Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 1 by Noah Shephard and Version 3 by Conner Chen.

In the United States, Climate Smart Forestry (CSF) has quickly become a popular topic within the academic, political, and industry realms. Southern plantation forests in the United States are one of the most globally productive timberland systems.

- climate change mitigation

- climate change adaptation

- monoculture

1. Introduction

Southern plantation forests in the United States are one of the most globally productive timberland systems. Primarily composed of loblolly pine (Pinus taeda L.), Southern pine timberlands represent 22% (24 million ha) of total forest area and an astonishing 51% (218 thousand m3 yr−1) of total forest growth in the Southern region [1]. More broadly, loblolly pine is the second most abundant U.S. tree species (22 billion; red maple, Acer rubrum L., 25 billion) and represents an incredible 8% of nationwide live aboveground biomass (1.8 billion Mg yr−1; 20% in South) [1]. Not surprisingly, vast productivity translates to Southern plantations accounting for 63% (178.8 million m3 yr−1) of nationwide softwood removals [1]. However, immense Southern pine productivity can be used effectively beyond traditional, economic goals. For example, fast-growing loblolly pine rotations, often less than 30 years, offer enormous potential to alleviate climate change effects, such as rising atmospheric carbon dioxide (CO2), through the transfer of such atmospheric carbon to biomass carbon. Southern private forests account for almost 60% (61 Tg C yr−1, circa 2018) of nationwide net aboveground biomass flux, a flux approximately 2.5 times greater than Northern private forests, and 10 times greater than Western private forests [2]. Timber industry, world leaders, non-governmental organizations, and non-industrial private forest landowners have acknowledged a synergistic relationship between economic goals and ecosystem services and have labeled it ‘Climate Smart Forestry’ (CSF).

CSF fundamentals emphasize enhanced forest carbon sinks; thus, forests are leveraged as a nature-based solution for climate change. In turn, forest carbon sinks can help nations meet emissions-related goals, such as the Paris Climate Agreement [3], and can help private landowners with environmental, social, and governance (ESG) benefits [4]. Fortunately, the scientific community has a firm understanding of forest carbon cycles [5], especially simple loblolly pine plantation carbon pools and fluxes [6], so it is well understood how to increase forest carbon capture. However, there are knowledge gaps in terms of CSF definition, the relationship between traditional silviculture and CSF silviculture, timber product carbon storage, and data collection for CSF—to mention only a few.

2. Loblolly Pine Silviculture

2.1. Aboveground Stand Production

CSF Application: Aboveground tree carbon is the easiest for silviculturists to manipulate for mitigation purposes. There can be select adaptation benefits from increased aboveground carbon. Southern pine plantation silviculture is truly a success story in terms of increased carbon storage. Pine plantations are now considered a large carbon sink at the stand [7][34] and landscape level [8][35] across the commercial range of loblolly pine. This was not always the case. In the 1950s, Southern pine plantations totaled forests less than 0.8 million hectares [9][36] with a net growing stock equal to 2900 Tgaboveground C. Now there are over 16 million hectares of planted Southern pine and a net growing stock of 5600 Tgaboveground C (+93%) [1]. Site carbon storage (stem productivity) has increased due to management options that have increased site quality such as improved genetics and silviculture [10][11][37,38]. Stem production is important because this is where the majority (~55%) of aboveground loblolly pine carbon is stored [6]. Silvicultural stem-production effects are often additive in nature [12][13][39,40].2.2. Improved Genetics

CSF Application: Tree improvement has increased landscape-level carbon capture (mitigation) and increased forest resilience to potential abiotic and biotic threats (adaptation). Planting genetically improved seedlings (1st and 2nd generation, half-sib) in the South has increased steadily since the 1960s [14][41]. Genetically improved seedlings are products of classical breeding techniques, not genetically modified organisms (GMOs), that have been selected for superior phenotypes based around stem volume, stem form, and fusiform rust (Cronartium quercuum f.sp. fusiforme) resistance [15][42]. As a result, stand volume production and stand carbon storage have increased. From 1968 to 2007, genetic improvement increased loblolly pine carbon storage by 13% (9865 Tg C), compared to non-improved loblolly pine carbon storage [8765 Tg C, 41]. Production gains are predicted to continue. Third-generation full-sib seedlings (+63% volume vs. non-improved) are now operational and 17% (136 million seedlings) of the 2018 planting season were full-sib seedlings [15][42]. Beyond production, genetic improvement has also benefited tree health. Improved seedlings have been linked to Southern pine Beetle (SPB, Dentroctonus frontalis Z.)-resistant trees [16][43]. Possible explanations for SPB resistance could be from increased resin flow [17][44], lower susceptibility to storm damage [13][40] from larger, deeper root systems [18][45], and lower fusiform rust incidence (healthier trees, [15][42]), potentially aided by genomic mapping efforts [19][46]. In-turn, improved stand health has increased carbon production via decreased mortality and increased tree vigor (i.e., [20][47]).2.3. Site Preparation

