The safe disposal of an enormous amount of waste glass (WG) in several countries has become a severe environmental issue. In contrast, concrete production consumes a large amount of natural resources and contributes to environmental greenhouse gas emissions. It is widely known that many kinds of waste may be utilized rather than raw materials in the field of construction materials. However, for the wide use of waste in building construction, it is necessary to ensure that the characteristics of the resulting building materials are appropriate. Recycled glass waste is one of the most attractive waste materials that can be used to create sustainable concrete compounds.

- waste glass

- recycling

- construction materials

- sustainable concrete

1. Introduction

23. Properties of Glass

2.1. Chemical Properties of Glass

3.1. Chemical Properties of Glass

Glass exists in various colors and types, with various chemical components. Table 1 and Table 2 show the chemical compositions of different colors and types of typical glass, respectively.| Color | Chemical Compositions | Refs. | ||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SiO | 2 | CaO | Na | 2 | O | Al | 2 | O | 3 | MgO | Fe | 2 | O | 3 | K | 2 | O | SO | 3 | TiO | 2 | Cr | 2 | O | 3 | Others |

| White | 70.39 | 6.43 | 16.66 | 2.41 | 2.59 | 0.32 | 0.23 | |||||||||||||||||||

| 7 | ||||||||||||||||||||||||||

| 6 | ||||||||||||||||||||||||||

| 11 | ||||||||||||||||||||||||||

2.2. Physical and Mechanical Properties of Glass

3.2. Physical and Mechanical Properties of Glass

The physical and mechanical properties of crushed WG are listed in Table 3 and Table 4, respectively.| Property | Refs. | |

|---|---|---|

| Property | Refs. | |

| Specific gravity | 2.4–2.8 | |

4.1. Compressive Strength

5.1. Compressive Strength

Incorporating glass waste into concrete reduces compressive strength. The researchers ascribed this behavior to (i) the sharp edges and smooth particle surfaces, leading to a poorer bond between cement mortar and glass particles at the interfacial transition zone (ITZ) [22][24][25][32][45][46][64][65][66][67][14,40,42,43,55,66,87,90,108,109]; (ii) increased water content of the glass aggregate mixes due to the weak ability of WG to absorb water [25][68][43,110]; and (iii) the cracks caused by expanding stress formed by the alkali-silica reaction produced from the silica in WG [22][40].

In order to better understand the impact of glass waste on the properties of the waste-glass concrete [69][70][71][72][111,112,113,114]. Omoding, Cunningham and Lane-Serff [73][115] investigated the concrete microstructure via SEM by replacing between 12.5–100% of the coarse aggregate with green waste glass with a size of 10–20 mm. The authors stated (i) that there is a weak connection between the waste glass and the cement matrix. This is because of a reduction in bonding strength between the waste glass and the cement paste because of the high smoothness of waste glass, consequently resulting in cracks and poor adherence between waste glass and cement paste; and (ii) as the content of waste glass increases, the proportion of cracks and voids increases in the concrete’s matrix.

However, some studies have stated that waste glass increases mechanical strength. This increase is primarily realized because of the surface texture and strength of the waste glass particles compared to natural sand [74][75][76][116,117,118] and the pozzolanic reaction of waste glass aggregate [77][78][79][119,120,121].

4.2. Splitting Tensile Strength

5.2. Splitting Tensile Strength

Past studies on the impact of WG aggregates on the splitting tensile strength of waste-glass concrete, which are summarized in Table 7, revealed that incorporating glass waste into concrete reduces tensile strength. Similarly, as in compressive strength, studies have attributed the main reason for this behavior to the poor bond between cement paste and glass particles at the ITZ.-

The workability of waste-glass-containing concrete mixtures for fine or coarse aggregates was less than for natural aggregate-containing mixtures. Nevertheless, despite the poorer workability, some studies found that the mixtures were still workable.

-

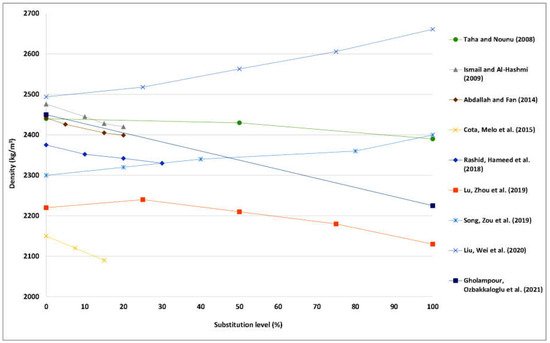

Most studies indicated that with the introduction of WG, the density of concrete decreased due to the decreased density and specific gravity of waste glass aggregates.

-

The findings of the literature have been somewhat indecisive regarding the properties of concrete, such as compressive strength, splitting tensile strength, flexural strength, and modulus of elasticity.

-

The findings revealed that the compressive strength, splitting tensile strength, and flexural strength of concrete deteriorated by integrating WG. Nevertheless, the findings concerning the elastic modulus of concrete were conflicting. This decrease was essential because of the sharp edges and smooth surface of the waste glass that caused the poorer bond between cement mortar and waste glass particles at the ITZ.

