1. Introduction

Within Euro-centric traditions of architecture, the significance of a building is often tied to its permanence. The Pantheon in Rome, for example, is a nearly 2000-year-old cementitious dome structure, whose resilience to time elevates it to a monumental status. Notwithstanding the significance of cultural and economic factors associated with the need for permanent buildings and structures, must all buildings be assembled with the goal of being permanent? Globally, the lifespans of buildings are rapidly decreasing. The average lifespan of buildings in China was recently reported to be 34 years

[1], and 25 years for residential buildings in Japan

[2]. To great detriment, buildings are more than ever being demolished prematurely and yet, use materials that are manufactured with energy-intensive processes and are expensive or impractical to recycle. In the United States alone, the Environmental Protection Agency (EPA) reported there was 600 million tons of construction and demolition waste generated in 2018

[3]. Structural materials, including wood, and architectural metals, such as steel, copper, and brass, are valuable commodities that can be reused and recycled. However, in present-day architectural assemblies, these materials nearly ubiquitously inter-face with expanded foams, plastics, and resins, sometimes in irreversible composites. For example, wood is widely treated with synthetic resins and glues to increase its resistance to decay or structural performance.

Fossil-fuel-based materials are versatile and economical. They are used to create building products such as floor and wall finishes, furniture, conduits, structural reinforcements, insulation, and sealants, to name a few. From their manufacture to their end-of-life, synthetic materials require significant amounts of energy and produce emissions that are harmful to environmental and human health. Plastics, such as polyvinyl chloride (PVC), use a known carcinogenic monomer (vinyl chloride) in their production

[4], and are often manufactured to be more ductile using phthalate plasticizers, a known class of toxins posing risks to the immune response, reproductive health, and embryonic development

[5]. Particularly in Europe, sorting programs are improving, and assessments of recycling products, such as PVC from window frames

[6], have demonstrated successful programs for those contexts. Still, only 3 percent of PVC is diverted from the waste stream in Europe

[4]. Expanded polystyrene (EPS), commonly used as a packaging material, is fully recyclable, but due to its low density, the cost of transporting it to be recycled quickly outweighs the benefit if performed over long distances

[7]. The EPA reports that only 0.6 percent of EPS waste produced in the United States is recovered

[8]. While the championing of recycling has kindled examples of robust systems that produce high recycling rates in Germany and Singapore

[9], the fate of most foams, plastics, and fossil-based composites is disposal in landfills, elimination through thermal incineration, or pyrolysis

[10].

At a time when buildings can be expected to have short, non-permanent lifespans that commonly result in landfill disposal, new building materials are needed that can help challenge

peo

ple'sur traditional perceptions of significance and building permanence, rethink what materials

peoplewe use to build, and gain awareness of where those materials go when

peoplewe are finished with using them. Wood has recently been championed for its potential as a low-cost and affordable building material, but a labor shortage during the COVID-19 pandemic caused the cost of wood to increase by nearly four times

[11], exposing the fragility of existing supply chains. In the face of material insecurity, there is a critical need to explore and test alternate low-energy and rapidly renewable building materials that contribute to circular material economies and lessen the impact of the architecture, engineering, and construction industries on climate change. Adopting new materials into the standards of contemporary and future construction is challenging, but necessary. Importantly, the way such new materials are used to design and build at the architectural scale cannot be assumed. Innovation is possible, and presenting physical demonstrations at the building scale is an important aspect of research needed to prove that an emerging material is viable for future building construction.

2. Mycelium Composite Materials

Fungi-based materials are among a class of biotechnologies showing promise in vastly offsetting the impact of the short lifespans of buildings in the modern era. In their most common form, lignocellulosic fibers sourced from agriculture or forestry material streams are bound together with an entangled web of

mycelia, the root-like structures of fungi

[12]. Commonly known as “myco-materials”, they are produced similarly to commercial mushroom farming, and can be composted at end-of-life. Myco-materials have become an international enterprise and are produced at an industrial scale. Companies such as Ecovative

[13], Mycoworks

[14], and Mogu

[15] have explored their unique and variable properties to create products through different forms of production. Products finding commercial success include packaging materials

[16][17][18][16,17,18], interior products such as lampshades and planters

[19], and acoustical panels

[15]. Mushroom leather products that serve as a sustainable alternative to animal leather are demonstrating increasing commercial success

[14][20][21][14,20,21], and are created through the use of different solid- and liquid-state techniques

[22].

