The food industry is quite interested in the use of (techno)-functional bioactive compounds from by-products to develop ‘Clean label’ foods in a circular economy. The aim of this review is to evaluate knowledge, scientific evidence, and practical application on the use of green extraction technologies (ultrasound-, microwave-, and enzymatic-assisted) of bioactive compounds from pomegranate peel by-products, and their potential application via the supplementation / fortification of vegetal matrixes to improve their quality, functional properties, and safety. Most studies are mainly focused on ultrasound extraction, which has been widely developed compared to microwave or enzymatic extractions, which should be deeply studied including combinations. After extraction, pomegranate peel by-products (in powders, liquid extract, and/or encapsulated, among others) have been incorporated into several food matrixes, as a good tool to preserve ‘Clean label’ foods without altering their composition and improving their functional properties. Future studies must clearly evaluate the energy efficiency/consumption, the cost, and the environmental impact leading to sustainable extraction of the key bio-compounds. Moreover, predictive models are needed to optimize the phytochemical extraction to help taking decisions along the supply chain

- Punica granatum

- peel

- food

- circular economy

- sustainability

- antioxidants

- phenolics

- encapsulation

- green-technology

- food losses

- clean label

- minimally processed

In accordance with Food and Agriculture Organization of the United Nations (FAO) definition, ‘food waste’ is the decrease in the quantity and/or quality of food obtaining from decisions and/or actions by retailers, food service providers and consumers, while ‘food loss’ refers to any food that is discarded along the previous food supply chain steps from harvest up to retail sale [1]. FAO indicates that around one third of the food production is globally lost or wasted at some step in the food chain. Depending on the state and the basket item, the losses level greatly varies.

In the case of fruit and vegetables (F&V) at the whole supply chain could reach up to ~50 % (Figure 1). FAO’s future challenges by 2050 is to reduce ~50 % of food waste, as one of the objectives for sustainable development (OSD). Circular economy has been considered as the principles for eco-innovation, being focused on a ‘zero waste’ society and economy, using wastes as raw materials.

Between 2016 and 2018, FAO Statistics Division developed a food loss estimation model called “The Food Loss and Waste database”, an online collection of data including food loss and food waste. Figure 1 shows the % loss of F&V (food loss + food waste) worldwide in each value chain step in the first 20 years of XXI century [2]. The boxes show where ~50 % of the collected data falls into, the mid-value of the percentage loss at every stage in the supply chain is shown by a line. In this sense, postharvest and retailing are the main steps in the food chain where the F&V losses represent the highest mean percentages. Mean percentage during processing is less than 10 %, but in some cases, it reaches ~40 %. Moreover, although the mean percentage during distribution represent less than 10 %, the range is from < 5 % to > 30 %. Therefore, several strategies of creating active packaging with encapsulated key compounds have been developed, to avoid high percentage of food waste/loss [3]. The range of each step is wide since the value depends on the type of F&V, the country, and the year.

Although, this review is focused on pomegranate by-products, percentage of food loss related to this fruit is not available in the mentioned official database. Nevertheless, knowing that the total production of pomegranate worldwide is three million tons, and its peel and seeds approximately represent the ~54 % of the fruit, these results in ~1.62 million tons of waste [4,5]. Therefore, it is a huge amount of waste produced, so it is crucial to find suitable methods to revalorize them by optimizing the bioactive compounds extraction of pomegranate residues and then, convert them into value-added products. Consequently, savings can also be made on other resources involved during production, harvesting, preservation and distribution, such as energy, water, and land, as well as contributing to the environment [5]

Parallelly, health, well-being, and sustainability are the current trend in the food market. Consumers and food producers are interested in ‘Clean label’ foods or ingredients [6,7]. It means that they are interested in foods or ingredients obtained by green-processing technologies (non-thermal, green-solvents), and bioactive compounds with health promoting properties (nutraceuticals), among others. The bioactive compounds obtained from F&V by-products present technological and functional features and can be incorporated within other food matrixes to enhance their nutritional, functional, and sensory quality [6,8]. Also, the use of bioactive compounds from F&V by-products has previously been classified as potential green-ingredients for the cosmetic and pharmaceutical industries, developing different products intended for specific populations such as sport-people [9].

