You're using an outdated browser. Please upgrade to a modern browser for the best experience.

Please note this is a comparison between Version 2 by Rita Xu and Version 1 by Milos Zarkovic.

Montenegro faces serious challenges in terms of waste tire management. The financial and economic justification of the implementation of the first phase of the project of collection, takeover and transport, sorting, and storage of waste tires from the three municipalities in Montenegro.

- waste tire management

- air emission

- cost–benefit analysis

- socio-economic benefits

1. Introduction

Environmental contaminants are toxic and undesirable compounds that can endanger human health and the survivorship of life on Earth. Thus, their removal from the environment has become a hot topic of numerous research works [1]. The application of advanced materials and new applied technologies gives very important results in various fields, such as in improving human life, eliminating environmental pollution, and environmental remediation. There is great interest in producing efficient photocatalytic compounds that can remove a wide spectrum of toxic pollutants to remediate the environment. Photocatalysis technology has undergone ultra-fast development during the past several decades and has been widely applied in many fields, such as photo-synthesis, pollutant treatment, and other chemical- or energy-related processes [2,3][2][3]. Photocatalysis is accepted as a beneficial and environmentally friendly solution for the removal of undesirable contaminants. This environmentally friendly technology uses non-hazardous reactants that do not lead to the problem of environmental contamination. The results of energy-saving, simplicity, and reproducibility are also important characteristics of this efficient technology [4]. Its most substantial advantage is the capability to mineralize a wide variety of contaminants. In recent years, a remarkable number of scientific papers have been reported on the utilization of oxide nanostructures to eliminate environmental pollution [5,6,7][5][6][7]. The energy gap for the nanophotocatalysts was determined, making the nanocomposites favorable for removing contaminants. With a completely environmentally friendly method in the photocatalytic process, utilizing sunlight in the presence of photocatalytic compounds, poisonous contaminants can be oxidized or even degraded [8,9][8][9]. Optimization studies for the photocatalytic decomposition of each contaminant demonstrated that the best performance could be achieved at a specific amount of contaminant and nanocatalyst [10].

Two major problems related to population growth, urbanization, and economic growth, environmental and public health concerns, as well as the depletion of non-renewable resources, are caused by the problem of inadequate waste management. According to the available data, the total world production of natural and synthetic rubber amounted to over 25 million tons [11], of which about 60% was used for the production of car tires. Preliminary estimates suggest that the total stock of waste tires is around 100 million tons, with only about 10% being recoverable [12,13][12][13].

Tires are a specific category of waste, as they are very durable and almost non-degradable [14[14][15],15], which is why they are a major environmental problem [16,17][16][17]. Waste tire management methods depend on various factors, such as country characteristics, industry development, and population. According to some projections, worldwide, waste raised from tires amounts to 1.5 billion tons/year and by the end of 2025, is expected to be more than 2.5 billion tons [18].

Results of certain studies conclude that Europe, Asia, and North America generate 90% of the total amount of scrap tires [19,20][19][20]. Eastern Europe has traditionally had disposal fees at a lower level than Western Europe, and lower safety standards have enabled the intensification of the trade of used tires and their reuse. A necessary condition for putting things under control is to increase disposal fees and strengthen safety regulations [21]. At the same time, some research suggests that the model of “manufacturer and importer responsibility” for tire recycling should be applied in other countries as well, as it has proven successful in most European countries [22,23][22][23].

Waste tire management includes a set of measures for the collection, takeover and transport, storage, and treatment of waste tires. After the end of the life cycle, numerous recycling alternatives (pyrolysis, retread, shredding, compacting rubberized concrete, crumbing, reclaiming, rubber modified asphalt) are carried out in the process of waste tire treatment, which creates conditions for using waste tires for energy purposes. European directives do not cover part of the management of waste tires, as is the case with electrical and electronic waste, waste batteries, and accumulators. Although the EU has banned the disposal of tires in landfills since 2009, most countries do not have specific legislation on waste tire collection. However, a number of countries are trying to find ways to extend their life cycle. Improperly collected and disposed waste tires can endanger the environment by polluting the air, soil, and water.

