in CO2 emissions when beams were shear strengthened with GFRP or CFRP, respectively, in comparison to the CO2 emissions resulting from demolishing and rebuilding the structural element. Furthermore, ozone depletion (ODP) was also reduced by approximately 14% when GFRP and CFRP were used for shear strengthening. Moreover, the authors of [12] investigated the environmental impact of GFRP fabric-strengthening solution used on a timber beam by applying the LCA methodology. The results indicate that, despite the negative influence of GFRP added to the timber, they were able to reduce the environmental impacts by reducing the amount of used timbers.

The LCA of FRP bars used as reinforcements in beams was compared to steel bar reinforcements, and it was investigated by different scholars. The results for some of these studies are summarized in Table 1 as a percentage of improvement for FRP compared to steel. Most of the studies showed an improvement when FRP was used as a replacement for steel, but negative effects were found in [4] when the CFRP-SWSSC beam achieved a worse environmental performance than the SRC beam in four categories out of eight, which were ozone depletion (SOD), freshwater eutrophication (FE), freshwater eco-toxicity (FRET) and fossil depletion (FD), and the GFRP-SWSSC beam performed worse than the SRC beam in two categories: freshwater eutrophication (FE) and fossil depletion (FD).

Table 2 summarizes the applications and the environmental impacts of different FRPs used in bridges.

Table 2. Environmental impact of FRPs used in bridges.

| Reference | Application | Environmental Impact after Using FRP | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| - | - | 29 | - | |||||||

| [13] | Bridge with a GFRP deck solution compared to (concrete/steel) bridge with a deteriorated concrete deck | Reduction of around 20% in carbon emissions. | ||||||||

| Global Warming Potential | 39 | - | - | 40 | 7 | - | 43 | |||

| [14] | CFRP-reinforced concrete, reinforced concrete and mild steel bridge | Lower GWP and ADPF, and AP is higher. | Energy consumption | 32 | - | - | 50 | - | - | 47 |

| [15] | FRP footbridge under severe environment compared to conventional concrete bridge | Reduces the total amount of carbon dioxide emissions. | Ozone depletion | - | 1 | 40 | - | 4 | −83 | - |

| [16] | FRP(GFRP/CFRP)-RC/PC bridge compared to CS-RC/PC bridge | The environmental impact is less in four out of five categories, namely AC, GWP, EU, and POC. | Terrestrial acidification | - | 15 | 43 | ||||

| [17 | - | 9 | 37 | - | ||||||

| ] | Steel–concrete bridge compared to steel bridge with FRP deck | Reduces the environmental impact (lower OD, FD, GWP and TA) but has higher FE. | Freshwater eutrophication | - | −97 | |||||

| [18] | Bonding CFRP plates compared to bonding steel plates |

| 85 | - | 13 | −107 | - | |||

| Marine eutrophication | |||||||||

| [19] | - | - | 42 | - | 17 | - | - | |||

| GFRP footbridge compared to a standard steel footbridge | Presents potentially worse environmental impacts. | Human toxicity | ||||||||

| [ | - | 2 | 78 | 20- | - | 1 | - | |||

| ] | FRP deck compared to a conventional concrete deck |

|

Photochemical oxidant formation | - | - | 47 | - | |||

| [21] | - | - | - | |||||||

| GFRP compared to traditional materials such as structural steel, stainless steel, aluminum and concrete for a bridge |

