You're using an outdated browser. Please upgrade to a modern browser for the best experience.

Please note this is a comparison between Version 3 by Beatrix Zheng and Version 2 by Beatrix Zheng.

Metal halide perovskites (MHPs) are thought to be among the most promising materials for smart electronic textiles because of their unique optical and electrical characteristics. Wearable perovskite devices have been developed that combine the excellent properties of perovskite with those of textiles, such as flexibility, light weight, and facile processability.

- perovskite

- flexible substrate

- textile

- optoelectronics

1. Wearable Solar Cells

Textile-based flexible perovskite solar cells have long been a question of great interest because of their unique properties, such as high flexibility, wearability, and ability to conform to any shape. Compared with conventional rigid solar cells, wearable perovskite solar cells can be easily deployed on curved or irregular surfaces of vehicles or tents. The wearability of PSCs mainly depends on the flexibility of the substrates, which defines not only the final efficiency, but also the mechanical and environmental stability. Furthermore, charge-transport layers (HTLs/ETLs) must have better stability against chemicals, oxygen, and water vapour to prevent corrosion and degradation [1][2][3].

The low-temperature synthesis of charge-transport layers and high-quality perovskite films is necessary to produce high-efficiency wearable perovskite solar cells. As mesoporous structure (e.g., TiO2 as the ETL) always demands high-temperature arrangements (≈500 °C), which are not suitable for flexible substrates, there are only a few scientific reports about the application of this architecture in this field [4][5][6]. Therefore the advancement in textile-based flexible perovskite solar cells is mostly reported in regular (n-i-p) or inverted (p-i-n) structures [7][8][9].

The first flexible perovskite solar cell was structured using ZnO nanorods as a mesoscopic scaffold layer and an ETL to allow the fabrication of low-temperature solution-based perovskite CH3NH3PbI3 solar cells. A PCE of 8.90% and 2.62% was recorded for rigid fluorine tin oxide (FTO) and flexible PET/ITO substrates, respectively [10]. Sisi et al. reported another effective strategy for the fabrication of textile-based PSCs by synthesising obelisk-like ZnO arrays on stainless steel fabric via a mild solution process. The perovskite CH3NH3PbI3 thin layer was formed by the dip-coating process, and the resulting solar cells showed a PCE of 3.3%, with only 7% variation after bending for 200 cycles [11].

A novel stainless steel fibre-shaped PSC with high flexibility and low cost was developed by continuously winding carbon nanotubes on a fibre substrate. Photoactive perovskite CH3NH3PbI3 was sandwiched in between them via the solution-processing technique, and the fibre-shaped PSC showed a PCE of 3.3%. The fibre-shaped PSC can be woven into smart textiles for large-scale applications [12].