The present review aims to evaluate scientific evidence and knowledge on the use of green technologies for the extraction of phenolic compounds from pomegranate by-products, and its further incorporation techniques and potential applications via the supplementation / fortification of F&V matrixes to improve their quality and safety in a circular economy. For this purpose, a literature review was conducted, focusing on ultrasound-, microwave-, and enzymatic-assisted technology to enhance phenolic compounds extraction from pomegranate peel by-products. Moreover, different incorporation techniques and applications have been reviewed. Results may provide the scientific community with the state of the art on pomegranate peel revalorization. The study may also help scientists, and food industry to develop solutions to better suit society demands.

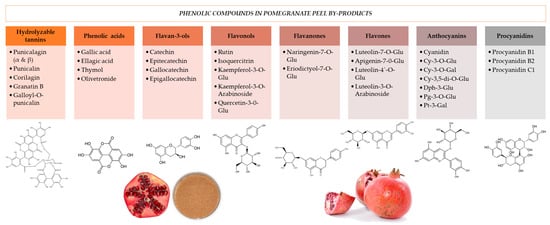

1. Nutritional Composition of Pomegranate Byproducts

2. Pomegranate Peel Byproducts Incorporation Techniques

2.1. Powders/Flours

Pomegranate peel powder/flour is commonly acquired by drying and grinding until obtaining the desired particle size. Similar drying technology applied to edible fruit and plant material could be used in F&V byproducts to avoid undesirable bioactive compound changes [12][69]. The most common drying technologies are convective drying, sun-drying, MW drying, and freeze-drying in which key variables should be optimized (for instance, temperature and time). Moreover, spray-drying is commonly catalogued as a good tool for byproducts drying. This powder could be applied as a solid ingredient for the fortification of different products such as meat-based, F&V-based, and bakery products (Section 6) since this material presented high dietary fiber and techno-functional properties (high water- and oil-holding capacity, and low water absorption) in previous studies [13][70]. Similarly, powders can be obtained from liquid extracts after bioactive compounds extraction using different technologies such as freeze-drying or spray-drying [14][71]. Such technologies are included in the section on encapsulation due to the need for different processes to be carried out (Section 5.3).2.2. Liquid Extracts

With pomegranate peel powders obtained as previously detailed, extraction techniques with different solvents can be used, including those reported in this review. These liquid extracts are not suitable for direct incorporation into the different food matrixes, except when the solvents may be classified as a food ingredient (e.g., water). Therefore, these solvents must be removed through evaporation. Once they have been evaporated, drying should be carried out (for instance convective or freeze-drying) to later redissolve it in water, as the most common liquid. In this way, the liquid extract is ready to be incorporated into the matrixes at different solid–liquid ratio, as observed in Section 6. In addition, liquid extracts can be used to obtain coatings, and can be encapsulated by different carriers and techniques.2.3. Encapsulation

