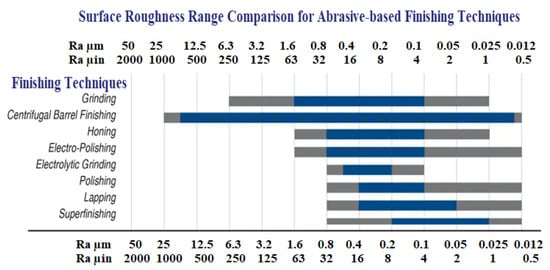

Various manufacturing industries have been using conventional procedures for finishing the components, such as grinding, honing, lapping, etc., to get the machining components’ desired finishing. However, these conventional procedures of finishing are restricted to very few geometries and cannot work on complex and intricate geometries as well as complicated profiles for finishing of high level, which is required while the operation of the component is in process. These limitations and restrictions in the finishing process have led the industries to develop advanced finishing procedures, known as “Abrasive flow machining (AFM)”. Advances in technology and refinement of available computational resources paved the way for the extensive use of computers to model and simulate complex real-world problems difficult to solve analytically. The appeal of simulations lies in the ability to predict the significance of a change to the system under study. The simulated results can be of great benefit in predicting various behaviors, such as the wind pattern in a particular region, the ability of a material to withstand a dynamic load, or even the behavior of a workpiece under a particular type of machining.

- abrasive-based machining processes

- AFM process

- molecular dynamic simulation

- artificial intelligence

- regression analysis

1. Introduction

1.1. An Overview of Abrasive-Based Machining Processes and Their Types

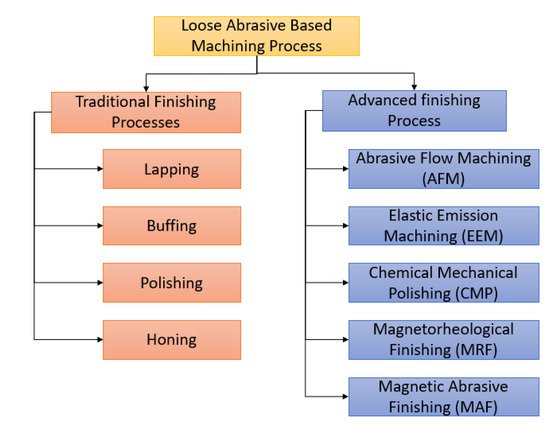

1.1.1. Loose Abrasive-Based Machining Processes

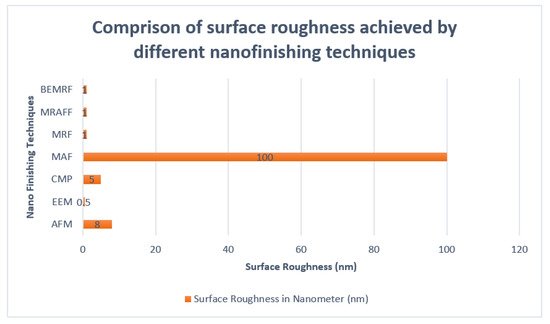

| S. No. | Loose Abrasive-Based Method | Typical Materials | Principle | Average Surface Roughness (Ra µm) | Application | Ref. | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1. | Traditional Finishing Processes | Lapping | Metals | Harden the trapped partials between the surface of the workpiece and a soft counter formal surface | 0.05 µm to 2.5 µm | Improving the surface finish in loose abrasive-based machining | [28] | |||||

| Buffing and Polishing | Metal and wood | Finishing the surface is performed through a wheel or an abrasive | 0.1 µm to 0.41 µm | Smoothing the material | [29] | |||||||

| Super abrasive machining | Titanium, nickel-based alloys and metal matrix composites, etc. | Finishing of Hard surfaces using polycrystalline diamond (PCD) or polycrystalline cubic boron nitride (PCBN) tools | 0.0127 µm–0.203 µm | Hard materials | [28] | |||||||

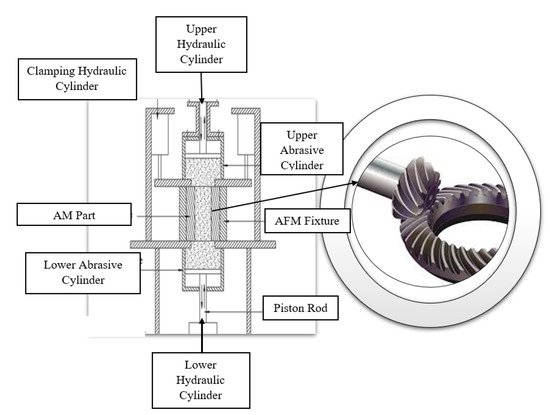

| 2 | Advanced finishing Process | Abrasive Flow Machining (AFM) | Hardened steel | Removing material from the surface of the material using sliding of abrasive particles of another material | 0.184 µm | Can deal with complex components | [26, | [ | 28, | 26 | 30] | ][28][30] |

| Elastic Emission Machining (EEM) | silicon | removing the material atom by atom with no cracks, deformation, or deep indentations | Less than 0.0005 µm | Removing material in loose abrasive-based machining | [28,30,31] | [28][30][31] | ||||||

| Chemical Mechanical Polishing (CMP) | silicon | A layer is formed between the workpiece and the slurry by chemical reaction. This layer is softer than the material of the original workpiece, which can be easily removed. | 0.005 µm to 0.01 µm | used in the finishing of the wafers made from silicon | [28,30,32] | [28][30][32] | ||||||

| Magnetic Abrasive Finishing (MAF) | silicon nitride | In this process, ferromagnetic particles are mixed with the particles of the workpiece. This mixture is brought close to the surface of the workpiece to be finished. | Less than 0.01 µm | Finishing the surface of nano-chips | ||||||||

