Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 3 by Conner Chen and Version 2 by Conner Chen.

Hot corrosion is due to the severe deterioration of metals due to sulfidation or oxidation reactions of the deposits in the form of liquid or semi-liquid at an operating temperature. In a gas turbine, there are corrosive particles in the environment and lower-grade fuel—for example, chlorine, sodium, sulfur, and vanadium.

- thermal spray coating

- high-velocity oxyfuel

- hot corrosion sulfidation

1. Introduction

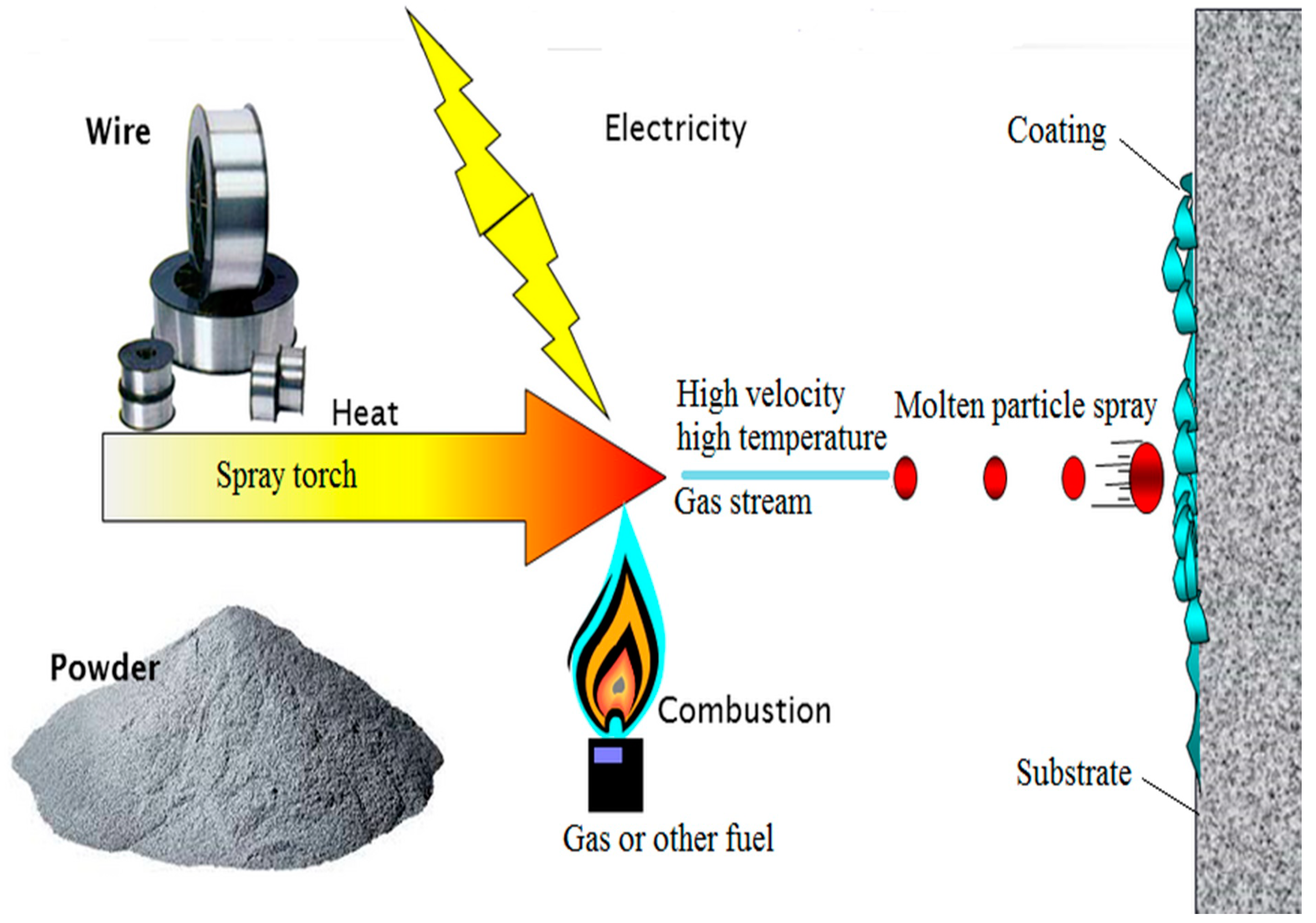

Thermal spray is a coating process by which the fine particles of a material in metal or non-metal form are deposited on the surface of a formulated substrate in a molten or semi-molten state [1]. The material to be coated can be deposited in various states, particularly wire, powders, rods, suspension, or molten form [2]. The torch converts particles depending on the energy supplied into a hot gas stream. For combustion, chemical energy is used, and electric power is used for plasma generation [3]. The coating material heated during combustion or plasma generation converts to a molten state and is propelled by the high velocity and high-temperature gas stream to the substrate. The particles distort when depositing the substrate’s surface to produce a splat. When new particles reach the surface, they combine to make multiple splat layers to complete the coating [4]. Figure 1 shows the thermal spray coating process. While selecting a coating material, it should be kept in mind that the thermal expansion coefficient of the substrate and the coating material must match each other [5].

Figure 1. Thermal spray process. Modified with permission from [6]. 2007, Sudhangshu Bose.

Naturally, thermal barrier coating contains four layers: a ceramic topcoat, a transitional metallic bond coat, a thermally grown oxide (TGO) layer, and a high-temperature base structural material made of superalloy [7]. The topcoat ceramic performs the function of an insulator, keeps the underlying substrate away from degradation due to the high temperature by providing protection, and resists heat transfer [8][9][10][11][12]. The bond coat