CSF Application: Site preparation has increased seedling survival (adaptation) and stem productivity (mitigation). Site preparation optimizes sunlight, nutrient, and water availability to shade-intolerant loblolly pine seedlings. This results in decreased interspecific competition and increased seedling survival [21][25]. In the Upper Coastal Plain and Piedmont, the practice has evolved from intensive mechanical practices, such as tillage and windrowing, to less-intensive chemical site preparation [22][27], due to decreased nutrient displacement [23][48]. Herbicide preparation treatments have increased (+10%, year six) seedling survival, compared to mechanical treatments such as burn-only and burn-chop treatments [24][49]. Operational chemical site preparation before planting (glyphosate, imazapyr, e.g., [25][50]), followed by burning increased volume production through year 21 in the Upper Coastal Plain and Piedmont [26][27][51,52]. Compared to a burn-only scenario, this translates to 56% (59.5 Mg C ha−1) to 60% (61.1 Mg C ha−1), dependent on application, more stem carbon storage at harvest (year 21, [24][49]). It should be noted, mechanical preparation (sub-soiling, bedding) is still used to create adequate bare mineral soil conditions on rocky sites (e.g., Upper Gulf Region, [28][53]) and increase soil drainage in excessively wet sites [29][54]. Additionally, herbicide-treated seedlings have greater vigor and resistance to pest-induced mortality such as pine tip moth (Rhyacionia spp.) [30][55].2.4. Herbaceous Weed and Woody Control

CSF Application: Vegetation management can increase stem carbon storage via decreased competition for soil nutrients and increased long-lived product (mitigation). Early (i.e., herbaceous weed control, ‘herbaceous weed control (HWC)’) and mid-rotation (i.e., ‘woody release’) vegetation management are two separate strategies commonly used to eliminate herbaceous and woody vegetation in favor of faster growing loblolly pine. HWC increases carbon gain early in rotation, compared to other treatments such as a woody release treatment or mid-rotation fertilization, which increases carbon later. One common strategy is imazapyr and/or glyphosate application after planting to control herbaceous weeds [31][57], along with sulfomethuron methyl and metsulfuron meythyl application to control early woody plant growth [32][58]. Later in rotation, if needed, the additional application of imazapyr and/or triclopyr can be used for woody release [33][59]. Competition control has increased stand-level stem carbon in various physiographic regions such as the Piedmont [34][60], Lower Coastal Plain [35][61], and the Florida Coastal Plain [36][62]. The magnitude of treatment response can be dependent on soil drainage and nutrient pools. On some Coastal Plain sites with poor drainage and low nutrient reserves, herbicide increased stem production by 70% (46 Mg C ha−1) [10][37]. Well-drained Piedmont and Upper Coastal sites with higher nutrient reserves had slightly lower responses, +60% (63 Mg C ha−1) [24][49]. Herbicide application also leads to greater sawtimber production [10][37], and the potential for more long-lived products (see 4.4). On a financial note, mid-rotation herbicide treatment (USD 153 ha−1) has recently been more cost-effective than fertilization (USD 240 ha−1) due to 1) decreased herbicide costs (−0.49% yr−1) 2), increased fertilizer costs (+0.46% yr−1), and current low sawtimber prices (~USD 25 ton−1) [37][63].2.5. Thinning

