The triboelectric nanogenerator (TENG) developed by Z. L. Wang’s team to harvest random mechanical energy is a promising new energy source for distributed sensing systems in the new era of the internet of things (IoT) and artificial intelligence (AI) for a smart world. In industry and academia, fluid dynamics sensing for liquid and air is urgently needed but lacking. In particular, local fluid sensing is difficult and limited to traditional sensors. Fortunately, with advantages for ordinary TENGs and TENGs as fluid dynamics sensors, fluid dynamics sensing can be better realized.

- triboelectric nanogenerators

- fluid dynamics sensing

1. Introduction

2. Introduction of TENG

Coupling the triboelectric effect and electrostatic induction, TENG was first invented by Wang’s group in 2012 to generate electricity through harvesting environmental mechanical energy that is ubiquitous but often wasted. More specifically, the electricity is converted by electrostatic induction through the electric field change, which is induced by mechanical separation after triboelectric or contact electrification transfers electrons from one surface of contacting materials to another according to the quantum mechanical transition model [6]. The model states that when two materials approach an atomically close distance, electrons move toward the lowest available states due to strongly overlapping electron waves. The electron transfer model could be extended from solid–solid to liquid–solid, liquid–gas, and even liquid–liquid cases [7].2.1. Principle of TENG

The fundamental physics model of TENG was presented according to Maxwell’s displacement current in 2017 [4][8][9][10]. The displacement current is from a transient electric field and media dielectric polarization and drives the conversion of mechanical energy into electricity. Mainly due to the independence of the surface charges on the electric field, a new term Ps, known as the Wang term, is added to Maxwell’s equations to explain TENG’s working mechanism [4]. The displacement current density (JD) is then expanded as follows:2.2. Advantages of Ordinary TENG

In addition to multiple modes of operation, ordinary TENG has many other advantages, including wide material availability, lightweight, low cost, and high efficiency even at low operating frequencies. In addition, its sensitivity to external incentives and self-powered characteristics also broaden its scope of application.3. TENG for Fluid Dynamics Sensing

