Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 2 by Sirius Huang and Version 1 by Afaque Manzoor Soomro.

Flexible strain sensors with high sensitivity, wide sensing range, and excellent long-term stability are highly anticipated due to their promising potential in user-friendly electronic skins, interactive wearable systems, and robotics.

- fluidic-type sensors

- conductive liquids

- wearable

- flexible

- robotics

1. Introduction

Flexible electronics is embarking on its journey by rapidly evolving in the field of electronics. The innovative methods of fabrication enable this field to be environmentally friendly, cost-effective, faster, and robust [1,2,3,4][1][2][3][4]. They can be reformed to tolerate mechanical deformations. They can bend [5], stretch [6], compress [7], twist [8], and warp [9] because the flex circuit or flex electronics are mounted on a flexible soft substrate [10]. Flexible electronics are becoming more popular since they are adaptable. They are inexpensive, customizable, and portable [11,12,13,14,15][11][12][13][14][15]. They have a whole new world of applications to set a benchmark, from collecting energy from temperature differences caused by our bodies and the environment, to folding phones, to wearable bioelectronics devices with sensors to evaluate and diagnose health issues [16,17,18,19,20,21,22][16][17][18][19][20][21][22]. They have huge potential for adoption in medicine, bioelectronics, or wearable devices [23].

Flexible devices draw great attention because of their efficiency, light weight, flexibility, and stretchability [24,25,26,27,28][24][25][26][27][28]. These devices are skin-friendly and made of soft materials attached to human skin, ensuring users’ comfort as much as possible while wearing them [29,30,31,32,33,34,35][29][30][31][32][33][34][35]. They are used in bioelectronics to calculate wrist pulses [36], glucose [25], body motion [37[37][38][39][40][41],38,39,40,41], temperature [40[40][42],42], and other physiological signals [43]. Among these devices, sensors [44,45,46][44][45][46] are popular because they have a wide variety of applications in bioelectronics as well as healthcare. They play an important role in these wearable devices because of their having of the capability of guaranteeing the accuracy of signal capture. Highly elastic sensors have been encouraged by wearable sensors for human activity detection, whereas strain sensors are super elastic and highly stretchable for wearable devices [47]. Among these strain sensors, fluidic sensors have been recently used in wearable devices [33,39,48,49,50,51,52][33][39][48][49][50][51][52] and a few robotic applications [44,45][44][45].

Recently, fluidic strain sensors have been in high demand because of their ability to monitor and sense physiological signals and are vital because they are cost-effective, highly compliant, weigh little, and can sense complex environments [26,49,53,54,55][26][49][53][54][55]. Because of their high sensitivity, mechanical flexibility, and stretchability, these strain sensors normally function by utilizing the resistive effect of conductive liquid [39,40,45,52,56][39][40][45][52][56]. Fluidic strain sensors combine conductive liquids within a flexible substrate’s narrow channel and fabricate specific patterns to improve stretchability [40,41,57][40][41][57]. Microfluidic strategies have been introduced lately because they are easy to fabricate with plastic and soft elastomers, and they are lightweight and consume less energy, which makes them suitable for large stretchable electronics [58]. Microfluidics is the main element in fluidic soft sensors. The conductive microfluidic fillers used by strain sensors can be ionic, metallic, or other chemically synthesized liquid solutions. Their detecting technique is based on the fact that when a particular amount of strain is given to the fluid, the fluid deviates from its original shape, allowing the sensor to perceive [59,60][59][60]. Flexible devices in challenging settings can use fluidic strain sensors in a broad range of ways. These sensors can be used in wearable electronics, surgical equipment, robot feedback sensing, and health monitoring systems [61,62,63][61][62][63].

2. Applications of Fluidic Type Strain Sensors

Fluidic strain sensors have been used in a wide range of applications, not only limited to wearable applications such as health monitoring, sports, and gaming, but also in robotics.2.1. Wearable Devices