-

Studies also showed that the optimal aggregate substitution level was about 20%. In addition, the glass color does not have a substantial influence on the strength. Although the results are indecisive, WG has the possibility to be an acceptable substitute for fine or coarse concrete aggregates in concrete.

-

Adding waste glass to the concrete mixture may improve certain mechanical characteristics of concrete, reduce concrete dead load, and provide an ecological substitute for normal aggregates.

| Refs. | Type of Composite | Source | Type of Sub. | WG Sub. Ratio% | WG Size (mm) | w/c or w/b | Addit. or Admix. | Split ten. str. of Control (MPa) | Outcomes | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| [80] | [81]2.51 (Green), 2.52 (Brown) | [22] | [40 | 0.19 | ] | 0.08 | - | 0.04 (MnO), 0.02 (Cl) | |||||||||||||||||||||

| CBR (California bearing ratio) (%) | Approx. 50–75. | [ | UHPC | 28] | [ | [ | 16 | ] | [ | 34 | ] | ||||||||||||||||||

| 46 | ] | WG | F.A | 25, 50, 75, & 100 (wt.%) | ≤0.6 | 0.19 | Steel fiber & HRWRA | 11.7 | Increased by 1%, 3%, 11%, and 7%, respectively. | Clear | 72.42 | 11.50 | 13.64 | 1.44 | 0.32 | 0.07 | 0.35 | 0.21 | 0.035 | Fineness Modulus | 4.25 0.44–3.290.002 |

[ | |||||||

| [81] | [82] | 23][24] | [ | - | 41,42] | [ | 17 | ] | [ | 35 | ] | ||||||||||||||||||

| Los Angeles Value (%) | 38.4 | [25][27] | [43,45] | Waste glass concrete | WG | F.A | 15 & 30 (vol.%) | ≤4.75 | 0.5 | - | 4.5 | Changed by +4%, and −1%, respectively. | Flint | 70.65 | 10.70 | 13.25 | 1.75 | 2.45 | 0.45 | 0.55 | 0.45 | - | - | - | [ | Bulk Density | 1360 kg/m | 318] | [ |

| 24.8–27.8 | |||||||||||||||||||||||||||||

| [60] | [84 | [26] | [44] | [25][26] | [43,44] | 36 | ] | ||||||||||||||||||||||

| ] | Waste glass concrete | WG | F.A | 5, 15, & 20 (vol.%) | 0.15–4.75 | 0.55 | - | 2.5 | Increased by 4%, 12%, and 24%, respectively. | Amber | 70.01 | 10.00 | 15.35 | 3.20 | 1.46 | - | 0.82 | 0.06 | 0.11 | - | |||||||||

| [32] | [ | 0.04 (MnO) | 55] | [ | 16 | ] | [ | 34 | ] | ||||||||||||||||||||

| Shape Index (%) | 30.5 | ||||||||||||||||||||||||||||

| 27.7 | [29] | [47] | SCC | WG | F.A | 10, 20, 30, 40, & 50 (vol.%) | 0.075–5 | 0.4 | SF & SP | 6.8 | Decreased by 9%, 15%, 16%, 24%, and 28%, respectively. | Brown | 71.19 | 10.38 | Flakiness Index | ||||||||||||||

| [82 | 84.3–94.7 | ][ | 13.16 | 27 | 2.38 | 1.70 | ] | 0.29 | 0.70 | 0.04 | 0.15 | [- | 85- | ][45 | [19] | [ | Cement concrete37] | ||||||||||||

| ] | Green | 72.05 | 10.26 | 14.31 | 2.81 | 0.90 | - | 0.52 | 0.07 | 0.11 | - | 0.04 (MnO) | [16] | [34] |

| Friction Angle | |||

| critical = 38 (Loose recycled glass) | |||

| [ | 28 | ] | [46] |

| critical = 51–61 (Dense recycled glass) | |||

| WG | |||

| F.A | |||

| 5, 10, 15, & 20 (vol.%) | 0.15–9.5 | 0.56 | - |

| [83] | [133] | Waste glass concrete | WG |

| 3.9 | ||||||||||||||||||||

| Decreased by 0%, 8%, 15%, and 23%, respectively. | ||||||||||||||||||||

| F.A | ||||||||||||||||||||

| 10, 20, 30, & 40 (wt.%) | ≤4.75 | 0.45 | - | 2.5 | Decreased by 2%, 8%, 10%, and 12%, respectively. | |||||||||||||||

| [84] | [72] | LCDGC | LCD | F.A | 20, 40, 60, & 80 (vol.%) | ≤4.75 | 0.38, 0.44, & 0.55 | - | 2.38 | Decreased by 1%, 7%, 8%, and 9%, respectively, for w/c of 0.44. | ||||||||||

