It is widely accepted that fossil fuel resources emit greenhouse gases (GHG), which are the leading cause for the climate crisis, with the manufacturing, energy, and agriculture sectors as main contributors. The agricultural sector is composed of diversified and potential mobilizable sources of waste which can become an attractive alternative to fossil fuels for energy production, and thus sequester and use carbon. Therefore, a paradigm shift towards more sustainable energy alternatives, efficient waste management, and new technologies is necessary. One good solution is the energetic valorization of lignocellulosic biomass (LCB) which can also originate from agricultural wastes. The biomass consists of cellulose, hemicellulose, and lignin, which are sources of fermentable sugars that can be used for bioethanol production. However, the recovery of sugars requires the pretreatment of LCB before enzymatic hydrolysis, due to its inaccessible molecular structure. Therefore, pretreatment is required to enhance enzyme accessibility as well as bioethanol production. Raw hemp biomass consists of 35-51% cellulose (dry basis, db), 13–28% hemicellulose (db), and 12-22% lignin (db). Chemical pretreatment, more specifically alkaline pretreatment, is the most commonly used for hemp biomass.

1. Introduction

Climate change is driven mainly by the burning of fossil fuels, which results in

greenhouse gases (GHG

) emissions into the atmosphere; it has been recorded that 89% of total carbon dioxide, a greenhouse gas, that was emitted into the atmosphere in 2018 originates from fossil fuel sources

[1][2][1,2]. However, following the menace of the COVID-19 pandemic, these GHG emissions have dropped by 4.6% in 2020 due to the hindered economic activity. Nevertheless, the emissions rose again significantly by 6.4% in 2021, with the manufacturing and energy sectors contributing the more substantially

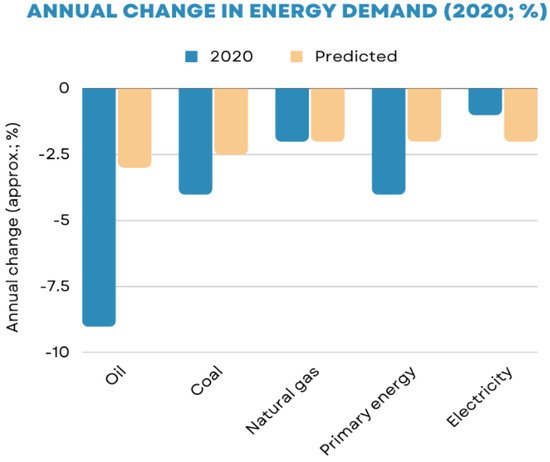

[3]. British Petroleum reported that fossil energy demand has declined in 2020 (

Figure 1), but also highlighted that the demand for renewable energy has noticeably increased

[4].

Figure 1.

Predicted vs. actual annual change in energy demand (2020; %).

Another important contributor to the emission of GHGs is the agricultural sector, as it has sought to achieve two goals: increase crop yields and maximize economic profit. To reach those outcomes, more modern practices were developed, including monoculture, rigorous tillage, irrigation, and chemical pest control. However, all these practices require fossil fuels for their application, in addition to the fossil fuels utilized for transportation and machinery

[5][6][7][8][9][5,6,7,8,9], implying that GHG is released into the atmosphere at every stage, from land to final product. For instance, farming releases considerable amounts of methane and nitrous oxide, which respectively originate from livestock during the digestion of foods in the animals’ digestive tract and mineral nitrogen fertilizers

[10].

Furthermore, this sector is also responsible for significant waste generation, which is consequently hazardous to food safety, the environment, and global health

[11][16]. One of the current priority of world leaders is to provide sufficient food and energy for the increasing population, all while reducing fossil fuel and solid wastes

[12][17]. Thus, as agriculture contributes to climate change, the latter harms the agricultural sector through changes in precipitation patterns and negative effects on crop yield, for example

[13][14][15][18,19,20]. In addition, many agricultural practices excessively exploit the earth’s natural resources, further negatively altering the environment

[16][21] (

Figure 2).

Figure 2. The effect of climate change and agriculture on each other [17]. The effect of climate change and agriculture on each other [22].