Encapsulation is a means to protect sensitive key bioactive compounds found in the food industry byproducts against undesirable heat, oxygen, light, and pH conditions [15][72]. The process needs a carrier agent and a technique to create the protective capsules. Different techniques may be used for the encapsulation of target compounds from F&V byproducts, such as spray-drying, freeze-drying, complex coacervation, and ion gelation [16][73], among others. Spray-drying is the liquid food drying method and has been widely used to obtain powders from F&V juices [12][17][18][19][69,74,75,76]. Currently, the transformation of F&V byproduct extracts (liquid) into powders using a spray-drier (the extracts are sprayed into a hot air chamber) has garnered attention because the process is complex, although this technique is one of the fastest, cheapest, and more reproducible, despite its complexity. In lyophilization as well as in spray-drying, a solution, dispersion, or emulsion is first obtained depending on the encapsulating agent and the active compound. The first step of freeze-drying-based encapsulation consists in creating an emulsion between the carriers and the target compounds, followed by a conversion into microcapsules by applying the freeze-drying technique [20][77], which consists of water removal by sublimation (primary drying) and secondary drying. Table 1 shows the main technologies (spray-drying, freeze-drying, double emulsion, and ion gelation) and the carriers used to encapsulate target bioactive compounds from pomegranate peel. It can be seen that there is an interest in using novel carriers such as citrus byproducts.| Technology | Carriers | Target Compound/Activity | Ref. |

|---|---|---|---|

| Spray-drying | Maltrodextrin | F-TPC, UPLC-TPC, Pn, EA, P, GA | [21][78[22],79] |

| Maltrodextrin + others: Tween 80 (99:1); Skimmed milk powder (50:50); Whey protein isolate (50:50); Gum arabic (50:50) | NA (Yield/Stability) | [23][24][28,80] | |

| Skimmed milk power | NA (Yield/Stability) | [23][24][28,80] | |

| Orange juice byproduct | F-TPC, DPPH | [25][26][81,82] | |

| Maltodextrin/Pectin | TPC, Pn, EA | [27][83] |

3.1. Fresh Whole Fruit and Vegetables

3.1. Fresh Whole F&V

In this case, more than 15 types of evidence have been found, in which pomegranate peel extracts were incorporated in different F&V (Table 25), being >25% incorporated into citrus fruits. The incorporation of pomegranate peel extract as a postharvest technique in fresh whole F&V has been reported in ~90% of the included studies. A coating enriched with pomegranate peel extract is described in 42% of them, the control formulation in which the extracts were added being chitosan and alginate solutions. Additionally, scientific evidence related to preharvest application is reported (pomegranate peel atomization in tomato leaves and the incorporation of the soil in a sage herb field). Table 25 shows specific information related to the drying technique, particle size, and cultivar of pomegranate; the extraction technique; the extracts formulation and incorporation method (atomization, liquid extracts, coating, dipping); and the main results obtained by the authors.3.2. Minimally Processed, or Fresh-Cut Fruit and Vegetables

3.2. Minimally Processed, or Fresh-Cut F&V

Since fresh-cut F&V usually present a short shelf life mainly due to enzymatic browning, dehydration, and microbial growth, it is necessary to look for innovative tools to preserve its quality and safety. Table 5 shows the scientific evidence in which pomegranate peel extracts were used in minimally processed or fresh-cut F&V. There is a need to focus on the different ways of incorporating extracts into other fresh-cut F&V, and salads (for instance, baby leaves and younger plants such as sprouts or microgreens). There is a lack of knowledge on the effect of pomegranate peel extracts on vegetable commodities.3.3. Fruit and Vegetables Based Beverages

3.3. F&V Based Beverages

The fortification of F&V based beverages with bioactive compounds has been recently reviewed and reported [52][8]. The goal of the fortification with target compounds could be to enhance functionality (high content of polyphenols and other compounds) and/or techno-functional properties (color maintenance, sensory quality, inhibition of microbial growth). Moreover, if the key biocompounds have been extracted by green technologies from F&V byproducts, their incorporation replaces or reduces synthetic additives. Table 2 shows the incorporation of pomegranate peel extracts in F&V juices as an alternative to enhance quality parameters. Future research should be focused on the fortification of other F&V-based matrixes such as cold/hot/dried soups and culinary sauces with pomegranate peel. For instance, a previous study indicated that the incorporation of horticultural byproducts improved the quality and shelf life of a kale pesto sauce [53][107].| Matrix | Pomegranate Peel Byproduct |