is used for oxidation resistance [13][14]. The excessively frequently used materials for the topcoat and bond coat are the materials that are heat resistant, such as yttria-stabilized zirconia (8YSZ) and MCrAlY (M: cobalt, nickel, or a combination of both elements), respectively [8]. Thermal spray techniques deposit the topcoat and bond coat on the metallic substrate [15]. The thermally grown oxide (TGO) layer is a barrier against oxygen diffusion [16][17]. A substrate is usually made of cobalt or nickel superalloy to tolerate the load mechanically [18]. During service, it must be kept in mind that the composition and microstructure of the layers change instantly, leading to the failure and degradation of the coating [19].

The life and performance of service materials have improved with the development and research of new thermal coatings [20][21][22][23][24][25][26][27]. Thakare et al. [18] have presented an overview of thermal spray coating materials and technology, the progression in deposition techniques, and the materials used in thermal spray coating. They also introduced the TBC system’s residual stresses, properties, high-temperature performance, and life prediction models. Wu et al. [28] summarized the preparation procedures and improvements in new ceramic materials as well as current problems and future trends. Mehboob et al. [7] reviewed the failure mechanisms of TBCs and methods to alleviate these failures. Gopi et al. [29] addressed the corrosion analysis, wear characteristics, hardness, microstructure, and surface roughness of tungsten carbide coatings sprayed by high-velocity oxyfuel coating. Gupta N. et al. [30] reviewed the mechanical and microstructural properties of the CrC coatings coated by HVOFhigh-velocity oxyfuel (HVOF) and their suitability for the applications of piston rings. Vats et al. [31] investigated the outcome of deposition process parameters on the mechanical, wear, physical, corrosion, and erosion properties of coatings deposited by HVOF. Kumar et al. [32] presented an analysis of nanocomposite coatings sprayed by HVOF and concluded that nanocomposite coatings sprayed by HVOF can alleviate the erosion of traditional coatings.

