Two-phase flow is commonly encountered in various engineering systems. Momentum fluctuation in two-phase flow can create undesirable and destructive vibrations. These vibrations have attracted considerable attention and are known as flow-induced vibrations (FIV). Different factors effecting FIV is two phase flow is discussed here in detail.

- flow-induced vibrations

- dimensionless forces

- dominant frequency

- multiphae flow

1. Effect of Flow Velocity

2. Effect of Pipe Geometry and Sizes

The flow behaviors in small diameter pipe bends and large diameter pipe bends are different. Schlegel et al. [8] reported that pipes can be characterized as small or large based on non-dimensional hydraulic diameter, D∗H, as shown in Equation below. Small pipes have D∗H less than 18.6 and larger pipes have D∗H greater than 40. With relevance to air-water two-phase flow, diameters < 0.0507 m correspond to D∗H = 16.8, while diameters >0.1091 m represent D∗H = 40. The region between these two extremes is known as the transition region and affects both large and small diameter pipes, as observed. Mishima and Ishii [9] and Schlegel et al. [8] reported that bubbly flow regime is present in small as well as large diameter pipes. Beyond the bubbly flow regime, as the superficial velocities increase, gas bubbles with larger dimensions begin to form in both small and larger diameter pipes. In small pipes, these bubbles grow and fill the entire pipe, creating long slugs, which are known as slug flow regime. In large pipes, these bubbles form cap bubbles, which are known as cap bubbly flow regime. By further increasing the velocity, the flow in smaller pipes remains as a stable slug flow, while a churn turbulent flow regime develops in pipes with a larger diameter.

3. Effect of Flow Regimes

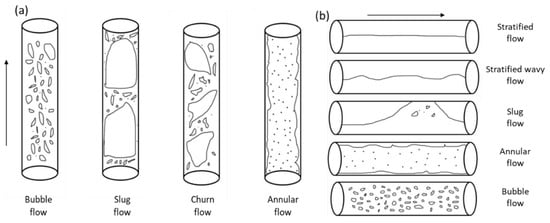

Two-phase flow can be divided into different flow regimes depending on their properties and appearances. Various flow regime maps are introduced over time to identify flow regimes using visual inspection and flow rates of phases involved [22][23]. Kaichiro and Ishii [9] used void fraction to identify criteria for different flow regimes and established a flow regime map with gas superficial velocity and liquid superficial velocity as horizonal and vertical coordinates. This criterion was developed for vertical two-phase flow and their results are comparable with the existing literature. More advanced methods, such as the measurement of void fraction using X-rays [24], electrical capacitance tomography [25], rotating electric field conductance gauge [26], conductivity and electrical impedance [27] are also being used to identify different flow regimes. Different flow regime visualizations are shown in Figure 14 to help in understanding and better visualizing the different types of flow regimes.

4. Effect of Void Fraction

Void fraction or liquid holdup is a dimensionless parameter and can be defined as the ratio of cross-sectional area of pipe occupied by vapor phase or gas to the total cross-sectional area.