| [63] | [107] | Waste glass concrete | CRT | F.A | 20, 40, 60, 80, & 100 (vol.%) | 4.75 | 0.45 | F.A. | 4.48 | Decreased by 6%, 6%, 13%, 15%, and 19%, respectively. | ||||||||||

| [85] | [128] | Waste glass concrete | WG | F.A | 25, 50., 75, & 100 (wt.%) | ≤5 | 0.5 | - | 3.6 | Decreased by 22%, 39%, 39%, and 44%, respectively. | ||||||||||

| Type | Uses | Chemical Compositions | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SiO | 2 | K | 2 | O | Na | 2 | O | Al | 2 | O | 3 | MgO | PbO | BaO | CaO | B | 2 | O | 3 | Others |

| Barium glasses | Optical-dense barium crown | 36 | 4 | 41 | 10 | 9% ZnO | ||||||||||||||

| Color TV panel | 65 | 9 | 7 | 2 | 2 | 2 | 2 | 2 | 10% SrO | |||||||||||

| Soda-Lime Glasses | Containers | 66–75 | 0.1–3 | 12–16 | 0.7–7 | 0.1–5 | 6–12 | |||||||||||||

| Light bulbs | 71–73 | |||||||||||||||||||

| Float sheet | 73–74 | |||||||||||||||||||

| Tempered ovenware | 0.5–1.5 | 13.5–15 | ||||||||||||||||||

| Lead glasses | Color TV funnel | 54 | 9 | 4 | 2 | 23 | ||||||||||||||

| Electronic parts | 56 | 9 | 4 | 2 | 29 | |||||||||||||||

| Neon tubing | 63 | 6 | 8 | 1 | 22 | |||||||||||||||

| Optical dense flint | 32 | 2 | 1 | 65 | ||||||||||||||||

| Aluminosilicate glasses | Combustion tubes | 62 | 1 | 17 | 7 | 8 | 5 | |||||||||||||

| Resistor substrates | 57 | 16 | 7 | 6 | 10 | 4 | ||||||||||||||

| Fiberglass | 64.5 | 0.5 | 24.5 | 10.5 | ||||||||||||||||

| Borosilicate | Chemical apparatus | 81 | 4 | 2 | 13 | |||||||||||||||

| Tungsten sealing | 74 | 4 | 1 | 15 | ||||||||||||||||

| Pharmaceutical | 72 | 1 | ||||||||||||||||||

34. Fresh Concrete Properties

3.1. Workability

4.1. Workability

The smooth surface and low absorption capacity of WG are also important factors in increasing workability [30][31][53,54]. For example, Ali and Al-Tersawy [32][55] substitute fine aggregate in self-compacting concrete (SCC) mixes with recycled WG at levels of 10% to 50% by volume. Constant content of water–cement ratio and various superplasticizer doses have been used. They stated that slump flow increased by 2%, 5%, 8%, 11%, and 85%, with the incorporating of 10%, 20%, 30%, 40% and 50% of WG, respectively. In addition, Liu, Wei, Zou, Zhou and Jian [33][56] substitute fine aggregate in ultra-high-performance concrete (UHPC) mixes with recycled liquid crystal display (CRT) glass at levels of 25% to 100% by volume. Constant content of water–cement ratio and various superplasticizer (SP) doses have been used. Moreover, they stated that flowability increased by 11, 14, 16, and 12 mm, compared to the control sample, incorporating 25%, 50%, 75%, and 100% WG, respectively. Enhancing the workability by including WG is a benefit of utilizing this recycled material [34][35][36][37][57,58,59,60]. There is potential to utilize glass to create HPC in which high workability is necessary. In addition, WG can be used to boost workability rather than employing admixtures such as HRWR or superplasticizers [38][39][40][41][61,62,63,64].

3.2. Bulk Density

4.2. Bulk Density

Past studies on the impact of WG aggregates on the bulk density, which are summarized in Figure 12, revealed that the majority of studies showed that incorporating glass waste into mixtures reduces density. This decrease can be ascribed to the lesser density of WG compared to natural aggregate [24][42][43][44][42,65,93,94], as well as the lower specific gravity [25][43][45][46][47][43,66,87,93,95].including waste glass into the mixes lowered workability. Nevertheless, such a decrease has been associated with sharp edges, higher glass particle aspect ratio, and angular form, with obstruction of the movement of particles and cement mortar [42][45][48][49][50][51][52][65,66,67,68,69,70,71].

On the other hand, Liu, Wei, Zou, Zhou and Jian [33][56] stated that concrete of 10 to 50% WG had a fresh density greater than reference. The authors substitute F.A in UHPC mixes with recycling CRT glass at levels of 25% to 100% by volume. They stated that the fresh density of waste-glass concrete mixtures increased by 1% 2.5%, 3.5%, and 6%, incorporating 25%, 50%, 75%, and 100% of WG, respectively. The authors attributed the reason to the fact that the density of CRT glass (2916 kg/m3) was larger than that of fine aggregate (2574 kg/m3) [53][54][55][56][57][100,101,102,103,104].