Additionally, due to mechanical abrasion, car tires release particles in the environment, and many studies point to the problem of car tires as a source of microplastics in the environment [24,25,26][24][25][26]. As the release of this abrasive material is not possible in the near future [27], the results of some recent research suggest that emission reduction of non-exhaust emission source [28] and tire wear and tear [29,30][29][30] should be given more prominence on the political agenda [31].

The problem of waste tires is rising from year to year, especially in countries in transition. The policy and mechanism of waste reuse and recycling is based on the rational use of resources, and not uncontrolled one-time use, or uncontrolled ignition and improper disposal in the case of tires. The combustion of tires produces many toxic substances [32,33,34][32][33][34] and is extremely harmful to all three media in the environment, suggesting that the problems are not only environmental, but also health-related. They are very hazardous waste and drastically impair air quality through the emission of combustion products [35], which requires an expensive air emission control system [36]. Atmospheric toxic pollutants emitted from burning tires directly endanger public health and safety [37[37][38],38], and cause various types of mild to severe diseases [39,40,41][39][40][41].

In order to alleviate the energy crisis and environmental degradation, it has become imperative to use technology to obtain energy from unconventional sources, such as municipal and/or industrial waste, in which used tires have a special place. Due to their high calorific value, tires are used as an energy source in some countries (controlled incineration) where incinerators contain the necessary systems for the purification and treatment of gases. As waste tires have a higher energy content than coal, scrap tire recycling can significantly contribute to reducing GHG emissions [42]. However, this is not the primary option in tire treatment. The literature suggests several processes for used tires, analyzes the environmental and economic aspects of these processes, and investigates different management schemes for used tires [43]. As the need for the recovery and recycling of waste is increasingly emphasized, efforts are being made for the development of new technologies for used tire treatment [44,45,46,47,48][44][45][46][47][48].