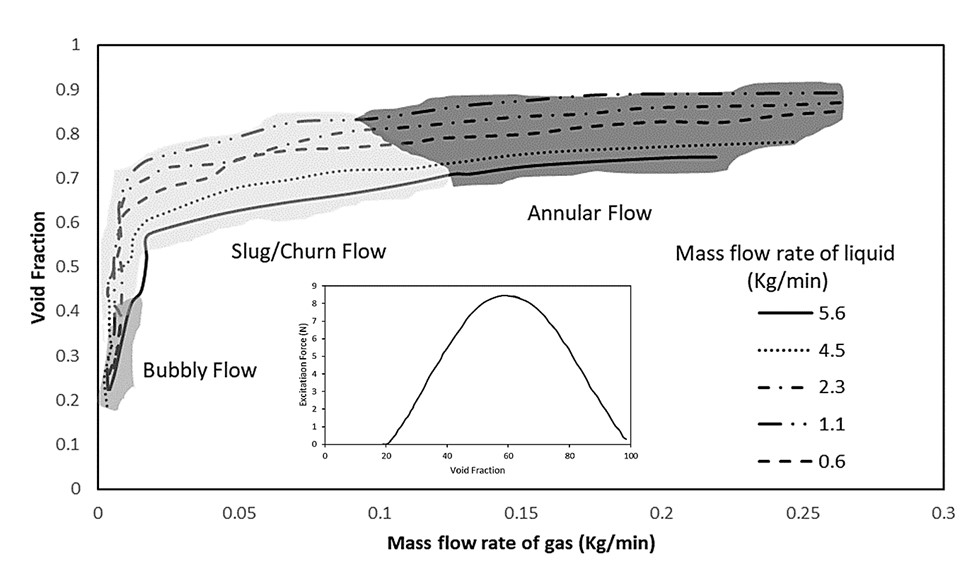

Riverin and Pettigrew [31][63] concluded from their experiments on multiphase flow in U-bend that excitation forces are indeed affected by the change in void fraction. In theirs study, the effect of excitation forces on bends at values of 25%, 50%, 75%, and 95% gas void fraction were studied. The authors reported that for a specific velocity, the excitation forces increase as void fraction increases. Maximum forces are reported between 50% to 60% gas void fraction. Beyond 60% gas void fraction, the excitation forces start to decrease. However, it is noteworthy that this effect is normally due to flow regime change. For void fractions between 50% and 60%, flow regime is normally associated with slug or churn flow, which possesses the maximum momentum flux. In addition, they are more prominent when it comes to excitation forces when compared to bubbly (25%) and annular (95%) flows.

Giraudeau et al. [32][64] conducted experiments to investigate flow-induced vibrations in 52 mm (2 inch) internal diameter U-bend, with a vertically upward two-phase flow. The range of gas void fraction tested during experiments are 25%, 50%, 75%, and 95%. From the force spectra data, it was concluded that the average void fraction signal corresponds to force spectra. It was reported that for a constant velocity, the excitation forces increase with void fraction until 75%, and then decrease with further increase in velocity. This behavior agrees with previous observations [31][63]. For 25% void fraction, forces start to increase after 3 m/s in bubbly flow. These forces are produced due to propagation of void fraction waves [33][34][93,94]. For 50% void fraction, the force increases with velocity until 7 m/s and after further increase in velocity, the forces do not show any increase, which can be explained by the transition of flow regime from unstable slug flow to bubbly flow regime. The same increasing behavior can be obtained for void fraction of 75% until velocity is increased to 14 m/s and after further increase in velocity, the force decreases. This was due to the transition of flow from unstable slug to churn flow regime. In 95% void fraction, the transition from churn to annular flow is observed at 20 m/s. Forces increase first and then start to decrease after 20 m/s due to less momentum variation in annular flow and void fraction when compared to slug and churn flow regimes.

Liu et al. [35][66] reported that void fraction fluctuations show a similar trend as force fluctuations, and thus it is important to determine the changes in void fraction when the two-phase flow passes through the pipe bend. Moreover, the authors observed the predominant frequency of void fraction fluctuation signals and found that for a fixed liquid superficial velocity, as superficial velocity of gas is increased from bubbly to slug flow, the predominant frequency of void fraction fluctuations reaches a maximum value, upon further increase the predominant frequency decreases in churn flow followed by an increase again in annular flow. Wang et al. [36][59] reported that when slug flow passes through a 90° bend, the flow regime transition affects the increase or decrease in void fraction after passing through the pipe bend. For slug flow, at a constant gas superficial velocity, void fraction decreases with the increasing liquid velocity after the slug passes through the pipe bend. However, an increasing gas superficial velocity has a minimal effect on this phenomenon. A relationship between void fraction, liquid and gas flow rates and flow regimes based on data available in the literature [37][95] has been developed as illustrated in Figure 25. Notably, these data are for upward vertical flow, a flow type widely used in the study of FIV. This figure concludes the effect of void fraction on excitation forces and its relation to flow regime. For a fixed mixture velocity, the excitation forces increase as gas void fraction increases, where the maximum forces were reported to be between 50% and 75% void fraction value, and upon further increase, the excitation forces start to decrease, as shown in Figure 25. In addition, Figure 2 5 shows that this range covers the slug/churn flow regime, which shows maximum momentum fluctuation and, in turn, produces the highest forces. The annular and bubbly flows occur outside this range of void fraction, which shows lesser forces due to the less turbulent nature. This change is attributed to the change in flow regime as thwe increased the void fraction, rather than the effect of void fraction.