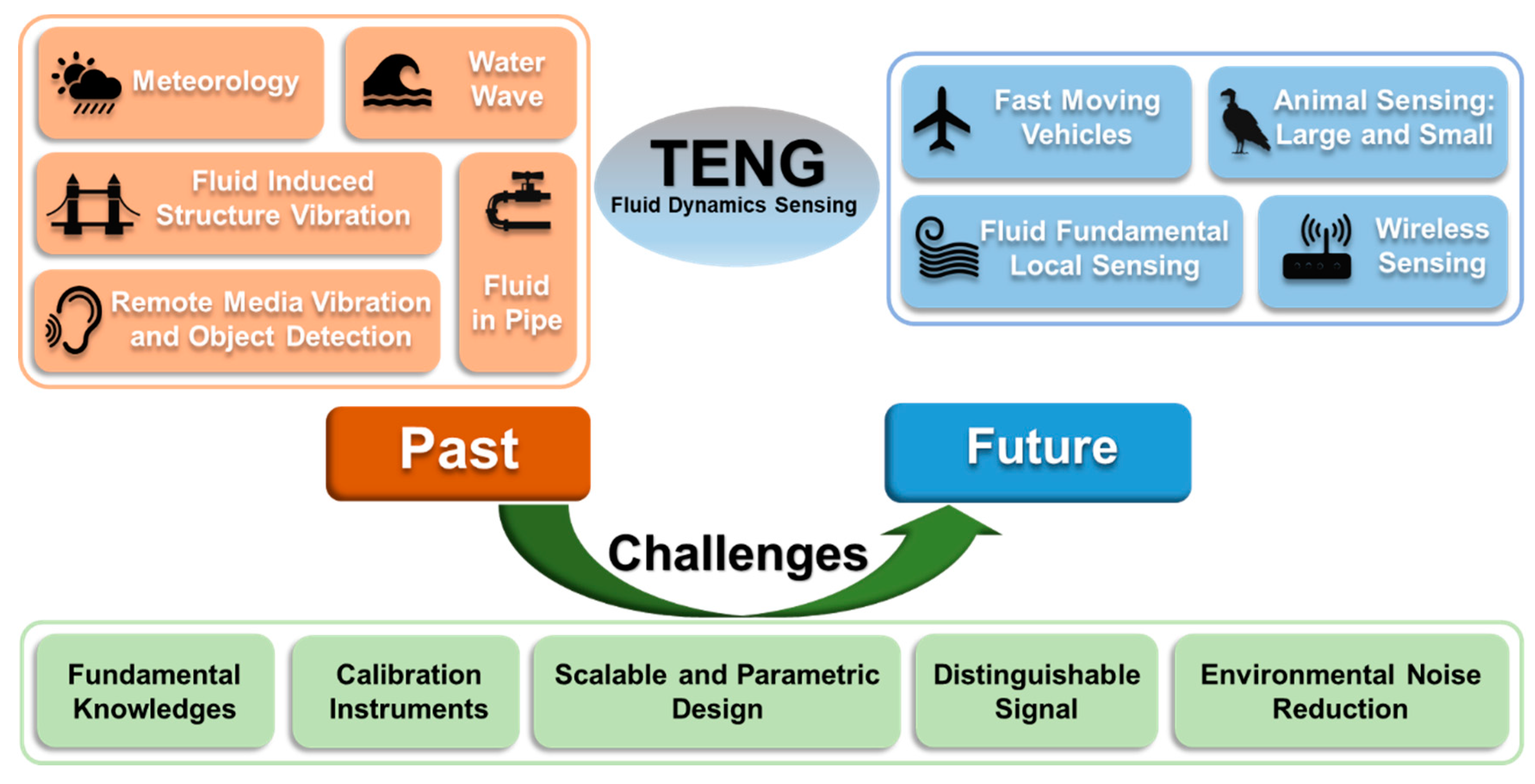

In physics and engineering, fluid dynamics is a branch of fluid mechanics that describes the flow of fluids, including aerodynamics (study of gases in motion) and hydrodynamics (study of liquids in motion). Here, we divide the fluid dynamics parameters that may be sensed by TENG sensors could be divided i into two groups by scale: large- and local-scale properties. The large-scale properties include ambient fluid motions, such as wind, rain, and water wave, and their speed, direction, and pressure; the local-scale properties include the flow pattern and force under various situations on the local scale, such as laminar and turbulence flow and their development, boundary layer and its separation, flow pattern around immersed bodies, rotational fluid such as vortex, and streamlines in the local flow field (Figure 1).

Figure 1. Opportunities and challenges of triboelectric nanogenerators for fluid dynamics sensing, from traditional fields to future technologies.