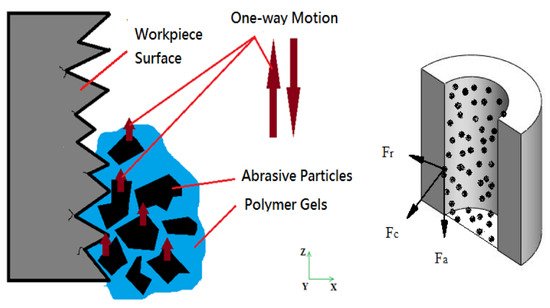

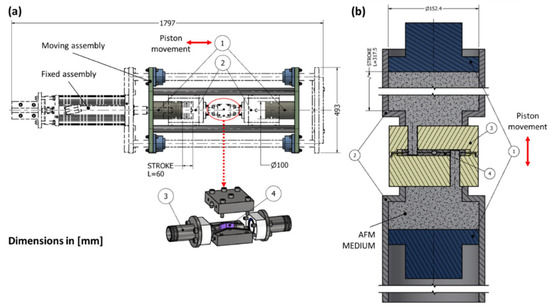

1.1.2. Abrasive Flow Machining (AFM)

1.1.3. Developments in AFM Process

-

“Elastic deformation”: it correlates with rubbing

-

“Plastic deformation (ploughing)”: it correlates with the material being displaced without being alleviated.

| [ | ||||||

| 28 | ||||||

| , | ||||||

| 30 | ||||||

| ] | ||||||

| [ | ||||||

| 28 | ||||||

| ] | [ | 30 | ] | |||

| Magnetorheological Finishing (MRF) | Flat BG7 glass | To finish the surface in this process, magnetorheological fluid (MR fluid) is used. This fluid consists of iron particles, carbonyl iron particles (CIPs), carrier fluid, and abrasive particles. The viscosity of this fluid is increased when it comes under the effect of the magnetic field. The CIPS arrange along the magnetic force line, and then the abrasive particles are entangled within the chains, and their motion causes the material removal |

Less than 0.001 µm | Finishing micro/Nano-chips | [28,30] | [28][30] |

| Magnetorheological Abrasive Flow Finishing (MRAFF) | This method is an extended version of MRF. the extrusion of the medium of the magnetorheological polishing is performed through the surface of the workpiece | Less than 0.001 µm | Finishing softer material than MRF | [30,33,34] | [30][33][34] | |

| Ball end Magnetorheological Finishing (BEMRF) | Metal mirror and glass | for the finishing, this process uses the rotating spot of the stiffened MR fluid | Less than 0.001 µm | Used in the finishing of the complex 3d geometry | [35] |

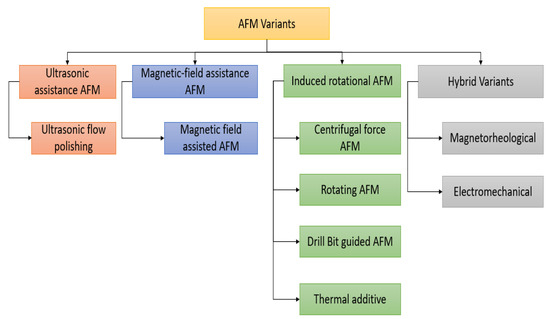

| S. No. | AFM Variants | Working Principles | Working Polishing Fluid (Media) | Commercial Process Names | ||||

|---|---|---|---|---|---|---|---|---|

| 1. | Ultrasonic-assistance | Use of ultrasonic vibration along the AFM fixture | Viscoelastic polymer-based media | Ultrasonic float polishing (UFP) Ultrasonic-assisted AFM (UAAFM) |

||||

| 2. | Rotational-assistance | Rotating the AFM fixture | Viscoelastic polymer-based media | Rotational AFF (R-AFF) Drill bit guided AFM (DBG-AFM) Helical AFM (HLX-AFM) |

||||

| 3. | Magnetic-assistance | Use of permanent magnet | Magnetic abrasive-based media | Magnetic AFM (MAFM) | ||||

| 4. | Magnetorheological assistance | Use of Electro-magnet and magnetorheological (MR) fluid | MR fluid-based media | Magnetorheological AFF AFF (MRAFF) Rotational-MRAFF (R-MRAFF) |

||||

| 4. | Electro-chemical assistance | Use of Electrochemical machining process along with AFM process | Electrolytes and Viscoelastic polymer-based media | Electro-chemical assisted AFM(ECAFM) Electro-chemical and Centrifugal force-assisted AFM (EC | 2 | A | 2 | FM) |

| 5 | Centrifugal force assistance | Use of Centrifugal forces | Viscoelastic polymer-based media | Centrifugal force-assisted AFM (CFAAFM) Thermal Additive centrifugal AFM (TACAFM) |

| S. No. | Ref. | Typical Materials | Application | Surface Roughness (µm) |

|---|---|---|---|---|

| 1. | Guo et al., 2020 [83] | Inconel 718 | AM parts | Ra 0.1 μm was the final surface roughness value. |

| 2. | Mali et al., 2018 [84] | ABS | FDM printed parts | Change in Ra 21.37 μm for the external surface and 6.27 μm for the internal surface was found. |

| 3. | Subramanian et al., 2016 [85] | Co-Cr alloy | Bio-implant, i.e., Hip Joint | It was found that the surface roughness decreased from beginning R, value 502 nm to final R, value 39 nm. |

| 4. | Kumar et al., 2015 [86] | Ti-6Al-4V | Bio-implant, i.e., Knee Joint | The final surface roughness was measured to be 35–78 nm. |

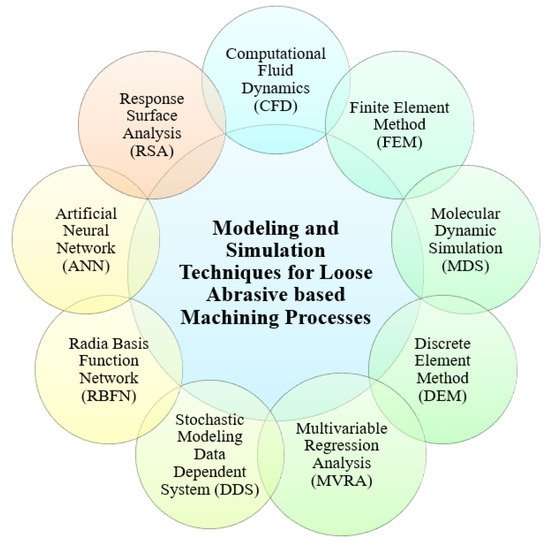

2. Mathematical Modeling and Simulation Approaches for Abrasive Machining Processes

Classification of Modeling and Simulation Techniques for Abrasive-Based Machining Processes