Figure 25. Relationship between void fraction with liquid and gas flowrates, and flow regimes and excitation forces.

5. Comparison of Dimensionless Forces

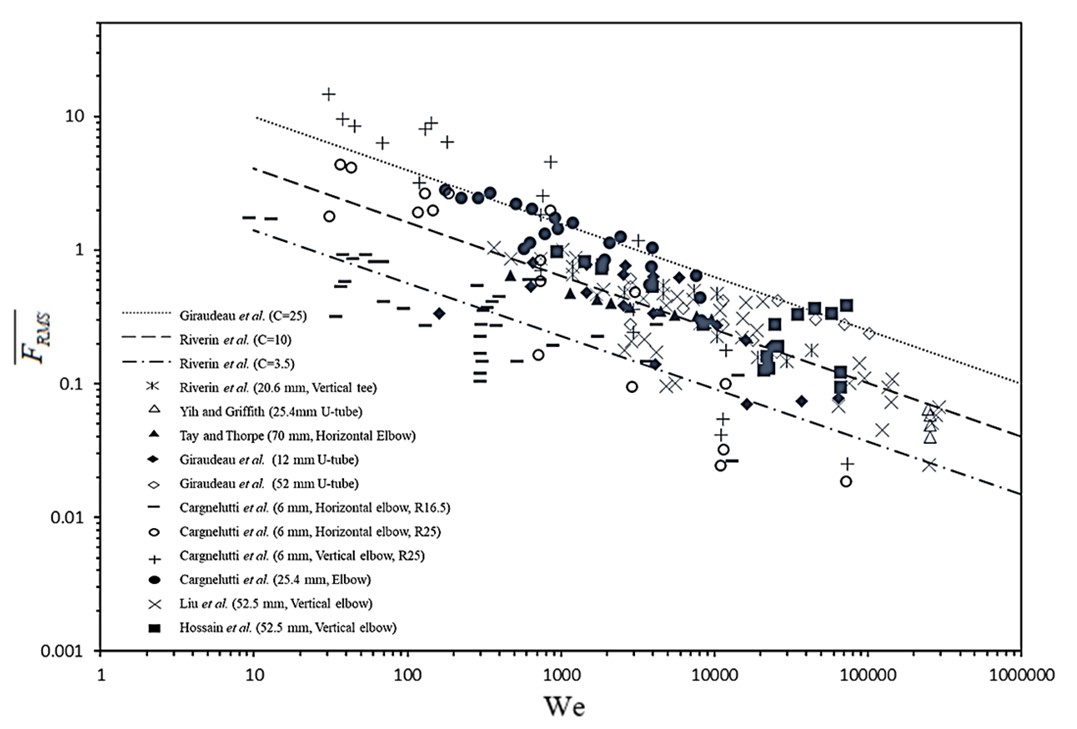

The dashed line shown in Figure 3Figure below is drawn using Riverin equation with C value of 10. This was proposed as a reasonable approximation of dimensionless forces. The dash dotted line shown in Figure is drawn using C of 3.5 and it is the best fit curve for slug flow regime. Giraudeau et al. proposed that to be conservative, an upper bound of dimensionless forces should be defined and from their experiments on 12 to 52 mm internal diameter U-bends, Cmax of 25 was proposed. This corresponds to the dotted line shown in Figure 3Figure . The experimental results for 12 and 52 mm U-bends are included here, which shows that Cmax = 25 is a good approximation for upper limit. The dimensionless forces due to slug flow from experiments conducted by Cargnelutti et al., in 6 mm internal diameter horizontal and vertical elbows for bend radii of 16.5 and 25 and the results for 25.4 mm (1 inch) internal diameter elbow, are also recorded in Figure 3Figure. Notably, both horizontal and vertical elbows are subjected to the horizontal two-phase flow in these experiments. The overall forces on vertical elbow are higher than the horizontal elbow, which was thought to be due to gravity. Notably, forces in vertical elbow are also higher than the maximum limit introduced by Giraudeau et al. at C of 25. The forces due to the 16.5 bend radius are lower than the 25 mm bend radius for the same diameter pipe, which shows that the bend radius affects the forces. Moreover, it can be observed that the forces in 25.4 mm (1 inch) pipe are higher than the 6 mm experiments. This behavior was unusual, considering that the 25.4 mm (1 inch) experiments contained more gas than the 6 mm experiments. Cargnelutti et al. reported that this can also be due to the difference of stiffness of material used (glass vs. perspex). Overall, the results of Cargnelutti experiments show higher forces than the Revirin experiments and results for 25.4 mm bend are higher than C = 10 line. Experimental results for 20 mm internal diameter tee [38][42], for elbow with 70 mm diameter under the horizontal flow [39][98], and for 6 to 25 mm diameter vertical