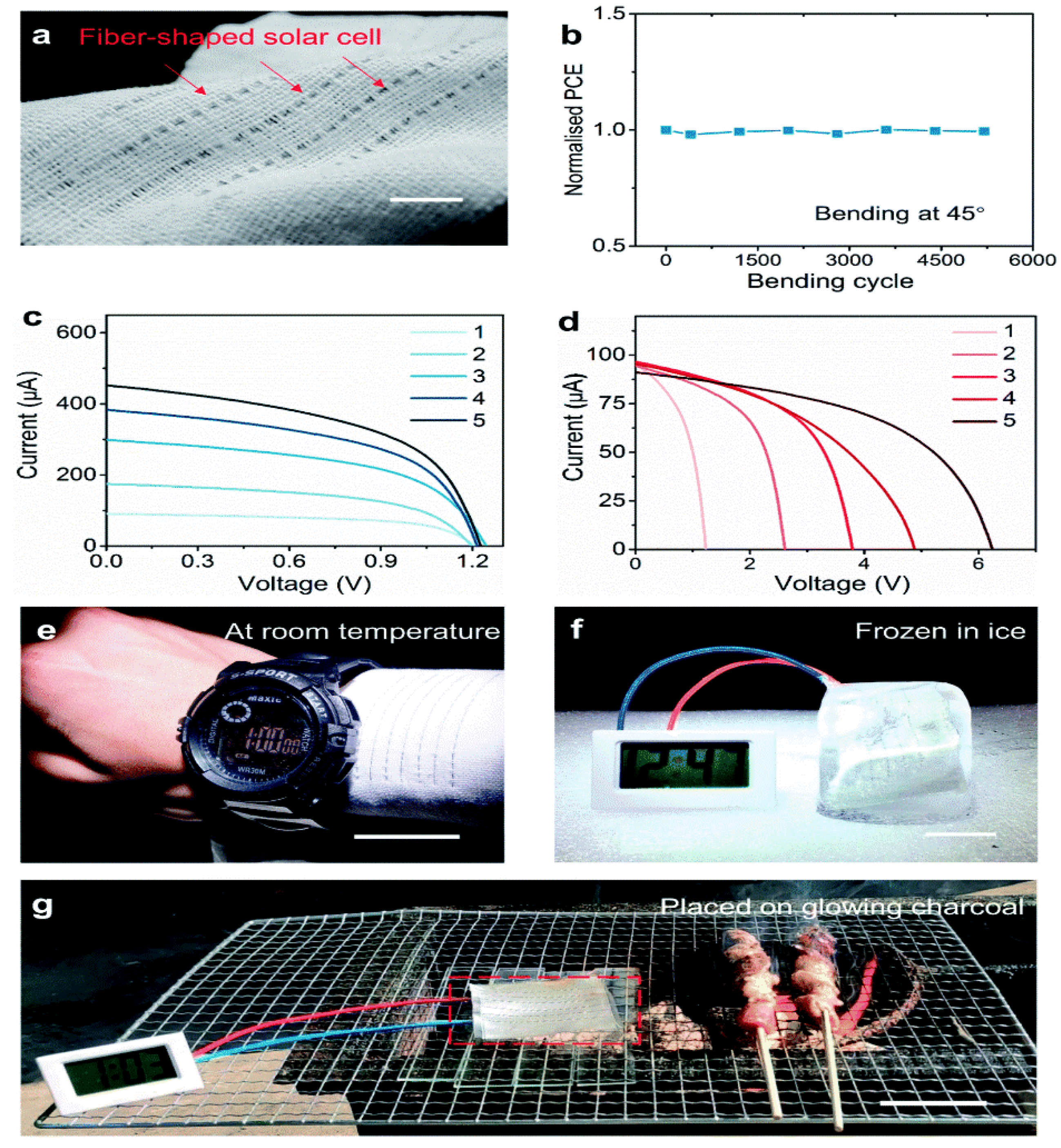

A recent study to develop a novel fibre-based solar cell textile (Figure 1a) that works at −40 °C to 160 °C was reported by Limin et al. Briefly, a family of inorganic perovskite solar cell fibres and textiles were made by multiple-sintering techniques to fully cover the curved surface of fibre substrate with large, uniform perovskite crystals. Firstly, CsPbBr3 quantum dots (QDs) were fabricated by a room-temperature ligand-assisted method. Then aligned TiO2 nanotubes were successfully grown on Ti wire and dipped into inorganic perovskite QDs to form a uniform layer on the fibre substrate.

Figure 1. Application and performance of the perovskite solar cell textile: (a) Photograph of a perovskite solar cell (scale bar = 1 cm). (b) Power conversion efficiency with a bending angle of 45° to the solar cell textile. (c,d) I–V curves of fibre-shaped perovskite solar cells connected in parallel and in series for (e) a textile perovskite solar cell powering an electronic watch at room temperature (scale bar = 2 cm), (f) a textile perovskite solar cell frozen in ice powering an electronic clock, and (g) testing of textile perovskite solar cells placed at charcoal powering an electronic clock (scale bar = 4 cm). Reproduced from [13], copyright 2020, Royal society of chemistry.

This modified fibre-shaped PSCs were woven into textiles for further applications. The solar cell textile maintained about 90% of its original PCE after bending at 45° for 500 cycles, as shown in Figure 1b. The fibre-shaped devices connected in parallel showed that the short-circuit current (Isc) increased linearly with the number of devices, whereas the open-circuit voltage (Voc) remained unchanged (Figure 1c). For the five devices connected in series, an Isc value of 0.09 mA and a Voc value of 6.22 were achieved (Figure 1d).

After that, a solar cell textile was used to power an electronic watch worn by a human (Figure 1e). In addition, it could also work under harsh working conditions, such as being frozen in ice or placed on red-hot charcoal (Figure 1f,g) [13]. The most recent studies available on textile-based perovskite photovoltaic applications are summarised in Table 1.

Table 1. Summary of the textile-based perovskite solar cells’ performance a.

| Textile Substrate | Perovskite Photoactive Layer |

Fabrication Method |

VOC (V) |

Jsc (mA/cm2) |

FF (%) |

PCE (%) |

Ref. |

|---|---|---|---|---|---|---|---|

| Polyester fabric | CH3NH3PbI3 | Bar coating | 0.88 | 12.44 | 49 | 5.72 | [14] |

| Stainless steel fabric | CH3NH3PbI3 | Dip coating | 0.55 | 3.72 | - | 3.80 | [11] |

| Stainless steel fibre | CH3NH3PbI3 | Dip coating | 0.66 | 10.20 | 48 | 3.30 | [12] |

| PAN/PU fabric | CH3NH3PbI3 | Spin coating | 0.80 | 8.86 | 57 | 4.06 | [15] |

| TiO2 modified Ti-fibre | CsPbBr3 | Dip coating | 1.19 | 6.48 | 70 | 5.37 | [13] |

| Acrylic elastomer | CH3NH3PbI3 | Spin coating | 1.06 | 17.05 | 65 | 14.80 | [16] |

| Carbon fabric | CsMAFAPbI3 − xBrx | Spin coating | 1.12 | 20.42 | 67 | 15.29 | [17] |

| PEN | CH3NH3PbI3 − xClx | Spin coating | 0.96 | 19.06 | 59 | 12.20 | [18] |

| Carbon fibre | CH3NH3PbI3 − xClx | Dip coating | 0.61 | 8.75 | 56 | 3.03 | [19] |

| Polyester fabric | (FAPbI3)0.85(MAPbBr3)0.15 | Spin coating | 1.09 | 22.41 | 72 | 17.68 | [19] |

a Abbreviations: Ti = titanium; PAN/PU = poly(acrylonitrile)/polyurethane; TiO2 = titanium dioxide.

