Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 2 by Dean Liu and Version 1 by Zonghai Chen.

With the development of the global economy, the automobile industry is also developing constantly. In recent years, due to the shortage of environmental energy and other problems, seeking clean energy as the power source of vehicles to replace traditional fossil energy could be one of the measures to reduce environmental pollution. Among them, fuel cell hybrid electric vehicles (FCHEVs) have been widely studied by researchers for their advantages of high energy efficiency, environmental protection, and long driving range.

- fuel cells

- hybrid electric vehicles

- energy management strategy

1. Introduction

Currently, energy shortages and ecological protection are gaining widespread attention in various countries, and the massive use of fossil fuels is further worsening environmental problems. Among various energy sources and technologies to replace fossil fuels, hydrogen energy and fuel cells are considered promising solutions to achieve zero-pollution emissions [1]. The automobile industry is an important industry in many countries, and automobiles are also a necessity in people’s daily lives. At present, traditional fuel vehicles still occupy a large share of the market, which will produce many air pollutants and greenhouse gases in the driving process. Replacing fossil fuels as power sources for vehicles with clean energy sources such as hydrogen and electricity can greatly reduce pollutant and greenhouse gas emissions [2].

The fuel cells discussed in this paper are proton exchange membrane fuel cells (PEMFCs), which use hydrogen energy as the energy source to generate electricity. The PEMFC directly converts the chemical energy contained in hydrogen into electricity, heat, and water [3]. The fuel cell suffers from a slow dynamic response [4] and is difficult to adapt to complex driving conditions [5]. The chemical reaction of the hydrogen in the fuel cell which supplies electrical energy is often smaller than the rate of change of the load. At the same time, rapid acceleration and deceleration and frequent start-stop operations during driving will affect the durability of the fuel cell. Based on these characteristics, fuel cells are often used in hybrid energy storage systems with other energy sources, such as batteries and ultracapacitors, for power applications [6,7][6][7]. Additionally, fuel cells are widely used in hybrid power systems with other energy sources. It is useful to reduce the consumption of hydrogen, reduce the size of fuel cells and increase the economy of hybrid power systems [8,9][8][9]. Fuel cell-based hybrid systems are widely used not only in fuel cell hybrid vehicles but also in other transportation equipment, such as unmanned aerial vehicles (UAVs) and trams [10]. This shows that hydrogen energy is playing an increasingly important role in the transportation industry.

Fuel cell hybrid vehicles usually use fuel cells as the main power source and are equipped with batteries or ultracapacitors as auxiliary energy sources. The working conditions of automobiles driving on the road are very complex. They often face various emergencies, and the required power demand will also have large fluctuations and sudden changes. However, if only fuel cells are used as the energy source, the output of large fluctuations in power can reduce the life of the fuel cell [11]. Therefore, the role of the auxiliary energy source is necessary. Batteries and ultracapacitors can play good roles in auxiliary energy sources. Batteries can recover excess energy and provide power to the system simultaneously with fuel cells when the load demand power is high. The ultracapacitor has the characteristics of a fast dynamic response, fast energy recovery, and high specific power, which can play the role of a timely response in the face of rapid changes in load demand [12]. At present, there are three main system structures of fuel cell hybrid vehicles. The first type is a hybrid system composed of fuel cells and batteries. The second is a hybrid system composed of fuel cells and ultracapacitors. The final type is a hybrid system composed of fuel cells, batteries, and ultracapacitors. The power system structure has been studied and analyzed for different types of fuel cell hybrid vehicles [13].