|

Particulate matter formation | - | 20 | 57 | - | 10 | 40 | - | |

| Terrestrial eco-toxicity | - | - | 52 | - | 12 | - | ||||

| Freshwater eco-toxicity | - | 4 | 84 | - | 15 | −8 | - | |||

| Marine eco-toxicity | - | - | 84 | - | 18 | - | - | |||

| Ionizing radiation | - | - | 26 | - | 4 | - | - | |||

| Agricultural land occupation | - | - | 48 | - | - | - | - | |||

| Urban land occupation | - | - | 44 | - | - | - | - | |||

| Natural land transformation | - | - | 36 | - | - | - | - | |||

| Water depletion | - | - | 24 | - | 6 | - | - | |||

| Metal depletion | - | - | 96 | - | - | - | - | |||

| Fossil depletion | - | −3 | 48 | - | 5 | −23 | - | |||

| Ozone formation: human health | - | - | - | - | 7 | - | - | |||

| Ozone formation: terrestrial ecosystems | - | - | - | - | 7 | - | - | |||

| Human carcinogenic toxicity | - | - | - | - | 21 | - | - | |||

| Human non-carcinogenic toxicity | - | - | - | - | 14 | - | - | |||

| Land use | - | - | - | - | 10 | - | - | |||

| Mineral resource scarcity | - | - | - | - | 20 | - | - |

2. Life Cycle Assessment of FRP Used in Bridges

Structural projects such as bridges affect natural environments negatively in variable ways during their total life cycle. In order to reduce environmental impacts and to improve sustainability resulting from bridge construction, some measures should be taken into account, such as reducing energy consumption, emissions to the environment, waste generation and the usage of raw materials. A study performed by the authors of [13] examined the sustainability of a bridge with a GFRP deck solution compared to an existing traditional composite (concrete/steel) bridge with a deteriorated concrete deck by taking into consideration its life cycle, construction process and maintenance. The study shows that the bridge with a GFRP deck causes a reduction of around 20% in carbon emissions compared to the concrete deck bridge. The authors of [14] investigated the environmental performance of CFRP-reinforced concrete, reinforced concrete and mild steel bridges, and it was concluded that the lowest global warming potential (GWP) and abiotic depletion of fossil (ADPF) resources are associated with the CFRP-reinforced bridge. In addition, the acidification potential (AP) of the CFRP-reinforced concrete bridge is higher than that of the other bridges. LCA was conducted in a study by the authors of [15], where a comparison was made between an FRP footbridge under a severe environment and a conventional concrete bridge. It was reported from the study that the FRP footbridge reduces the total amount of carbon dioxide emissions compared to the conventional PC bridge due to the light weight of the FRP footbridge. The environmental implications of two designs alternatives for a bridge were studied by the authors [16], and an LCA study was conducted to compare an FRP (GFRP/CFRP)-reinforced concrete (RC)/pre-stressed concrete (PC) bridge to a traditional carbon steel (CS)-reinforced concrete/pre-stressed concrete bridge, and the results show that the environmental impact of the FRP-RC/PC design is smaller in four out of five categories, namely acidification (AC), global warming (GWP), eutrophication (EU) and photochemical oxidant creation (POC), compared to the CS-RC/PC design due to its shorter service life. A life cycle assessment was conducted by the authors of [17] for a traditional steel–concrete bridge design, compared to another steel bridge with an FRP deck. The study shows that the steel bridge with the FRP deck has a smaller environmental impact than the traditional concrete-reinforced bridge, where FRP composites in the FPP deck steel bridge contribute less to ozone depletion (OD), fossil depletion (FD), global warming (GWP) and terrestrial acidification (TA), even though freshwater eutrophication (FE) is less in the steel–concrete bridge. The authors of [18] analyzed the LCA of a highway bridge with different maintenance strengthening strategies, where bonding steel plates and bonding CFRP plates were used. The obtained results show that strengthening the bridge with bonding CFRP plates is a better choice than steel plates from an environmental protection perspective, given that the acidification potential (AP) and eutrophication potential (EP) are lower when CFRP plates are used compared to steel plates, and it should be noticed that the biggest contribution to global warming potential comes from the detouring stage, accounting for around 50% of the whole life cycle. An LCA analysis framework was used by the authors of [19] to analyze the environmental impacts of a GFRP footbridge compared to a standard steel footbridge. It was concluded from the paper that the FRP bridge presents potentially worse environmental impacts resulting from the production of FRP compared to the steel bridge. The life cycle environmental performance of an FRP deck in a UK highway bridge was compared to a conventional concrete deck by the authors of [20]. The results show that the accumulation of carbon emissions during the service life of 120 years for the FRP deck resulted in fewer carbon emissions at the initial constriction stage, and the pre-stressed concrete deck resulted in approximately 13% fewer carbon emissions than the FRP deck over its entire life service, which makes is more desirable over its entire design life. The author of [21] investigated the environmental advantages of using GFRP composite material compared to traditional materials such as structural steel, stainless steel, aluminum and concrete for a two-span pedestrian bridge in terms of energy consumption. The results indicate that the GFRP bridge requires less than half of the energy input compared to bridges made of other traditional materials.