Jung et al. performed a series of experiments on fully solution-processed perovskite (CH3NH3PbI3) solar cells fabricated on PU-coated polyester fabric. A thin layer of PU was coated as a planarisation layer that effectively improved the wettability, processability, and surface morphology of the textile surface. The textile-based flexible PSCs were successfully fabricated, and PCE of 5.72% was achieved by using solution-processed anode, HTL, and ETL materials [14]. In another textile-based PSC report, low-temperature tin oxide (SnO2) ETL, perovskite (CH3NH3PbI3), and a novel encapsulation layer were obtained. An ITO/PEN flexible substrate was chosen to fabricate the most efficient textile-based PSC with improved wash capability and ambient stability. A 15% PCE of this unique textile-based PSC was recorded, with future potential in wearable device applications [16].

In the development of wearable power sources, highly flexible, lightweight, efficient PSCs based on PEN/ITO substrates with a PCE of 12.2% have been reported. In addition, bending stability was recorded for solar devices with three effective bending radii of 400 mm, 10 mm, and 4 mm for the human neck, wrist, and finger, respectively. In the case of a human finger, the PCE significantly dropped to 50% of the initial value after 1000 cycles. It was noted that the origin of degradation was due to the fracture in the ITO layer on the PEN substrate [18].

2. Photodetectors for Wearable Optoelectronics

Textile-based photodetectors (PDs) are a major area of interest within the fields of video imaging, bioinspired sensing, optical communication, and biomedical imaging. In recent years, wearable PDs have been fabricated on a variety of flexible substrates because of their possible applications in touchscreens, wearable electronic devices, and pressure-induced sensing [20]. Several key factors define the final efficiency of wearable PDs, such as the morphology of substrates, and the retention of initial performance values after repeated bending, stretching, or folding. Therefore, the main components of wearable PDs—such as substrates, charge-transport layers, and electrodes—should be stable enough to resist environmental and mechanical hazards. In addition, MHPs can be easily synthesised by low-temperature solution-processing techniques, which is helpful in making wearable PDs [21][22][23].