CSF Application: Density management results in increased residual stem production, carbon storage (mitigation), and greater resistance to abiotic and biotic events (adaptation). Thinning is a tool to remove unwanted stems and increase the growth of residual stems. In mid-rotation loblolly pine plantations, ‘thin-from-below’ is common with canopy closure, i.e., when interspecific competition and density-dependent mortality rises. Decreased stand-density (thinning) results in lower stand-level aboveground biomass (carbon) [38][64]. Despite lower stand-biomass, thin-from-below is a production- and health-oriented strategy to ultimately increase sawtimber proportion [39][65]. For example, in the Lower Gulf Region, in year 7 and 14, below thinning increased the average tree diameter by 45% (21.8 cm thin, 15.0 cm non-thin) by age 17 [40][66]. Additionally, Hennessey, et al. [41][67] found that 21-year-old non-thinned stands had approximately six-times more mortality than thinned stands. Production-wise this equates to 33% of trees in non-thinned stands classified as sawtimber, whereas 92% of trees in thinned stands can be classified as sawtimber [41][67]. The future Southern landscape is predicted to have greater Southern pine Beetle infestation [42][68] and more severe wind events [43][69]. Thinning can limit stand susceptibility to such insect outbreaks and extreme weather events. Thinning has significantly decreased Southern pine beetle infestation severity [44][70], spread [44][70], and outbreak number [16][43]. Speaking to weather, mid-rotation thinning can mitigate steam breakage due to extreme winds [45][71], and in some cases, decrease mortality from ice-accumulation [46][72]. These few examples highlight the trend that stand density management is essential for mitigating events that can limit carbon accumulation.2.6. Fertilization

CSF Application: Nutrient amendments lead to increased aboveground carbon storage (mitigation), shorter rotation age (adaptation), and increased long-lived product (mitigation). Fertilization has increased carbon storage across precipitation and soil texture gradients in loblolly pine’s commercial range [7][47][48][34,73,74]. Research has established a common mid-rotation prescription of 28 kg P ha−1 and 225 kg N ha−1 (e.g., [49][75]) to increase stem production and shorten rotation age. On average, nutrient amendments can increase volume production by 60% over eight years (+0.14 Mg C ha−1 yr−1, [50][76]); when fertilization follows mid-rotation, the thinning effects on diameter growth are often synergistic [51][77]. From fertilization, net ecosystem carbon storage increased in stands located in the Upper Gulf (xeric, well-drained), Piedmont (mesic, well-drained), and Lower Coastal Plain (mesic, poorly drained) regions [7][34]. Additional nutrient availability can typically decrease rotation age [50][76] and increase sawtimber product proportion [52][78]. Such additional benefits have the ability to increase stand and wood product carbon over multiple rotations [53][79]. Fertilizer’s contribution to greenhouse gas (GHG) emissions is complicated since its impact is dependent on the product generated, e.g., pulpwood, sawtimber, or biomass [54][80]. Generally, sawtimber products can accumulate and offset carbon more effectively than pulpwood products [52][55][78,81]. Across 100-years, life-cycle-analysis (LCA) showed that sawtimber rotations with fertilization stored 135% (61 Mg C ha−1) more carbon than pulpwood rotations with fertilization (26 Mg C ha−1), due to a greater product lifespan, less product landfill accumulation, and increased product half-life [53][79]. In specific circumstances, fertilization can be justified on short, bioenergy-focused rotations. If emissions savings from increased bioenergy use and reduced coal use are greater than fertilization manufacturing, there will likely be net carbon savings [56][57][82,83]. This is especially true when pulpwood rotations, which lead to net GHG emissions, are compared to biomass rotations, which lead to net GHG reductions [54][80]. Despite predicted increased fertilizer use [49][75], fertilized forest area has decreased from 640 thousand ha in 1999 to 240 thousand ha in 2016 [58][84]. This has been attributed to low sawtimber prices in the late 2000s [58][84] and lower, nuanced fertilizer prescriptions [51][77]. As mentioned in 2.4, herbicide application is now more cost-effective. Fertilizer application for increased stem carbon has compromises. There are environmental consequences from cradle-to-gate from fertilizer use such as increased global warming potential and eutrophication. Fertilized stands (site preparation, herbicide, thinning, plus fertilization) compared to non-fertilized (site preparation, herbicide, thinning only) can have 1331% (6.15 × 10−2 kg C msawlog−3) more global warming potential and 1340% (8.30 × 10−4 kg N eq. msawlog−3) more eutrophication potential [59][56]. Though the percent increases are drastic for global warming and eutrophication potential, absolute values are low on a per sawlog basis.2.7. Harvest