3. Life Cycle Assessment of FRP Waste Management

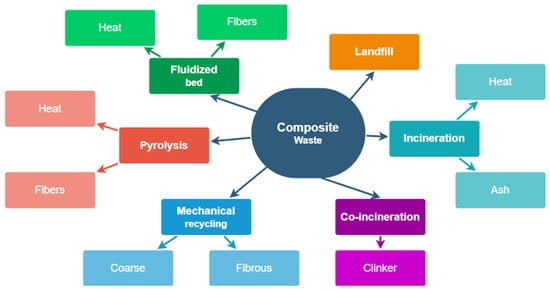

Fiber-reinforced polymer composites have been used progressively over the past few years in different applications of civil engineering. Despite the advantages accompanied by the use of FRP, their growing use increases the amount of FRP waste, which raises environmental and economic concerns regarding the need to recycle FRP waste. The main end-of-life pathways for FRP waste are as follows: (1) Landfill: underground storage for waste when no recycling technique is available; (2) Incineration: a thermal technique with partial energy recovery from heat generated by waste combustion; (3) Co-incineration: allows material recovery in addition to energy recovery; (4) Mechanical Recycling: a process to separate fibers from the matrix by a grinding technique. Two fractions result from the process, which are: one that is coarse and rich with a matrix and fibrous, and another part that is rich in fiber; (5) Pyrolysis: a thermal technique that decomposes the matrix at approximately 400–600 °C to recover fibers, (6) Fluidized Bed: the hot air flow fluidizes the sand at 450–550 °C, which volatilizes the matrix and releases the fibers [22][23][24]. The main end-of-life pathways are summarized in Figure 1.

Figure 1. End-of-life pathways for FRP composites.

An LCA was conducted by the authors of [23] to evaluate and compare the environmental impacts of different FRP waste pathways. The Mechanical Recycling, Pyrolysis and Fluidized bed techniques were compared to the Landfill, Incineration and Co-incineration techniques for CFRP and GFRP. The results show that the Pyrolysis technique is the best recycling option for CFRP, and Co-incineration is considered to be more promising for GFRP from an environmental perspective. Another study by the authors of [25] evaluated different waste disposal options for GFRP and CFRP wastes through LCA, targeting the thermal recycling path to reproduce and recycle CFRP and GFRP into recycled composites. Additionally, waste disposal options were compared, including the Landfill technique, Incineration with energy recovery and feedstock in cement kiln production. The LCA results indicate that recycling CFRP wastes using a thermal recycling path results in smaller environmental impacts, with good potential to replace virgin CFRP. Furthermore, using GFRP wastes as a feedstock in cement kiln production showed smaller environmental impacts compared to those thermally recycled. The LCA model was developed by the authors of [26] to quantify the environmental impacts of mechanical recycling for CFRP, and they compared it to the Landfill and Incineration disposal routes. It was concluded that the Landfilling route is not favorable from an environmental perspective and that Incineration experienced the smallest energy demand for processing CFRP waste; however, it has the highest GHG emissions compared to other methods. Furthermore, mechanical recycling was found to be the only path that can reduce GHG emissions and energy consumption, but this method is only applicable if the recycled carbon fibers displace the virgin carbon fiber on a large scale to increase revenue. Furthermore, three end-of-life treatment methods, namely Landfilling, Incineration and Pyrolysis recycling for CFRP waste, were studied by the authors of [27] using the LCA method to evaluate their environmental benefits. The results indicate that the recycling option appears to be the best environmental option compared to Landfilling and Incineration options when virgin carbon fiber (VCF) is replaced with recycled carbon fiber (RCF), but it is not preferable when virgin glass fiber (VGF) is replaced with RCF.