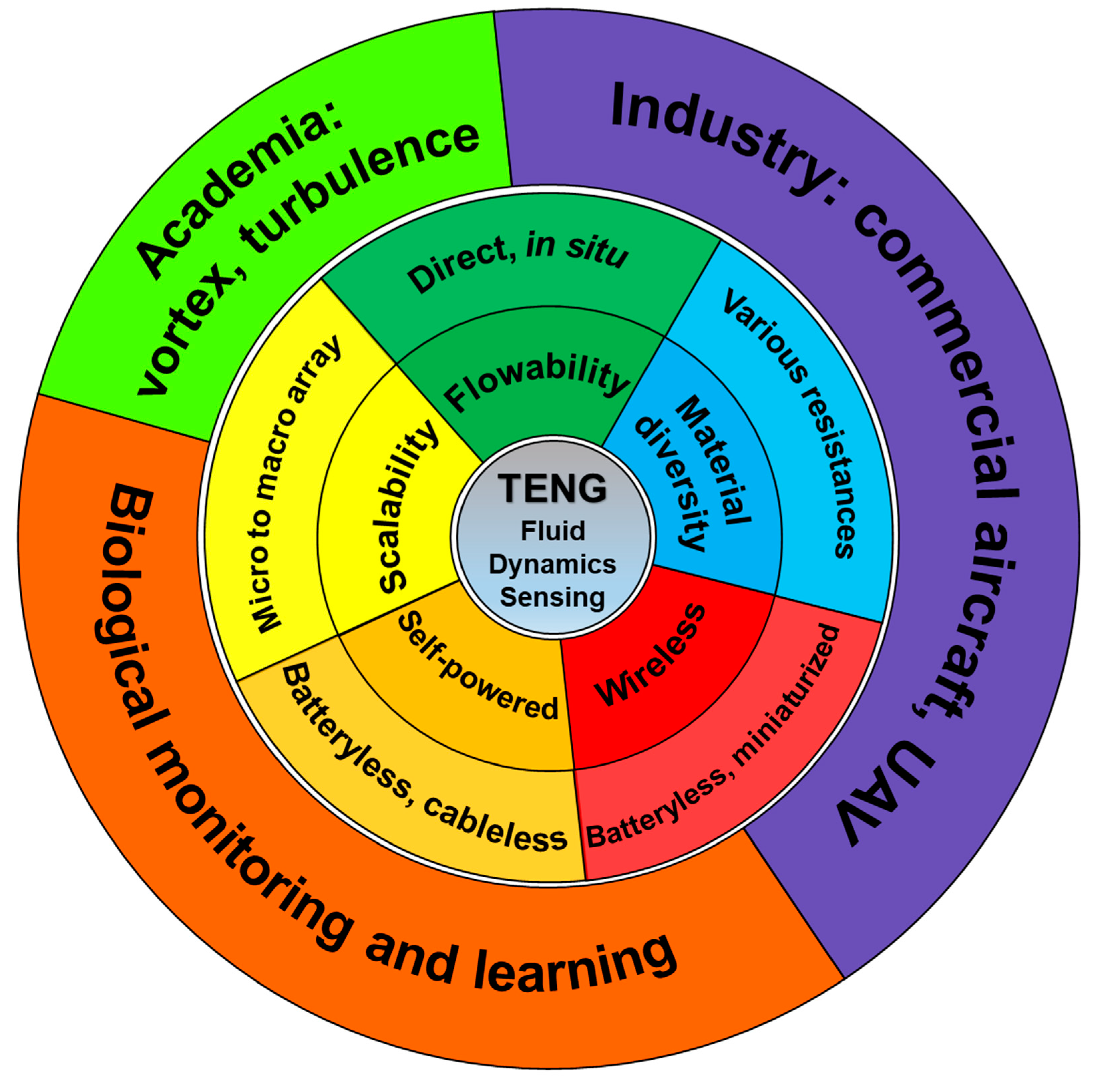

However, to reveal the full potential of TENG for fluid dynamics sensing, itwe is necessaryneed to take advantage of TENG and , and ultimately fill the gaps and meet the needs of industry and academia. In academia, alternative methods are needed to measure the in situ local fluid situations, e.g., vortex, boundary layer, and turbulence transition. The most reliable method to observe fluid dynamics is optical techniques, such as particle image velocimetry (PIV) and Schlieren imaging. However, these techniques require a sophisticated setup and critical experimental environment in the laboratory, making them not suitable for multi-scale field measurements, which play very important roles in the validation and application of fundamental theories. In industry, especially aerospace, non-invasive sensors are in large demand, for flight safety, flight data acquisition, and aircraft design optimization by monitoring the local in situ fluid situation in real flight. The critical parameters include aircraft airspeed, friction drag force, vortex and boundary layer separation near the wing surface, and wing vibration. However, most of the traditional sensors need power with cables that will increase the weight. In addition, since most third-party sensors are not pre-designed in the body, the power supply and cables of the sensors will expose to the extreme atmosphere, creating a difficult scenario for high-speed aircraft because the fast-moving air may damage the cables, which also in turn disturb the airflow field and thus the flight condition and safety. As for light-weighted unmanned aerial vehicles (UAV), the increased weight from the whole sensor system could be another critical problem for efficient flight. Thus, the industry craves suitable sensors with the features of lightweight, plug-and-play, in situ, and battery-less, so that significant progress can be made in the aerodynamics theory development, aircraft design, and safety monitoring. Fortunately, TENG sensors have the potential to fulfill some of the above needs in fluid dynamics sensing thanks to the following advantages: self-powered sensing, wireless signal transfer, scalability, material diversity, and flowability (Figure 2). TENGs can actively generate electrical signals and have the potential to generate enough power to save and even transmit signals by the TENG alone, making the sensor setup and maintenance much easier than the conventional ones. Tao et al. designed a hierarchical honeycomb-structured structure for morphing airplane energy harvest, claimed as the first TENG used for aircraft, showing the feasibility of energy harvesting and self-powered sensing in the aerospace industry [14].

