Food production is highly complex due to the various chemo-physical and biological processes that must be controlled to transform ingredients into final products. Further, production processes must be adapted to the variability of the ingredients, e.g., due to seasonal fluctuations of raw material quality. Digital twins are known from Industry 4.0 as a method to model, simulate, and optimize processes. However, such a digital food twin has to consider the changes within the food due to micro-biological, chemical, and physical processes. Consequently, we propose the concept of a hybrid digital twin, which integrates simulation and data science (i.e., machine learning) to combine a data-driven perspective, simulations, and scientific models to describe the food product and the food processing process.

Food production is highly complex due to the various chemo-physical and biological processes that must be controlled to transform ingredients into final products. Further, production processes must be adapted to the variability of the ingredients, e.g., due to seasonal fluctuations of raw material quality. Digital twins are known from Industry 4.0 as a method to model, simulate, and optimize processes. Such a digital food twin has to consider the changes within the food due to micro-biological, chemical, and physical processes. Consequently, researchers propose the concept of a hybrid digital twin, which integrates simulation and data science (i.e., machine learning) to combine a data-driven perspective, simulations, and scientific models to describe the food product and the food processing process.

- digital twin

- food processing

- Industry 4.0

- artificial intelligence

1. Introduction

2. System Model of a Hybrid Digital Food Twin

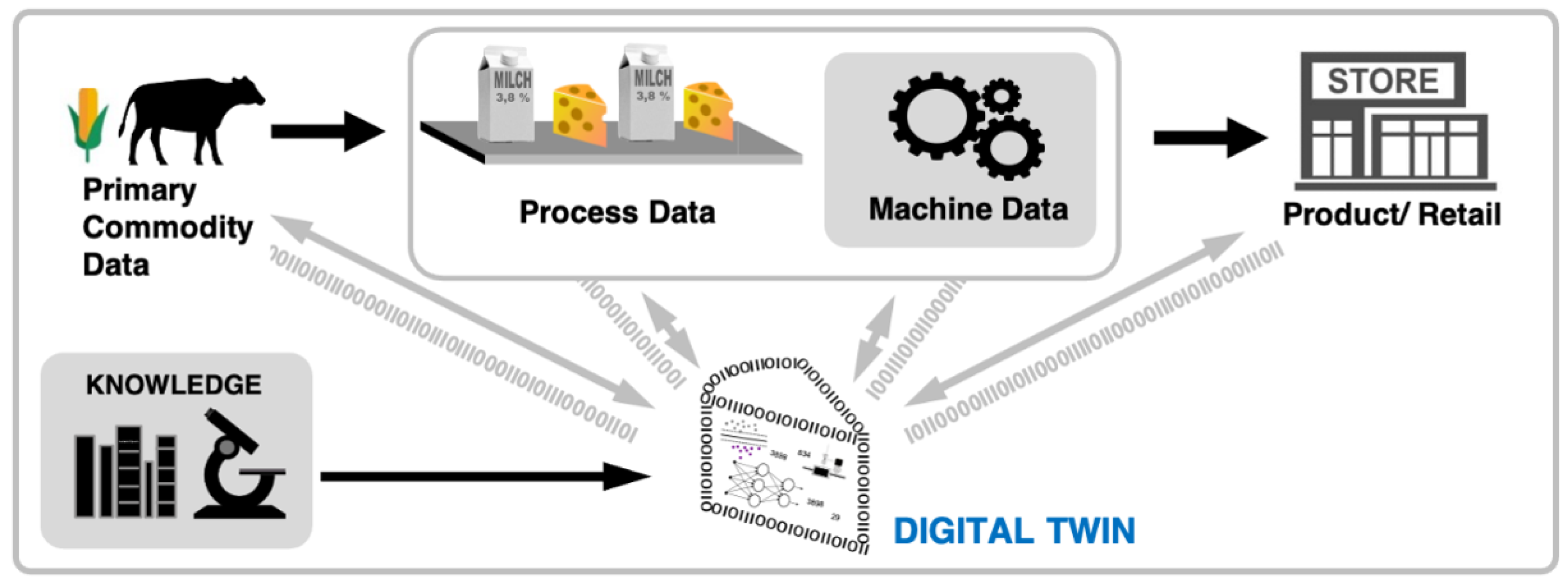

With the help of machine learning and artificial intelligence, the digital twin is generated from production data and additional data sources (e.g., scientific models, process data, or raw material data) to ensure the traceability of the production and the food status, but also to enable the simulation of the variability of the food in the process operation. Figure 1 shows ourthe concept of the digital twin. In the figure and the following, weresearchers focus on the example of a dairy product (e.g., cheese). The digital twin gets its data from the production site (i.e., sensor, machine, and processing data, e.g., temperature, pressure, or pH value) and also integrates raw material data, complaints, and knowledge from experts (e.g., about the handling of production issues). Using different simulation methods based on chemo-physical models and numerical simulations from food science, the digital twin provides information about food processing and supports real-time feedback on the food process operation. Additionally, those simulations based on scientific models help predict how the product will be changed through the processes and conditions. This information can be used to generate forecasts on how the process steps might influence the quality of the product. Accordingly, the digital twin is suitable for a retrospective but also predictive analytics of the process and product quality.

References

- Stark, R.; Damerau, T. Digital Twin. In CIRP Encyclopedia of Production Engineering; Chatti, S., Tolio, T., Eds.; Springer: Berlin/Heidelberg, Germany, 2019; pp. 1–8.

- Rohleder, B.; Minhoff, C. Die Ernährung 4.0-Status Quo, Chancen und Herausforderungen. 2019. Available online: https://www.bitkom.org/sites/default/files/2019-03/Bitkom-Charts%20190326%20Digitalisierung%20der%20Ern%C3%A4hrungsindustrie.pdf (accessed on 25 July 2022).

- Krupitzer, C.; Roth, F.M.; VanSyckel, S.; Schiele, G.; Becker, C. A Survey on Engineering Approaches for Self-adaptive Systems. Pervasive Mob. Comput. 2015, 17, 184–206.