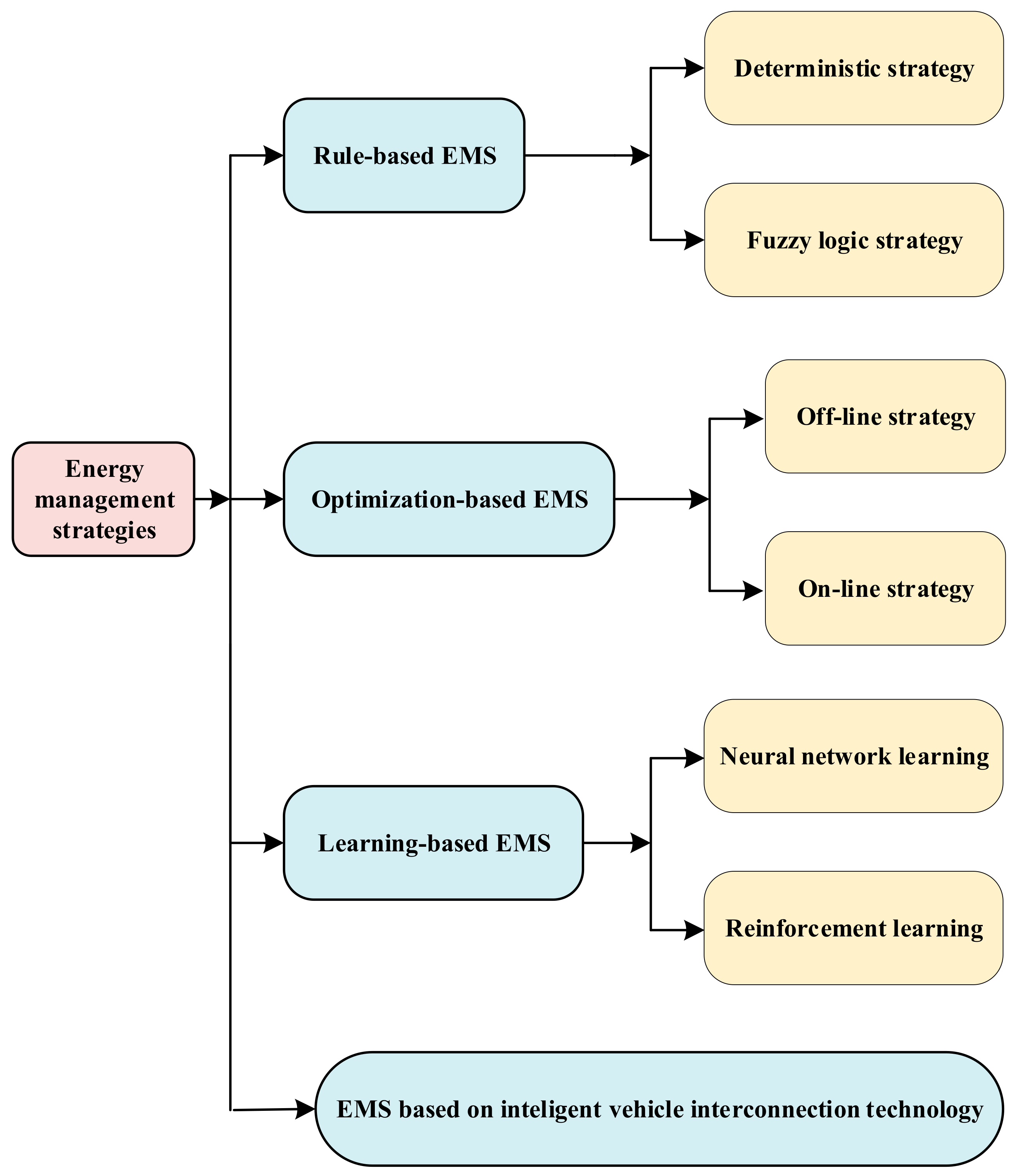

EMSs play a significant role in the performance and efficiency of fuel cell hybrid vehicles [14]. Its main objective is distributing power between different energy sources while achieving two goals: first, reducing hydrogen consumption or minimizing equivalent energy consumption [15]; and second, extending fuel cell life, which also means increasing the economy of the hybrid system [16]. A large number of energy management strategies are focused on these two optimization goals. The first type of EMSs is the rule-based method. This usually requires obtaining the power map of the fuel cell to obtain the highest efficiency operating point. It can also adjust the power distribution of the fuel cell and the energy storage system (battery or ultracapacitor), according to the power system state. However, it has many disadvantages, such as the parameters that are affected by the test operating conditions, lacking adaptability to different operating conditions, and the control results are not optimal. Optimization-based energy management strategies are some of the most studied types and can be divided into two categories: online optimization strategies; and offline optimization strategies. Among them, the real-time optimal energy management strategy based on model predictive control (MPC) has been widely discussed in the past two years. The third category are the learning-based energy management strategies. Its basic idea is to use large data sets of real-time and historical information to train the parameters of the strategy to obtain optimal control [17]. An energy management strategy based on intelligent vehicle interconnection technology has also been recently proposed by researchers and is discussed in this paper. The classification of common energy management strategies for fuel cell hybrids is shown in Figure 1. Regardless of the type of energy management strategy, the core of the optimization is represented by two aspects: optimizing energy consumption; and extending the life of fuel cells and other components [18].

Figure 1. Classification of common energy management strategies.

2. Typical Topologies of FCHEVs

Fuel cells are often combined with other auxiliary energy sources to form a hybrid system to supply energy to hybrid electric vehicles. These auxiliary power sources are batteries, ultracapacitors (UCs), superconducting magnetic energy storage (SMES), solar photovoltaics (SPVs), and flywheels. The most commonly used auxiliary energy sources are batteries and ultracapacitors [19]. Batteries are easy to install, low maintenance, and low cost. Therefore, fuel cell/battery hybrid electric vehicles are widely used in production and are the most common topology. An ultracapacitor is a storage unit to enhance the dynamic response. It can be used to quickly provide load or recover energy when the load fluctuates rapidly [20]. Compared with batteries and ultracapacitors, the application of other auxiliary energy storage elements is not as extensive [21]. A SMES is an energy storage device with high power output and low energy density. The working conditions required by SMES are relatively severe. Due to the consideration of vehicle cost, the application in fuel cell hybrid vehicles is also relatively rare. SPV is a sustainable, nonpolluting power generation device, but its energy generation depends on sunlight irradiation with large uncertainty. Therefore, it is not a very ideal auxiliary energy for automobiles. When torque is applied to the flywheel, the flywheel will store energy in the form of mechanical energy. When the system requires greater power, the flywheel can release the mechanical energy and convert it into electrical energy to supply energy to the system. It requires high security and is often used in power grid systems.