U-tubes, are also reported. All these results are in agreement with Riverin et al. approximation at C of 10. Results for 52.5 mm vertical elbow are also presented and these results are spread over a wide range from C of 3.51 to 25 lines. This can be attributed to the fact that 0 to 100% void fraction was considered, covering a wide range of flow conditions. The simulation results of Hossain et al. for vertical elbow of 52.5 mm diameter are presented and they mostly lie between C of 10 and 25 lines. Figure 3Figure below can serve as a database for comparison and can also be used to validate the simulation results.

Figure 3.: Comparison of dimensionless forces plotted against the Weber

Comparison of dimensionless forces plotted against the Weber number

number

References

- Riverin, J.L.; Pettigrew, M.J. Vibration Excitation Forces Due to Two-Phase Flow in Piping Elements. J. Press. Vessel Technol. Trans. ASME 2007, 129, 7–13. Riverin, J.L.; de Langre, E.; Pettigrew, M.J. Fluctuating Forces Caused by Internal Two-Phase Flow on Bends and Tees. J. Sound Vib. 2006, 298, 1088–1098.

- Giraudeau, M.; Mureithi, N.W.; Pettigrew, M.J. Two-Phase Flow-Induced Forces on Piping in Vertical Upward Flow: Excitation Mechanisms and Correlation Models. J. Press. Vessel Technol. Trans. ASME 2013, 135, 1–16. Riverin, J.L.; Pettigrew, M.J. Vibration Excitation Forces Due to Two-Phase Flow in Piping Elements. J. Press. Vessel Technol. Trans. ASME 2007, 129, 7–13.

- Park, J.W.; Drew, D.A.; Lahey, R.T. The Measurement of Void Waves in Bubbly Two-Phase Flows. Nucl. Eng. Des. 1994, 149, 37–52. Giraudeau, M.; Mureithi, N.W.; Pettigrew, M.J. Two-Phase Flow-Induced Forces on Piping in Vertical Upward Flow: Excitation Mechanisms and Correlation Models. J. Press. Vessel Technol. Trans. ASME 2013, 135, 1–16.

- Sun, B.; Yan, D.; Zhang, Z. The Instability of Void Fraction Waves in Vertical Gas-Liquid Two-Phase Flow. CNSNS 1999, 4, 181–186. Hossain, M.; Chinenye-Kanu, N.M.; Droubi, G.M.; Islam, S.Z. Investigation of Slug-Churn Flow Induced Transient Excitation Forces at Pipe Bend. J. Fluids Struct. 2019, 91, 102733.

- Liu, Y.; Miwa, S.; Hibiki, T.; Ishii, M.; Morita, H.; Kondoh, Y.; Tanimoto, K. Experimental Study of Internal Two-Phase Flow Induced Fluctuating Force on a 90° Elbow. Chem. Eng. Sci. 2012, 76, 173–187.