Fluidic strain sensors are widely applicable in motion detection applications by wearing them on different parts of the body, such as the knee, elbow, or finger. Sensors are attached to the skin, and adhesive tape is used to make them easily accessible. strain sensor designed to monitor movements [73][64] are shown in Figure 1a whereas In [40], the strain sensor was designed to detect the motion of the finger. Here, the sensor was attached to the index finger, detecting whether the fist is closed or the finger is extended as shown in Figure 1b. Similarly, finger movement, rotation of the wrist, and water drinking were detected in [31]. The sensor was attached to the skin to distinguish the static as well as dynamic motion of the body. Similarly, Choi et al. [39] showed a sensor applicable for health monitoring, smart clothing, and virtual reality systems by detecting the responses of the electrical resistance caused by deformations. Furthermore, low-cost and highly stretchable sensors were designed in [19,49,91][19][49][65] for medical, flexible, and wearable applications. Similarly, wearable sensor to detect elbow flexation [104][66] has been designed and shown in Figure 1c. Gao et al. in [100][67] present a sensor with outstanding mechanical deformability that can be attached to joints, fingers, wrists, etc., For the detection of skin movements. sensor worn to detect bicep muscle tuning were reported in [109][68] as shown in Figure 1d. For chronic monitoring applications, interfacing low-power wearable electronics with low sensor resistance but good strain sensors was presented in [76][69]. Moreover, wearable sensor to detect the motion of the knee was introduced in [91][65] and can be shown in Figure 1e. Another sensor has been designed in [110][70] for the firefighter’s glove for the motion detection which can be seen in Figure 1f.

Figure 1. Applications of wearable strain sensors: (a) strain sensor designed to monitor movements [73][64]; (b) wearable strain sensor to detect finger movement [40]; (c) wearable sensor to detect elbow flexation [103][71]; (d) sensor worn to detect bicep muscle tuning [109][68]; (e) wearable sensor to detect the motion of the knee [91][65]; (f) attaching a sensor to a firefighter’s glove to detect motion [110][70].