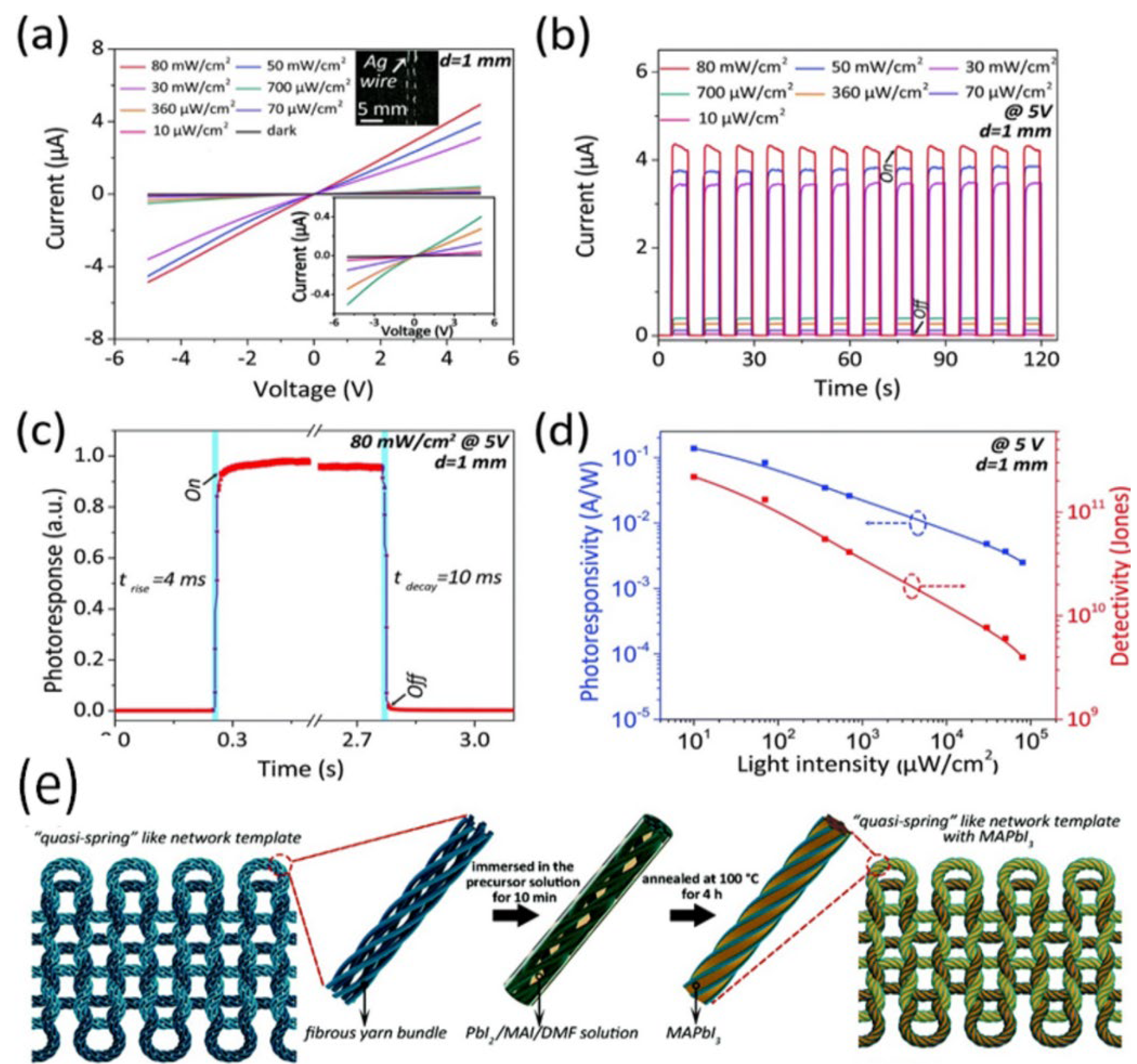

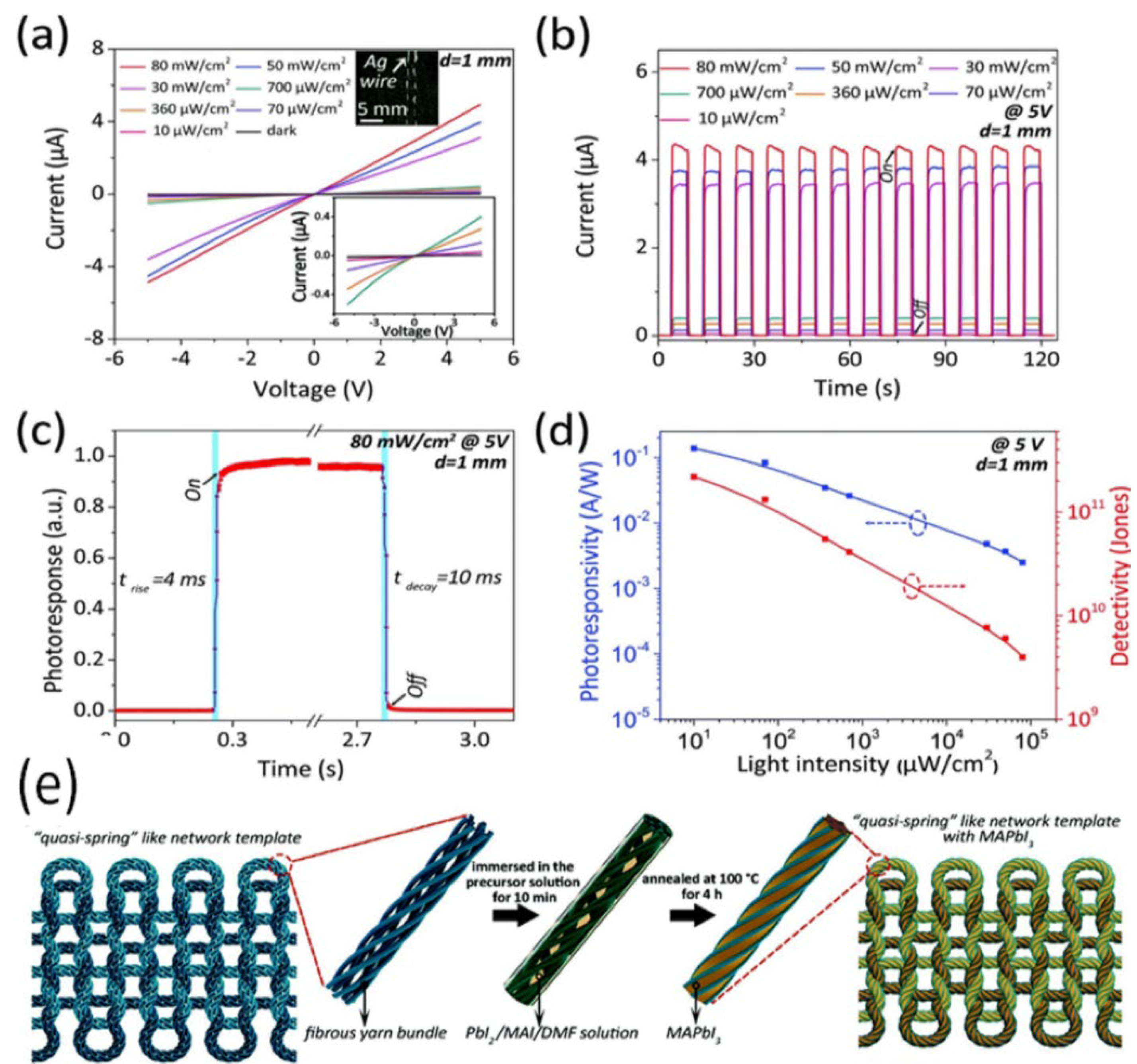

Dong et al. reported highly flexible fibrous yarn bundles and their knitted structure as a template to fabricate MAPbI3-based PDs (Figure 2e). They fabricated quasi-spring-like network-based wearable PDs consisting of silver (Ag) electrode/perovskite (MAPbI3)/yarn bundles, and their photoelectric properties were examined. In Figure 2a, the I–V curves depict a linear behaviour with an increase in voltage, confirming the ohmic contact between the perovskite and the Ag electrodes. After illumination, the current gradually increased with an increase in the power from 10 mWcm−2 to 80 mWcm−2, and the time-dependent photocurrent was also recorded under the same power conditions (Figure 2b). During repeated on/off cycles, good stability and repeatable light-sensing behaviour were observed. Furthermore, the PDs showed a fast photoresponse speed (trise~4 ms, tdecay~10 ms) and high detectivity (2.2 × 1011 jones) at 10 mW/cm2 (Figure 2c,d) [24].

Figure 2. Photoelectric characteristics of perovskite photodetectors: (a) I–V curves in dark and light exposure with different power densities of the photodetectors. (b) Time-dependant (I–t) curves under light illumination with different power densities at a bias voltage of 5 V. (c) Photoresponse with light switched on and off at a fixed light power density of 80 mW/cm2 and a bias voltage of 5 V. (d) Photoresponsivity and detectivity as functions of light intensity. (e) Illustration of the fabrication process of quasi-spring-like network-structured photodetectors. Reproduced from [24], copyright 2019, Royal Society of Chemistry.