References

- Ebead, U.; Marzouk, H. Fiber-Reinforced Polymer Strengthening of Two-Way Slabs. Struct. J. 2004, 101, 650–659.

- Ferrari, G.; Miyamoto, M.; Ferrari, A. New Sustainable Technology for Recycling Returned Concrete. Constr. Build. Mater. 2014, 67, 353–359.

- Inman, M.; Thorhallsson, E.R.; Azrague, K. A Mechanical and Environmental Assessment and Comparison of Basalt Fibre Reinforced Polymer (BFRP) Rebar and Steel Rebar in Concrete Beams. Energy Procedia 2017, 111, 31–40.

- Dong, S.; Li, C.; Xian, G. Environmental Impacts of Glass- and Carbon-Fiber-Reinforced Polymer Bar-Reinforced Seawater and Sea Sand Concrete Beams Used in Marine Environments: An LCA Case Study. Polymers 2021, 13, 154.

- Garg, N.; Shrivastava, S. Environmental and Economic Comparison of FRP Reinforcements and Steel Reinforcements in Concrete Beams Based on Design Strength Parameter. In Proceedings of the UKIERI Concrete Congress, Jalandhar, India, 5–8 March 2019; Dr B R Ambedkar National Institute of Technology: Jalandhar, India, 2019.

- Pavlović, A.; Donchev, T.; Petkova, D.; Staletović, N. Sustainability of Alternative Reinforcement for Concrete Structures: Life Cycle Assessment of Basalt FRP Bars. Constr. Build. Mater. 2022, 334, 127424.

- Fořt, J.; Kočí, J.; Černý, R. Environmental Efficiency Aspects of Basalt Fibers Reinforcement in Concrete Mixtures. Energies 2021, 14, 7736.

- Palacios-Munoz, B.; Gracia-Villa, L.; Zabalza-Bribián, I.; López-Mesa, B. Simplified Structural Design and LCA of Reinforced Concrete Beams Strengthening Techniques. Eng. Struct. 2018, 174, 418–432.

- Maxineasa, S.G.; Taranu, N.; Bejan, L.; Isopescu, D.; Banu, O.M. Environmental Impact of Carbon Fibre-Reinforced Polymer Flexural Strengthening Solutions of Reinforced Concrete Beams. Int. J. Life Cycle Assess. 2015, 20, 1343–1358.

- Zhang, Y.; Huang, T.; Wang, Y.; Zhang, J.; Wang, J. Environmental Assessment of Concrete Beams Strengthened with Fibre-Reinforced Polymer. Proc. Inst. Civ. Eng. Eng. Sustain. 2020, 174, 37–45.

- Maxineasa, S.G.; Isopescu, D.N.; Entuc, I.S.; Taranu, N.; Lupu, L.M.; Hudisteanu, I. Environmental Performances of Different Carbon and Glass Fibre Reinforced Polymer Shear Strengthening Solutions of Linear Reinforced Concrete. Bull. Transilv. Univ. Bras. 2018, 11, 107–115.

- Taranu, N.; Maxineasa, S.G.; Entue, I.S.; Oprisan, G.; Secu, A. Assessing the environmental impact of a glass fibre reinforced polymer strengthening solution for timber beams. In Proceedings of the 15th International Multidisciplinary Scientific Geoconference Sgem 2015, Albena, Bulgaria, 18–24 June 2015; pp. 65–72.