Commonly, there are five topological classifications of FCHEVs: fully FC; FC + battery hybridization; FC + UC hybridization; FC + battery + UC hybridization; and FC + other hybridization.

2.1. Fully FCEV

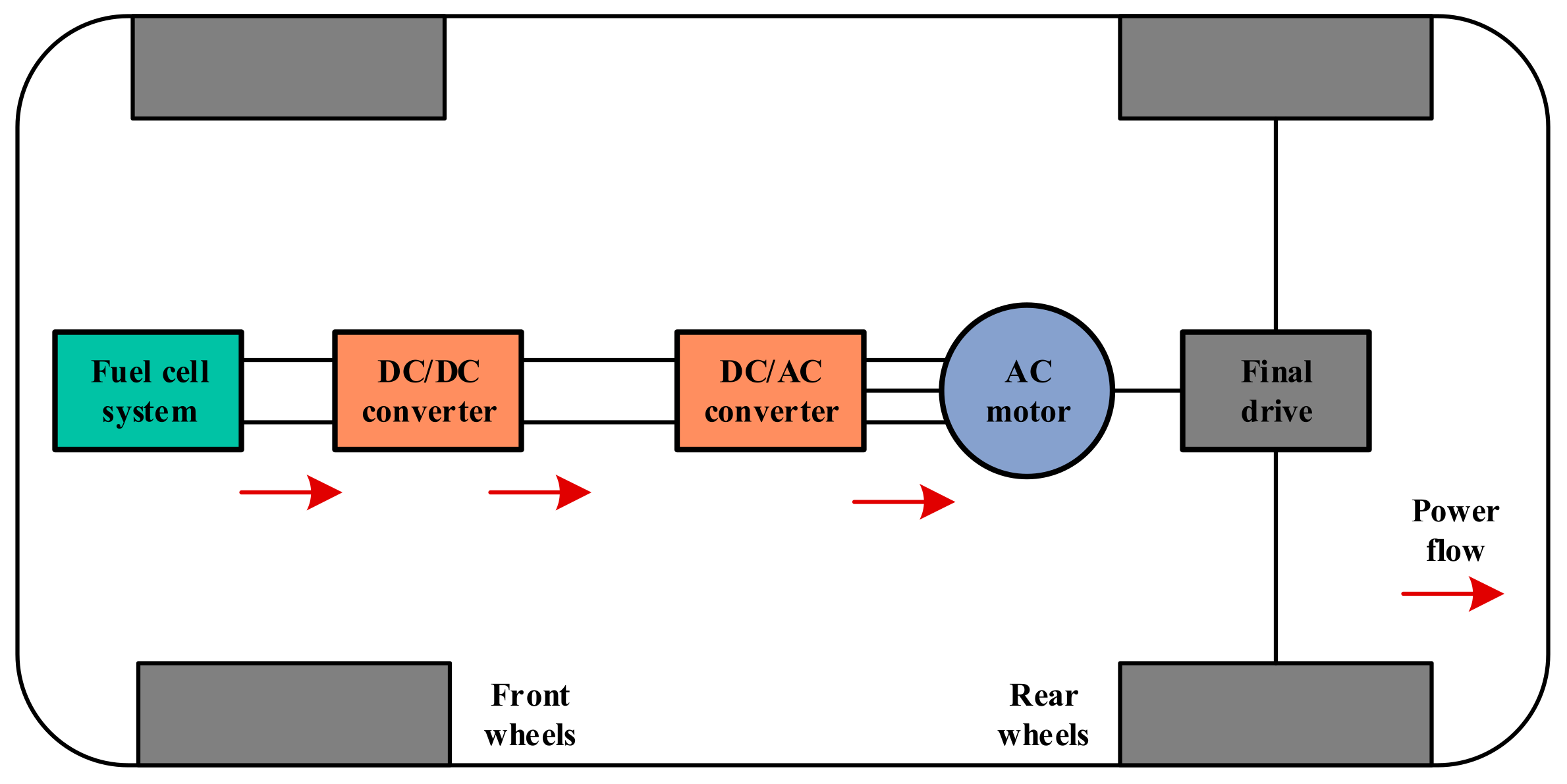

Fuel cell electric vehicles only use fuel cells to power the transmission system, with no auxiliary energy source. This topology is simple, as seen in Figure 2, and consists only of a fuel cell stack, DC/DC converter, inverter, and electric motor. Because of its simple structure, it has the characteristics of being easy to control and realize. Commonly used applications are mainly in low-speed vehicles, such as forklifts, buses, aviation vehicles, trams, and marine vehicles [22].

Figure 2. Full FCEV topology.