Poly (vinylidene fluoride) (PVDF)-based flexible and self-powered PDs were fabricated that use a mixed-cation perovskite (FAPbI3)1−x (MAPbBr3)x as the photoactive material. These wearable PDs have the advantages of light weight, low cost, and the ability to reshape in any form for the human body without any physical restrictions. The synthesised PDs showed good performance, with a fast response speed (trise = 82 ms, tdecay = 64 ms) and high detectivity (7.21 × 1010 jones at zero bias) under 254 UV illumination, and excellent mechanical stability at some bending angles [2524]. In another study, PVDF was reported as a flexible substrate to integrate CsPbBr3 nanosheets into ZnO nanowires and graphene. The resultant p–n junction due to ZnO and CsPbBr3 can facilitate the enhanced transportation of photogenerated charge carriers, leading to a high Ilight/Idark ratio of ~103. The flexible thin-film PDs can be easily attached to human skin for wearable applications [2625].

Polymer/perovskite composite nanofibers were prepared by the electrospinning technique to demonstrate their potential for stretchable and wearable PDs. The poly (vinylpyrrolidone)/MAPBI3 nanofibrous membranes showed the ability to endure 15% strain, and started to break at 20% strain. At 15% strain, the detectivity and photoresponsivity of the wearable PDs at λ = 550 nm were 51.2 mWA−1 and 2.23 × 1011 jones, respectively [2726].

3. Fibre- and Fabric-Based Perovskite Light-Emitting Diodes

Alongside the development of PSCs, perovskite LEDs (PeLEDs) have exciting potential to be the first next-generation LEDs based on their excellent electro-optical properties. Since the first demonstration of PeLEDs incorporating 3D perovskite in 2014, intense efforts have been dedicated to developing high-performance PeLEDs [27][28][29]. As they have shown good performance on rigid substrates, the next important direction for PeLEDs is their integration with textile-based optoelectronics for wearable applications. Wearable LEDs can meet the requirements of lightweight and portable electronic devices. For wearable LEDs, tremendous efforts have been reported for preparing different components of PeLEDs, such as flexible electrodes and HTLs/ETLs.

A recent study by Shan and Wei involved a hybrid strategy to fabricate wearable and tuneable perovskite quantum-dot-based light-emitting/detecting bifunctional fibres. In this method, a transparent PET fibre coated with PEDOT:PSS was used as a working electrode for the synthesis of flexible electroluminescent (EL) fibres, as presented in Figure 3a,b. In Figure 3c,d, the current density–luminance–voltage curves of the green EL fibres (FWHM = 19 nm) show luminance of ~100 cd/m2 at 7 V and current efficiency of 1.67 cd/A. Red EL fibres (Figure 3e) were also prepared with the same composition, and exhibited the chromaticity coordinates of (0.65, 0.27). The bending test of EL perovskite fibres was also performed along a round-shaped radius of about 4.5 mm (Figure 3f) [30].

Figure 3. Device structure and electric behaviour of light-emitting perovskite fibres: (a) Illustration of the working mechanism of light-emitting perovskite fibres. (b) Schematic of the perovskite fibre; inset: cross-sectional SEM image of the fibre. (c) Luminance and current–density curves of perovskite fibres. (d,e) Electroluminescent spectra of green and red perovskite fibres, respectively; inset: photographs of the red and green perovskite fibres, respectively. (f) Photographs of the bent perovskite fibre and its electroluminescent behaviour under bending. Reproduced from [30], copyright 2020, Springer Nature.