Therefore, in light of the multiple environmental issues that the planet is facing today, there has been a rising awareness about the repercussions of these issues and an increasing demand for a shift toward more sustainable strategies and practices, as well as for more sustainable energy alternatives. The latter include solar energy, hydropower, geothermal power, wind energy, and biomass

[18][23]. The alternatives are presented as more natural solutions, and they all allow for the reduction of GHG emissions. However, the additional advantage of biomass is that it can stem from wastes and can be transformed into various forms of products, such as heat when burned or biofuel when processed. Planting crops specifically for biofuel production, in itself, induces environmental stress, as there will be no variation in planting

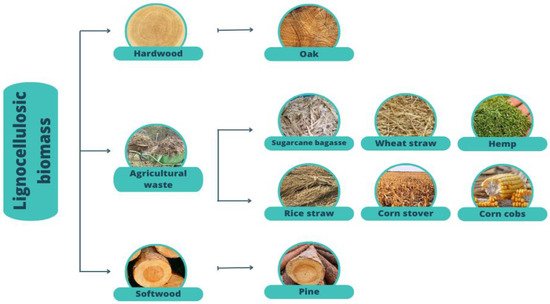

[19][20][24,25]. However, since biomass can also originate from wastes, this valorization becomes an asset in reducing wastes left in the environment. There exist different types of biomasses for the production of biofuels; these biomasses can be starch-based, sugar-based, or lignocellulosic, meaning they are composed of cellulose, hemicellulose, and lignin. As for lignocellulosic biomass, they are of three types, shown in

Figure 3 along with some examples of each

[21][26].

Figure 3.

The three types of lignocellulosic biomass with some examples of each.

The literature describes distinct types of promising biomasses tested for bioethanol production, and whose chemical composition is described in

Table 1. Overall,

lignocellulosic biomass (LCB

) are promising raw materials because they are abundant and economic. For instance, wheat is considered one of the most ancient and most important crops worldwide, with a world production of 779,243 (1000 MT) in 2021

[22][23][27,28]. Moreover, the hemp market has risen in popularity, even if about 50% of the world’s hemp fiber supply is produced in China, which planted 667 km

2 of hemp in 2019

[24][29]. Additionally, the U

nited States' (U.S.

) grew approximately 220 km

2 of industrial hemp in the open in 2021, and the E.U. cultivated approximately 350 km

2 in 2019

[25][26][30,31]. Furthermore, corn is one of the most distributed crops worldwide, in addition to being the U.S.’s leading crop, having planted 97,000 km

2 of land with corn in 2019

[27][28][32,33]. Rice, on the other hand, is a primary necessity for over half of the world’s population. The U.S. Department of Agriculture (USDA) estimates World Rice Production to reach 514.76 million metric tons in 2022–2023, which represents a 0.23% increase in worldwide rice production compared to 2021–2022

[29][30][34,35]. Finally, sugarcane is also classified as one of the world’s most important crops, especially that 267,743 km

2 were harvested worldwide in 2016. Moreover, Brazil ranked first worldwide in sugarcane production volume, with a volume equivalent to 41% of world production in 2017

[31][36]. The abundance and mass production of these crops implies a significant generation of agricultural wastes. The latter is also inexpensive and is characterized with its naturally complex structure, so its valorization for energy production can be presented as promising and as an attractive alternative.

Table 1.

Chemical composition of promising lignocellulosic biomasses.

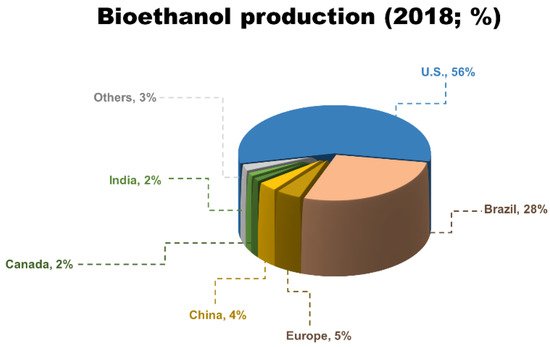

It is worth noting that the production of biofuels from biomasses has already been taken to an industrial level, with several facilities built around the world: 86 million tons of bioethanol were produced in 2018, with the main producers divided as shown in

Figure 4. Additionally, the U.S. Energy Information Administration (EIA) reported that 4835 trillion British thermal units (TBTu) were provided by biomass in 2021, and that is equivalent to 1.416 × 10

16 kWh

[43][48].