2.2. High-End Feedback for Soft Robotics Systems

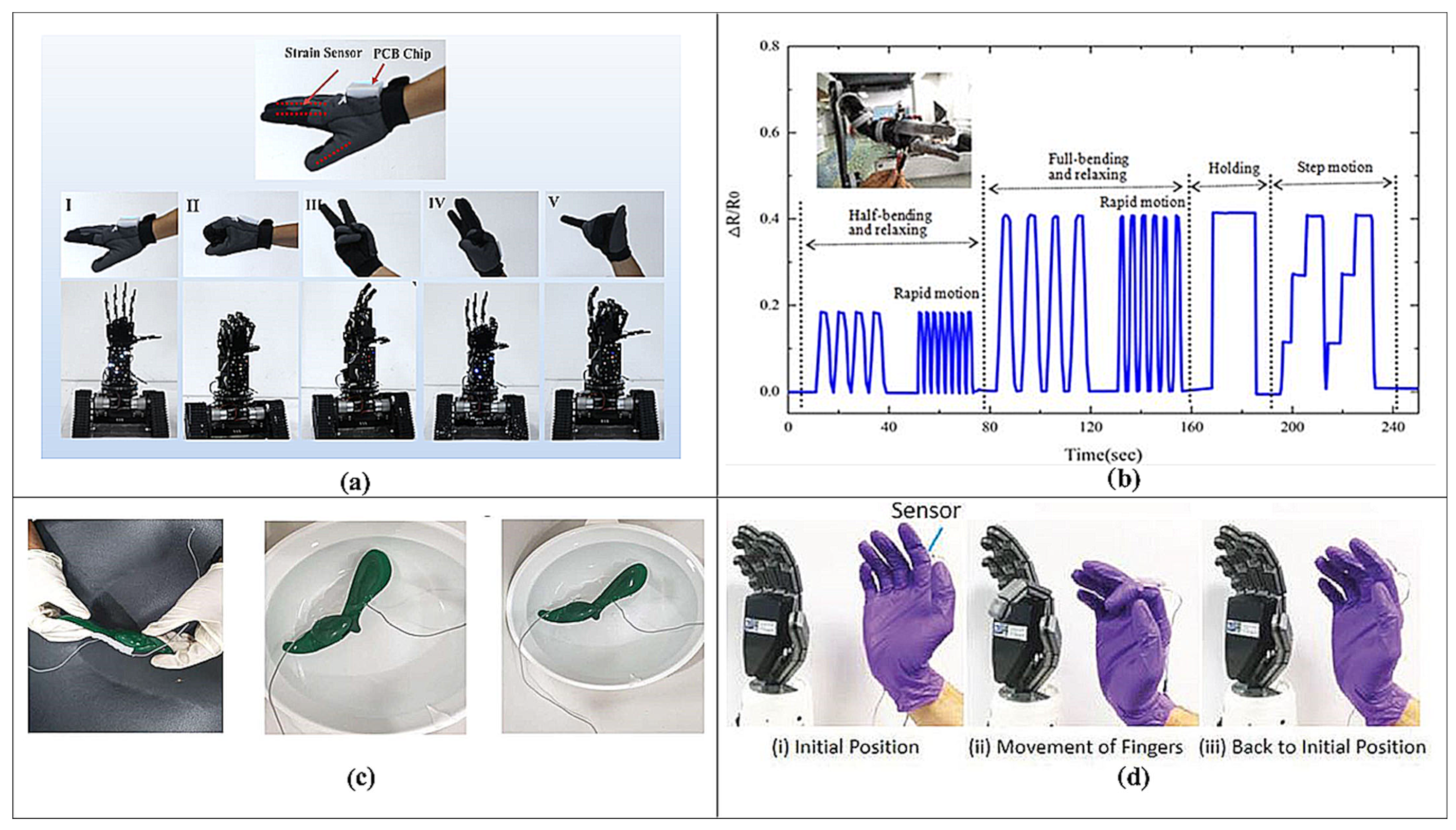

Fluidic strain sensor applications are not limited to health monitoring and other medical applications only but have broad applications in the field of robotics too. Soft sensors are necessary for wearable robots or other functional robots to allow for soft human–robot contact and feedback control of the robotic actions. These robots might be therapeutic wearable robots, transporting robots, or soft robotic grippers. These fluidic sensors are applied in conventional as well as soft robotics. Wu et al. in [72] tried to remotely control the position of the robotic hand by providing gestures with a glove-mounted sensor, as shown in Figure 2a where different motions of the fingers were analyzed by making a hard fist as shown in Figure 2a(I) and analyzing the motion by closing and opening number of fingers as shown in Figure 2a(II–V). Furthermore, for soft robotics, the stretchable strain sensor was designed in [77[73][74],94], showing the potential to implement the strain sensors in soft robotics as shown in Figure 2b where the study in [77][73] presented a robot which is designed with the help of strain sensors to analyze the motion of the robot joint.

Figure 2. Flexible strain sensor application in robotics: (a) controlling a robotic hand from the remote position [72]; (I) original state (II) hard fist (III) bending 3 fingers (IV) bending 2 fingers and (V) and bending 4 fingers (b) the sensor is attached to the robot joint to analyze the movement [77][73]; (c) the sensor attached to the legs under water [45]; (d) to move the robotic finger as feedback, the sensor is attached in the human finger [37].

References

- Khanna, V.K. Flexible Electronics. Flex. Electron. 2019, 3, 1–417.

- Qi, K.; He, J.; Wang, H.; Zhou, Y.; You, X.; Nan, N.; Shao, W.; Wang, L.; Ding, B.; Cui, S. A Highly Stretchable Nanofiber-Based Electronic Skin with Pressure-, Strain-, and Flexion-Sensitive Properties for Health and Motion Monitoring. ACS Appl. Mater. Interfaces 2017, 9, 42951–42960.

- Cai, L.; Song, L.; Luan, P.; Zhang, Q.; Zhang, N.; Gao, Q.; Zhao, D.; Zhang, X.; Tu, M.; Yang, F.; et al. Super-stretchable, Transparent Carbon Nanotube-Based Capacitive Strain Sensors for Human Motion Detection. Sci. Rep. 2013, 3, 1–9.

- Bae, G.Y.; Han, J.T.; Lee, G.; Lee, S.; Kim, S.W.; Park, S.; Kwon, J.; Jung, S.; Cho, K. Pressure/Temperature Sensing Bimodal Electronic Skin with Stimulus Discriminability and Linear Sensitivity. Adv. Mater. 2018, 30, 1–8.

- Iglio, R.; Mariani, S.; Robbiano, V.; Strambini, L.; Barillaro, G. Flexible Polydimethylsiloxane Foams Decorated with Multiwalled Carbon Nanotubes Enable Unprecedented Detection of Ultralow Strain and Pressure Coupled with a Large Working Range. ACS Appl. Mater. Interfaces 2018, 10, 13877–13885.

- Kim, S.J.; Mondal, S.; Min, B.K.; Choi, C.-G. Highly Sensitive and Flexible Strain–Pressure Sensors with Cracked Paddy-Shaped MoS2/Graphene Foam/Ecoflex Hybrid Nanostructures. ACS Appl. Mater. Interfaces 2018, 10, 36377–36384.

- Thaheem, I.; Ali, S.; Waqas, M.; Hussain, A.; Soomro, A.M.; Bhutto, Z.; Shah, S.A.R.; Muhammad, W.; Shah, J. Electrochemical Performance of NiCo2O4 Spinel Cathodes for Intermediate Temperature Solid Oxide Fuel Cells. Phys. Status Solidi 2021, 219, 2100542.