2.2. FC + Battery Hybridization

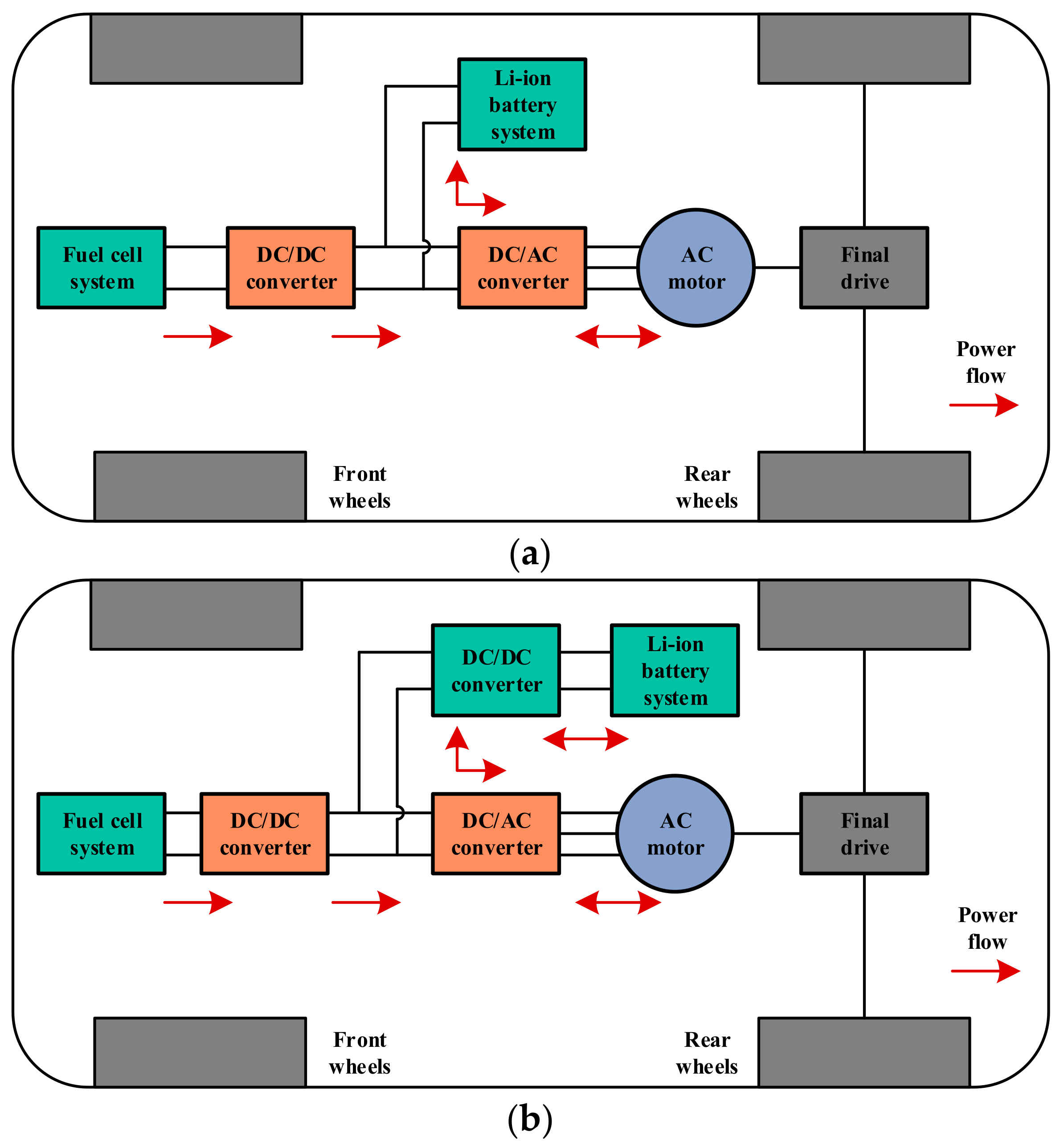

The hybrid power system composed of fuel cells and batteries is the most common topology. Batteries have the advantages of high energy density, low maintenance and low cost. The average life cycle of battery is 4–6 years. Therefore, this type of hybridization is widely used in production and are the most common topology [23]. There are two common topologies of FC + battery hybridization. The first is the battery directly connected to the DC bus. In addition, the other is the battery connected to the DC bus after the DC/DC converter, as shown in Figure 3. In this system, fuel cells are used as the main power source to provide most of the power for the load. This system has the advantages of recovering braking energy. However, its dynamic response is slower than FC + UC hybridization.

Figure 3. Topologies of FC + battery: (a) batteries disconnected to the DC/DC converter; (b) batteries connected to the DC/DC converter.