Figure 4.

Bioethanol production (%) by the six main producers: the U.S., Brazil, Europe, China, Canada, and India (2018).

However, some of these facilities are operational, while others are either ceased, planned, still under construction, or empty. The main reasons for the lack of operational facilities are due to financial difficulties or lack of adequate technology

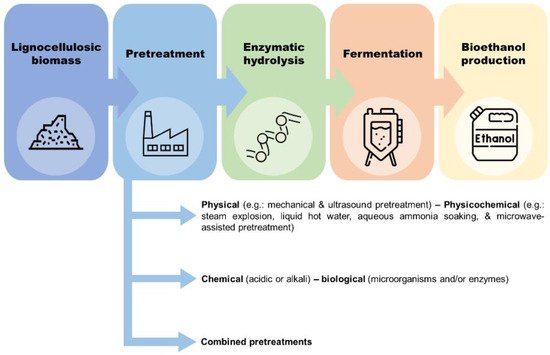

[44][49]. In fact, it is important to know that the structure and organization of the three polymers constituting lignocellulosic biomass depend on the types of biomasses, which also have a varying composition of each polymer. Furthermore, the multi-scale structure of those fibers, as well as the presence of lignin, is recalcitrant to enzymatic hydrolysis, which is applied to allow the release of fermentable sugars that will, in their turn, yield bioethanol following fermentation

[45][46][47][50,51,52]. Therefore, this biomass requires a pretreatment to enhance the accessibility of the enzymes to the fibers, hence increasing the bioconversion and fermentation yields. The various other kinds and varieties of lignocellulosic biomass, as well as the different pretreatment parameters to be considered, led to the suggestion of numerous pretreatment techniques for different types of available lignocellulosic biomasses, and were presented with the overall procedure in

Figure 5. Choosing the appropriate pretreatment technique and conditions plays a role in the outcomes of subsequent processes. Therefore, several factors need to be considered, such as energy cost, eco-friendliness, duration of pretreatment, and conservation of the fermentable sugars. In general, the efficiency of pretreatment for biofuel production is often defined by the lignin, cellulose, and hemicellulose contents after pretreatment, reducing sugar yield/concentration obtained following enzymatic hydrolysis, and biofuel yield/concentration obtained following fermentation.

Figure 5.

General overview of bioethanol production from lignocellulosic biomass.

2. Pretreatment of Hemp Biomass

Raw hemp biomass consists of 35–51% cellulose (dry basis, db), 13–28% hemicellulose (db), and 12–22% lignin (db), a compositional difference that can be explained by the presence of various hemp cultivars

[48][49][50][53,54,55] and the focus on different parts of the biomass (stems, woody core, hurds). Generally, the raw biomass is subject to drying to reduce its moisture content, as the latter critically affects the pretreatment’s conversion proficiency

[51][56]. Furthermore, hemp biomass is subject to particle size reduction (milling, grinding, sieving, etc.), before pretreatment, to increase the surface area accessibility, hence allowing better enzyme digestibility of the biomass’s constituents

[52][53][57,58].

Improvement of enzyme digestibility is the key purpose for pretreatment, which can be physical, chemical, biological, or a combination of two or more. Chemical pretreatment, more specifically alkaline pretreatment, is the most commonly used for hemp biomass

[54][55][56][57][58][59][59,60,61,62,63,64], as it has been proven most effective for de-lignification

[60][65], which will in its turn improve enzymatic hydrolysis by diminishing the biomass’s recalcitrance. Sodium hydroxide (NaOH)-based pretreatments were performed using 1–3% NaOH, temperatures greater than 90 °C, and for durations of 0.5–5 h

[54][55][59,60]. High temperatures are employed because they play a role in lignin deformation, enhancing enzymatic hydrolysis

[61][66]. Other experiments that have used NaOH have also utilized sulfuric acid (H

2SO

4) and Liquid Hot Water (LHW)

[57][62], acetic acid (HOAc)

[58][63], or sodium chlorite solution (NaClO

2)

[59][64]. However, NaOH-based pretreatment was more effective in biomass treatment than H

2SO

4-based processes or LHW

[57][62]; it was also performed alongside NaClO

2-based pretreatment to finally obtain differently treated samples of varying cellulose, hemicellulose, and lignin contents. The latter yielded holocellulose hemp hurd (HHH, 32.73% hemicellulose), lignin-containing hemp hurds (LHH, 17.99% lignin), and α-cellulose hemp hurds (AHH, 78.03% cellulose). Moreover, NaOH-treated samples were subject to two-volume (II-VW) washing, then merged with HOAc–treated samples to eliminate NaOH-soluble lignin

[58][63]. The outcomes of these pretreatment experiments were summarized in

Table 2.