- Chethikkattuveli Salih, A.R.; Hyun, K.; Asif, A.; Farooqi, H.M.U.; Kim, Y.S.; Kim, K.H.; Lee, J.W.; Huh, D.; Choi, K.H. Extracellular Matrix Optimization for Enhanced Physiological Relevance in Hepatic Tissue-Chips. Polymers 2021, 13, 3016.

- Soomro, A.M.; Jabbar, F.; Ali, M.; Lee, J.-W.; Mun, S.W.; Choi, K.H. All-range flexible and biocompatible humidity sensor based on poly lactic glycolic acid (PLGA) and its application in human breathing for wearable health monitoring. J. Mater. Sci. Mater. Electron. 2019, 30, 9455–9465.

- Gao, W.; Ota, H.; Kiriya, D.; Takei, K.; Javey, A. Flexible Electronics toward Wearable Sensing. Acc. Chem. Res. 2019, 52, 523–533.

- Borini, S.; White, R.; Wei, D.; Astley, M.; Haque, S.; Spigone, E.; Harris, N.; Kivioja, J.; Ryhänen, T. Ultrafast Graphene Oxide Humidity Sensors. ACS Nano 2013, 7, 11166–11173.

- Pignanelli, J.; Schlingman, K.; Carmichael, T.B.; Rondeau-Gagné, S.; Ahamed, M.J. A comparative analysis of capacitive-based flexible PDMS pressure sensors. Sens. Actuators A Phys. 2018, 285, 427–436.

- Xue, J.; Zhu, Z.; Xu, X.; Gu, Y.; Wang, S.; Xu, L.; Zou, Y.; Song, J.; Zeng, H.; Chen, Q. Narrowband Perovskite Photodetector-Based Image Array for Potential Application in Artificial Vision. Nano Lett. 2018, 18, 7628–7634.

- Kim, H.B.; Sajid, M.; Kim, K.T.; Na, K.H.; Choi, K.H. Linear humidity sensor fabrication using bi-layered active region of transition metal carbide and polymer thin films. Sens. Actuators B Chem. 2017, 252, 725–734.

- Varghese, O.K.; Kichambre, P.D.; Gong, D.; Ong, K.G.; Dickey, E.C.; Grimes, C.A. Gas sensing characteristics of multi-wall carbon nanotubes. Sens. Actuators B Chem. 2001, 81, 32–41.

- Huang, J.-Q.; Zhang, Q.; Wei, F. Multi-functional separator/interlayer system for high-stable lithium-sulfur batteries: Progress and prospects. Energy Storage Mater. 2015, 1, 127–145.

- Ali, S.; Waqas, M.; Jing, X.; Chen, N.; Chen, D.; Xiong, J.; He, W. Carbon–Tungsten Disulfide Composite Bilayer Separator for High-Performance Lithium–Sulfur Batteries. ACS Appl. Mater. Interfaces 2018, 10, 39417–39421.

- Liang, Z.; Zhao, Y.; Li, Y. Electrospun Core-Shell Nanofiber as Separator for Lithium-Ion Batteries with High Performance and Improved Safety. Energies 2019, 12, 3391.

- Zeeshan; Ahmed, R.; Chun, W.; Oh, S.J.; Kim, Y. Power Generation from a Hybrid Generator (TENG-EMG) Run by a Thermomagnetic Engine Harnessing Low Temperature Waste Heat. Energies 2019, 12, 1774.

- Waqas, M.; Ali, S.; Chen, D.; Boateng, B.; Han, Y.; Zhang, M.; Han, J.; Goodenough, J.B.; He, W. A robust bi-layer separator with Lewis acid-base interaction for high-rate capacity lithium-ion batteries. Compos. Part B Eng. 2019, 177, 107448.

- Neudeck, S.; Mazilkin, A.; Reitz, C.; Hartmann, P.; Janek, J.; Brezesinski, T. Effect of Low-Temperature Al2O3 ALD Coating on Ni-Rich Layered Oxide Composite Cathode on the Long-Term Cycling Performance of Lithium-Ion Batteries. Sci. Rep. 2019, 9, 1–11.

- Corzo, D.; Tostado-Blázquez, G.; Baran, D. Flexible Electronics: Status, Challenges and Opportunities. Front. Electron. 2020, 1, 594003.

- Khalid, M.A.U.; Kim, S.W.; Lee, J.; Soomro, A.M.; Rehman, M.M.; Lee, B.-G.; Choi, K.H. Resistive switching device based on SrTiO3/PVA hybrid composite thin film as active layer. Polymer 2020, 189, 122183.