3. Review of Simulation Techniques for Abrasive-Based Machining Processes

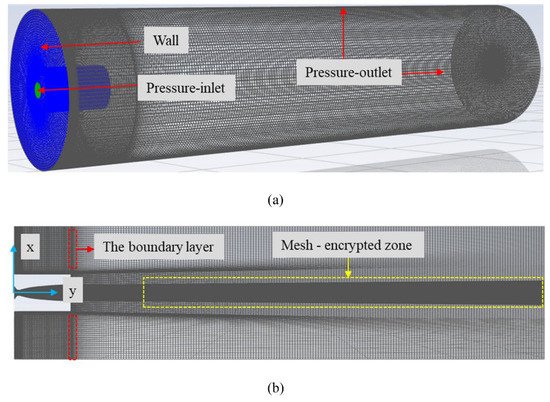

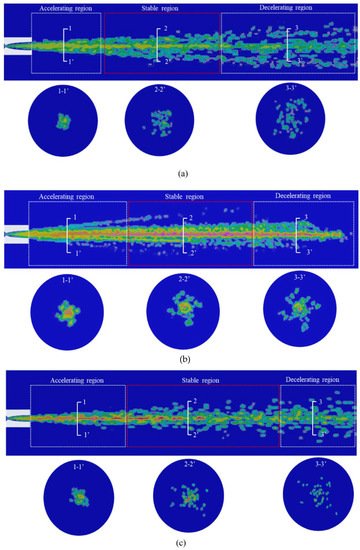

3.1. Computational Fluid Dynamics (CFD)

3.1.1. Pre-Processing

3.1.2. Meshing

3.1.3. Solving

3.1.4. Post-Processing

3.1.5. Applications

| References | Work-Piece Material | Type of Abrasive-Based Process | Important Input and Output Variable Considered | Software Tool | Remarks | |||

|---|---|---|---|---|---|---|---|---|

| [94] | [119] | hard materials | Magnetic field-assisted finishing (MFAF) | Continuity and momentum | - | The active abrasive grain axial force is higher than the force of the reaction due to the strength of the material. CFD is an effective tool for predicting the surface roughness in abrasive flow-based machining. |

||

| [93] | [120] | Silicon carbide | Abrasive flow machining (AFM) | Shear modulus, elastic modulus, damping factor, stiffness | ANSYS CFX | CFD is an effective tool for predicting the surface roughness in abrasive flow-based machining. | ||

| [115] | [100] | - | Abrasive flow machining (AFM) | “Density, the extrusion pressure, piston velocity, abrasive hardness, particle hardness and media viscosity, workpiece hardness.” |

ANSYS FLUENT | The process was a precision finishing operation. Therefore, the removed material is low. This amount can be increased with the increase in the number of cycles. The modeling and the simulation are very important due to the high number of parameters | ||

| [121] | [106] | Visco-elastic materials | “Ultrasonic assisted abrasive flow machining (UAAFM)” | “Fluid pressure, the velocity profile of the fluid, temperature distribution in the working fluid, wall shear, angle of impact, and finishing rate” | Commercial simulation tool for CFD | The impact angle ‘ | θ | ’ plays a major role in the machining process and improves effectiveness. Wall shear helps predict if the process has better finishing rates. |

| [134] | [121] | Turbine blades | Abrasive wear | Size and shape of quartz particles, leakage flow through clearance gaps, blade life, and efficiency. | When compared with the data from the actual erosion in turbines, the CFD results give more information. The leakage flow through clearance gaps of guide vanes causes erosion in the runner blade inlet. |

References

- Sushil, M.; Vinod, K.; Harmesh, K. Experimental Investigation and Optimization of Process Parameters of Al/SiC MMCs Finished by Abrasive Flow Machining. Mater. Manuf. Process. 2015, 30, 902–911.

- Dixit, N.; Sharma, V.; Kumar, P. Experimental investigations into abrasive flow machining (AFM) of 3D printed ABS and PLA parts. Rapid Prototyp. J. 2021, 28, 161–174.

- Wang, X.; Li, S.; Fu, Y.; Gao, H. Finishing of additively manufactured metal parts by abrasive flow machining. In Proceedings of the 2016 International Solid Freeform Fabrication Symposium, University of Texas at Austin, Austin, TX, USA, 8–10 August 2016; p. 3.

- Sun, W.; Yao, B.; Chen, B.; He, Y.; Cao, X.; Zhou, T.; Liu, H. Noncontact Surface Roughness Estimation Using 2D Complex Wavelet Enhanced ResNet for Intelligent Evaluation of Milled Metal Surface Quality. Appl. Sci. 2018, 8, 381.

- Bremerstein, T.; Potthoff, A.; Michaelis, A.; Schmiedel, C.; Uhlmann, E.; Blug, B.; Amann, T. Wear of abrasive media and its effect on abrasive flow machining results. Wear 2015, 342–343, 44–51.

- Han, S.; Salvatore, F.; Rech, J.; Bajolet, J. Abrasive flow machining (AFM) finishing of conformal cooling channels created by selective laser melting (SLM). Precis. Eng. 2020, 64, 20–33.

- Rhoades , L. Abrasive flow machining: A case study. J. Mater. Processing Technol. 1991, 28, 107–116.

- Sambharia, J.; Mali, H.S. Characterization and optimization of rheological parameters of polymer abrasive gel for abrasive flow machining. J. Mater. Sci. Surf. Eng. 2017, 5, 549–555.

- Petare, A.C.; Jain, N.K. Improving spur gear microgeometry and surface finish by AFF process. Mater. Manuf. Process. 2018, 33, 923–934.

- Mali, H.S.; Sambharia, J. Developing alternative polymer abrasive gels for abrasive flow finishing process. In Proceedings of the 5th International & 26th All India Manufacturing Technology, Design and Research Conference (AIMTDR 2014), Guwahati, India, 12–14 December 2014; pp. 12–14.

- Basha, S.M.; Basha, M.M.; Venkaiah, N.; Sankar, M.R. A review on abrasive flow finishing of metal matrix composites. Mater. Today Proc. 2021, 44, 579–586.