- Mara, V.; Haghani, R.; Harryson, P. Bridge Decks of Fibre Reinforced Polymer (FRP): A Sustainable Solution. Constr. Build. Mater. 2014, 50, 190–199.

- Stoiber, N.; Hammerl, M.; Kromoser, B. Cradle-to-Gate Life Cycle Assessment of CFRP Reinforcement for Concrete Structures: Calculation Basis and Exemplary Application. J. Clean. Prod. 2021, 280, 124300.

- Shimomura, T.; Nishizaki, I.; Tanaka, H. Report on JSCE Committee Activities on LCA and LCC of FRP Infrastructure. Structure 2009, 1, 2.

- Cadenazzi, T.; Dotelli, G.; Rossini, M.; Nolan, S.; Nanni, A. Life-Cycle Cost and Life-Cycle Assessment Analysis at the Design Stage of a Fiber-Reinforced Polymer-Reinforced Concrete Bridge in Florida. Adv. Civ. Eng. Mater. 2019, 8, 20180113.

- Mara, V.; Haghani, R.; Sagemo, A.; Storck, L.; Nilsson, D. Comparative Study of Different Bridge Concepts Based on Life-Cycle Cost Analyses and Life-Cycle Assessment. In Proceedings of the 4th Asia-Pacific Conference on FRP in Structures, APFIS 2013, Melbourne, Australia, 11–13 December 2013; pp. 1–6.

- Pang, B.; Yang, P.; Wang, Y.; Kendall, A.; Xie, H.; Zhang, Y. Life Cycle Environmental Impact Assessment of a Bridge with Different Strengthening Schemes. Int. J. Life Cycle Assess. 2015, 20, 1300–1311.

- Jena, T.; Kaewunruen, S. Life Cycle Sustainability Assessments of an Innovative FRP Composite Footbridge. Sustainability 2021, 13, 13000.

- Zhang, C.; Lin, W.X.; Abududdin, M.; Canning, L. Environmental Evaluation of FRP in UK Highway Bridge Deck Replacement Applications Based on a Comparative LCA Study. Adv. Mater. Res. 2011, 374–377, 43–48.

- Daniel, R.A. A Composite Bridge Is Favoured by Quantifying Ecological Impact. Struct. Eng. Int. 2010, 20, 385–391.

- Vo Dong, P.A.; Azzaro-Pantel, C.; Cadene, A.-L. Economic and Environmental Assessment of Recovery and Disposal Pathways for CFRP Waste Management. Resour. Conserv. Recycl. 2018, 133, 63–75.

- Vo Dong, P.A.; Azzaro-Pantel, C.; Boix, M.; Jacquemin, L.; Domenech, S. Modelling of Environmental Impacts and Economic Benefits of Fibre Reinforced Polymers Composite Recycling Pathways. Comput. Aided Chem. Eng. 2015, 37, 2009–2014.

- Ribeiro, M.; Fiúza, A.; Ferreira, A.; Dinis, M.; Meira Castro, A.; Meixedo, J.; Alvim, M. Recycling Approach towards Sustainability Advance of Composite Materials’ Industry. Recycling 2016, 1, 178–193.

- Karuppannan Gopalraj, S.; Deviatkin, I.; Horttanainen, M.; Kärki, T. Life Cycle Assessment of a Thermal Recycling Process as an Alternative to Existing CFRP and GFRP Composite Wastes Management Options. Polymers 2021, 13, 4430.

- Li, X.; Bai, R.; McKechnie, J. Environmental and Financial Performance of Mechanical Recycling of Carbon Fibre Reinforced Polymers and Comparison with Conventional Disposal Routes. J. Clean. Prod. 2016, 127, 451–460.

- Witik, R.A.; Teuscher, R.; Michaud, V.; Ludwig, C.; Månson, J.-A.E. Carbon Fibre Reinforced Composite Waste: An Environmental Assessment of Recycling, Energy Recovery and Landfilling. Compos. Part A Appl. Sci. Manuf. 2013, 49, 89–99.

More