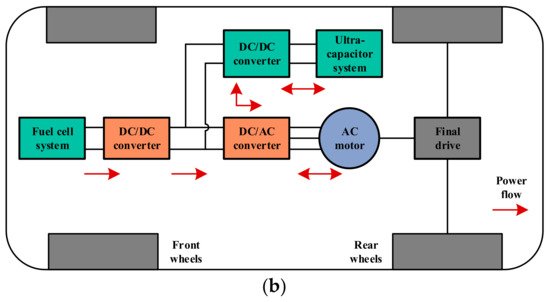

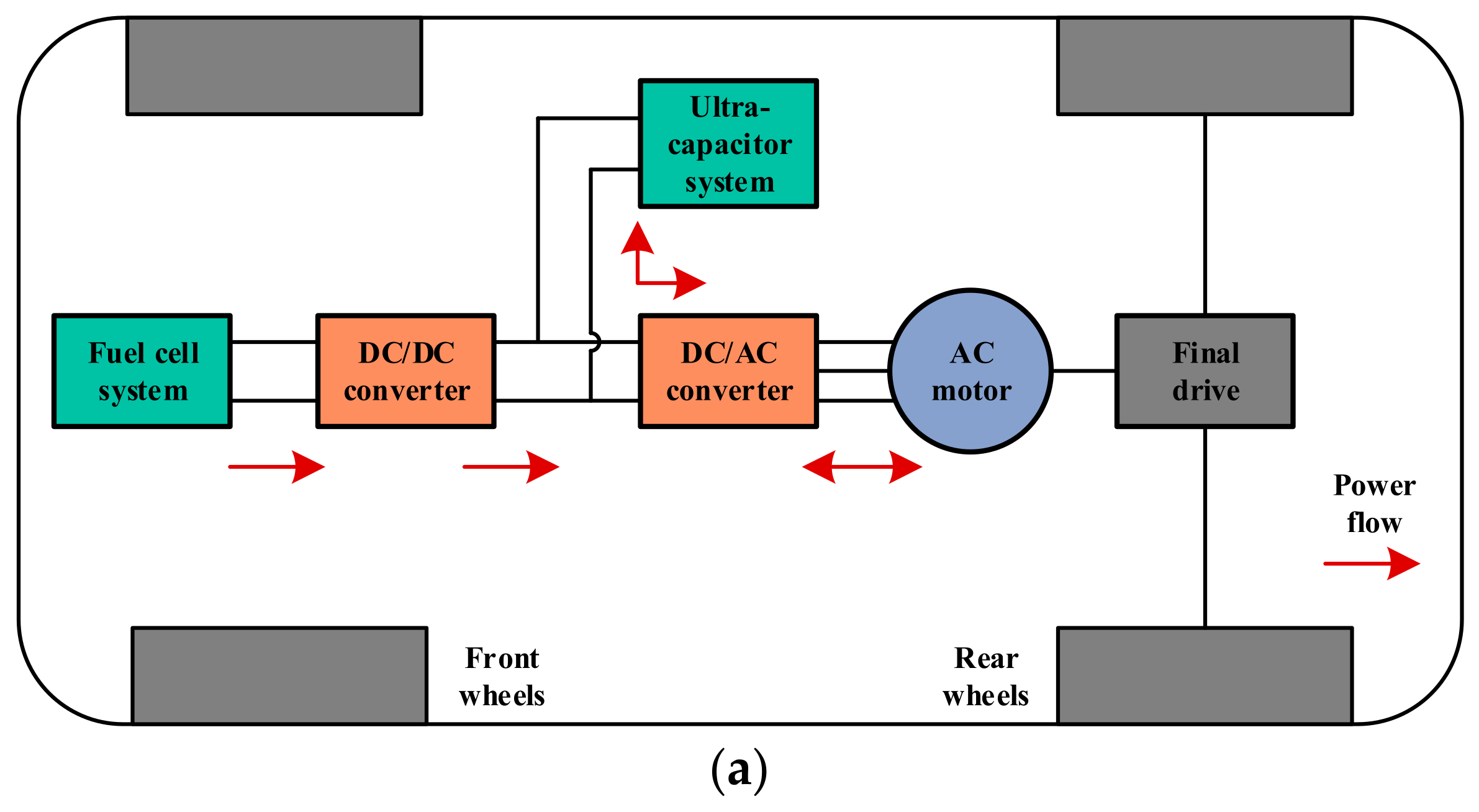

2.3. FC + UC Hybridization

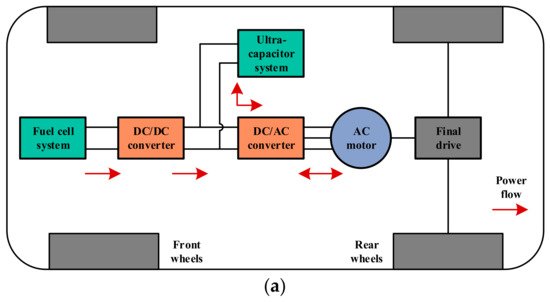

Compared with the disadvantages of batteries, such as low energy density, large size, and small instantaneous charge and discharge current, ultracapacitors have the advantages of fast charge and discharge, and of being able to be used more times. Additionally, the average life cycle of UC is 12–20 years [24]. According to whether the ultracapacitor is connected to the DC bus through a DC/DC converter, the hybrid system can also be divided into two types, as shown in Figure 4. Because the voltage fluctuation of the ultracapacitor is too large, a fully active topology, as shown in Figure 4b, is generally adopted. This system has the advantages of more efficient power recovery and better dynamic response to instantaneous high-power demand. It also has the disadvantages of high economic cost and low energy density; therefore, it is not as widely used as hybrid power systems with fuel cells and batteries.