CSF Application: Net carbon storage is achieved through silviculture, harvests, and replanting (mitigation). When clear-cut harvests are followed by replanting, there is greater overall long-term carbon accumulation compared to no-harvest scenarios [60][85]. On average, plantation silviculture can yield 2.72 Mg Csawlog ha−1 yr−1 on a 30-year rotation [59][56]. This translates to 235 Mg Cstem needed to produce 139 Mg Clumber or 1 m3 of planed, dry lumber [61][88]. In the big-picture, 100-year models indicated four consecutive loblolly pine rotations stored 542 Mg C ha−1 between stand, wood product, and landfill pools [62][89]. When harvests do not occur, stands can be overstocked, experience decreased growth, have increased mortality, and have decreased carbon pools [60][85]. Compared to naturally regenerated loblolly pine stands, site preparation with planting can considerably decrease rotation age from 47 to 29 years and increase carbon storage rate from 0.47 Mg C ha−1 yr−1 to 1.66 Mg C ha−1 yr−1. Further treatments of herbaceous weed control (HWC) + thinning + fertilization can raise carbon storage to 3.51 Mg C ha−1 yr−1 and shorten rotation age to about 25 years. Speaking to adaptation, production-minded silviculture may decrease the risk of natural disturbances (e.g., [63][90]) through shorter rotation ages.3. Timber Products

3.1. Carbon Reduction Pathways

Timber products can be leveraged to decrease atmospheric emissions [64][86]. Compared to carbon accumulation in no-harvest scenarios, there can be greater net carbon storage when harvests occur and timber products are manufactured [60][65][66][85,97,98]. Product type is important to consider. As mentioned in 2.6 and 2.7, sawtimber products are more effective at reducing carbon emissions than pulpwood products due to longer product lifespan, lower biogenic carbon emissions, and greater potential fossil-fuel carbon displacement. Such discrepancy brings to light the different ways timber products decrease atmospheric CO2. Some common pathways are storage, energy, and avoidance [65][97]. The storage pathway physically incorporates wood into products, so the wood does not rot, burn, and emit CO2. The energy pathway displaces fossil fuel combustion with biomass combustion that results in lower net CO2 emissions. The avoidance pathway substitutes wood products for carbon-intensive products such as steel and concrete, where less fossil fuel carbon is emitted. Timber products typically utilize a combination of storage, energy, and avoidance pathways [65][97].3.2. Avoidance Pathway

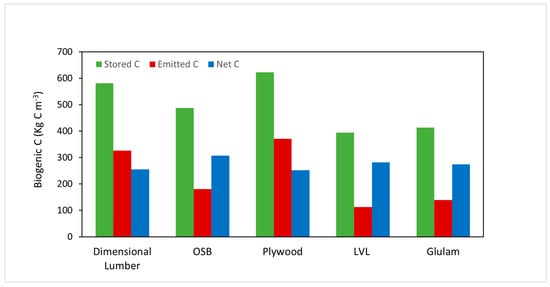

The avoidance pathway could be the most promising pathway due to the enormous carbon footprint of raw material procurement. Globally, material production is a substantial source of CO2 that has trended upwards. From 1995 to 2015, global material production rose 120% from 1.4 Gt C yr−1 to 3.0 Gt C yr−1 [67][99]. In 2015 terms, material production represented a quarter of global CO2 emissions [67][99]. Key contributors to emissions were iron and steel (31%, 0.9 Gt C yr−1), along with cement, lime, and plaster (24%, 0.7 Gt yr−1) [67][99]. Clearly, simple steel, iron, and cement manufacture avoidance will result in carbon savings. This can be achieved under an increased timber-product use scenario, where the avoidance pathway controls carbon savings with storage and energy as minor carbon-saving pathways [65][97]. Compared to iron, steel, and cement production, wood production can be considered carbon neutral. This is first supported by wood product carbon storage throughout the manufacturing process (Figure 1) and product lifespan.

Figure 1. Biogenic carbon (temporary storage) for Southern-sourced wood products from raw material extraction through product installation. OSB = oriented strand board; LVL = laminated veneer lumber; Glulam = glue laminated lumber. Data from CORRIM Library of LCAs on Wood Products (https://corrim.org/lcas-on-wood-products-library (accessed on 19 July 2022) [68][100]).