2. Hot Corrosion in Gas Turbine Blades

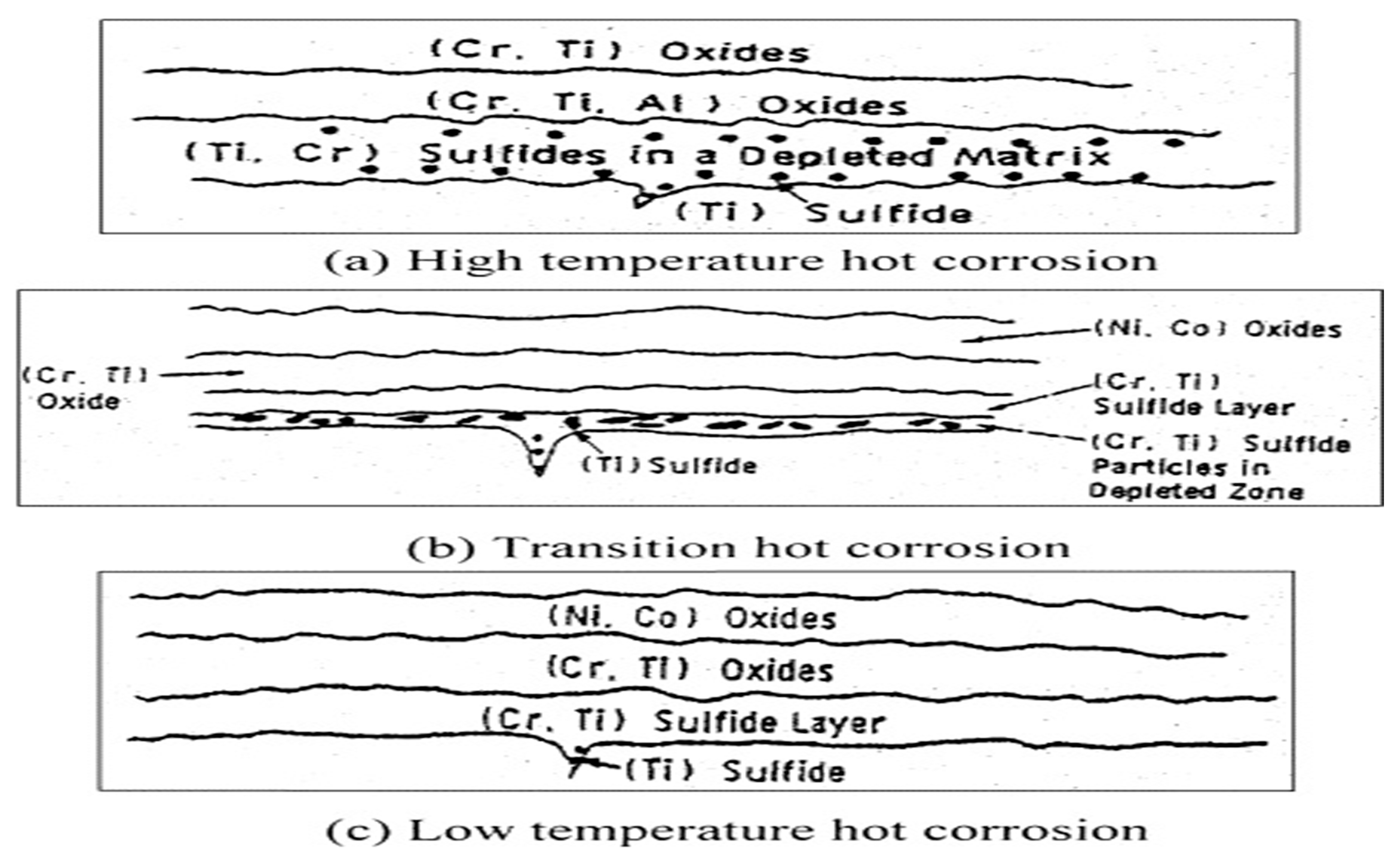

Due to combustion gases in gas turbines, the environment is not clean [33]. There are impurities in the fuel or combustion air, such as sea water aerosol containing vanadium and sulfates, deposited on the surface of turbine blades. Hot corrosion is due to the severe deterioration of metals due to sulfidation or oxidation reactions of the deposits in the form of liquid or semi-liquid at an operating temperature. Corrosion has a destructive impact on the structure of components [34]. Corrosion can be prevented by using protective measurements [35]. In the case of gas turbines, the temperature can reach 1500 °C. Typically, the material used for coating is made of YSZ, which is stable up to 1200 °C. Above this temperature, the coating starts to damage. Due to this, the turbine’s lifetime is decreased at high temperatures. The corrosion of superalloys or materials in the presence of oxidizing gas due to molten salt at a high temperature of 700–925 °C is called hot corrosion. The oxidation rate is fast at this temperature when alloys and metals are contaminated with salts. As a result, the protective oxide layer breaks down, and salts reach the metal surface, causing degradation [36]. Due to this degradation, the bond coat and topcoat are affected because of the porosity of the APS method in YSZ coating. Through pores and cracks, the molten salt penetrates the YSZ and reacts with a bond coat. [37] It is different from corrosion at low temperatures. Suppose the hot corrosion occurs at a temperature equal to the melting point of salt layers. In that case, it is hot corrosion of type 1, and the corrosion occurring at a temperature less than the melting point of the salt layers is called type 2 hot corrosion. The temperature range for high-temperature corrosion is 800 to 900 °C, and for low temperatures, it is 700 to 800 °C. Figure 2 represents the hot corrosion mechanism at low and high temperatures of a substrate. In a gas turbine, there are corrosive particles in the environment and lower-grade fuel—for example, chlorine, sodium, sulfur, and vanadium [38]. Corrosion in the topcoat is because of lead (Pb) and vanadium in the fuel. Vanadium forms vanadium pentoxide by reacting with oxygen. Sulfur is also present in the fuel that reacts with NaCl and oxygen in the air intake to produce Na2SO4. These two products are hazardous for the topcoat [39]. These species have pits and voids at the grain boundary responsible for the flow of corrosive particles that react with the metal to deteriorate them, and in this way, the life of the components is decreased. Corrosion in the bond coat can be produced due to chlorides and sulfates of sulfur or potassium gas. In the air, potassium or sodium chloride reacts with sulfur and oxygen in the fuel to have potassium or sodium sulfates. These sulfates are the reason for corrosion in the bond coat. Despite the fuel or air, corrosion can also be produced after combustion due to the contaminants in the fuel that deposit on the surface. After that, these corrosive products stick on the surface of hot sections such as turbine blades. A non-defensive porous