2. Current Status of Waste Tire Management: The Case of Montenegro

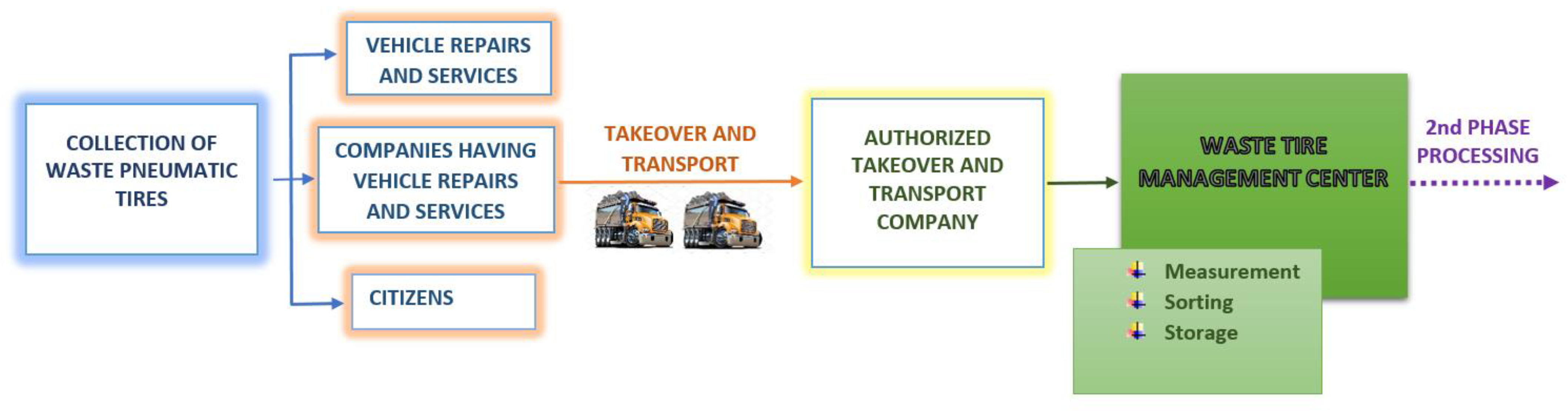

In 1996, the Collaborative Working Group on Solid Waste Management in low- and middle-income countries developed a framework system for integrated and sustainable waste management (ISWM), emphasizing public health, the environment, and resource recovery. In order to establish a satisfying and sustainable ISWM, in addition to technical elements, it is necessary to systematically include all stakeholders in the planning, implementing, and monitoring phases [89][49]. In relation to the above, sustainable development is significantly based on the management of tire waste, including its environmental, economic, and social effects. The United Nations has emphasized the key elements of waste management systems: policies and regulations, supporting institutions, proper financial mechanisms, stakeholder participation, and supporting technologies [90][50]. In many developing countries, waste tire management has not received the attention it deserves, and the processing, treatment, and disposal of waste tires are still in their initial phase. In some countries (e.g., Mexico and Russia), an integrated reverse logistics (RL) model has been proposed, which includes the processes of re-manufacturing and diversification, providing an economical and sustainable system of waste management. The same model has been successfully applied in some developed countries (Japan, Spain, and Germany), and contributes to the improvement of other strategies in the EU, Japan, Colombia, Italy, and Romania, [91][51]. However, developed countries also need more efficient and innovative methods related to recovery and recycling in waste tire management, regardless of the progress made. In some developing countries, until recently, waste tires were dumped in legal and illegal landfills and have posed a serious environmental problem. By harmonizing legislation with EU law, the practice of treating waste tires as an important resource for the production of various rubber products or energy in cement plants is introduced [92][52]. Generally, in the second half of the previous decade, methods for managing waste tires have been adopted worldwide, with minimal threat to the environment and people. The main alternatives for end-of-life tire management have also been accepted, and this is viewed in the context of 4R: reduction, reuse, recovery, and recycling. Many developing and transition countries have faced knowledge inadequacies in order to implement integrated programs that include “environmental sustainability, stockpiling of whole tires at landfills, lack of consistent and systematic approaches to tire regulation, lack of methods and tools to update tire data and trends, limited application of technology to process and treat WTs, and lack of societal acceptance” [93][53]. In the meantime, used tire recycling management schemes have been developed and identified in the literature, including extended producer responsibility (EPR), free market, and government [43]. Montenegro has not yet resolved the issue of waste tire management and rubber technical products in an appropriate, environmentally and economically sustainable way. The problem is further complicated by the fact that the amount of waste tires generated annually in the capital of Podgorica and Montenegro is growing, primarily due to the growth of all types of motor vehicles. Based on previous experiences, it can be stated that the management of waste tires—pneumatics in the Capital Podgorica, and in Montenegro in general—has not been adequately addressed. Namely, the Law on Waste Management [94][54] prescribes the obligation of manufacturers and importers of pneumatics to ensure the functioning of the waste tire management system. Another way to solve the problem is to get involved in the organized system managed by a company listed in the register of organized systems for waste collection and treatment. So far, there have been authorized collectors of waste tires (verified by the Environment Protection Agency), as well as authorized freight forwarders, who have not transported waste tires to legal landfills. In the previous period, there were no authorized companies for receiving waste tires in Montenegro and Podgorica, nor legal warehouses for storing waste tires. The recommendation of the competent bodies of the European Commission emphasizes the need to preserve the environment and to organize a space where waste tires can be collected, stored, and treated, as in highly developed EU countries. Acquiring the status of a candidate country and opening Chapter 27 for