- Azami, A.; Azizi, A.; Khoshanjam, A.; Hadad, M. A new approach for nanofinishing of complicated-surfaces using rotational abrasive finishing process. Mater. Manuf. Process. 2020, 35, 940–950.

- Aggarwal, A.; Singh, A.K. Development of grinding wheel type magnetorheological finishing process for blind hole surfaces. Mater. Manuf. Process. 2021, 36, 457–478.

- Mali, H.S.; Manna, A. Simulation of surface generated during abrasive flow finishing of Al/SiCp-MMC using neural networks. Int. J. Adv. Manuf. Technol. 2012, 61, 9–12.

- Sankar, M.R.; Ramkumar, J.; Jain, V.K. Experimental investigation and mechanism of material removal in nano finishing of MMCs using abrasive flow finishing (AFF) process. Wear 2009, 266, 688–698.

- Sonia, P.; Jain, J.K.; Saxena, K.K. Influence of ultrasonic vibration assistance in manufacturing processes: A Review. Mater. Manuf. Process. 2021, 36, 1451–1475.

- Mulik, R.S.; Pandey, P.M. Mechanism of Surface Finishing in Ultrasonic-Assisted Magnetic Abrasive Finishing Process. Mater. Manuf. Process. 2010, 25, 1418–1427.

- Kala, P.; Kumar, S.; Pandey, P.M. Polishing of Copper Alloy Using Double Disk Ultrasonic Assisted Magnetic Abrasive Polishing. Mater. Manuf. Process. 2013, 28, 200–206.

- Walia, R.S.; Shan, H.S.; Kumar, P. Parametric Optimization of Centrifugal Force-Assisted Abrasive Flow Machining (CFAAFM) by the Taguchi Method. Mater. Manuf. Process. 2006, 21, 375–382.

- Mali, H.S.; Manna, A. Current status and application of abrasive flow finishing processes: A review. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2009, 223, 809–820.

- Jain, V.; Adsul, S. Experimental investigations into abrasive flow machining (AFM). Int. J. Mach. Tools Manuf. 2000, 40, 1003–1021.

- Shekhar, M.; Yadav, S. Diamond abrasive based cutting tool for processing of advanced engineering materials: A review. Mater. Today Proc. 2020, 22, 3126–3135.

- Ali, P.; Dhull, S.; Walia, R.; Murtaza, Q.; Tyagi, M. Hybrid Abrasive Flow Machining for Nano Finishing—A Review. Mater. Today Proc. 2017, 4, 7208–7218.

- Sankar, M.R.; Jain, V.K.; Ramkumar, J.; Joshi, Y.M. Rheological characterization of styrene-butadiene based medium and its finishing performance using rotational abrasive flow finishing process. Int. J. Mach. Tools Manuf. 2011, 51, 947–957.

- Sankar, M.R.; Jain, V.K.; Rajurkar, K.P. Nano-finishing studies using elastically dominant polymers blend abrasive flow finishing medium. Procedia CIRP 2018, 68, 529–534.

- Cheng, K.C.; Wang, A.C.; Chen, K.Y.; Huang, C.Y. Study of the Polishing Characteristics by Abrasive Flow Machining with a Rotating Device. Processes 2022, 10, 1362.

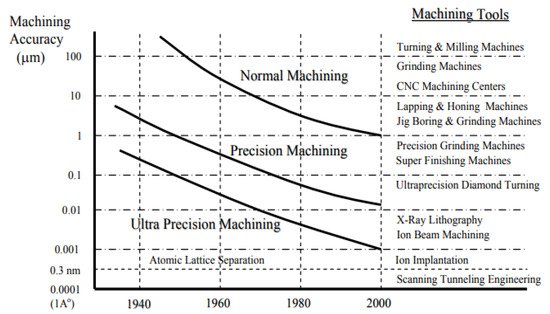

- Taniguchi, N. Current Status in, and Future Trends of, Ultraprecision Machining and Ultrafine Materials Processing. CIRP Ann. 1983, 32, 573–582.

- Jain, V.K. Nanofinishing Science and Technology; CRC Press: Boca Raton, FL, USA, 2017.

- Chang, Y.-H.; Tsay, Y.-S.; Huang, C.-T.; Tseng’s, W.-L. The moisture buffering effect of finishing coatings on wooden materials. In Indoor Air; Blackwell Munksgaard: Ghent, Belgium, 2016.

- Kumar, M.; Alok, A.; Kumar, V.; Das, M. Advanced abrasive-based nano-finishing processes: Challenges, principles and recent applications. Mater. Manuf. Process. 2022, 37, 372–392.

- Mori, Y.; Yamauchi, K.; Endo, K. Elastic emission machining. Precis. Eng. 1987, 9, 123–128.

- Tian, Y.B.; Ang, Y.J.; Zhong, Z.W.; Xu, H.; Tan, R. Chemical Mechanical Polishing of Glass Disk Substrates: Preliminary Experimental Investigation. Mater. Manuf. Process. 2013, 28, 488–494.

- Kathiresan, S.; Mohan, B. Experimental Analysis of Magneto Rheological Abrasive Flow Finishing Process on AISI Stainless steel 316L. Mater. Manuf. Process. 2018, 33, 422–432.

- Das, M.; Jain, V.; Ghoshdastidar, P. Fluid flow analysis of magnetorheological abrasive flow finishing (MRAFF) process. Int. J. Mach. Tools Manuf. 2008, 48, 415–426.

- Kumar, A.; Alam, Z.; Khan, D.A.; Jha, S. Nanofinishing of FDM-fabricated components using ball end magnetorheological finishing process. Mater. Manuf. Process. 2019, 34, 232–242.

- Peng, C.; Fu, Y.; Wei, H.; Li, S.; Wang, X.; Gao, H. Study on Improvement of Surface Roughness and Induced Residual Stress for Additively Manufactured Metal Parts by Abrasive Flow Machining. Procedia CIRP 2018, 71, 386–389.

- Guo, C.; Shi, Z.; Mullany, B.A.; Linke, B.S.; Yamaguchi, H.; Chaudhari, R.; Hucker, S.; Shih, A. Recent Advancements in Machining With Abrasives. J. Manuf. Sci. Eng. 2020, 142, 11.