oxide scale is produced on the surface, and the material is consumed quickly. As a result, the ability of a material to carry a load is diminished, which is the reason for the failure of the components. On the other hand, molten deposits are also responsible for the hot corrosion of thermal barrier coatings. The first mode of corrosion by molten deposits is chemical reaction attack by-products—for example, vanadium and sulfur. These products react with ceramic oxides to form corrosive melts. The second mode is mineralization due to the phase reaction of nonreactive liquid, which moves the nonequilibrium phase to the equilibrium phase. The third mode is the corrosion of the bond coat, in which corrodent melts or corrosive gases can enter the zirconia layer under some conditions and corrode the bond coat, eventually leading to the failure of TBC. The fourth mode is the physical damage of coating by the penetration of molten salt through the grains of TBC [40]. So, there is a need to keep the hot segment parts away from molten salt particles at high temperatures. A potentiodynamic polarization test in the saline solution measures the corrosion resistance. The current density for corrosion is between the range of 10−5 to 10−6 A/cm2 [41]. If the turbine blade is not coated, then pitting and corrosion can affect the blade, and the consequences may be severe if there is a salty environment.

Figure 2. Hot corrosion mechanism in a gas turbine blade. Reprinted with permission from [42]. 2004, M.R Khajavi, M. H Shariat.

References

- Chagnon, P.; Fauchais, P. Thermal spraying of ceramics. Ceram. Int. 1984, 10, 119–131.

- Sampath, S.; Jiang, X.; Matejicek, J.; Prchlik, L.; Kulkarni, A.; Vaidya, A. Role of thermal spray processing method on the microstructure, residual stress and properties of coatings: An integrated study for Ni–5 wt.% Al bond coats. Mater. Sci. Eng. A 2004, 364, 216–231.

- Cizek, J.; Matejicek, J. Medicine meets thermal spray technology: A review of patents. J. Therm. Spray Technol. 2018, 27, 1251–1279.

- Fanicchia, F.; Axinte, D.; Kell, J.; McIntyre, R.; Brewster, G.; Norton, A. Combustion flame spray of CoNiCrAlY & YSZ coatings. Surf. Coat. Technol. 2017, 315, 546–557.

- Kang, Y.; Bai, Y.; Fan, W.; Yuan, T.; Gao, Y.; Bao, C.; Li, B. Thermal cycling performance of La2Ce2O7/50 vol.% YSZ composite thermal barrier coating with CMAS corrosion. J. Eur. Ceram. Soc. 2018, 38, 2851–2862.

- Bose, S. Chapter 5—High-Temperature Corrosion. In High Temperature Coatings; Bose, S., Ed.; Butterworth-Heinemann: Burlington, VT, USA, 2007; pp. 53–70.

- Mehboob, G.; Liu, M.-J.; Xu, T.; Hussain, S.; Mehboob, G.; Tahir, A. A review on failure mechanism of thermal barrier coatings and strategies to extend their lifetime. Ceram. Int. 2020, 46, 8497–8521.

- Meng, G.-H.; Zhang, B.-Y.; Liu, H.; Yang, G.-J.; Xu, T.; Li, C.-X.; Li, C.-J. Highly oxidation resistant and cost effective MCrAlY bond coats prepared by controlled atmosphere heat treatment. Surf. Coat. Technol. 2018, 347, 54–65.

- Zhang, B.-Y.; Yang, G.-J.; Li, C.-X.; Li, C.-J. Non-parabolic isothermal oxidation kinetics of low pressure plasma sprayed MCrAlY bond coat. Appl. Surf. Sci. 2017, 406, 99–109.