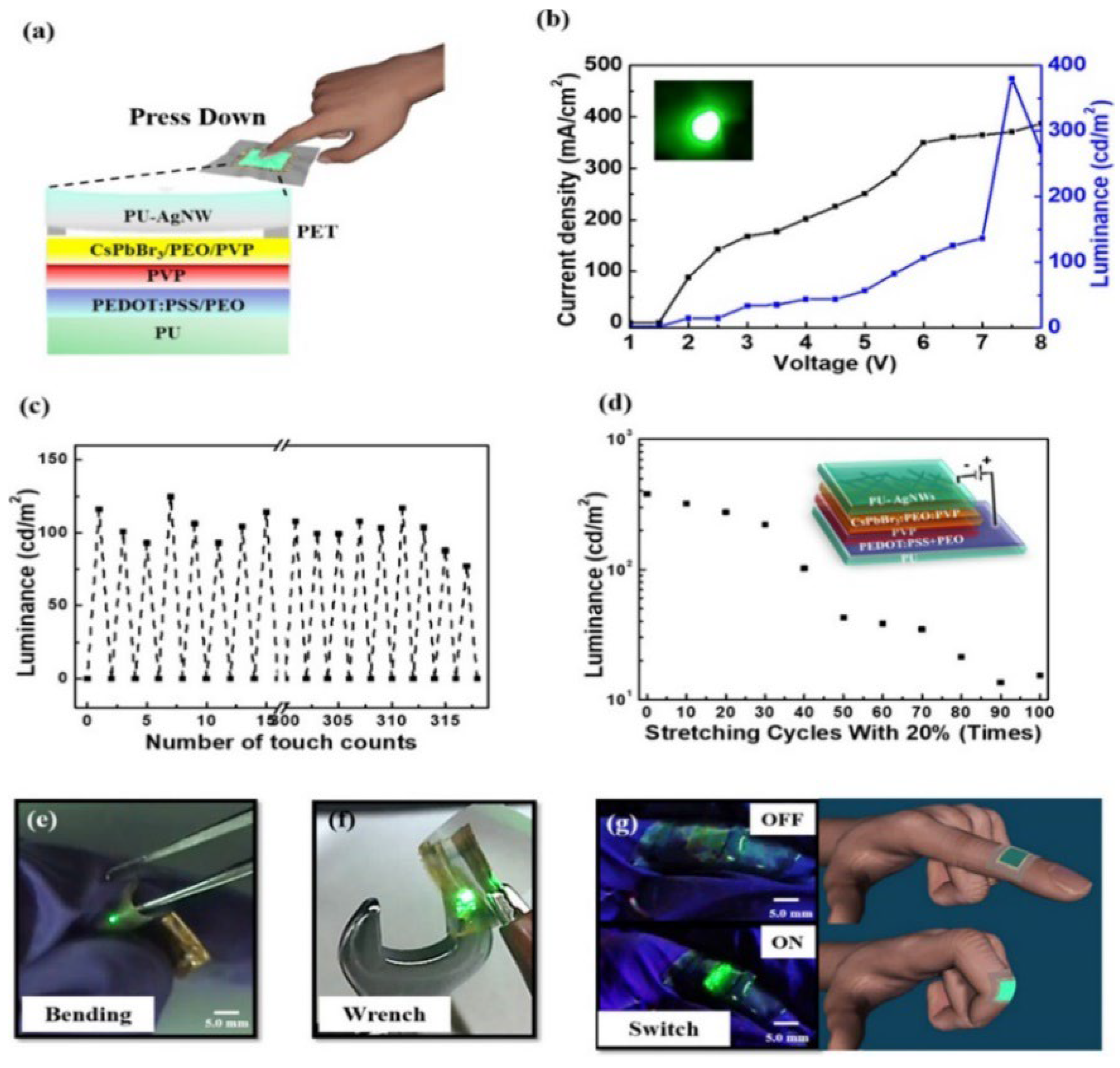

Jiang et al. demonstrated stretchable touch-responsive PeLEDs by using a highly conductive and transparent polyurethane (PU)/Ag nanowire composite electrode, as shown in Figure 4a. Moreover, a stretchable perovskite active layer was synthesised by mixing poly (vinylpyrrolidone) and poly (ethylene oxide) with CsPbBr3. When the pressure was applied to the PU/Ag, a connection between the electrode and the perovskite layer allowed electrons and holes to recombine when voltage was applied. As the pressure was released, the PU/Ag electrodes disconnected from the emissive layer and returned to their original position. The device exhibited a luminance of 380.5 cd/m2 at 7.5 V, with good touch responsivity after 315 cycles (Figure 4b,c). In addition, the fabricated device showed a certain stretchability before 40 stretching cycles (Figure 4d). Figure 4e–g present the flexibility of touch-responsive PeLEDs to emit instantaneous light when bent around different mechanical objects [31].

Figure 4. Photograph of stretchable perovskite light-emitting diodes: (a) Current density–voltage and luminance–voltage characteristics of perovskite light-emitting diodes with stretchable electrodes. (b) Durability test before and after pressure was applied to the flexible electrodes under a voltage of 3 V. (c) Luminance characteristics after 315 cycles. (d) Changes in luminance characteristics after repetitive stretching cycles at strains of 20%. (e–g) Bending behaviour of stretchable perovskite light-emitting diodes, touched with a wrench and a finger at a voltage of 7 V. Reproduced from [31], copyright 2020, American Chemical Society.

A significant discussion of the influence of solvent trapped in ITO/PEN substrates on the efficiency of flexible PeLEDs was presented by Kim et al. In device fabrication, cleaning and ultraviolet–ozone treatment are considered important for uniform perovskite deposition. However, the trapped solvents can easily generate radicals that are adsorbed on the ITO surface. This leads to effects on the sheet resistance and Fermi level. The complete removal of solvents helps to enhance the luminance from 87.2 cd/m2 to 329.6 cd/m2 at 4 V [3229]. Some researchers also highlight the importance of monolayered graphene for flexible photonic applications. This unique material can be used as an anode for flexible LEDs due to its high light transparency and theoretical resistance (>6.4 k Ω/sq) [3330].

To solve the intrinsic instability and crystal friability of MHPs, a facile approach using liquid-to-liquid encapsulation inkjet printing was presented. Perovskite inks were directly inkjet-printed into the liquid PDMS to synthesise the single-crystal embedded PDMS structures in situ. The space-confined effect of liquid PDMS is the key to producing single-crystal arrays in PDMS, which can effectively control the crystallisation process and help to form the single-crystal perovskite structures. This technique can lead to the scalable formation of air-stable single-crystal perovskite structures for wearable light-emitting devices [3431].

References

- Tang, G.; Yan, F. Recent progress of flexible perovskite solar cells. Nano Today 2021, 39, 101155.

- Yuan, K.; Hu, T.; Chen, Y. Flexible and wearable solar cells and supercapacitors. In Flexible and Wearable Electronics for Smart Clothing; John Wiley & Sons: Hoboken, NJ, USA, 2020.

- Hashemi, S.A.; Ramakrishna, S.; Aberle, A.G. Recent progress in flexible–wearable solar cells for self-powered electronic devices. Energy Environ. Sci. 2020, 13, 685–743.