negotiations between the EU and Montenegro intensifies the obligations of Montenegro in the implementation of regulations that are in line with European legislation. This increases the possibilities for providing greater financial support from EU pre-accession funds in the form of grants or quality credit lines to address waste management issues. In Podgorica, problems in the management of waste pneumatic tires are evident and more intense. A significant number of waste tires are disposed of in illegal and unregulated landfills in the capital, while some tires are disposed of in containers together with mixed municipal waste. These illegal landfills are becoming, especially in the summer, potential places for fires due to the intentional and uncontrolled combustion of tires (or accidental, due to electric discharge), which sometimes burn for months. Thus, gases are emitted in large quantities, which is dangerous for people and all living beings. This situation has imposed the need to urgently address the problem of waste tire management. After determining the location (within the sanitary landfill of non-hazardous municipal waste, “Livade”, in Podgorica), the next step in solving this problem is to analyze the justification of the first phase of waste tire management. This phase includes collection, transport, sorting, and storage in the Waste Tire Management Center in Podgorica. The total area of the municipal waste landfill is 575,000 m2, while the selected location for waste tires within this landfill has an area of 9600 m2. The subject location is about 5 km away from the center of Podgorica. The distance of the existing watercourses, in the territory of Podgorica, from the subject location is from 0.5 to 4.5 km. On the southwest side of the selected location there is a suburban settlement, and the nearest buildings are at a distance of about 180 m. Northeast of the location is the recycling center building (as part of the landfill) at a distance of about 70 m, while on the south and southeast side there are no buildings, but the vineyards are at the closest distance of about 190 m. To the east of the selected location, there are sanitary baths for municipal waste disposal. Prior to the project implementation, it will be necessary to perform direct measurements of air quality at the selected location—the “zero state”. The obtained results will be the starting point for comparing possible future cumulative impacts in this area. Adequate resolution of this issue should result in the prevention of soil, water, and air pollution, as the interaction with these environments is minimal when preparing a quality substrate for waste disposal. The defined location is sufficient for the realization of the first phase of the process (the collection, takeover and transport, sorting, and storage of waste pneumatic tires), but also for the realization of the second phase (the processing of waste car tires and other rubber technical products). All the necessary infrastructure (road, water, electricity, sewage) for the selected location of the Center for Waste Tire Management can be provided. In providing the necessary inputs for the feasibility analysis of establishing a Center for Waste Tire Management, it was most difficult to define the process of collecting waste pneumatic tires. There are no accurate records of all sites with the replacement or repair of tires, nor accurate data on which companies produce waste pneumatic tires, based on existing fleets. With the legal framework (adoption of a special regulation), the obligation of all producers of waste tires (car repair shops, construction and other companies, physical persons, etc.) will be to deliver the waste tires to authorized companies, which will be in charge of their collection and transport to the established locations. The collection of waste pneumatic tires should be entrusted to authorized collectors and transporters of waste car tires, licensed by the Environment Protection Agency of Montenegro. The authorized collector will have a legal obligation to collect and transport automobile tire waste directly to the Waste Tire Management Center. The competent state administration body should decide on waste management fees, which will be paid by entities that generate waste tires. The establishment of such a Center requires the construction of a space for the collection, takeover and transport, storage, and sorting of waste pneumatic tires, the procurement of equipment, and all infrastructure construction for this type of waste. Figure 1 shows the final technological scheme of waste tire management in Podgorica for the first phase of the project.