Figure 4. Topologies of FC + UC: (a) UC disconnected to the DC/DC converter; (b) UC connected to the DC/DC converter.

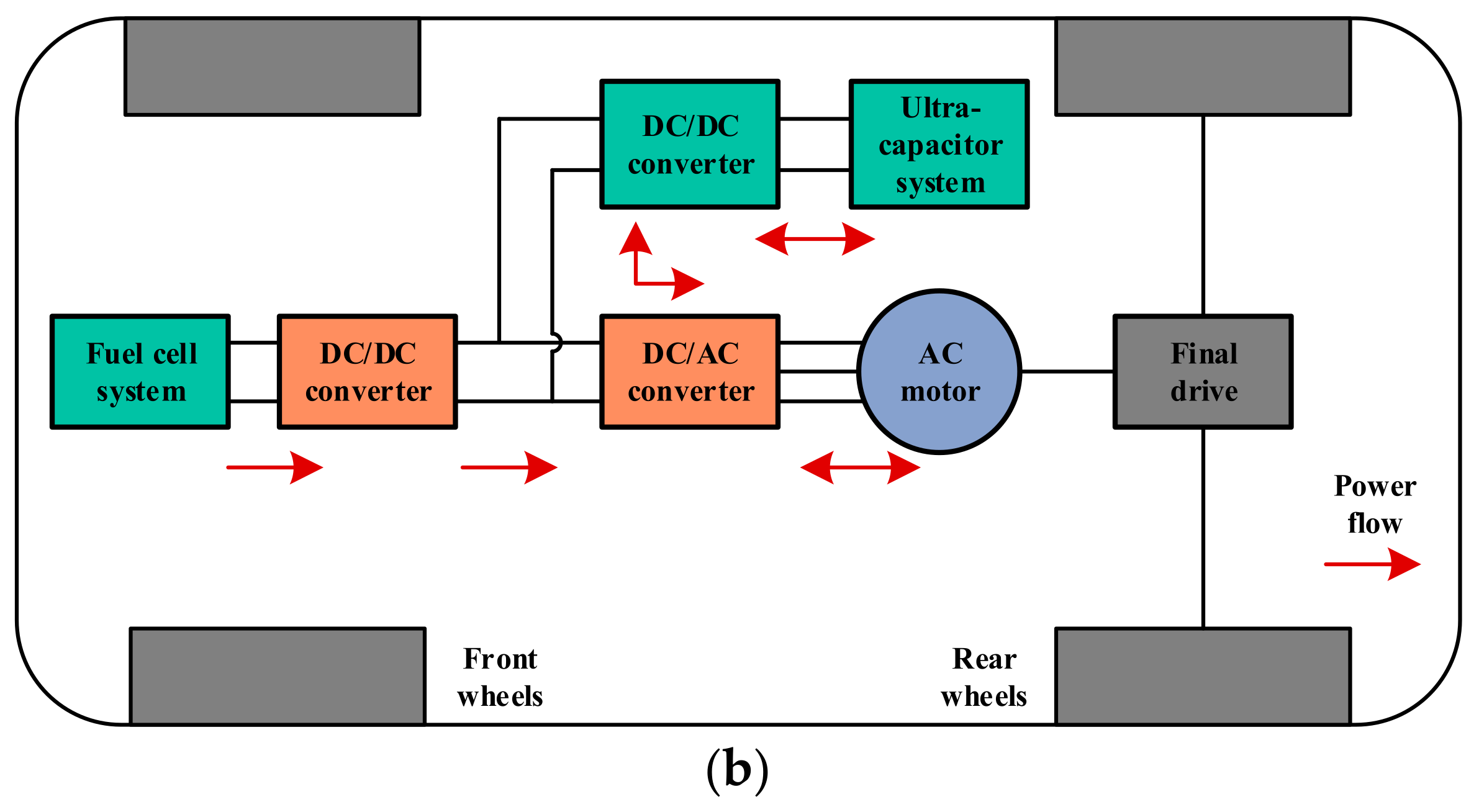

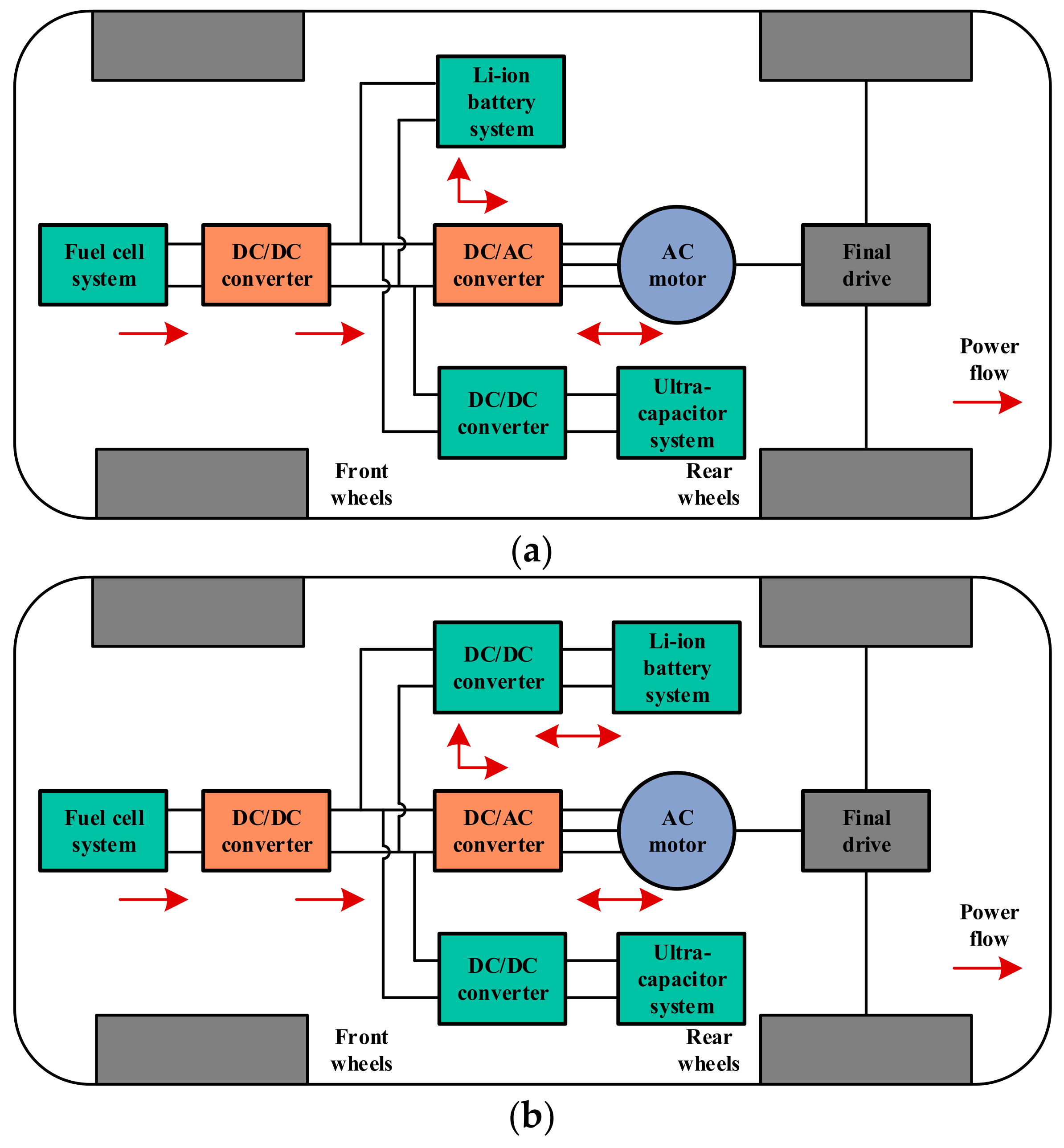

2.4. FC + Battery + UC Hybridization

The topology of the fuel cell + battery + UC hybrid power system is shown in Figure 5. The hybrid system still uses fuel cells as the main energy source to provide the average power demand of the load. The characteristics of batteries and ultracapacitors are considered comprehensively so that they can work in different states. Ultracapacitors have the characteristics that can charge and discharge rapidly with high current but have small energy storage. Ultracapacitors can be used to provide instantaneous power or energy recovery when the power required by the load has large sudden changes. However, due to the complex structure of the hybrid system and the strong coupling between the power sources, the control strategy of this system is complicated.

Figure 5. Topologies of FC + battery + UC: (a) battery disconnected to the DC/DC converter; (b) battery connected to the DC/DC converter.

2.5. FC + Other Hybridization