- Ali, M.; Khalid, M.A.U.; Kim, Y.S.; Soomro, A.M.; Hussain, S.; Doh, Y.H.; Choi, K.H. MWCNTs/PEDOT: PSS Composite as Guiding Layer on Screen-Printed Carbon Electrode for Linear Range Lactate Detection. J. Electrochem. Soc. 2021, 168, 037507.

- Lee, J.-W.; Soomro, A.M.; Waqas, M.; Khalid, M.A.U.; Choi, K.H. A highly efficient surface modified separator fabricated with atmospheric atomic layer deposition for high temperature lithium ion batteries. Int. J. Energy Res. 2020, 44, 7035–7046.

- Soomro, A.M.; Lee, J.-W.; Waqas, M.; Kim, Y.S.; Ali, M.; Khalid, M.A.U.; Choi, K.H. A Robust Surface-Modified Separator Fabricated with Roll-to-Roll Atomic Layer Deposition and Electrohydrodynamic Deposition Techniques for High Temperature Lithium Ion Batteries. J. Electrochem. Soc. 2020, 167, 160507.

- Soomro, A.M.; Memon, F.H.; Lee, J.-W.; Ahmed, F.; Kim, K.H.; Kim, Y.S.; Choi, K.H. Fully 3D printed multi-material soft bio-inspired frog for underwater synchronous swimming. Int. J. Mech. Sci. 2021, 210, 106725.

- Ali, M.; Kim, Y.S.; Khalid, M.A.U.; Soomro, A.M.; Lee, J.-W.; Lim, J.-H.; Choi, K.H.; Ho, L.S. On-chip real-time detection and quantification of reactive oxygen species in MCF-7 cells through an in-house built fluorescence microscope. Microelectron. Eng. 2020, 233, 111432.

- Zhao, Y.; Huang, Y.; Hu, W.; Guo, X.; Wang, Y.; Liu, P.; Liu, C.; Zhang, Y. Highly sensitive flexible strain sensor based on threadlike spandex substrate coating with conductive nanocomposites for wearable electronic skin. Smart Mater. Struct. 2018, 28, 035004.

- Herrmann, J.; Müller, K.-H.; Reda, T.; Baxter, G.R.; Raguse, B.; De Groot, G.J.J.B.; Chai, R.; Roberts, M.E.; Wieczorek, L. Nanoparticle films as sensitive strain gauges. Appl. Phys. Lett. 2007, 91, 183105.

- Qi, Z.; Bian, H.; Yang, Y.; Nie, N.; Wang, F. Graphene/Glycerin Solution-Based Multifunctional Stretchable Strain Sensor with Ultra-High Stretchability, Stability, and Sensitivity. Nanomaterials 2019, 9, 617.

- Aziz, S.; Chang, S.-H. Smart-fabric sensor composed of single-walled carbon nanotubes containing binary polymer composites for health monitoring. Compos. Sci. Technol. 2018, 163, 1–9.

- Wan, J.; Wang, Q.; Zang, S.; Huang, X.; Wang, T.; Liu, G.; Li, C.; Ren, X. Highly stretchable and sensitive liquid-type strain sensor based on a porous elastic rope/elastomer matrix composite structure. Compos. Sci. Technol. 2019, 182, 107707.

- Wu, G.; Wu, X.; Xu, Y.; Cheng, H.; Meng, J.; Yu, Q.; Shi, X.; Zhang, K.; Chen, W.; Chen, S. High-Performance Hierarchical Black-Phosphorous-Based Soft Electrochemical Actuators in Bioinspired Applications. Adv. Mater. 2019, 31, 1806492.

- Costa, J.C.; Spina, F.; Lugoda, P.; Garcia-Garcia, L.; Roggen, D.; Munzenrieder, N. Flexible Sensors—From Materials to Applications. Technologies 2019, 7, 35.

- Khalid, M.A.U.; Ali, M.; Soomro, A.M.; Kim, S.W.; Kim, H.B.; Lee, B.-G.; Choi, K.H. A highly sensitive biodegradable pressure sensor based on nanofibrous dielectric. Sensors Actuators A Phys. 2019, 294, 140–147.

- Bhattacharjee, M.; Soni, M.; Escobedo, P.; Dahiya, R. PEDOT:PSS Microchannel-Based Highly Sensitive Stretchable Strain Sensor. Adv. Electron. Mater. 2020, 6, 2000445.

