Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 1 by Melissa Greta Galloni and Version 2 by Rita Xu.

Olive oil production in Mediterranean countries represents a crucial market, especially for Spain, Italy, and Greece. Waste generated from olive oil production processes can be divided into solid waste and olive mill wastewaters (OMWW).

- olive oil production

- olive mill

- wastewater remediation

- polyphenols

1. Introduction

Olive oil production is a fundamental sector for several European (EU) States, especially Spain, Italy, and Greece. In particular, Spain has the largest area of olive cultivation (estimated at ca. 2.47 million ha), followed by Italy (ca. 1.16) and Greece (about 0.81 million ha) [1][2][1,2]. However, olive oil production is responsible for several environmental concerns (soil contamination, underground seepage, water-body pollution, and odor emissions) due to poor waste management practices [3]. In this scenario, concerning olive mill wastewaters (OMWW), special attention must be paid to their high phenolic content, which is responsible for their antibacterial effect, phytotoxic effect, and dark colour.

Recently, phenols, fatty acids, and volatile acids have been recognized as potentially hazardous for environmental health: the former have pronounced antimicrobial and phytotoxic properties, whereas the latter show toxicity due to their long alkyl chain.

All these components make OMWW toxic to anaerobic bacteria, thus inhibiting conventional secondary and anaerobic treatments in municipal water plants. Furthermore, the high BOD (biological oxygen demand) and COD (chemical oxygen demand) levels, which cannot be reduced by anaerobic digestion, represent a further threat to receivers [2][4][2,4]. Moreover, land spreading and treatment in evaporation ponds could lead to problems related to groundwater pollution. The use of olive oil waste in agriculture may also affect the acidity, salinity, N immobilization, microbial response, leaching of nutrients, and concentration of lipids, organic acids, and phenolic compounds [5].

Alternative approaches based on physical treatments, such as dilution, evaporation, centrifugation, or sedimentation guarantee a high level of OMWW purification. However, they are expensive and energy-consuming, thus leading to an exponential increase in the processing cost. The olive oil industry, in its current status, composed of small and dispersed factories, cannot bear such high costs [6][7][8][9][10][11][12][13][6,7,8,9,10,11,12,13].

In recent years, advanced oxidation processes (AOPs), including photolysis, photo-oxidation, Fenton, and photo-Fenton reaction, have emerged as promising alternatives for simplicity and high organic removal efficiencies [14][15][16][17][18][19][20][14,15,16,17,18,19,20]. In particular, heterogeneous photocatalysis seems to be a successful technology in water decontamination due to its non-toxicity, low cost, and mineralization efficacy. However, due to the OMWW matrices’ complexity, it is not easy to develop and successively optimize efficient photocatalytic systems that are so far characterized by common limitations (i.e., difficult recovery, poor stability, low reusability, fast deactivation).

2. An Insight into the EU Legislation

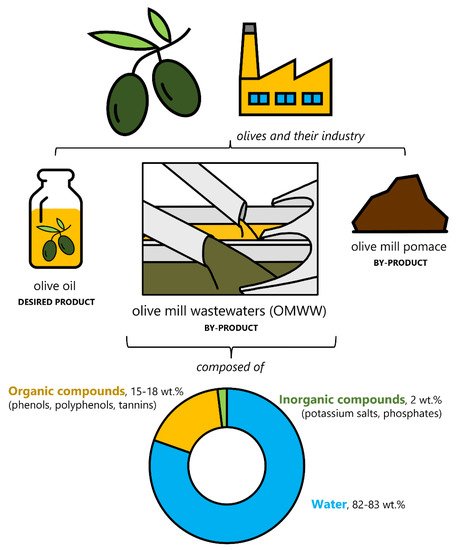

Olive oil is the desired product of the olives industry. Unfortunately, olive mill pomace and wastewater represent undesired by-products, requiring proper disposal treatments because of their complex composition (Figure 1).

Figure 1. Scheme of products and by-products from the olive oil industry.

3. Emerging Innovative Approaches for Olive Oil Production

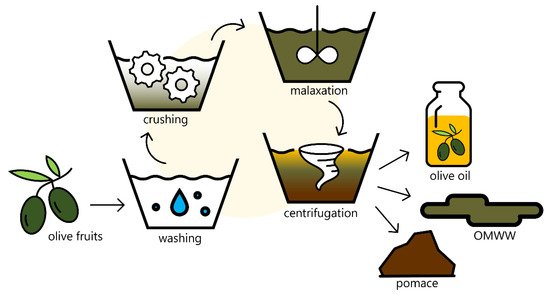

Conventional techniques in olive oil extraction have not significantly changed in the last 25 years. Three main steps can be identified (Figure 2): crushing and malaxation, which mainly affect the oil quality and yield, and centrifugation [26][27][26,27].

Figure 2. Scheme of olive oil production.

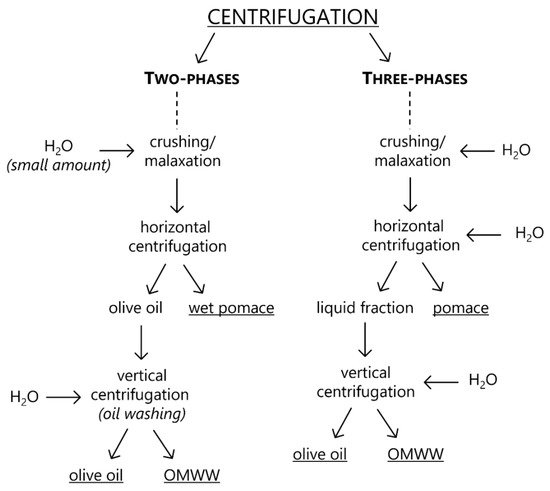

Figure 3. Scheme of two-phases and three-phases centrifugation strategies.