Hybrid power systems composed of fuel cells and other auxiliary energy sources are still applied in a small range in the field of hybrid vehicles. Flywheels can replace batteries as auxiliary energy sources. The energy stored in the flywheel is high-speed mechanical energy, which is converted into electrical energy when the motor needs power. However, because flywheel operation requires a high level of security, it is not widely used. Similarly, SMES is not used on a large scale due to its high cost. SPVs are also not widely used because of their dependence on solar energy and the large uncertainty of the energy supply. This paper mainly focuses on hybrid power systems composed of fuel cells, batteries, and ultracapacitors, and does not elaborate too much on other auxiliary energy sources.

References

- Luderer, G.; Madeddu, S.; Merfort, L.; Ueckerdt, F.; Pehl, M.; Pietzcker, R.; Rottoli, M.; Schreyer, F.; Bauer, N.; Baumstark, L.; et al. Impact of declining renewable energy costs on electrification in low-emission scenarios (vol 7, pg 32, 2022). Nat. Energy 2022, 7, 380–381.

- Chang, X.Y.; Ma, T.; Wu, R. Impact of urban development on residents’ public transportation travel energy consumption in China: An analysis of hydrogen fuel cell vehicles alternatives. Int. J. Hydrogen Energy 2019, 44, 16015–16027.

- Pan, R.; Yang, D.; Wang, Y.J.; Chen, Z.H. Performance degradation prediction of proton exchange membrane fuel cell using a hybrid prognostic approach. Int. J. Hydrogen Energy 2020, 45, 30994–31008.