- Kagenda, C.; Lee, J.W.; Memon, F.H.; Ahmed, F.; Samantasinghar, A.; Akhtar, M.W.; Khalique, A.; Choi, K.H. Silicone Elastomer Composites Fabricated with MgO and MgO-Multi-Wall Carbon Nanotubes with Improved Thermal Conductivity. Nanomaterials 2021, 11, 3418.

- Choi, D.Y.; Kim, M.H.; Oh, Y.S.; Jung, S.-H.; Jung, J.H.; Sung, H.J.; Lee, H.W.; Lee, H.M. Highly Stretchable, Hysteresis-Free Ionic Liquid-Based Strain Sensor for Precise Human Motion Monitoring. ACS Appl. Mater. Interfaces 2017, 9, 1770–1780.

- Xu, S.; Vogt, D.M.; Hsu, W.-H.; Osborne, J.; Walsh, T.; Foster, J.R.; Sullivan, S.K.; Smith, V.C.; Rousing, A.W.; Goldfield, E.C.; et al. Biocompatible Soft Fluidic Strain and Force Sensors for Wearable Devices. Adv. Funct. Mater. 2018, 29, 1807058.

- Zhou, T.; Guo, B.; Xu, J. Highly Filled Glycerol/Graphite Suspensions as Fluidic Soft Sensors and Their Responsive Mechanism to Shear. Adv. Mater. Technol. 2020, 5, 2000508.

- Yang, G.; Pang, G.; Pang, Z.; Gu, Y.; Mantysalo, M.; Yang, H. Non-Invasive Flexible and Stretchable Wearable Sensors with Nano-Based Enhancement for Chronic Disease Care. IEEE Rev. Biomed. Eng. 2019, 12, 34–71.

- Wang, P.; Hu, M.; Wang, H.; Chen, Z.; Feng, Y.; Wang, J.; Ling, W.; Huang, Y. The Evolution of Flexible Electronics: From Nature, Beyond Nature, and To Nature. Adv. Sci. 2020, 7, 2001116.

- Jabbar, F.; Soomro, A.M.; Lee, J.-W.; Ali, M.; Kim, Y.S.; Lee, S.-H.; Choi, K.H. Robust Fluidic Biocompatible Strain Sensor Based on PEDOT:PSS/CNT Composite for Human-wearable and High-end Robotic Applications. Sensors Mater. 2020, 32, 4077.

- Soomro, A.M.; Khalid, M.A.U.; Shah, I.; Kim, S.W.; Kim, Y.S.; Choi, K.H. Highly stable soft strain sensor based on Gly-KCl filled sinusoidal fluidic channel for wearable and water-proof robotic applications. Smart Mater. Struct. 2019, 29, 025011.

- Asif, A.; Park, S.H.; Soomro, A.M.; Khalid, M.A.U.; Salih, A.R.C.; Kang, B.; Ahmed, F.; Kim, K.H.; Choi, K.H. Microphysiological system with continuous analysis of albumin for hepatotoxicity modeling and drug screening. J. Ind. Eng. Chem. 2021, 98, 318–326.

- Bringans, R.D.; Veres, J. Challenges and Opportunities in Flexible Electronics. In Proceedings of the 2016 IEEE International Electron Devices Meeting (IEDM), San Francisco, CA, USA, 3–7 December 2016; Volume 6.4.1–6.4.2.

- Zhang, S.-H.; Wang, F.-X.; Li, J.-J.; Peng, H.-D.; Yan, J.-H.; Pan, G.-B. Wearable Wide-Range Strain Sensors Based on Ionic Liquids and Monitoring of Human Activities. Sensors 2017, 17, 2621.

- Russo, S.; Ranzani, T.; Liu, H.; Nefti-Meziani, S.; Althoefer, K.; Menciassi, A. Soft and Stretchable Sensor Using Biocompatible Electrodes and Liquid for Medical Applications. Soft Robot. 2015, 2, 146–154.

- Keulemans, G.; Pelgrims, P.; Bakula, M.; Ceyssens, F.; Puers, R. An Ionic Liquid Based Strain Sensor for Large Displacements. Procedia Eng. 2014, 87, 1123–1126.

- Xu, M.; Qi, J.; Li, F.; Zhang, Y. Highly stretchable strain sensors with reduced graphene oxide sensing liquids for wearable electronics. Nanoscale 2018, 10, 5264–5271.

- Dickey, M.D. Stretchable and Soft Electronics using Liquid Metals. Adv. Mater. 2017, 29, 1606425.