References

- Wu, C.; Wang, A.C.; Ding, W.; Guo, H.; Wang, Z.L. Triboelectric Nanogenerator: A Foundation of the Energy for the New Era. Adv. Energy Mater. 2019, 9, 1802906.

- Fan, F.R.; Tian, Z.Q.; Wang, Z.L. Flexible Triboelectric Generator. Nano Energy 2012, 1, 328–334.

- Gao, Q.; Cheng, T.; Wang, Z.L. Triboelectric Mechanical Sensors—Progress and Prospects. Extrem. Mech. Lett. 2021, 42, 101100.

- Wang, Z.L. On the First Principle Theory of Nanogenerators from Maxwell’s Equations. Nano Energy 2020, 68, 104272.

- Wang, Z.L. Triboelectric Nanogenerators as New Energy Technology for Self-Powered Systems and as Active Mechanical and Chemical Sensors. ACS Nano 2013, 7, 9533–9557.

- Zou, H.; Guo, L.; Xue, H.; Zhang, Y.; Shen, X.; Liu, X.; Wang, P.; He, X.; Dai, G.; Jiang, P.; et al. Quantifying and Understanding the Triboelectric Series of Inorganic Non-Metallic Materials. Nat. Commun. 2020, 11, 2093.

- Wang, Z.L.; Wang, A.C. On the Origin of Contact-Electrification. Mater. Today 2019, 30, 34–51.

- Wang, Z.L. On Maxwell’s Displacement Current for Energy and Sensors: The Origin of Nanogenerators. Mater. Today 2017, 20, 74–82.

- Wang, Z.L.; Jiang, T.; Xu, L. Toward the Blue Energy Dream by Triboelectric Nanogenerator Networks. Nano Energy 2017, 39, 9–23.

- Wang, Z.L. On the Expanded Maxwell’s Equations for Moving Charged Media System—General Theory, Mathematical Solutions and Applications in TENG. Mater. Today 2022, 52, 348–363.

- Wang, H.; Wang, J.; Yao, K.; Fu, J.; Xia, X.; Zhang, R.; Li, J.; Xu, G.; Wang, L.; Yang, J.; et al. A Paradigm Shift Fully Self-Powered Long-Distance Wireless Sensing Solution Enabled by Discharge-Induced Displacement Current. Sci. Adv. 2021, 7, eabi6751.

- Wang, H.; Fu, J.; Wang, J.; Su, L.; Zi, Y. Tribophotonics: An Emerging Self-Powered Wireless Solution toward Smart City. Nano Energy 2022, 97, 107196.

- Wang, Z.L.; Lin, L.; Chen, J.; Niu, S.; Zi, Y. Triboelectric Nanogenerators; Green Energy and Technology; Springer International Publishing: Cham, Switzerland, 2016.

- Tao, K.; Chen, Z.; Yi, H.; Zhang, R.; Shen, Q.; Wu, J.; Tang, L.; Fan, K.; Fu, Y.; Miao, J.; et al. Hierarchical Honeycomb-Structured Electret/Triboelectric Nanogenerator for Biomechanical and Morphing Wing Energy Harvesting. Nano-Micro Lett. 2021, 13, 123.

- Zhao, H.; Xu, M.; Shu, M.; An, J.; Ding, W.; Liu, X.; Wang, S.; Zhao, C.; Yu, H.; Wang, H.; et al. Underwater Wireless Communication via TENG-Generated Maxwell’s Displacement Current. Nat. Commun. 2022, 13, 3325.

- Zhang, C.; Chen, J.; Xuan, W.; Huang, S.; Shi, L.; Cao, Z.; Ye, Z.; Li, Y.; Wang, X.; Dong, S.; et al. Triboelectric Nanogenerator-Enabled Fully Self-Powered Instantaneous Wireless Sensor Systems. Nano Energy 2022, 92, 106770.

- Howell, L.L. Compliant Mechanisms. In 21st Century Kinematics; McCarthy, J.M., Ed.; Springer: London, UK, 2013; pp. 189–216.