- Kim, J.-H.; Seok, H.-J.; Seo, H.-J.; Seong, T.-Y.; Heo, J.H.; Lim, S.-H.; Ahn, K.-J.; Kim, H.-K. Flexible ITO films with atomically flat surfaces for high performance flexible perovskite solar cells. Nanoscale 2018, 10, 20587–20598.

- Zeng, P.; Deng, W.; Liu, M. Recent Advances of Device Components toward Efficient Flexible Perovskite Solar Cells. Sol. RRL 2020, 4, 1900485.

- Luo, Q.; Ma, H.; Hou, Q.; Li, Y.; Ren, J.; Dai, X.; Yao, Z.; Zhou, Y.; Xiang, L.; Du, H.; et al. All-Carbon-Electrode-Based Endurable Flexible Perovskite Solar Cells. Adv. Funct. Mater. 2018, 28, 1706777.

- Albrecht, S.; Saliba, M.; Baena, J.P.C.; Lang, F.; Kegelmann, L.; Mews, M.; Steier, L.; Abate, A.; Rappich, J.; Korte, L.; et al. Monolithic perovskite/silicon-heterojunction tandem solar cells processed at low temperature. Energy Environ. Sci. 2016, 9, 81–88.

- Qin, M.; Ma, J.; Ke, W.; Qin, P.; Lei, H.; Tao, H.; Zheng, X.; Xiong, L.; Liu, Q.; Chen, Z.; et al. Perovskite Solar Cells Based on Low-Temperature Processed Indium Oxide Electron Selective Layers. ACS Appl. Mater. Interfaces 2016, 8, 8460–8466.

- Kumar, N.S.; Naidu, K.C.B. A review on perovskite solar cells (PSCs), materials and applications. J. Materiomics 2021, 7, 940–956.

- Kumar, M.H.; Yantara, N.; Dharani, S.; Graetzel, M.; Mhaisalkar, S.; Boix, P.P.; Mathews, N. Flexible, low-temperature, solution processed ZnO-based perovskite solid state solar cells. Chem. Commun. 2013, 49, 11089–11091.

- He, S.; Qiu, L.; Fang, X.; Guan, G.; Chen, P.; Zhang, Z.; Peng, H. Radically grown obelisk-like ZnO arrays for perovskite solar cell fibers and fabrics through a mild solution process. J. Mater. Chem. A 2015, 3, 9406–9410.

- Qiu, L.; Deng, J.; Lu, X.; Yang, Z.; Peng, H. Integrating Perovskite Solar Cells into a Flexible Fiber. Angew. Chem. Int. Ed. 2014, 53, 10425–10428.

- Xu, L.; Fu, X.; Liu, F.; Shi, X.; Zhou, X.; Liao, M.; Chen, C.; Xu, F.; Wang, B.; Zhang, B.; et al. A perovskite solar cell textile that works at −40 to 160 °C. J. Mater. Chem. A 2020, 8, 5476–5483.

- Jung, J.W.; Bae, J.H.; Ko, J.H.; Lee, W. Fully solution-processed indium tin oxide-free textile-based flexible solar cells made of an organic–inorganic perovskite absorber: Toward a wearable power source. J. Power Sources 2018, 402, 327–332.

- Zhai, J.; Yin, X.; Song, L.; Chen, W.-H.; Du, P.; Xiong, J. Preparationof fabric-like transparent electrodefor flexible perovskite solar cell. Thin Solid Films 2021, 729, 138698.

- Lam, J.-Y.; Chen, J.-Y.; Tsai, P.-C.; Hsieh, Y.-T.; Chueh, C.-C.; Tung, S.-H.; Chen, W.-C. A stable, efficient textile-based flexible perovskite solar cell with improved washable and deployable capabilities for wearable device applications. RSC Adv. 2017, 7, 54361–54368.

- Gholipour, S.; Correa-Baena, J.-P.; Domanski, K.; Matsui, T.; Steier, L.; Giordano, F.; Tajabadi, F.; Tress, W.; Saliba, M.; Abate, A.; et al. Highly Efficient and Stable Perovskite Solar Cells based on a Low-Cost Carbon Cloth. Adv. Energy Mater. 2016, 6, 1601116.

- Kim, B.J.; Kim, D.H.; Lee, Y.-Y.; Shin, H.-W.; Han, G.S.; Hong, J.S.; Mahmood, K.; Ahn, T.K.; Joo, Y.-C.; Hong, K.S.; et al. Highly efficient and bending durable perovskite solar cells: Toward a wearable power source. Energy Environ. Sci. 2015, 8, 916–921.

- Li, R.; Xiang, X.; Tong, X.; Zou, J.; Li, Q. Wearable Double-Twisted Fibrous Perovskite Solar Cell. Adv. Mater. 2015, 27, 3831–3835.

- Hao, D.; Zou, J.; Huang, J. Recent developments in flexible photodetectors based on metal halide perovskite. InfoMat 2020, 2, 139–169.

- Jing, H.; Peng, R.; Ma, R.-M.; He, J.; Zhou, Y.; Yang, Z.; Li, C.-Y.; Liu, Y.; Guo, X.; Zhu, Y.; et al. Flexible Ultrathin Single-Crystalline Perovskite Photodetector. Nano Lett. 2020, 20, 7144–7151.