- Wang, Z.; He, Y.P.; Li, M.Z.; Qiu, M.; Huang, C.; Liu, Y.D.; Wang, Z. Fluid—Structure Interaction of Two-Phase Flow Passing Through 90° Pipe Bend Under Slug Pattern Conditions. China Ocean Eng. 2021, 35, 914–923. Wang, L.; Yang, Y.; Li, Y.; Wang, Y. Dynamic Behaviours of Horizontal Gas-Liquid Pipes Subjected to Hydrodynamic Slug Flow: Modelling and Experiments. Int. J. Press. Vessel. Pip. 2018, 161, 50–57.

- Ghajar, A.J.; Bhagwat, S.M. Frontiers and Progress in Multiphase Flow I; Springer: Berlin/Heidelberg, Germany, 2014; ISBN 9783319043586. Wang, Z.; He, Y.P.; Li, M.Z.; Qiu, M.; Huang, C.; Liu, Y.D.; Wang, Z. Fluid—Structure Interaction of Two-Phase Flow Passing Through 90° Pipe Bend Under Slug Pattern Conditions. China Ocean Eng. 2021, 35, 914–923.

- Chen, W.; Ji, C.; Williams, J.; Xu, D.; Yang, L.; Cui, Y. Vortex-Induced Vibrations of Three Tandem Cylinders in Laminar Cross-Flow: Vibration Response and Galloping Mechanism. J. Fluids Struct. 2018, 78, 215–238. Schlegel, J.P.; Miwa, S.; Chen, S.; Hibiki, T.; Ishii, M. Experimental Study of Two-Phase Flow Structure in Large Diameter Pipes. Exp. Therm. Fluid Sci. 2012, 41, 12–22.

- Tay, B.L.; Thorpe, R.B. Hydrodynamic Forces Acting on Pipe Bends in Gas-Liquid Slug Flow. Chem. Eng. Res. Des. 2014, 92, 812–825. Kaichiro, M.; Ishii, M. Flow Regime Transition Criteria for Upward Two-Phase Flow in Vertical Tubes. Int. J. Heat Mass Transf. 1984, 27, 723–737.

- Yih, T.; Griffith, P. Unsteady Momentum Fluxes in Two-Phase Flow and the Vibration of Nuclear Reactor Components; Massachusetts Institute of Technology: Cambridge, MA, USA, 1968.

- Chinenye-Kanu, N.M.; Hossain, M.; Droubi, M.G.; Islam, S.Z. Numerical Investigation of Two-Phase Flow Induced Local Fluctuations and Interactions of Flow Properties through Elbow. Lect. Notes Mech. Eng. 2019, 2019, 124–141.

- Asiegbu, N.M.; Hossain, M.; Droubi, G.M.; Islam, S.Z. Investigation of the Effects of Pipe Diameter of Internal Multiphase Flow on Pipe Elbow Vibration and Resonance. Proc. Inst. Mech. Eng. Part E J. Process. Mech. Eng. 2022, 2022, 095440892211155.

- Belfroid, S.P.; Nennie, E.; Lewis, M. Multiphase Forces on Bends—Large Scale 6” Experiments. In Proceedings of the SPE Annual Technical Conference and Exhibition, Dubai, United Arab Emirates, 26–28 September 2016.

- Tay, B.L.; Thorpe, R.B. Effects of Liquid Physical Properties on the Forces Acting on a Pipe Bend in Gas-Liquid Slug Flow. Chem. Eng. Res. Des. 2004, 82, 344–356.

- Nennie, E.D.; Belfroid, S.P.C.; van Bokhorst, E.; Remans, D. Multiphase Fluid Structure Interaction in Pipe Systems with Multiple Bends. In Proceedings of the 10th International Conference on Flow-Induced Vibration, Dublin, Ireland, 3–6 July 2012; TNO Publications: The Hague, The Netherlands.