Table 2.

Summary of the recent experiments done for pretreatment of hemp biomass.

Additionally, aqueous ammonia soaking was conducted using 10% NH

4OH for a process held at 70 °C for 22 h; it is important to note that time and temperature pairs (high temperature-short duration or low temperature-long duration) were described for acidic pretreatments

[61][66], but appear also to be applied to alkaline pretreatments.

On another note, a combined biological-chemical pretreatment was achieved using white-rot fungi and alkaline oxidative pretreatment (3% NaOH and 3% H

2O

2)

[62][67]. The combined pretreatment was performed over 24 h at 40 °C, and four other fungi were tested, of which

Pletorus eryngii exhibited the best performance.

Chemical and combined pretreatment have notably resulted in a significant decrease in lignin content, from 12–22% to 7–18%. In contrast, the content of cellulose, the polymer of interest for hydrolysis and subsequent fermentation, has noticeably increased from 35–51% to reach 62–78%, which could be caused by the removal of lignin that was blocking the cellulose before pretreatment

[63][68].

Following pretreatment, Simultaneous Saccharification and Fermentation (SSF) was accomplished

[54][55][57][59,60,62] with optimization by Response Surface Methodology (RSM)

[55][60] or by individually-elaborated experimental conditions

[54][59]. The latter consisted of four scenarios in which the composition of the fermentation medium (cellulase, hemicellulase, and presence/absence of Tween 80) was different for the four SSF trials. The fourth case (30 FPU/g cellulase, 140 FXU/g hemicellulase, and milling (size = 0.22 mm)) proved to be most efficient. Moreover, regular enzymatic hydrolysis was also performed following pretreatment

[57][59][63][62,64,68].

Finally, ethanol content produced varies remarkably following chemical pretreatment and saccharification. For instance, 6.5 g/L produced after 96 h of fermentation

[55][60] as opposed to 76.92 g/L also produced after 96 h of fermentation

[54][59], despite both studies undergoing an optimization process. The lower ethanol concentration could result from of the increased lignin content following chemical pretreatment, which consequently affects the efficiency of SSF. On the other hand, the second optimized process using the four different cases allowed the comprehension between ethanol concentration and solid loading, which exhibited a significantly negative quadratic correlation. Therefore, fermentation was repeated at the focus point of the quadratic model defined for the fourth scenario (30 FPU/g cellulase, 140 FXU/g hemicellulase, and milling (size = 0.22 mm)), which resulted in 76.92 g/L of ethanol. In addition, 20.1 g/L of ethanol was obtained after 72 h of fermentation

[58][63], a concentration that can be attributed to the efficiency of the pretreatment in removing lignin (from 14.56% to 9.21%), which allowed for an effective hydrolysis.

To conclude, NaOH remains the most effective chemical agent in hemp biomass pretreatment as it has confirmed its efficiency in de-lignification, hence the reduction of recalcitrance to enzymatic hydrolysis. Moreover, these studies confirm that solid loading also plays an important role in final ethanol concentration

[54][59]. Nevertheless, more information should be gathered about the efficiency of other non NaOH-based pretreatments, or treatments based on the application of NaOH and other agents, in relation to bioethanol production. The industrialization of lignocellulosic ethanol has already begun, with many countries having already installed plants. Nevertheless, to achieve this industrialization, manufacturers are faced with diverse obstacles: (1) more profound understanding of raw materials, their properties, their restrictive factors during pretreatment (inhibition, mass transfer, etc.), (2) development of low-cost enzymatic hydrolysis technique with optimum performance, and (3) a deeper understanding of microorganisms and their metabolic activities to enhance fermentation efficiency further, which also includes the engineering of specific strains.