- Wan, S.; Ang, Y.J.; Sato, T.; Lim, G.C. Process modeling and CFD simulation of two-way abrasive flow machining. Int. J. Adv. Manuf. Technol. 2014, 71, 1077–1086.

- Hamdi, H.; Valiorgue, F.; Mabrouki, T. Material Removal Processes by Cutting and Abrasion: Numerical Methodologies, Present Results and Insights. In Thermomechanical Industrial Processes; Bergheau, J.-M., Ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2014; pp. 187–246.

- Samoilenko, M.; Lanik, G.; Brailovski, V. Towards the Determination of Machining Allowances and Surface Roughness of 3D-Printed Parts Subjected to Abrasive Flow Machining. J. Manuf. Mater. Process. 2021, 5, 111.

- Sankar, M.R.; Jain, V.K.; Ramkumar, J. Abrasive flow machining (AFM): An Overview. In Proceedings of the INDO-US Workshop on Smart Machine Tools, Intelligent Machining Systems and Multi-Scale Manufacturing, Tamil Nadu, India, 18 December 2008; p. 10.

- Li, J.; Sun, F.; Wei, L.; Zhang, X.; Xu, Y. The single factor experiment of the non-linear tube in abrasive flow machining. J. Meas. Eng. 2017, 5, 11–18.

- Li, X.; Li, Q.; Ye, Z.; Zhang, Y.; Ye, M.; Wang, C. Surface Roughness Tuning at Sub-Nanometer Level by Considering the Normal Stress Field in Magnetorheological Finishing. Micromachines 2021, 12, 997.

- Jackson, M.J. Recent advances in ultraprecision abrasive machining processes. SN Appl. Sci. 2020, 2, 7.

- Kumari, C.; Chak, S.K. A review on magnetically assisted abrasive finishing and their critical process parameters. Manuf. Rev. 2018, 5, 13.

- Sambharia, J.K.; Mali, H.S.; Garg, V. Experimental investigation on unidirectional abrasive flow machining of trim die workpiece. Mater. Manuf. Process. 2018, 33, 651–660.

- Das, M.; Jain, V.K.; Ghoshdastidar, P.S. Analysis of magnetorheological abrasive flow finishing (MRAFF) process. Int. J. Adv. Manuf. Technol. 2008, 38, 613–621.

- Chawla, G.; Mittal, V.K.; Mittal, S. Experimental Investigation of Process Parameters of Al-SiC-B4C MMCs Finished by a Novel Magnetic Abrasive Flow Machining Setup. Walailak J. Sci. Technol. 2021, 18, 18.

- Bhardwaj, A.; Ali, P.; Walia, R.S.; Murtaza, Q.; Pandey, S.M. Development of Hybrid Forms of Abrasive Flow Machining Process: A Review. In Advances in Industrial and Production Engineering; Springer: Berlin/Heidelberg, Germany, 2019; pp. 41–67.

- Gov, K.; Eyercioglu, O. Effects of abrasive types on the surface integrity of abrasive-flow-machined surfaces. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2016, 232, 1044–1053.

- Tzeng, H.-J.; Yan, B.-H.; Hsu, R.-T.; Chow, H.-M. Finishing effect of abrasive flow machining on micro slit fabricated by wire-EDM. Int. J. Adv. Manuf. Technol. 2007, 34, 649–656.

- Tzeng, H.-J.; Yan, B.-H.; Hsu, R.-T.; Lin, Y.-C. Self-modulating abrasive medium and its application to abrasive flow machining for finishing micro channel surfaces. Int. J. Adv. Manuf. Technol. 2007, 32, 1163–1169.

- Ferchow, J.; Baumgartner, H.; Klahn, C.; Meboldt, M. Model of surface roughness and material removal using abrasive flow machining of selective laser melted channels. Rapid Prototyp. J. 2020, 26, 1165–1176.

- Kumari, C.; Chak, S.K. Study on influential parameters of hybrid AFM processes: A review. Manuf. Rev. 2019, 6, 23.

- Orbital and/or Reciprocal Machining with a Viscous Plastic Medium. 1 November 1989. Available online: https://patents.google.com/patent/CA2001970C/en (accessed on 18 January 2022).

- Xu, Y.C.; Zhang, K.H.; Lu, S.; Liu, Z.Q. Experimental Investigations into Abrasive Flow Machining of Helical Gear. Key Eng. Mater. 2013, 546, 65–69.

- Dhull, S.; Mishra, R.; Walia, R.; Murtaza, Q.; Niranjan, M. Innovations in Different Abrasive Flow Machining Processes: A Review. J. Physics Conf. Ser. 2021, 1950, 012048.

- Li, Y.; Ren, C.; Wang, H.; Hu, Y.; Ning, F.; Wang, X.; Cong, W. Edge surface grinding of CFRP composites using rotary ultrasonic machining: Comparison of two machining methods. Int. J. Adv. Manuf. Technol. 2019, 100, 3237–3248.

- Wang, H.; Ning, F.; Hu, Y.; Cong, W. Surface grinding of CFRP composites using rotary ultrasonic machining: A comparison of workpiece machining orientations. Int. J. Adv. Manuf. Technol. 2018, 95, 2917–2930.

- Wang, H.; Cong, W.; Ning, F.; Hu, Y. A study on the effects of machining variables in surface grinding of CFRP composites using rotary ultrasonic machining. Int. J. Adv. Manuf. Technol. 2018, 95, 3651–3663.

- Dixit, N.; Sharma, V.; Kumar, P. Research trends in abrasive flow machining: A systematic review. J. Manuf. Process. 2021, 64, 1434–1461.

- Ge, J.-Q.; Ren, Y.-L.; Xu, X.-S.; Li, C.; Li, Z.-A.; Xiang, W.-F. Numerical and experimental study on the ultrasonic-assisted soft abrasive flow polishing characteristics. Int. J. Adv. Manuf. Technol. 2021, 112, 3215–3233.

- Wang, J.; Zhu, J.; Liew, P.J. Material Removal in Ultrasonic Abrasive Polishing of Additive Manufactured Components. Appl. Sci. 2019, 9, 5359.

- Li, J.; Zhu, F.; Yu, J. An ultrasonic-assisted soft abrasive flow processing method for mold structured surfaces. Adv. Mech. Eng. 2019, 11, 1–17.