- Belfroid, S.P.C.; Cargnelutti, M.F.; Schiferli, W.; Van Osch, M. Forces on Bends and T-Joints Due to Multiphase Flow. Am. Soc. Mech. Eng. Fluids Eng. Div. FEDSM 2010, 3, 613–619.

- Cargnelutti, M.F.; Belfroid, S.P.C.; Schiferli, W.; Van Osch, M. Two-Phase Flow-Induced Forces on Bends in Small Scale Tubes. J. Press. Vessel. Technol. 2009, 132, 1–9.

- Cargnelutti, M.F.; Belfroid, S.P.C.; Schiferli, W.; Van Osch, M. Multiphase Fluid Structure Interaction in Bends and T-Joints. In Proceedings of the ASME 2010 Pressure Vessels and Piping Division/K-PVP Conference, Bellevue, DC, USA, 18–22 July 2016; pp. 1–8.

- Kim, S.; Park, J.H.; Kojasoy, G.; Kelly, J.M.; Marshall, S.O. Geometric Effects of 90-Degree Elbow in the Development of Interfacial Structures in Horizontal Bubbly Flow. Nucl. Eng. Des. 2007, 237, 2105–2113.

- Yamano, H.; Tanaka, M.; Murakami, T.; Iwamoto, Y.; Yuki, K.; Sago, H.; Hayakawa, S. Unsteady Elbow Pipe Flow to Develop a Flow-Induced Vibration Evaluation Methodology for Japan Sodium-Cooled Fast Reactor. J. Nucl. Sci. Technol. 2011, 48, 677–687.

- Yamano, H.; Tanaka, M.A.; Kimura, N.; Ohshima, H.; Kamide, H.; Watanabe, O. Development of Flow-Induced Vibration Evaluation Methodology for Large-Diameter Piping with Elbow in Japan Sodium-Cooled Fast Reactor. Nucl. Eng. Des. 2011, 241, 4464–4475.

- Taitel, Y.; Barnea, D.; Dukler, A.E. Modelling Flow Pattern Transitions for Steady Upward Gas-Liquid Flow in Vertical Tubes. AIChE J. 1980, 26, 345–354.

- Mandhane, J.M.; Gregory, G.A.; Aziz, K. A Flow Pattern Map for Gas—Liquid Flow in Horizontal Pipes. Int. J. Multiph. Flow 1974, 1, 537–553.

- Jones, O.C.; Zuber, N. The Interrelation between Void Fraction Fluctuations and Flow Patterns in Two-Phase Flow. Int. J. Multiph. Flow 1975, 2, 273–306.

- Wang, H.X.; Zhang, L.F. Identification of Two-Phase Flow Regimes Based on Support Vector Machine and Electrical Capacitance Tomography. Meas. Sci. Technol. 2009, 20, 114007.

- Merilo, M.; Dechene, R.L.; Cichowlas, W.M. Void Fraction Measurement With a Rotating Electric Field Conductance Gauge. J. Heat Transfer 1977, 99, 330–332.

- Juliá, J.E.; Liu, Y.; Paranjape, S.; Ishii, M. Upward Vertical Two-Phase Flow Local Flow Regime Identification Using Neural Network Techniques. Nucl. Eng. Des. 2008, 238, 156–169.

- Enoki, K.; Ono, M.; Okawa, T.; Kristiawan, B.; Wijayanta, A.T. Water Flow Boiling Heat Transfer in Vertical Minichannel. Exp. Therm. Fluid Sci. 2020, 117, 110147.

- Enoki, K.; Ono, M.; Okawa, T.; Akisawa, A.; Mori, H.; Kristiawan, B.; Wijayanta, A.T. Two-Phase Flow Regimes of Refrigerant R134a in an Oscillating Horizontal Rectangular Minichannel Conduit. Int. J. Refrig. 2020, 118, 261–268.

- Taitel, Y.; Dukler, A.E. A Model for Predicting Flow Regime Transitions in Horizontal and near Horizontal Gas-liquid Flow. AIChE J. 1976, 22, 47–55.