Extraction | Incorporation Method | Benefit | Ref. | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Fresh whole F&V (pre- and postharvest) | Tomato | Drier (50–60 °C, 72 h) Fine powder (more information NA) cv information NA |

Ratio 3:10 EtOH 48 h + evaporator (65 °C) + re-dissolved in sterile distilled water (0.05%, 0.5%, 1% and 5% w/v) |

Preharvest. Tomato plants were sprayed in the leaves (bacteria inoculation) with the aqueous extract + 24 h drying |

Antibacterial activity at least 15 days Replacing, reducing, or even alternating treatments involving copper compounds |

[54][108] | ||||

| Sage herb | Air dried (more information NA) Grinder (more information NA) cv information NA |

1:10 solid–liquid ratio in water or EtOH 80% 24 h + evaporator + water dilution | Preharvest. Added in the soil (2, 4, and 6 g per plot) |

Higher dry mass and essential oils Inhibition of free radical scavenging |

[55][109] | |||||

| Olive | Oven drier (40 °C) Powder home grinder (more information NA) Wonderful cv |

120 g/L EtOH solvent (50 and 80%) + 1% Citric acid | Postharvest. Treatment of 1 × 1-mm injuries and inoculated (C. acutatum) by 10 µL of pomegranate peel extract (12, 1.2, or 0.12 g/L) |

Reduction of fungal and bacterial population | [56][110] | |||||

| Potato tubers | Air drier (28 °C, 10–15 days) Fine powder (more information NA) Baladi cv |

1:10 solid–liquid (MetOH) 48 h 28 °C + evaporator + oven 50 °C 48 h | Postharvest. Wound (3 × 3 mm φ and deep) + inoculation (F. sambucinum) (24 h) + dipping (1.25, 2.5, 5, 10, and 20 mg/mL water) + air dried (2 h at 28 °C). |

Antifungal activity on the mycelial growth and spore germination | [57][111] | |||||

| Strawberry | Drying and particle size information NA Dente di caballo cv |

US 40 °C 80% A 3 min (3 on, 8 off) Ratio 1:10 (H2O 25%, propanol 25%, ethanol 25% and methanol 25%) + evaporator + Freeze-drier + re-dissolved in water |

Postharvest. Immersion (30 s in a 2 L solution of pomegranate peel extract) + air-drying (1 h) |

Extension of shelf life Substitution of synthetic pesticides |

[58][112] | Whey protein | Pn, EA, P, GA | |||

| Sweet cherry | Oven drier (40 °C) Particle size NA Mollar de Elche cv | [22][79] | ||||||||

| EtOH solvent (50 and 80%) + 1% Citric acid +evaporator + Water dilution | Postharvest. | Dipping (2 min) in the pomegranate extract (12, 2.4 or 1.2 g/L) + air drying (2 h, 28 °C) + storage at 1 °C | Inhibition of all fungal spore germination | [59][113] | Arabic gum | Pn, EA | [28][84] | |||

| Fresh whole F&V (pre- and postharvest) | Sweet cherry | Oven drier (40 °C) Fine powder < 470 µm cv information NA |

1:8 solid–liquid ratio (Water 28 °C 24 h) | Postharvest. Immersion in pomegranate peel extracts (3 min 20 °C) + room temperature drying |

Pomegranate peel extracts and calcium sulphate coatings, alone or in combination, decreased weight loss, decay, respiration rate, and increased acidity, firmness, ascorbic acid, DPPH, TPC, and TAC | [ | Chitosan | Pn, EA | [28][29][84,85] | |

| Pectin | Pn, EA | [28][84] | ||||||||

| 60 | ] | [ | 114 | ] | ||||||

| Apple | Oven drier (40 °C) Particle size NA Mollar de Elche cv |

EtOH solvent (50 and 80%) + 1% citric acid + evaporator + water dilution | Postharvest. Wounds treated with 10 μL of pomegranate peel extract (12, 1.2 or 0.12 g/L) + inoculation (10 μL P. expansum) |