Growing myco-materials involves propagating fungal hyphae (often from the phylum Basidiomycota) into a fibrous substrate for several days under correct environmental conditions until it forms a composite mass. Mycelium biomass is formally agnostic, having the capacity to be grown into nearly any shape by packing fibers inoculated with a living fungus into a formwork composed of a breathable non-cellulose-based material (usually plastic) to avoid the mycelium from permanently adhering to the mold. The limitations for growth are biological and environmental. Important precautions are proper sterility to avoid the contamination of unwanted organisms, access to food and nutrients, maximal darkness, and access to warm, humid air. Depending on the region, the fungal species being grown, and the scale of production, growth chambers may need to be actively controlled to maintain an optimal temperature and humidity, representing a likely demand for energy resources. A common issue myco-material growers face is the emergence of contaminants, sometimes dangerous molds, and other organisms that thrive in similar environmental conditions. Typically, the fibrous substrates into which mycelia are grown need to be steam-sterilized or pasteurized, which can also be prohibitively expensive due to the equipment and energy needed for such processing. Another important precaution that relates to design with myco-materials is that at certain thicknesses, mycelia do not grow sufficiently due to a lack of oxygen, presenting a chance for contamination.

Once fully grown, parts are typically actively dried to stop growth

[23], resulting in a material that resembles expanded polyurethane or polystyrene foam with a flame spread resistance comparable to gypsum and low thermal conductivity. The numerous complexities associated with growing myco-materials make it difficult to control the associated material properties (whether mechanical, thermal, acoustical, or other) and are understood to be a reported average. Different combinations of mycelium strains and fibrous substrates yield varying properties of structural integrity, density, thermal conductivity, moisture resistance, and visual quality

[24]. Studies have reported on mechanical qualities

[25][26][25,26], the impact of moisture

[27], acoustical properties based on mycelial growth

[28], fire resistance

[29], and their biodegradability

[30], and their aesthetic capacities

[31], among several others.

One of the most significant challenges of using mycelium in large-scale structural applications is that it is an inherently weak material (0.1–0.2 MPa of compressive stress on average without mechanical compaction) and assumed to work best in compression. Despite this limitation, myco-materials are also very lightweight, giving them advantageous strength-to-weight ratios compared to concrete. This suggests that through advantageous material placement large-scale and even long-span structures are possible. In the last decade, several large-scale pavilion structures have demonstrated the potential of myco-materials to be used for building structures. An important distinction must be determined between those which use mycelium in a load-bearing capacity, and those which use the material as a surface or cladding application. Pavilions such as “Shell Mycelium” in India

[32], the “Living Pavilion” in the Netherlands

[33], and the pavilion at the Rensselaer Polytechnique Institute, Troy, NY, USA

[34], used mycelium cladding panels or units over wooden frame structures. Ecovative used mycelium panels as the insulation of a tiny house

[35]. While these serve as examples of the building-scale use of myco-materials, they are definitively non-structural applications. Curiously, there has been little diversity in approaches to building with myco-materials, with fabrication techniques used to assemble myco-structures remaining canonically familiar to architecture and engineering. These include logical adaptations of assembly systems with bricks or blocks, monolithic castings, 3D printing-based, and hybrid techniques, which are described below.

3. Brick and Block Myco-Structures

The most common approach is based on the production of bricks or blocks grown in custom-made molds, actively dried in ovens, transported to the site and assembled, typically with the assistance of a temporary formwork and scaffolding structures. An early structural application of myco-materials was the “Myco-tectural Alpha”

[36], a small catenary barrel vault built from bricks grown from reishi. The largest, and perhaps most widely publicized mycelium structure was the “Hi-Fi”

[37], a 40-foot tower installation by David Benjamin and The Living in 2014, engineered by ARUP. The mycelium bricks sourced from Ecovative were stacked atop of a wood and steel supporting structure. The “MycoTree” exhibited at the 2017 Seoul Biennale

[38] demonstrated how the structural capacity of mycelium can be exploited maximally by placing it in compression-only configurations. In each previous example, the structures were formed with the assumption that the material would only work in compression, with dome/vault, tower, and column structural forms dominating the literature. The masonry units themselves were grown in plastic formworks. Three-dimensional printing techniques for myco-materials have also been explored, with much attention being paid to the formulae of viscous living pastes to be extrude with techniques adopted from digital ceramics

[39]. Unit-based column structures have been demonstrated by teams in Europe at Lund University, Lund, Sweden

[40], and by Blast Studio, London, the UK

[41]. Among the numerous exciting prospects of 3D printing myco-materials, a significant benefit is that custom-designed building units can be produced without needing a plastic formwork.