- Masoule, S.T.; Valefi, Z.; Ehsani, N.; Lavasani, H.Q. Thermal insulation and thermal shock behavior of conventional and nanostructured plasma-sprayed TBCs. J. Therm. Spray Technol. 2016, 25, 1684–1691.

- Sivakumar, G.; Banerjee, S.; Raja, V.; Joshi, S.V. Hot corrosion behavior of plasma sprayed powder-solution precursor hybrid thermal barrier coatings. Surf. Coat. Technol. 2018, 349, 452–461.

- Sivakumar, S.; Praveen, K.; Shanmugavelayutham, G.; Yugeswaran, S.; Mostaghimi, J. Thermo-physical behavior of atmospheric plasma sprayed high porosity lanthanum zirconate coatings. Surf. Coat. Technol. 2017, 326, 173–182.

- Meng, G.-H.; Zhang, B.-Y.; Liu, H.; Yang, G.-J.; Xu, T.; Li, C.-X.; Li, C.-J. Vacuum heat treatment mechanisms promoting the adhesion strength of thermally sprayed metallic coatings. Surf. Coat. Technol. 2018, 344, 102–110.

- Chen, X.; Zhao, Y.; Gu, L.; Zou, B.; Wang, Y.; Cao, X. Hot corrosion behaviour of plasma sprayed YSZ/LaMgAl11O19 composite coatings in molten sulfate–vanadate salt. Corros. Sci. 2011, 53, 2335–2343.

- Afrasiabi, A.; Saremi, M.; Kobayashi, A. A comparative study on hot corrosion resistance of three types of thermal barrier coatings: YSZ, YSZ+Al2O3 and YSZ/Al2O3. Mater. Sci. Eng. A 2008, 478, 264–269.

- Yang, L.; Liu, Q.; Zhou, Y.-C.; Mao, W.; Lu, C. Finite element simulation on thermal fatigue of a turbine blade with thermal barrier coatings. J. Mater. Sci. Technol. 2014, 30, 371–380.

- Bahamirian, M.; Hadavi, S.; Farvizi, M.; Rahimipour, M.; Keyvani, A. Enhancement of hot corrosion resistance of thermal barrier coatings by using nanostructured Gd2Zr2O7 coating. Surf. Coat. Technol. 2019, 360, 1–12.

- Thakare, J.G.; Pandey, C.; Mahapatra, M.M.; Mulik, R.S. Thermal Barrier Coatings—A State of the Art Review. Met. Mater. Int. 2020, 27, 1947–1968.

- Clarke, D.R.; Oechsner, M.; Padture, N.P. Thermal-barrier coatings for more efficient gas-turbine engines. MRS Bull. 2012, 37, 891–898.

- Prashar, G.; Vasudev, H. Structure-property correlation and high-temperature erosion performance of Inconel625-Al2O3 plasma-sprayed bimodal composite coatings. Surf. Coat. Technol. 2022, 439, 128450.

- Vasudev, H.; Thakur, L.; Singh, H.; Bansal, A. Effect of addition of Al2O3 on the high-temperature solid particle erosion behaviour of HVOF sprayed Inconel-718 coatings. Mater. Today Commun. 2022, 30, 103017.

- Prashar, G.; Vasudev, H.; Thakur, L. Influence of heat treatment on surface properties of HVOF deposited WC and Ni-based powder coatings: A review. Surf. Topogr. Metrol. 2021, 9, 043002.

- Prashar, G.; Vasudev, H.; Thakur, L. High-Temperature Oxidation and Erosion Resistance of Ni-Based Thermally-Sprayed Coatings Used in Power Generation Machinery: A Review. Surf. Rev. Lett. 2022, 29, 2230003.

- Prashar, G.; Vasudev, H. A review on the influence of process parameters and heat treatment on the corrosion performance of Ni-based thermal spray coatings. Surf. Rev. Lett. 2022, 29, 2230001.

- Singh, P.; Bansal, A.; Vasudev, H.; Singh, P. In situ surface modification of stainless steel with hydroxyapatite using microwave heating. Surf. Topogr. Metrol. 2021, 9, 035053.

- Vasudev, H.; Thakur, L.; Singh, H.; Bansal, A. Erosion behaviour of HVOF sprayed Alloy718-nano Al2O3 composite coatings on grey cast iron at elevated temperature conditions. Surf. Topogr. Metrol. 2021, 9, 035022.