Figure 1. Technological scheme of the first phase of the project.

References

- Zinatloo-Ajabshir, S.; Mousavi-Kamazani, M. Recent advances in nanostructured Sn−Ln mixed-metal oxides as sunlight-activated nanophotocatalyst for high-efficient removal of environmental pollutants. Ceram. Int. 2021, 47, 23702–23724.

- Liang, L.; Shi, L.; Wang, F.; Wang, H.; Yan, P.; Cong, Y.; Yao, L.; Yang, Z.; Qi, W. Sustainable production of value-added chemicals and fuels by using a citric acid-modified carbon nitride optical semiconductor. Appl. Catal. A Gen. 2020, 599, 117618.

- Fang, K.; Shi, L.; Cui, L.; Shi, C.; Si, W. Synthesis and photocatalytic properties of magnetically separable and recyclable p–n heterojunction CoFe2O4/Bi12O17Cl2 photocatalys. CrystEngComm 2021, 23, 4475–4485.

- Zaleska-Medynska, M.; Marchelek, M.; Diak, M.; Grabowska, E. Noble metal-based bimetallic nanoparticles: The effect of the structure on the optical, catalytic and photocatalytic properties. Adv. Colloid Interfac. 2016, 229, 80–107.

- Zinatloo-Ajabshir, S.; Salavati-Niasari, M. Preparation and characterization of nanocrystalline praseodymium oxide via a simple precipitation approach. J. Mater. Sci. Mater El. 2015, 26, 5812–5821.

- Salehi, Z.; Zinatloo-Ajabshir, S.; Salavati-Niasari, M. Novel synthesis of Dy2Ce2O7 nanostructures via a facile combustion route. RSC Adv. 2016, 6, 26895–26901.

- Tabatabaeinejad, S.M.; Zinatloo-Ajabshir, S.; Amiri, O.; Salavati-Niasari, M. Magnetic Lu2Cu2O5-based ceramic nanostructured materials fabricated by a simple and green approach for an effective photocatalytic degradation of organic contamination. RSC Adv. 2021, 11, 40100–40111.

- Vasilaki, E.; Vernardou, D.; Kenanakis, G.; Vamvakaki, M.; Katsarakis, N. TiO2/WO3 photoactive bilayers in the UV–Vis light region. Appl. Phys. A Mater. 2017, 123, 231.

- Pirhashemi, M.; Habibi-Yangjeh, A. Ultrasonic-assisted preparation of plasmonic ZnO/Ag/Ag2WO4 nanocomposites with high visible-light photocatalytic performance for degradation of organic pollutants. J. Colloid Interfac. 2017, 491, 216–229.

- Mahdavi, K.; Zinatloo-Ajabshir, S.; Yousif, Q.A.; Salavati-Niasari, M. Enhanced photocatalytic degradation of toxic contaminants using Dy2O3-SiO2 ceramic nanostructured materials fabricated by a new, simple and rapid sonochemical approach. Ultrason. Sonochem. 2022, 82, 105892.

- Beroe. Styrene Butadiene Rubber (SBR) Commodity Report; Beroe: Raleigh, NC, USA, 2019.

- Araujo-Morera, J.; Verdejo, R.; López-Manchado, M.A.; Hernández Santana, M. Sustainable mobility: The route of tires through the circular economy model. Waste Manag. 2021, 126, 309–322.

- Shulman, V.L. Tire Recycling. In Waste; Academic Press: London, UK, 2019; pp. 489–515.

- Derakhshan, Z.; Ghaneian, M.T.; Mahvi, A.H.; Conti, G.O.; Faramarzian, M.; Dehghani, M.; Ferrante, M. A new recycling technique for the waste tires reuse. Environ. Res. 2017, 158, 462–469.

- Gonullu, M. Waste Tire Management. In Solid Waste Recycling Technologies Seminar; Rubber Manufacturers Association: Washington, DC, USA, 2014; pp. 125–133.

- Herrera-Sosa, E.S.; Martínez-Barrera, G.; Barrera-Díaz, C.; Cruz-Zaragoza, E.; Ureña-Núñez, F. Recovery and modification of waste tire particles and their use as reinforcements of concrete. Int. J. Polym. Sci. 2015, 2, 1–8.

- Mehdiabadi, A.; Amirabdollahian, S.; Rohani, A.; Farahani, N.M. Qualitative quantitative analysis of tire industry of Iran by using fuzzy DEMATEL and systemic method until 1404. Int. J. Sci. Eng. Res. 2013, 4, 1939–1946.

- Symeonides, D.; Loizia, P.; Zorpas, A.A. Tire waste management system in Cyprus in the framework of circular economy strategy. Environ. Sci. Pollut. R. 2019, 26, 35445–35460.

- Osayi, J.I.; Iyuke, S.; Ogbeide, S.E. Biocrude production through pyrolysis of used tyres. J. Catal. 2014, 2014, 1–9.

- Roy, C.; Labrecque, B.; de Caumia, B. Recycling of scrap tires to oil and carbon black by vacuum pyrolysis. Resour. Conserv. Recycl. 1990, 4, 203–213.