- Yang, P.K.; Lin, Z.H.; Pradel, K.C.; Lin, L.; Li, X.; Wen, X.; He, J.H.; Wang, Z.L. Paper-Based Origami Triboelectric Nanogenerators and Self-Powered Pressure Sensors. ACS Nano 2015, 9, 901–907.

- Chen, C.; Wen, Z.; Shi, J.; Jian, X.; Li, P.; Yeow, J.T.W.; Sun, X. Micro Triboelectric Ultrasonic Device for Acoustic Energy Transfer and Signal Communication. Nat. Commun. 2020, 11, 4143.

- Deng, Z.; Xu, L.; Qin, H.; Li, X.; Duan, J.; Hou, B.; Wang, Z.L. Rationally Structured Triboelectric Nanogenerator Arrays for Harvesting Water Current Energy and Self-Powered Sensing. Adv. Mater. 2022, 2205064.

- Vogel, S. Life in Moving Fluids: The Physical Biology of Flow; Princeton University Press: Princeton, NJ, USA, 1994.

- Vogel, S. Life’s Devices: The Physical World of Animals and Plants; Princeton University Press: Princeton, NJ, USA, 1988.

- Hu, D.L.; Chan, B.; Bush, J.W.M. The Hydrodynamics of Water Strider Locomotion. Nature 2003, 424, 663–666.

- Kim, B.H.; Li, K.; Kim, J.T.; Park, Y.; Jang, H.; Wang, X.; Xie, Z.; Won, S.M.; Yoon, H.J.; Lee, G.; et al. Three-Dimensional Electronic Microfliers Inspired by Wind-Dispersed Seeds. Nature 2021, 597, 503–510.

- Zhang, S.; Chi, M.; Mo, J.; Liu, T.; Liu, Y.; Fu, Q.; Wang, J.; Luo, B.; Qin, Y.; Wang, S.; et al. Bioinspired Asymmetric Amphiphilic Surface for Triboelectric Enhanced Efficient Water Harvesting. Nat. Commun. 2022, 13, 4168.

- Wang, X.; Shi, Y.; Yang, P.; Tao, X.; Li, S.; Lei, R.; Liu, Z.; Wang, Z.L.; Chen, X. Fish-Wearable Data Snooping Platform for Underwater Energy Harvesting and Fish Behavior Monitoring. Small 2022, 18, 2107232.

- Li, W.; Pei, Y.; Zhang, C.; Kottapalli, A.G.P. Bioinspired Designs and Biomimetic Applications of Triboelectric Nanogenerators. Nano Energy 2021, 84, 105865.

- Hanke, W.; Witte, M.; Miersch, L.; Brede, M.; Oeffnet, J.; Michael, M.; Hanke, F.; Leder, A.; Dehnhardt, G. Harbor Seal Vibrissa Morphology Suppresses Vortex-Induced Vibrations. J. Exp. Biol. 2010, 213, 2665–2672.

- Zhang, R.; Lin, L.; Jing, Q.; Wu, W.; Zhang, Y.; Jiao, Z.; Yan, L.; Han, R.P.S.; Wang, Z.L. Nanogenerator as an Active Sensor for Vortex Capture and Ambient Wind-Velocity Detection. Energy Environ. Sci. 2012, 5, 8528–8533.

- Wang, Y.; Liu, X.; Chen, T.; Wang, H.; Zhu, C.; Yu, H.; Song, L.; Pan, X.; Mi, J.; Lee, C.; et al. An Underwater Flag-like Triboelectric Nanogenerator for Harvesting Ocean Current Energy under Extremely Low Velocity Condition. Nano Energy 2021, 90, 106503.

- Wang, Y.; Hu, S.; Xiong, T.; Huang, Y.; Qiu, L. Recent Progress in Aircraft Smart Skin for Structural Health Monitoring. Struct. Health Monit. 2021, 21, 2453–2480.

- Na, X.; Gong, Z.; Dong, Z.; Shen, D.; Zhang, D.; Jiang, Y. Flexible Skin for Flight Parameter Estimation Based on Pressure and Velocity Data Fusion. Adv. Intell. Syst. 2022, 4, 2100276.