- Wang, T.; Chen, D.; Zhang, W.; An, L. Study on key parameters of a new abrasive flow machining (AFM) process for surface finishing. Int. J. Adv. Manuf. Technol. 2019, 101, 39–54.

- Walia, R.S.; Shan, H.; Kumar, P. Modelling of Centrifugal-Force-Assisted Abrasive Flow Machining. 2009. Available online: https://www.semanticscholar.org/paper/Modelling-of-centrifugal-force-assisted-abrasive-Walia-Shan/d191af51ec105ef9d349682af75a7cbaf0d7c109 (accessed on 21 November 2021).

- Bradley, C.; Wong, Y. Surface Texture Indicators of Tool Wear—A Machine Vision Approach. Int. J. Adv. Manuf. Technol. 2001, 17, 435–443.

- Hashmi, A.W.; Mali, H.S.; Meena, A.; Khilji, I.A.; Chilakamarry, C.R.; Saffe, S.N.B.M. Experimental investigation on magnetorheological finishing process parameters. Mater. Today Proc. 2021, 48, 1892–1898.

- Jha, S.; Jain, V.K. Design and development of the magnetorheological abrasive flow finishing (MRAFF) process. Int. J. Mach. Tools Manuf. 2004, 44, 1019–1029.

- Sankar, M.R.; Taye, D.; Manohar, M.; Sarkar, D.; Basu, B. Nano Finishing of HDPE/Al2O3/HAp Ternary Composite Based Acetabular Socket using Polymer Rheological Abrasive Semisolid Medium. Int. J. Nanobiotechnology 2016, 2, 5–8.

- Ali, P.; Walia, R.S.; Murtaza, Q.; Singari, R. Material Removal Analysis of Hybrid EDM-Assisted Centrifugal Abrasive Flow Machining Process for Performance Enhancement. 2020. Available online: https://www.semanticscholar.org/paper/Material-removal-analysis-of-hybrid-EDM-assisted-Ali-Walia/fcf01761d2c2e7ac5db54cdfcc79025aa51855de (accessed on 21 November 2021).

- Brar, B.S.; Walia, R.S.; Singh, V.P. Electrochemical-aided abrasive flow machining (ECA2FM) process: A hybrid machining process. Int. J. Adv. Manuf. Technol. 2015, 79, 329–342.

- Singh, S.; Sankar, M.R.; Jain, V.K.; Ramkumar, J. Modeling of Finishing Forces and Surface Roughness in Abrasive Flow Finishing (AFF) Process using Rheological Properties. In Proceedings of the 5th International & 26th All India Manufacturing Technology, Design and Research Conference (AIMTDR 2014), Assam, India, 12–14 December 2014; p. 6.

- Jayant, V.K.J. Analysis of finishing forces and surface finish during magnetorheological abrasive flow finishing of asymmetric workpieces. J. Micromanufacturing 2019, 2, 133–151.

- Li, J.; Wang, L.; Zhang, H.; Hu, J.; Zhang, X.-M.; Zhao, W. Mechanism Research and Quality Discussion on Precision Machining of Fifth-Order Variable-Diameter Pipe by Abrasive Flow. 2020. Available online: https://www.semanticscholar.org/paper/Mechanism-Research-and-Quality-Discussion-on-of-by-Li-Wang/76744b89f28eb96660f0a5a4e306fbe985b2125f (accessed on 18 January 2022).

- Dabrowski, L.; Marciniak, M.; Szewczyk, T. Analysis of Abrasive Flow Machining with an Electrochemical Process Aid. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2006, 220, 397–403.

- Kumar, S.S.; Hiremath, S.S. A Review on Abrasive Flow Machining (AFM). Procedia Technol. 2016, 25, 1297–1304.

- Wang, X.; Williams, R.E.; Sealy, M.P.; Rao, P.K.; Guo, Y. Stochastic Modeling and Analysis of Spindle Power During Hard Milling With a Focus on Tool Wear. J. Manuf. Sci. Eng. 2018, 140, 111011.

- Jain, N.K.; Jain, V.K.; Deb, K. Optimization of process parameters of mechanical type advanced machining processes using genetic algorithms. Int. J. Mach. Tools Manuf. 2007, 47, 900–919.

- Dhull, S.; Murtaza, Q.; Walia, R.S.; Niranjan, M.S.; Vats, S. Abrasive Flow Machining Process Hybridization with Other Non-Traditional Machining Processes: A Review. In International Conference in Mechanical and Energy Technology; Springer: Singapore, 2020; pp. 101–109.

- Vaishya, R.; Walia, R.; Kalra, P. Design and Development of Hybrid Electrochemical and Centrifugal Force Assisted Abrasive Flow Machining. Mater. Today Proc. 2015, 2, 3327–3341.

- Uhlmann, E.; Roßkamp, S. Modelling of Material Removal in Abrasive Flow Machining. Int. J. Autom. Technol. 2018, 12, 883–891.

- Guo, J.; Song, C.; Fu, Y.; Au, K.H.; Kum, C.W.; Goh, M.H.; Ren, T.; Huang, R.; Sun, C.-N. Internal Surface Quality Enhancement of Selective Laser Melted Inconel 718 by Abrasive Flow Machining. J. Manuf. Sci. Eng. 2020, 142, 101003.

- Mali, H.S.; Prajwal, B.; Gupta, D.; Kishan, J. Abrasive flow finishing of FDM printed parts using a sustainable media. Rapid Prototyp. J. 2018, 24, 593–606.

- Subramanian, K.T.; Balashanmugam, N.; Shashi Kumar, P.V. Nanometric finishing on biomedical implants by abrasive flow finishing. J. Inst. Eng. Ser. C 2016, 97, 55–61.

- Kumar, S.; Jain, V.K.; Sidpara, A. Nanofinishing of freeform surfaces (knee joint implant) by rotational-magnetorheological abrasive flow finishing (R-MRAFF) process. Precis. Eng. 2015, 42, 165–178.