Inhibition of fungal spore germination and decay of artificial inoculations | [59][113] | Modified starch | Pn, TPC, HTC, DPPH | [30 | ||

| Mango | Freeze drying (−45 °C, 94 h) Particle size and cv information NA |

MetOH 45 °C 30 min + Bath US + evaporator + water dilution | Postharvest. Chitosan (2%) in 0.5% citric acid solution + Pullulan (2%) in water (50:50 ratios). During stiring: 1% glycerol + 5% of pomegranate peel extract (0.02 g/mL). Dipping for 2 min |

Increase of firmness, TPC and AOX. Prolonged the shelf life | [61][115] | ][86] | ||||

| Apricot | Drier (60 °C, 48 h) Particle size < 0.251 mm cv information NA |

80% EtOH 25 °C + evaporator | Postharvest. Chitosan coating solution (1% chitosan in glacial acetic 1% + 0.8% glycerol + Tween 80 + 0.50, 0.75, and 1% pomegranate peel extract) |

Reduction of % decay and weight loss. Maintenance of DPPH radical scavenging activity, ascorbic acid content, titratable acidity and firmness. | [62][116] | Alginate | ||||

| Figs | NA (Yield/Stability) | Air dried few days (more information NA) Pulverized (more information NA) cv information NA[29][85] |

||||||||

| Alcoholic buffer (EtOH 50%) | Postharvest. | Alginic acid: agar (70:30) + 0.25 and 0.5% pomegranate peel extract Dipping in the coating solution + coating gelation |

Prolonged the shelf life | [63][117] | Freeze-drying | Soy phosphatidylcholine liposomes | Pn, EA, rutin, epifallocatechin, TPC | [31][87] | ||

| Dates | Drier (48 °C, 52 h) Ground peels (more information NA)cv information NA |

EtOH 70% + evaporator + Water dilution | Postharvest. 1% Chitosan, 1% nanochitosan or 1% pomegranate peel extract in 1% glacial acetic |

Growth inhibition of any fungal spore after 48 h of coating. | [64 | Maltodextrin (5 and 10%) and b-cyclodextrin (5 and 10%). | F-TPC, FRAP | [32][38] | ||

| Prunus armeniaca gum exudates | FRAP, DPPH | [33][88] | ||||||||

| ] | [ | 118 | ] | Chitosan | FRAP, DPPH | [33][88] | ||||

| Maltrodextrin | TPC, TFC, Pn, EA, FRAP, DPPH | [34][89] | ||||||||

| Maltodextrin and calcium alginate | ANCs, FRAP, DPPH | [35][ | ||||||||

| Citrus | Hot air drier (50 °C, 48 h) Particle size 0.250 mm cv information NA |

2.5:10 Solid–liquid ratio (Ac, EtOH, MetOH, H2O, DMSO) + shaking (6 h) + re-extracted with water evaporation | Postharvest. Immersion of wounded lemons (2 × 1 mm long and wide tip) in pomegranate peel extract (pre-infection and post-infection with P. digitatum) + air drying |

Prevention and control of P. digitatum | [65][119] | |||||

| Fresh whole F&V (pre- and postharvest) | Grapefruit | Oven drier (40 °C) Particle size information NA Mollar de Elche cv |

EtOH solvent (50 and 80%) + 1% citric acid evaporator + water dilution |

Postharvest. Wounds treated with 10 μL of pomegranate peel extract (12, 1.2 or 0.12 g/L) + inoculation 10 μL P. digitatum and P. italicum |

Inhibition of all fungal spore germination and decay of artificial inoculations | [66][120] | ||||

| Lemon | Oven drier (40 °C) Particle size information NA Mollar de Elche cv |

EtOH solvent (50 and 80%) + 1% citric acid + evaporator + water dilution | Postharvest. Wounds treated with 10 μL of pomegranate peel extract (12, 1.2 or 0.12 g/L) + inoculation 10 μL P. digitatum and P. italicum |