- Zhang, M.; Lu, Q.; Wang, C.; Dai, H.; He, J.; Mohamed, Z.; Chen, X.; Ge, B. High-performance and stability bifacial flexible self-powered perovskite photodetector by surface plasmon resonance and hydrophobic treatments. Org. Electron. 2021, 99, 106330.

- Yu, F.; Hu, M.; Kang, F.; Lv, R. Flexible photodetector based on large-area few-layer MoS2. Prog. Nat. Sci. 2018, 28, 563–568.

- Ding, D.; Li, H.; Yao, H.; Liu, L.; Tian, B.; Su, C.; Wang, Y.; Shi, Y. Template growth of perovskites on yarn fibers induced by capillarity for flexible photoelectric applications. J. Mater. Chem. C 2019, 7, 9496–9503. Nguyen, T.M.H.; Lee, S.K.; Kim, S.; Bark, C.W. Practical Demonstration of Deep-Ultraviolet Detection with Wearable and Self-Powered Halide Perovskite-Based Photodetector. ACS Appl. Mater. Interfaces 2021, 13, 57609–57618.

- Nguyen, T.M.H.; Lee, S.K.; Kim, S.; Bark, C.W. Practical Demonstration of Deep-Ultraviolet Detection with Wearable and Self-Powered Halide Perovskite-Based Photodetector. ACS Appl. Mater. Interfaces 2021, 13, 57609–57618. Liu, S.; Liu, X.; Zhu, Z.; Wang, S.; Gu, Y.; Shan, F.; Zou, Y. Improved flexible ZnO/CsPbBr3/Graphene UV photodetectors with interface optimization by solution process. Mater. Res. Bull. 2020, 130, 110956.

- Liu, S.; Liu, X.; Zhu, Z.; Wang, S.; Gu, Y.; Shan, F.; Zou, Y. Improved flexible ZnO/CsPbBr3/Graphene UV photodetectors with interface optimization by solution process. Mater. Res. Bull. 2020, 130, 110956. Kim, H.-J.; Oh, H.; Kim, T.; Kim, D.; Park, M. Stretchable Photodetectors Based on Electrospun Polymer/Perovskite Composite Nanofibers. ACS Appl. Nano Mater. 2022, 5, 1308–1316.

- Kim, H.-J.; Oh, H.; Kim, T.; Kim, D.; Park, M. Stretchable Photodetectors Based on Electrospun Polymer/Perovskite Composite Nanofibers. ACS Appl. Nano Mater. 2022, 5, 1308–1316. Dong, Q.; Lei, L.; Mendes, J.; So, F. Operational stability of perovskite light emitting diodes. J. Physics: Mater. 2020, 3, 012002.

- Dong, Q.; Lei, L.; Mendes, J.; So, F. Operational stability of perovskite light emitting diodes. J. Physics: Mater. 2020, 3, 012002. Miyasaka, T. Perovskite Photovoltaics and Optoelectronics: From Fundamentals to Advanced Applications; John Wiley & Sons: Weinheim, Germany, 2022.

- Miyasaka, T. Perovskite Photovoltaics and Optoelectronics: From Fundamentals to Advanced Applications; John Wiley & Sons: Weinheim, Germany, 2022. Kim, S.; Oh, H.; Jeong, I.; Kang, G.; Park, M. Influence of a Solvent Trap in ITO/PEN Substrates on the Performance of Flexible Perovskite Solar Cells and Light-Emitting Diodes. ACS Appl. Electron. Mater. 2021, 3, 3207–3217.

- Shan, Q.; Wei, C.; Jiang, Y.; Song, J.; Zou, Y.; Xu, L.; Fang, T.; Wang, T.; Dong, Y.; Liu, J.; et al. Perovskite light-emitting/detecting bifunctional fibres for wearable LiFi communication. Light. Sci. Appl. 2020, 9, 163. Kim, H.; Ahn, J.-H. Graphene for flexible and wearable device applications. Carbon 2017, 120, 244–257.

- Jiang, D.-H.; Liao, Y.-C.; Cho, C.-J.; Veeramuthu, L.; Liang, F.-C.; Wang, T.-C.; Chueh, C.-C.; Satoh, T.; Tung, S.-H.; Kuo, C.-C. Facile Fabrication of Stretchable Touch-Responsive Perovskite Light-Emitting Diodes Using Robust Stretchable Composite Electrodes. ACS Appl. Mater. Interfaces 2020, 12, 14408–14415. Gu, Z.; Huang, Z.; Hu, X.; Wang, Y.; Li, L.; Li, M.; Song, Y. In Situ Inkjet Printing of the Perovskite Single-Crystal Array-Embedded Polydimethylsiloxane Film for Wearable Light-Emitting Devices. ACS Appl. Mater. Interfaces 2020, 12, 22157–22162.

- Kim, S.; Oh, H.; Jeong, I.; Kang, G.; Park, M. Influence of a Solvent Trap in ITO/PEN Substrates on the Performance of Flexible Perovskite Solar Cells and Light-Emitting Diodes. ACS Appl. Electron. Mater. 2021, 3, 3207–3217.

- Kim, H.; Ahn, J.-H. Graphene for flexible and wearable device applications. Carbon 2017, 120, 244–257.

- Gu, Z.; Huang, Z.; Hu, X.; Wang, Y.; Li, L.; Li, M.; Song, Y. In Situ Inkjet Printing of the Perovskite Single-Crystal Array-Embedded Polydimethylsiloxane Film for Wearable Light-Emitting Devices. ACS Appl. Mater. Interfaces 2020, 12, 22157–22162.

More