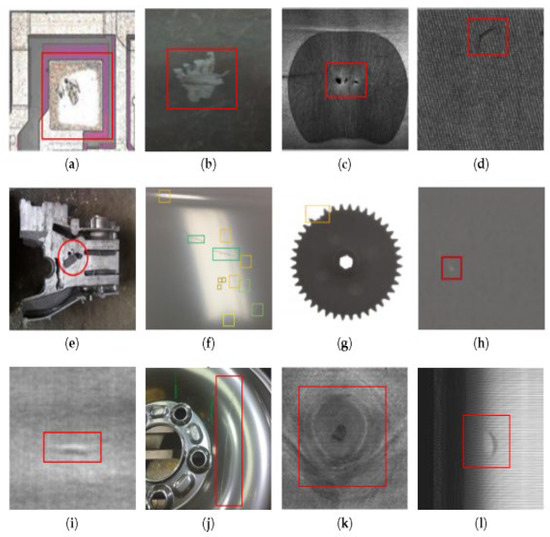

- Yang, J.; Li, S.; Wang, Z.; Dong, H.; Wang, J.; Tang, S. Using Deep Learning to Detect Defects in Manufacturing: A Comprehensive Survey and Current Challenges. Materials 2020, 13, 5755.

- Uhlmann, E.; Schmiedel, C.; Wendler, J. CFD Simulation of the Abrasive Flow Machining Process. Procedia CIRP 2015, 31, 209–214.

- Das, M.; Jain, V.K.; Ghoshdastidar, P. A 2D CFD simulation of MR polishing medium in magnetic field-assisted finishing process using electromagnet. Int. J. Adv. Manuf. Technol. 2015, 76, 173–187.

- Jain, K.; Jain, V.K. Stochastic simulation of active grain density in abrasive flow machining. J. Mater. Process. Technol. 2004, 1, 17–22.

- Mohammadian, N.; Turenne, S.; Brailovski, V. Surface finish control of additively-manufactured Inconel 625 components using combined chemical-abrasive flow polishing. J. Mater. Processing Technol. 2018, 252, 728–738.

- Williams, R.E.; Rajurkar, K.P. Stochastic Modeling and Analysis of Abrasive Flow Machining. J. Eng. Ind. 1992, 114, 74–81.

- Dash, R.; Maity, K. Simulation of abrasive flow machining process for 2D and 3D mixture models. Front. Mech. Eng. 2015, 10, 424–432.

- Sambharia, J.; Mali, H.S. Recent developments in abrasive flow finishing process: A review of current research and future prospects. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2019, 233, 388–399.

- Petare, A.C.; Jain, N.K. A critical review of past research and advances in abrasive flow finishing process. Int. J. Adv. Manuf. Technol. 2018, 97, 741–782.

- Chih-Hua, W.; Wai, K.C.; Ming, W.S.Y.; Muhammad, A.B.A. Numerical and experimental investigation of abrasive flow machining of branching channels. Int. J. Adv. Manuf. Technol. 2020, 108, 2945–2966.

- Fu, Y.; Wang, X.; Gao, H.; Wei, H.; Li, S. Blade surface uniformity of blisk finished by abrasive flow machining. Int. J. Adv. Manuf. Technol. 2016, 84, 1725–1735.

- Shen, R.; Jiao, Z.; Parker, T.; Sun, Y.; Wang, Q. Recent application of Computational Fluid Dynamics (CFD) in process safety and loss prevention: A review. J. Loss Prev. Process Ind. 2020, 67, 104252.

- Matko, T.; Chew, J.; Wenk, J.; Chang, J.; Hofman, J. Computational fluid dynamics simulation of two-phase flow and dissolved oxygen in a wastewater treatment oxidation ditch. Process Saf. Environ. Prot. 2021, 145, 340–353.

- Badshah, M.; Badshah, S.; Jan, S. Comparison of computational fluid dynamics and fluid structure interaction models for the performance prediction of tidal current turbines. J. Ocean Eng. Sci. 2020, 5, 164–172.

- Maity, K.P.; Dash, R. Modelling of Material Removal in Abrasive Flow Machining Process Using CFD simulation. J. Basic Appl. Eng. Res. 2014, 2, 73–78.

- Jeon, D.H. Computational fluid dynamics simulation of anode-supported solid oxide fuel cells with implementing complete overpotential model. Energy 2019, 188, 116050.

- Yang, J. Computational fluid dynamics studies on the induction period of crude oil fouling in a heat exchanger tube. Int. J. Heat Mass Transf. 2020, 159, 120129.

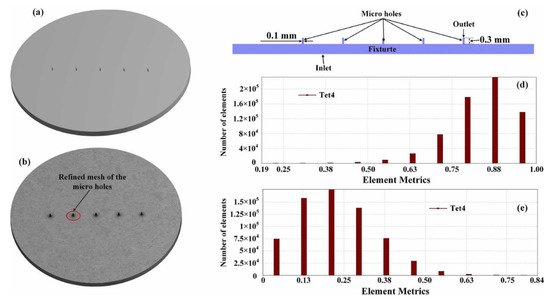

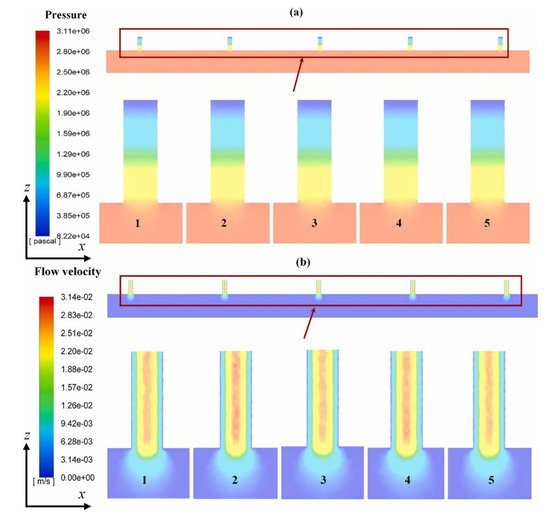

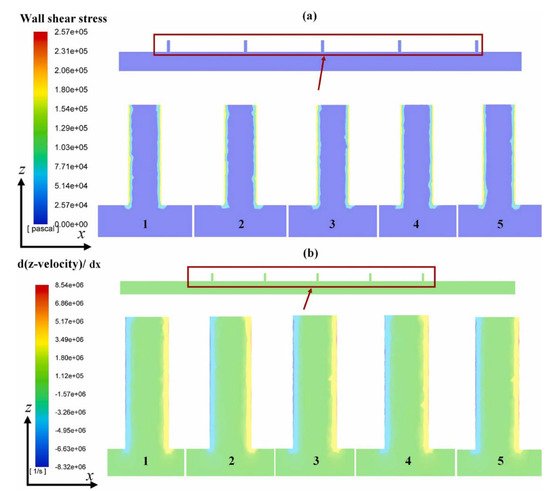

- Baraiya, R.; Babbar, A.; Jain, V.; Gupta, D. In-situ simultaneous surface finishing using abrasive flow machining via novel fixture. J. Manuf. Process. 2020, 50, 266–278.