- Vasudev, H.; Thakur, L.; Singh, H.; Bansal, A. An investigation on oxidation behaviour of high velocity oxy-fuel sprayed Inconel718-Al2O3 composite coatings. Surf. Coat. Technol. 2020, 393, 125770.

- Wu, S.; Zhao, Y.; Li, W.; Liu, W.; Wu, Y.; Liu, F. Research Progresses on Ceramic Materials of Thermal Barrier Coatings on Gas Turbine. Coatings 2021, 11, 79.

- Gopi, R.; Saravanan, I.; Devaraju, A.; Ponnusamy, P. Tribological behaviour of thermal sprayed high velocity oxy-fuel coatings on tungsten carbide–A review. Mater. Today Proc. 2021, 39, 292–295.

- Gupta, N.; Singh, S.K.; Pandey, S.M. Tribological characterisation of thermal sprayed CrC alloyed coating–A review. Adv. Mater. Process. Technol. 2021, 7, 660–683.

- Vats, A.; Kumar, A.; Patnaik, A.; Meena, M. Influence of deposition parameters on Tribological Performance of HVOF Coating: A review. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2021; p. 012015.

- Kumar, R.; Bhandari, D.; Goyal, K.J. A Review of the Mechanical Properties and Erosion Behavior of HVOF Sprayed Nanocomposite Coatings. In Advancement in Materials, Manufacturing Energy Engineering; Springer: Berlin/Heidelberg, Germany, 2022; Volume 1, pp. 277–287.

- Puspitasari, W.; Ahmad, F.; Ullah, S.; Raza, M.R.; Hussain, P.; Yusoff, P.; Yasmin, A. The study of corrosion behaviour of intumescent fire retardant coating with structural steel substrate. Int. J. Electrochem. Sci. 2018, 13, 9916–9930.

- Kabeb, S.M.; Hassan, A.; Mohamad, Z.; Sharer, Z.; Mokhtar, M.; Ahmad, F.J.C.E.T. Synergistic effect of graphene oxide/halloysite in anticorrosion performance and flame retardancy properties of epoxy nanocomposite coating. Chem. Eng. Trans. 2020, 78, 529–534.

- Kabeba, S.M.; Hassanb, A.; Mohamadb, Z.; Sharerb, Z.; Mokhtarb, M.; Ahmadc, F. Exploring the effects of nanofillers of epoxy nanocomposite coating for sustainable corrosion protection. Chem. Eng. Trans. 2019, 72, 121–126.

- Leyens, C.; Wright, I.G.; Pint, B.A. Hot Corrosion of an EB-PVD Thermal-Barrier Coating System at 950 °C. Oxid. Met. 2000, 54, 401–424.

- Chatha, S.S.; Sidhu, H.S.; Sidhu, B.S. High temperature hot corrosion behaviour of NiCr and Cr3C2–NiCr coatings on T91 boiler steel in an aggressive environment at 750 °C. Surf. Coat. Technol. 2012, 206, 3839–3850.

- Jonnalagadda, K.P.; Eriksson, R.; Peng, R.; Li, X.-H.; Johansson, S. Factors affecting the performance of thermal barrier coatings in the presence of V2O5 and Na2SO4. J. Ceram. Sci. Technol. 2016, 7, 409–415.

- Jones, R.L. Some aspects of the hot corrosion of thermal barrier coatings. J. Therm. Spray Technol. 1997, 6, 77–84.

- Berger, J.E.; Schulz, R.; Savoie, S.; Gallego, J.; Kiminami, C.S.; Bolfarini, C.; Botta, W.J. Wear and corrosion properties of HVOF coatings from Superduplex alloy modified with addition of boron. Surf. Coat. Technol. 2017, 309, 911–919.

- Conde, J.; Erdös, E.; Rahmel, A. Mechanisms of hot corrosion. In High Temperature Alloys for Gas Turbines; Springer: Dordrecht, The Netherlands, 1982; pp. 99–148.

- Khajavi, M.; Shariat, M. Failure of first stage gas turbine blades. Eng. Fail. Anal. 2004, 11, 589–597.

- Vasudev, H.; Prashar, G.; Thakur, L.; Bansal, A. Prevention Electrochemical Corrosion Behavior and Microstructural Characterization of HVOF Sprayed Inconel-718 Coating on Gray Cast Iron. J. Fail. Anal. Prev. 2021, 21, 250–260.

More