4. Monolithic and Bio-Welded Myco-Structures

Though much weaker and lighter than concrete, grow-in-place monolithic mycelium techniques can inherit many of the advantages (and challenges) of cast-in-place concrete techniques, including the use of traditional board, plank, sheeting, and flexible fabric formwork techniques. Without some means of aeration, beyond a certain thickness (150 mm or so), there is a risk that the fungi die prematurely from a lack of oxygen. Beyond assemblies of discrete element techniques, other research has focused on stereotomic approaches and monolithically growing large colonies of myco-materials in situ.

4.1. Monolithic Myco-Structures

Monolithic mycelium requires the design and fabrication of complex formworks that permit the fungi to fully grow. Due to such challenges associated with the cultivation of large volumes of live myco-materials and the constructing of formworks to facilitate such growth, very little work on monolithic mycelium has been accomplished in the context of architecture and structural design. In 2016, a master’s of science thesis on civil engineering at Miami University, in Coral Gables, FL, USA

[42] suggested analytical methods for mycelium-based monolithic domes, but did not validate them through physical means. At a small scale, Dutch artist Eric Klarenbeek demonstrated structural monolithic growth

[43] in combination with 3D printing to create furniture. Ecovative experimented with monolithic mycelium and exhibited a chair in 2018

[44] that used a proprietary process that aerated the growing colonies of myco-materials, allowing them to be grown at greater thicknesses. A dissertation from the University of Newcastle in Newcastle upon Tyne, the UK, explored the potential of monolithic mycelium chair structures

[45] grown in a conventional plastic formwork. Another interesting application of monolithic mycelium was a functional canoe

[46] that was over 2 m long, grown by a student at Wayne State College in Wayne, NE, USA, in 2020.

Beyond these examples in product and furniture design, very few examples of architectural structures have been attempted. A series of three prototype structures was previously presented by the author of this

respape

archr [47], proving that grow-in-place monolithic mycelium structures were feasible through novel constructive approaches. Two arch structures (

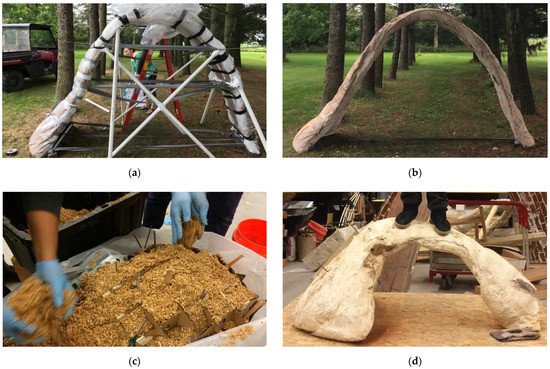

Figure 1) brought to light crucial considerations for successfully growing monolithic mycelium structures. First, the external formwork must be strong enough to support the weight of a wet substrate while maintaining its precise form, it must be composed of removable non-cellulose materials, and must be sufficiently porous to allow promoting the mycelia to breathe. Second, internal reinforcing strategies are advisable to handle eccentric loadings and formal accuracy, and must be composed of a cellulose-based material to permit the mycelia to bind and grow through the reinforcing structure.

Figure 1. (a) Formwork for the “Mycoarch” composed of active bent PVC and plastic sheeting; (b) completed arch (late 2017, since renamed the “Diamond A Arch”), which collapsed due to inaccurate form and a myco-material matrix that had not sufficiently dried; (c) packing the internal reinforcing for the “Thick and Thin Arch” composed of recycled cardboard; (d) complete “Thick and Thin Arch” (early 2018) held seventy-five kilograms. Photos by the author.

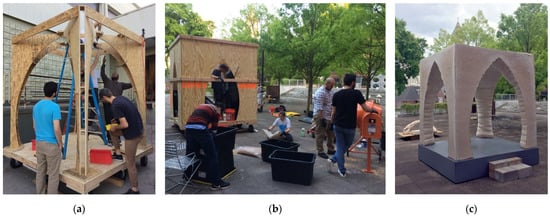

A third prototype structure, called the Monolito Micelio (Figure 2), was an architectural-scale monolithic mycelium structure, grown in early 2018 from a one-ton colony of mycelium-stabilized hemp procured from Ecovative. The structure was designed and executed in the context of a graduate research seminar at the Georgia Tech School of Architecture. The vaulted pavilion was a critical response to the observed monotony of brick/block-based myco-fabrication methods and built upon the constructive principles of structures before it. The pavilion demonstrated that myco-materials could inherit fabrication logics from cast-in-place concrete techniques, including traditional board formwork and flexible fabric formwork techniques. Importantly, the structure showed that much more work was needed to uncover new and previously unimaginable construction logics that go beyond the architectural cannon of traditional materials.