- Pan, R.; Yang, D.; Wang, Y.J.; Chen, Z.H. Health degradation assessment of proton exchange membrane fuel cell based on an analytical equivalent circuit model. Energy 2020, 207, 118185.

- Wang, Y.; Wang, L.; Li, M.; Chen, Z. A review of key issues for control and management in battery and ultra-capacitor hybrid energy storage systems. Etransportation 2020, 4, 100064.

- Wang, L.; Li, M.C.; Chen, Z.H. An Energy Management Strategy for Hybrid Energy Storage Systems coordinate with state of thermal and power. Control Eng. Pract. 2022, 122, 105122.

- Wang, Y.J.; Sun, Z.D.; Li, X.Y.; Yang, X.Y.; Chen, Z.H. A comparative study of power allocation strategies used in fuel cell and ultracapacitor hybrid systems. Energy 2019, 189, 116142.

- Wang, L.; Li, M.C.; Wang, Y.J.; Chen, Z.H. Energy Management Strategy and Optimal Sizing for Hybrid Energy Storage Systems Using an Evolutionary Algorithm. IEEE Trans. Intell. Transp. Syst. 2021, 1–11.

- Mince, L.; Li, W.; Yujie, W.; Zonghai, C. Sizing Optimization and Energy Management Strategy for Hybrid Energy Storage System Using Multiobjective Optimization and Random Forests. IEEE Trans. Power Electron. 2021, 36, 11421–11430.

- Wang, Y.J.; Sun, Z.D.; Chen, Z.H. Energy management strategy for battery/supercapacitor/fuel cell hybrid source vehicles based on finite state machine. Appl. Energy 2019, 254, 113707.

- Zhang, H.T.; Li, X.G.; Liu, X.Z.; Yan, J.Y. Enhancing fuel cell durability for fuel cell plug-in hybrid electric vehicles through strategic power management. Appl. Energy 2019, 241, 483–490.

- Kasimalla, V.K.; Srinivasulu, N.G.; Velisala, V. A review on energy allocation of fuel cell/battery/ultracapacitor for hybrid electric vehicles. Int. J. Energy Res. 2018, 42, 4263–4283.

- Alcazar-Garcia, D.; Martinez, J.L.R. Model-based design validation and optimization of drive systems in electric, hybrid, plug-in hybrid and fuel cell vehicles. Energy 2022, 254, 123719.

- Sulaiman, N.; Hannan, M.A.; Mohamed, A.; Ker, P.J.; Majlan, E.H.; Daud, W.R.W. Optimization of energy management system for fuel-cell hybrid electric vehicles: Issues and recommendations. Appl. Energy 2018, 228, 2061–2079.

- Li, Q.; Yang, H.Q.; Han, Y.; Li, M.; Chen, W.R. A state machine strategy based on droop control for an energy management system of PEMFC-battery-supercapacitor hybrid tramway. Int. J. Hydrogen Energy 2016, 41, 16148–16159.

- He, H.; Jia, C.; Li, J. A new cost-minimizing power-allocating strategy for the hybrid electric bus with fuel cell/battery health-aware control. Int. J. Hydrogen Energy 2022, 47, 22147–22164.

- Pisal, P.S.; Vidyarthi, D.A. An optimal control for power management in super capacitors/battery of electric vehicles using Deep Neural Network. J. Power Sources 2022, 542, 231696.

- Li, S.Q.; He, H.W.; Zhao, P.F. Energy management for hybrid energy storage system in electric vehicle: A cyber-physical system perspective. Energy 2021, 230, 120890.

- Iqbal, M.; Becherif, M.; Ramadan, H.S.; Badji, A. Dual-layer approach for systematic sizing and online energy management of fuel cell hybrid vehicles. Appl. Energy 2021, 300, 117345.

- Fu, Z.; Zhu, L.; Tao, F.; Si, P.; Sun, L. Optimization based energy management strategy for fuel cell/battery/ultracapacitor hybrid vehicle considering fuel economy and fuel cell lifespan. Int. J. Hydrogen Energy 2020, 45, 8875–8886.

- Luo, Y.; Wu, Y.; Li, B.; Qu, J.; Feng, S.-P.; Chu, P.K. Optimization and cutting-edge design of fuel-cell hybrid electric vehicles. Int. J. Energy Res. 2021, 45, 18392–18423.

- Das, H.S.; Tan, C.W.; Yatim, A.H.M. Fuel cell hybrid electric vehicles: A review on power conditioning units and topologies. Renew. Sustain. Energy Rev. 2017, 76, 268–291.

- Lu, X.; Qu, Y.; Wang, Y.; Qin, C.; Liu, G. A comprehensive review on hybrid power system for PEMFC-HEV: Issues and strategies. Energy Convers. Manag. 2018, 171, 1273–1291.

- Zhou, W.; Yang, L.; Cai, Y.S.; Ying, T.X. Dynamic programming for new energy vehicles based on their work modes Part II: Fuel cell electric vehicles. J. Power Sources 2018, 407, 92–104.

More