- Van Beukering, P.J.; Janssen, M.A. Trade and recycling of used tyres in Western and Eastern Europe. Resour. Conserv. Recycl. 2001, 33, 235–265.

- Monier, V.; Hestin, M.; Cavé, J.; Laureysens, I.; Watkins, E.; Reisinger, H.; Porsch, L. Development of guidance on extended producer responsibility (EPR); Final Report; European Commission, DG Environment: Brussels, Belgium, 2014.

- Khudyakova, T.; Shmidt, A.; Shmidt, S. Sustainable development of smart cities in the context of the implementation of the tire recycling program. Entrep. Sust. Issues 2020, 8, 698.

- Sundt, P.; Schulze, P.E.; Syversen, F. Sources of microplastic-pollution to the marine environment. Mepex Nor. Environ. Agency 2014, 1032, 1–86.

- Essel, R.; Engel, L.; Carus, M.; Ahrens, R.H. Sources of microplastics relevant to marine protection in Germany. Texte 2015, 64, 656–660.

- Lassen, C.; Hansen, S.F.; Magnusson, K.; Hartmann, N.B.; Rehne Jensen, P.; Nielsen, T.G.; Brinch, A. Microplastics: Occurrence, Effects and Sources of Releases to the Environment in Denmark; Danish Environmental Protection Agency: Copenhagen, Denmark, 2015; pp. 1–206.

- Sommer, F.; Dietze, V.; Baum, A.; Sauer, J.; Gilge, S.; Maschowski, C.; Gieré, R. Tire abrasion as a major source of microplastics in the environment. Aerosol Air Qual. Res. 2018, 18, 2014–2028.

- Panko, J.M.; Hitchcock, K.M.; Fuller, G.W.; Green, D. Evaluation of tire wear contribution to PM2.5 in urban environments. Atmosphere 2019, 10, 99.

- Lu, P.; Deng, S.; Li, G.; Li, J.; Xu, K.; Lu, Z. Spatial Distribution of Primary and Secondary PM2.5 Concentrations Emitted by Vehicles in the Guanzhong Plain, China. Atmosphere 2022, 13, 347.

- Samek, L.; Styszko, K.; Stegowski, Z.; Zimnoch, M.; Skiba, A.; Turek-Fijak, A.; Gorczyca, Z.; Furman, P.; Kasper-Giebl, A.; Rozanski, K. Comparison of PM10 Sources at Traffic and Urban Background Sites Based on Elemental, Chemical and Isotopic Composition: Case Study from Krakow, Southern Poland. Atmosphere 2021, 12, 1364.

- Kole, P.J.; Löhr, A.J.; Van Belleghem, F.G.; Ragas, A.M. Wear and tear of tyres: A stealthy source of microplastics in the environment. Int. J. Environ. Res. Pub. Health 2017, 14, 1265.

- Yang, X.; You, Z.; Perram, D.; Hand, D.; Ahmed, Z.; Wei, W.; Luo, S. Emission analysis of recycled tire rubber modified asphalt in hot and warm mix conditions. J. Hazard. Mater. 2019, 365, 942–951.

- Marć, M.; Tsakovski, S.; Tobiszewski, M. Emissions and toxic units of solvent, monomer and additive residues released to gaseous phase from latex balloons. Environ. Res. 2021, 195, 110700.

- Ortíz-Rodríguez, O.O.; Ocampo-Duque, W.; Duque-Salazar, L.I. Environmental impact of end-of-life tires: Life cycle assessment comparison of three scenarios from a case study in Valle Del Cauca, Colombia. Energies 2017, 10, 2117.

- Reisman, J.I.; Lemieux, P.M. Air Emissions from Scrap Tire Combustion. In Air Emissions from Scrap Tire Combustion; EPA: Washington, DC, USA, 1997. Available online: https://www3.epa.gov/ttncatc1/dir1/tire_eng.pdf (accessed on 2 February 2022).

- Abed, I.; Paraschiv, M.; Loubar, K.; Zagrouba, F.; Tazerout, M. Thermogravimetric investigation and thermal conversion kinetics of typical North-Africa and middle-east lignocellulosic wastes. BioResources 2012, 7, 1120–1220.