Figure 2. The Monolito Micelio, grown in early 2018 with students at Georgia Institute of Technology. (a) Construction of the wooden internal reinforcing; (b) in a manner resembling cast-inplace concrete, mycelilum composite materials were processed on-site with water and nutritional additives and immediately packed into the plywood and geo-textile formwork; (c) finished structure, used as a stage and pavilion for a choir performance and exhibited at the School of Architecture. Photos by the author.

The success of the project was also met with numerous failures, which provided the grounds for such a future inquiry. Notably, as part of a super-structure, myco-materials are highly susceptible to expansion and contraction in the face of external elements, making them unsuitable for external use, unless for temporary structures where the lifespan of the structure is understood to be short. Temperature swings and precipitation caused the material matrix of the Monolito Micelio to crack, decay, and become infested by other unfavorable organisms, including potentially dangerous mold (Figure 3). Furthermore, the materials used for the internal reinforcing system were much stronger and rigid than the myco-materials, which further exacerbated the cracking and decay of the structure.

Figure 3. Decay of the Monolito Micelio. (a) Cracking and decay of the structure after three months caused by expansion and contraction of the material matrix against the internal reinforcing structure; (b) cracking, decay, and infestation of the structure after four months. Photos by the author.

While, in many regional contexts, there are minor active energy inputs needed to grow myco-materials, their reliance on plastics and molds that have limited reusability presents an ethical dilemma. For example, the plastic-lined plywood and woven nylon fabric formwork system used for the Monolito Micelio was a waste byproduct that resulted in land-fill disposal. The issue of formwork resulting in waste is an issue that has since been taken up by researchers interested in monolithic mycelium. A prototype structure by the multi-disciplinary collaboration in Europe called the FUNGAR project

[48] provided early evidence that woven Kagome structures are an advantageous replacement for the polymeric in-situ formworks and molds typically needed to grow myco-materials. Such weaving crafts are globally ubiquitous, formally flexible, and often use natural lignocellulosic materials that are readily available. Such strong porous surfaces allow the fungi to breathe, provide a humid environment, and serve as a source of nutrition for the fungi. In contrast to plastic formworks, myco-weaves encourage mycelia to grow into the formwork and integrate into the biomass. More recently, the author of this

rpape

searchr grew a two-meter-tall monolithic mycelium column

[49] along with students at Kansas State University that used basket weaving techniques. The woven formwork both participated in the visual expression of the column and potentially strengthened the assembly due to the deep bonds between the myco-materials and exoskeleton (

Figure 4a).

Figure 4. Monolithic and myco-welded structures grown by the author and students at Kansas State University in spring 2021, shown in their final installation sites. The structures were both larger than the available resources for actively drying the structures to stop growth, resulting in the emergence of fruiting bodies on the structures. (a) Two-meter-tall woven monolithic mycelium column; (b) half-scale myco-welded staircase with visible fruiting bodies that resulted from the two-stage growing process inherent to the myco-fabrication technique. Photos by the author.

4.2. Bio-Welded Myco-Structures

An increasingly popular technique called “bio-welding”, or “myco-welding”, involves assembling structures with discreet living parts and growing them together into monolithic wholes. Myco-welding is challenging because it requires two stages of growth. First, individual units are grown from loose inoculated substrates in molds. Second, assemblies of living units are kept in an intended formal configuration for several days, while maintaining necessary sanitary and environmental conditions. Drying and stopping the growth of large assemblies is also a challenge inherent to myco-welding large assemblies. If not completed quickly enough, fruiting bodies often grow on the structure (

Figure 4b), which, depending on the application or context, may or may not be desirable. The technique has been demonstrated for small arch structures

[50], furniture

[51], for making monolithic blocks for use with robotic-controlled abrasive wire cutting

[52], and a load-bearing half-scale spiral staircase recently grown by the author and their students

[49]. At the large scale, the technique was demonstrated in the form of a triumphal arch at a short-term art installation in Europe

[53].