- Yao, G.; Yin, C.; Wang, Q.; Zhang, T.; Chen, S.; Lu, C.; Zhao, K.; Xu, W.; Pan, T.; Gao, M.; et al. Flexible bioelectronics for physiological signals sensing and disease treatment. J. Materiomics 2020, 6, 397–413.

- Ali, A.; Hantanasirisakul, K.; Abdala, A.; Urbankowski, P.; Zhao, M.-Q.; Anasori, B.; Gogotsi, Y.; Aïssa, B.; Mahmoud, K.A. Effect of Synthesis on Performance of MXene/Iron Oxide Anode Material for Lithium-Ion Batteries. Langmuir 2018, 34, 11325–11334.

- Ota, H.; Chen, K.; Lin, Y.; Kiriya, D.; Shiraki, H.; Yu, Z.; Ha, T.-J.; Javey, A. Highly deformable liquid-state heterojunction sensors. Nat. Commun. 2014, 5, 5032.

- Agaoglu, S.; Diep, P.; Martini, M.; Kt, S.; Baday, M.; Araci, I.E. Ultra-sensitive microfluidic wearable strain sensor for intraocular pressure monitoring. Lab Chip 2018, 18, 3471–3483.

- Cheung, Y.-N.; Zhu, Y.; Cheng, C.-H.; Chao, C.; Leung, W.W.-F. A novel fluidic strain sensor for large strain measurement. Sens. Actuators A Phys. 2008, 147, 401–408.

- He, R.; Liu, H.; Niu, Y.; Zhang, H.; Genin, G.M.; Xu, F. Flexible Miniaturized Sensor Technologies for Long-Term Physiological Monitoring. NPJ Flex. Electron. 2022, 6, 1–11.

- Ashraf, H.; Shah, B.; Soomro, A.M.; Safdar, Q.-U.; Halim, Z.; Shah, S.K. Ambient-noise Free Generation of Clean Underwater Ship Engine Audios from Hydrophones using Generative Adversarial Networks. Comput. Electr. Eng. 2022, 100, 107970.

- Khan, H.; Soomro, A.M.; Samad, A.; Ullah, I.; Waqas, M.; Ashraf, H.; Khan, S.A.; Choi, K.H. Highly sensitive mechano-optical strain sensors based on 2D materials for human wearable monitoring and high-end robotic applications. J. Mater. Chem. C 2022, 10, 932–940.

- Ahmed, F.; Waqas, M.; Shaikh, B.; Khan, U.; Soomro, A.M.; Kumar, S.; Ashraf, H.; Memon, F.H.; Choi, K.H. Multi-material Bio-inspired Soft Octopus Robot for Underwater Synchronous Swimming. J. Bionic Eng. 2022, 19, 1229–1241.

- Ahmed, F.; Waqas, M.; Javed, B.; Soomro, A.M.; Kumar, S.; Ashraf, H.; Khan, U.; Kim, K.H.; Choi, K.H. Decade of bio-inspired soft robots: A review. Smart Mater. Struct. 2022, 31, 073002.

- Khalid, M.A.U.; Kim, K.H.; Salih, A.R.C.; Hyun, K.; Park, S.H.; Kang, B.; Soomro, A.M.; Ali, M.; Jun, Y.; Huh, D.; et al. High performance inkjet printed embedded electrochemical sensors for monitoring hypoxia in a gut bilayer microfluidic chip. Lab Chip 2022, 22, 1764–1778.

- Yan, H.-L.; Chen, Y.-Q.; Deng, Y.; Zhang, L.-L.; Hong, X.; Lau, W.-M.; Mei, J.; Hui, D.; Yan, H.; Liu, Y. Coaxial printing method for directly writing stretchable cable as strain sensor. Appl. Phys. Lett. 2016, 109, 083502.

- Asif, A.; Kim, K.H.; Jabbar, F.; Sejoong, K.; Choi, K.H. Real-time sensors for live monitoring of disease and drug analysis in microfluidic model of proximal tubule. Microfluid. Nanofluid 2020, 24, 1–10.

- Votzke, C.; Daalkhaijav, U.; Mengue, Y.; Johnston, M.L. Highly-Stretchable Biomechanical Strain Sensor using Printed Liquid Metal Paste. In Proceedings of the 2018 IEEE Biomedical Circuits and Systems Conference (BioCAS), Cleveland, OH, USA, 17–19 October 2018; pp. 1–4.

- Gao, Q.; Li, H.; Zhang, J.; Xie, Z.; Zhang, J.; Wang, L. Microchannel Structural Design for a Room-Temperature Liquid Metal Based Super-stretchable Sensor. Sci. Rep. 2019, 9, 1–8.