- Melendez, J.; Reilly, D.; Duran, C. Numerical investigation of ventilation efficiency in a Combat Arms training facility using computational fluid dynamics modelling. Build. Environ. 2020, 188, 107404.

- Comminal, R.; da Silva, W.R.L.; Andersen, T.J.; Stang, H.; Spangenberg, J. Modelling of 3D concrete printing based on computational fluid dynamics. Cem. Concr. Res. 2020, 138, 106256.

- Gudipadu, V.; Sharma, A.K.; Singh, N. Simulation of media behaviour in vibration assisted abrasive flow machining. Simul. Model. Pr. Theory 2015, 51, 1–13.

- Kim, K.J.; Kim, Y.G.; Kim, K.H. Characterization of deburring by abrasive flow machining for AL6061. Appl. Sci. 2022, 12, 2048.

- Fu, Y.; Gao, H.; Yan, Q.; Wang, X.; Wang, X. Rheological characterisation of abrasive media and finishing behaviours in abrasive flow machining. Int. J. Adv. Manuf. Technol. 2020, 107, 3569–3580.

- Pradhan, S.; Das, S.R.; Jena, P.C.; Dhupal, D. Machining performance evaluation under recently developed sustainable HAJM process of zirconia ceramic using hot SiC abrasives: An experimental and simulation approach. Proc. Inst. Mech. Eng. Part C: J. Mech. Eng. Sci. 2022, 236, 1009–1035.

- Pradhan, S.; Dhupal, D.; Das, S.R.; Jena, P.C. Experimental investigation and optimization on machined surface of Si3N4 ceramic using hot SiC abrasive in HAJM. Mater. Today Proc. 2021, 44, 1877–1887.

- Amar, A.K.; Tandon, P. Investigation of gelatin enabled abrasive water slurry jet machining (AWSJM). CIRP J. Manuf. Sci. Technol. 2021, 33, 1–14.

- Zou, T.; Yan, Q.; Wang, L.; An, Y.; Qu, J.; Li, J. Research on quality control of precision machining straight internal gear by abrasive flow based on large eddy simulation. Int. J. Adv. Manuf. Technol. 2022, 119, 5315–5334.

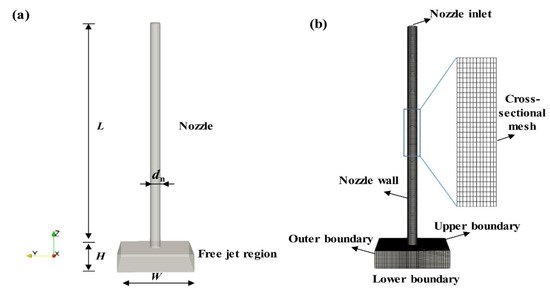

- Chen, C.; Liu, Y.; Tang, J.; Zhang, H. Effect of nozzle pressure ratios on the flow and distribution of abrasive particles in abrasive air jet machining. Powder Technol. 2022, 397, 117114.

- Zhang, B.-C.; Chen, S.-F.; Khiabani, N.; Qiao, Y.; Wang, X.-C. Research on the underlying mechanism behind abrasive flow machining on micro-slit structures and simulation of viscoelastic media. Adv. Manuf. 2022, 1–15.

- Zhang, B.; Qiao, Y.; Khiabani, N.; Wang, X. Study on rheological behaviors of media and material removal mechanism for abrasive flow machining (AFM) micro structures and corresponding simulations. J. Manuf. Process. 2021, 73, 248–259.

- Zhang, B.; Chen, S.; Wang, X. Machining uniformity and property change of abrasive media for micro-porous structures. J. Mater. Process. Technol. 2022, 307, 117675.

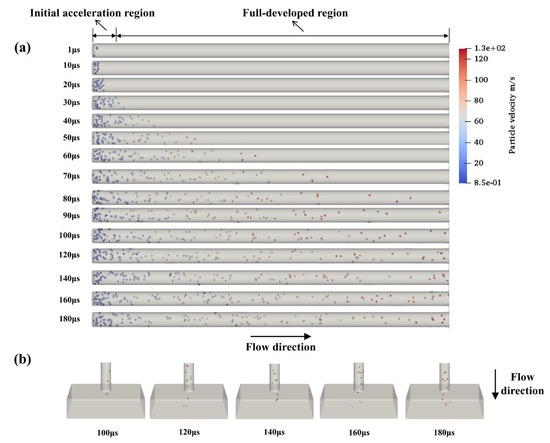

- Zhu, G.; Li, H.; Wang, Z.; Zhang, T.; Liu, M. Semi-resolved CFD-DEM modeling of gas-particle two-phase flow in the micro-abrasive air jet machining. Powder Technol. 2021, 381, 585–600.

- Hashmi, A.W.; Mali, H.S.; Meena, A. Experimental investigation on abrasive flow Machining (AFM) of FDM printed hollow truncated cone parts. Mater. Today Proc. 2022, 56, 1369–1375.

- Hashmi, A.W.; Mali, H.S.; Meena, A.; Khilji, I.A.; Hashmi, M.F.; Saffe, S.N.B.M. Artificial intelligence techniques for implementation of intelligent machining. Mater. Today Proc. 2022, 56, 1947–1955.

- Gautam, S.; Neopane, H.P.; Acharya, N.; Chitrakar, S.; Thapa, B.S.; Zhu, B. Sediment erosion in low specific speed francis turbines: A case study on effects and causes. Wear 2020, 442–443, 203152.