- Hassanien, M.A. Risk assessment of atmospheric toxic pollutants over Cairo, Egypt. Wit. Trans. Ecol. Envir. 2009, 123, 353–363.

- Nova Scotia Environment. Interdepartmental Committee on Used-Tire Management in Nova Scotia. Report to the Minister of Environment. 2008. Available online: http://www.novascotia.ca/nse/waste/docs/TireStrategy.pdf (accessed on 22 February 2022).

- Karagiannidis, A.; Kasampalis, T. Resource recovery from end-of-life tyres in Greece: A field survey, state-of-art and trends. Waste Manag. Res. 2010, 28, 520–532.

- Environmental Protection Agency (EPA). Air Quality Index: A Guide to Air Quality and Your Health. 2000. Available online: http://www.njaqinow.net/App_AQI/AQI.en-US.pdf (accessed on 28 February 2022).

- Blackman, A.; Palma, A. Scrap tires in Ciudad Juarez and El Paso: Ranking the risks. J. Environ. Dev. 2002, 11, 247–266. Available online: http://ageconsearch.umn.edu/bitstream/10583/1/dp020046.pdf (accessed on 1 March 2022).

- Pehlken, A.; Roy, G. Identifying LCA-elements in scrap tire recycling. WIT Trans. Ecol. Environ. 2006, 92, 1–9.

- Sitepu, M.H.; Matondang, A.R.; Sembiring, M.T. Used tires recycle management and processing: A review. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2020.

- Barbooti, M.M.; Mohamed, T.J.; Hussain, A.A.; Abas, F.O. Optimization of pyrolysis conditions of scrap tires under inert gas atmosphere. J. Anal. Appl. Pyrol. 2004, 72, 165–170.

- Önenç, S.; Brebu, M.; Vasile, C.; Yanik, J. Copyrolysis of scrap tires with oily wastes. J. Anal. Appl. Pyrol. 2012, 94, 184–189.

- Frigo, S.; Seggiani, M.; Puccini, M.; Vitolo, S. Liquid fuel production from waste tyre pyrolysis and its utilisation in a Diesel engine. Fuel 2014, 116, 399–408.

- İlkılıç, C.; Aydın, H. Fuel production from waste vehicle tires by catalytic pyrolysis and its application in a diesel engine. Fuel Process. Technol. 2011, 92, 1129–1135.

- Laresgoiti, M.F.; Caballero, B.M.; de Marco, I.; Torres, A.; Cabrero, M.A.; Chomón, M.J. Characterization of the liquid products obtained in tyre pyrolysis. J. Anal. Appl. Pyrol. 2004, 71, 917–934.

- Wilson, D.C.; Scheinberg, A. What is good practice in solid waste management? Waste Manage. Res. 2010, 28, 1055–1056.

- Mrad, M.; El-Samra, R. Waste tire management: Lebanon case study. J. Waste Manage. Dispos. 2020, 3, 101.

- Uriarte-Miranda, M.L.; Caballero-Morales, S.O.; Martinez-Flores, J.L.; Cano-Olivos, P.; Akulova, A.A. Reverse logistic strategy for the management of tire waste in Mexico and Russia: Review and conceptual model. Sustainability 2018, 10, 3398.

- Stanojević, D.D.; Rajković, M.B.; Tošković, D.V. Upravljanje korišćenim gumama, dometi u svetu i stanje u Srbiji. Hem. Ind. 2011, 65, 727–738.

- Mmereki, D.; Machola, B.; Mokokwe, K. Status of waste tires and management practice in Botswana. J. Air Waste Manage. Assoc. 2019, 69, 1230–1246.

- Government of Montenegro. Law on Waste Management. Off. Gaz. Monten. 2016, 39, 4–10.

- Government of Montenegro. Decree on the manner and procedure of establishing a system of collection, takeover and treatment of waste tires and the operation of that system. Off. Gaz. Monten. 2012, 39.

More