- Yang, Y.; Wang, H.; Hou, Y.; Nan, S.; Di, Y.; Dai, Y.; Li, F.; Zhang, J. MWCNTs/PDMS composite enabled printed flexible omnidirectional strain sensors for wearable electronics. Compos. Sci. Technol. 2022, 226, 109518.

- Chong, H.; Lou, J.; Bogie, K.M.; Zorman, C.A.; Majerus, S.J.A. Vascular Pressure–Flow Measurement Using CB-PDMS Flexible Strain Sensor. IEEE Trans. Biomed. Circuits Syst. 2019, 13, 1451–1461.

- Ko, Y.; Kim, J.-S.; Vu, C.; Kim, J. Ultrasensitive Strain Sensor Based on Pre-Generated Crack Networks Using Ag Nanoparticles/Single-Walled Carbon Nanotube (SWCNT) Hybrid Fillers and a Polyester Woven Elastic Band. Sensors 2021, 21, 2531.

- Sahlberg, A.; Nilsson, F.; Berglund, A.; Nguyen, H.; Hjort, K.; Jeong, S.H. High-Resolution Liquid Alloy Patterning for Small Stretchable Strain Sensor Arrays. Adv. Mater. Technol. 2018, 3, 1700330.

- Wu, Y.; Zhou, Y.; Asghar, W.; Liu, Y.; Li, F.; Sun, D.; Hu, C.; Wu, Z.; Shang, J.; Yu, Z.; et al. Liquid Metal-Based Strain Sensor with Ultralow Detection Limit for Human–Machine Interface Applications. Adv. Intell. Syst. 2021, 3, 2000235.

- Chen, J.; Zhang, J.; Luo, Z.; Zhang, J.; Li, L.; Su, Y.; Gao, X.; Li, Y.; Tang, W.; Cao, C.; et al. Superelastic, Sensitive, and Low Hysteresis Flexible Strain Sensor Based on Wave-Patterned Liquid Metal for Human Activity Monitoring. ACS Appl. Mater. Interfaces 2020, 12, 22200–22211.

- Yoon, S.G.; Koo, H.-J.; Chang, S.T. Highly Stretchable and Transparent Microfluidic Strain Sensors for Monitoring Human Body Motions. ACS Appl. Mater. Interfaces 2015, 7, 27562–27570.

- Wu, Y.-H.; Zhen, R.-M.; Liu, H.-Z.; Liu, S.-Q.; Deng, Z.-F.; Wang, P.-P.; Chen, S.; Liu, L. Liquid metal fiber composed of a tubular channel as a high-performance strain sensor. J. Mater. Chem. C 2017, 5, 12483–12491.

- Cheng, S.; Wu, Z. A Microfluidic, Reversibly Stretchable, Large-Area Wireless Strain Sensor. Adv. Funct. Mater. 2011, 21, 2282–2290.

- Soter, G.; Garrad, M.; Conn, A.T.; Hauser, H.; Rossiter, J. Skinflow: A Soft Robotic Skin Based on Fluidic Transmission. In Proceedings of the 2019 2nd IEEE International Conference on Soft Robotics (RoboSoft), Seoul, Korea, 14–18 April 2019; pp. 355–360.

- Chossat, J.-B.; Park, Y.-L.; Wood, R.J.; Duchaine, V. A Soft Strain Sensor Based on Ionic and Metal Liquids. IEEE Sensors J. 2013, 13, 3405–3414.

- Yepes, L.R.; Demir, E.; Lee, J.Y.; Sun, R.; Smuck, M.; Araci, I.E. Skin Mountable Capillaric Strain Sensor with Ultrahigh Sensitivity and Direction Specificity. Adv. Mater. Technol. 2020, 5, 2000631.

- Niu, B. Design, Fabrication and Characterization of Flexible, Wearable and Highly Durable Strain Sensors Assisted by Bioin-Spired Polydopamine. . 2021. Available online: https://theses.lib.polyu.edu.hk/handle/200/11150 (accessed on 8 September 2022).

- Yoon, S.G.; Park, B.J.; Chang, S.T. Highly sensitive microfluidic strain sensors with low hysteresis using a binary mixture of ionic liquid and ethylene glycol. Sens. Actuators A Phys. 2017, 254, 1–8.

- Khalid, M.A.U.; Chang, S.H. Flexible strain sensors for wearable applications fabricated using novel functional nanocomposites: A review. Compos. Struct. 2022, 284, 115214.

More