Inhibition of all fungal spore germination and decay of artificial inoculations | [59][66][113,120] | |||||

| Mandarin | Drier (70 °C, 48 h) Ground peels (more information NA) Shirine Shahvar cv |

0.25:10 solid–liquid ratio (60% EtOH + 0.1% citric acid) | Postharvest. Wounded (1 × 2 mm φ and depth) + dipping 1 min in pomegranate peel extract concentrations (25, 50, 75, 100%) + inoculation (P. italicum and P. digitatum) + drying |

Reduction of % infected wound and lesion φ (75% or/and 100% extract). Increase of TPC, TFC, and PAL activity (75% or/and 100% extract) | [67][121] | 90] | ||||

| Orange | Drier (35 °C, 2 days) Particle size NA Gabsi cv |

1:10, 0.6:10, 0.3:10 solid–liquid ratio (MetOH or Water) + evaporated + drying (40 °C or freeze-drying) + re-dissolved in water | Postharvest. Chitosan coating solution (1% chitosan in glacial acetic 1% + 0.5% Locust bean gum + 20% glycerol + 7, 18, and 36% dry waster/MetOH pomegranate peel extract). Wounded oranges (4 times: 3 × 3 mm φ × deep) + Inoculation (20 μL of a P. digitatum) + drying + dipping in different coating solutions (2 min) |

Controlled growth of Penicillium digitatum Reduction of postharvest decay |

[68][122] | Maltodextrin and soy lecitin | NA (Yield/Stability) | [36][91 | ||

| Orange | ] | |||||||||

| Oven drier (40 °C) | Particle size NA Mollar de Elche cv |

EtOH solvent (50 and 80%) + 1% citric acid + evaporator + water dilution | Postharvest. Wounded oranges (3 times 2 × 2 mm φ and deep) + 20 μL pomegranate peel extract (12 g/L) + Inoculation (20 μL of a P. digitatum) + 1% citric acid + drying |

Enhanced defense pathways (antibiotic biosynthesis) | [69][123] | Double emulsion | Water1 in Oil in Water2: Water1 (ethanolic solutions) in Oil (castor, soybean, sunflower, medium chain triglyceride and orange) in Water2 (aqueous solution with Tween80 | |||

| Fresh whole F&V (pre- and postharvest) | ) | NA (Yield/Stability) | Guava | Drier (60 °C, 72 h) Particle size 0.420 mm [37][92] |

||||||

| Bhagwa cv | 1:10 solid–liquid ratio (80% EtOH) + evaporation | Postharvest. | Chitosan (1% chitosan in glacial acetic 1% + 0.75% glycerol) and alginate solution (2% alginate + 10% glycerol + 2% calcium chloride) with 1% pomegranate peel extract | Preserved quality for 20 d under refrigeration | [70][124] | Ion gelation | Chitosan gel (1%):gelatin 2:1 | F-TPC, DPPH | [ | |

| Capsicum | Drier (60 °C, 72 h) Particle size 0.420 mm Bhagwa cv |

1:10 solid–liquid ratio (80% EtOH) + evaporation | 38][93] | |||||||

| Postharvest. | Chitosan (1% chitosan in glacial acetic 1% + 0.75% glycerol) and alginate solution (2% alginate + 10% glycerol + 2% calcium chloride) with 1% pomegranate peel extract | Inhibition of microbial growth. Preserved sensory quality. | Extension of shelf life up to 25 d at 10 °C |

[71][125] | Spirulina | TPC, DPPH | [ | |||

| Pear | Drier (60 °C, 72 h) Particle size 0.420 mm Bhagwa cv | 15][72] | ||||||||

| 1:10 solid–liquid ratio (80% EtOH) + evaporation | Postharvest. | Chitosan (1% chitosan in glacial acetic 1% + 0.75% glycerol) and alginate solution (2% alginate + 10% glycerol + 2% calcium chloride) with 2% pomegranate peel extract | Lowered the cell wall degrading enzymes activity (firmness preservation) | [72][126] | Microalgae | EA | [39][94] | |||

| Chitosan + others: Dialdehyde guar gum Gelatin-based materials |

F-TPC, DPPH | [40][95] |

3. Potential Applications in the Food Industry

Pomegranate peel (in powders, liquid extract, and/or encapsulated, among others) have been reported in several food matrixes [43][98] such as F&V-based (Table 5), meat-based [7][15], fish-based [| Fresh-cut/Minimally processed F&V | ||||||

| Fruit salad: nectarine and | ||||||

| pineapple in cubes | ||||||

| covered with | ||||||

| fructose syrup | ||||||

| Oven drier (38 °C, 48 h) | ||||||

| Particle size 500 mm | ||||||

| Wonderful cv | ||||||

| Powder | ||||||

| 2.5–5% ( | ||||||

| w | ||||||

| / | ||||||

| v | ) of pomegranate peel powder at the container bottom | Inhibition of mesophilic bacteria, total psychrotrophic microorganisms, yeasts, and lactic acid bacteria | No negative effect on sensory characteristics | [ | 73][127] | |

| Fresh-cut pear, apple and melon (plugs) |

Oven drier (40 °C) Particle size NA Mollar de Elche cv |

EtOH solvent (50 and 80%) + 1% citric acid + evaporator + water dilution | Inoculated plugs were dipped (10 min, 150 rpm) + dried (25 °C 30 min) | Reduction of Listeria monocytogenes | [74][128] | |

| Fresh-cut Golden apple wedges: thickness 30-mm and 30 g |

Drying and particle size information NA Dente di cavallo cv |

Pulsed UAE (10 min, <50 °C, 1:40, 26 kHz, 200 W, 40% A, 50% duty cycle) + encapsulation with pectin from citrus peel by spray drying | Enrichment with microencapsulates reconstituted in water 1:1 | Reduction of enzymatic browning. Color preservation | [75][129] | |

| Beverages | Carrot juice | Oven drier (40 °C) Grounded in a colloid mill (more information NA) cv information NA |

High pressure-assisted extraction | 5 mg pomegranate peel extract per mL of carrot juice | Improvement of microbiological safety and AOX during storage. Color preservation | [76][77][130,131] |

| Beverages | Apple juice | Oven drier (55 °C, 12 h) Particle size and cv information NA |

Maceration extraction (1:50, 80% EtOH 1 h shaking) | Different% of pomegranate peel extract (0–2%) | Enhancing sensory quality and AOX. Low toxicity with 1% of pomegranate peel extract | [78][132] |

| Kiwi juice | Information NA | Commercial pomegranate extract (PureBulk, Roseburg) | Extract incorporation (180 μg/mL kiwi juice) + US bath (40 kHz, 180 W, 20 °C, 10–30 min) | US and pomegranate extract combined treatment: higher reductions on yeast and molds | [79][133] | |

| Red wine | Green decoction: Boiled in water 60 min (1:40) Freeze-drying of the extract Wonderful cv |

Powder | Purification to obtain the tannins. 8 analyzed tannins (1 g L−1 wine solution) |

Increase of protein stability Increase of color stability Reduction of sulfites |

[80][134] | |

| Symbiotic drink powder |

Hot oven (40 °C, 48 h) Particle size Kitchen-miller (more information NA) cv information NA |

Ethanolic extract (80%; 1:15) + evaporator + Freeze-drier | Formulation: beetroot peel extract powder (3%), pomegranate peel extract powder (1%), grape pomace extract powder (1.5%), quince seed gum (0.5%), stevia (4%), mint (0.1%) and water (89.9%). Pasteurization: 72 °C, 90 s | Maintenance of L. casei viability of the recommended level of 10−7 CFU/g | [81][135] |