2. Composition of Coconut

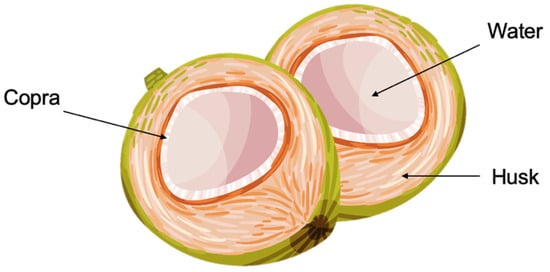

Coconut that grows on the coconut palm is consumed worldwide, particularly in Southeast Asia and the Caribbean. Its composition is determined by several factors, such as age and variety. Every month, a new cluster of coconuts grows from the previous one. Over the course of a year, both the weight of the kernel and volume composition of the coconut water alter significantly as the coconuts expand in size. The composition of different coconut parts (

Figure 1) before and after different processing methods is listed in

Table 1.

Figure 1.

Parts of the coconut.

Table 1. Composition of different coconut parts before and after being applied with different kinds of processing treatments. Data presented on an as-fed basis adapted from previous studies

[7][13][14][15][16][17][18][19][20][21][22][23][24][25][26][27][7,13,14,15,16,17,18,19,20,21,22,23,24,25,26,27].

| Coconut Part |

Component |

Composition |

Source |

| Water |

Water |

94.18–94.99% |

[7][13][14][15][16][7,13,14,15,16] |

| Protein |

0.12–0.72% |

| Total lipid (fat) |

0.07–0.2% |

| Ash |

0.39–0.87% |

| Carbohydrate |

3.71–4.76% |

| Sucrose |

0.06–10.7% |

| Glucose |

1.48–7.25% |

| Fructose |

1.43–5.25% |

| Calcium |

27.35 mg/100 g |

| Iron |

0.02 mg/100 g |

| Magnesium |

6.4 mg/100 g |

| Phosphorus |

4.66 mg/100 g |

| Potassium |

203.7 mg/100 g |

| Sodium |

1.75 mg/100 g |

| Vitamin C |

7.41 mg/100 dm3 |

| Riboflavin (B2) |

0.01 mg/100 dm3 |

| Milk |

Water |

54% |

[17][18][19][20][21][17,18,19,20,21] |

| Moisture |

62.6–93.4% |

| Fat |

18.83–37% |

| Protein |

2–4% |

| Carbohydrates |

2–5% |

| Ash |

0.63–0.96% |

| Total sugars |

0.82–1.62% |

| Total solids |

6.6–25.3% |

| Non-fat solids |

1.6–2.7% |

| pH |

5.9 |

| Copra |

Moisture |

3.94–4.3% |

[22][23][22,23] |

| Fat |

59.8–71.62% |

| Protein |

8.80–10.2% |

| Carbohydrates |

6.90–24.3% |

| Crude fiber |

7–7.15% |

| Ash |

1.4–1.59% |

| Testa |

Moisture |

2.27–4.27% |

[22][24][22,24] |

| Fat |

7.93–59% |

| Protein |

9.3–32.22% |

| Carbohydrates |

26.3–59.24% |

| Crude fiber |

11.6% |

| Ash |

1.4–5.3% |

| Copra oil |

Lauric acid |

44.84–51.8% |

[23][25][23,25] |

| Myristic acid |

18.5–21.86% |

| Caprilic acid |

0.13–9.5% |

| Palmitic acid |

7.5–9.99% |

| Oleic acid |

5.0–8.82% |

| Capric acid |

3.5–4.91% |

| Stearic acid |

2.71–3.51% |

| Linoleic acid |

1.0–1.9% |

| Husk |

Cellulose |

23–55.17% |

[26][27][26,27] |

| Hemicellulose |

3–12.26% |

| Lignin |

35–45% |

| Ash |

0.89–2.56% |

Coconut water is used in a variety of ways and considered to be one of the functional natural products available. Because it is nutritious and healthful, this pleasant beverage is consumed all around the world. Recently, there has been growing scientific support regarding the importance of coconut water in therapeutic applications and health. Its vast range of applications can be attributed to its chemical composition, which includes carbohydrates, phytohormones, amino acids, minerals, and vitamins

[13]. The (+)-catechin was 0.344 g/mL, and (−)-epicatechin was 0.242 g/mL in coconut water

[28]. Additionally, as a nutrient-dense medium, coconut milk; fluids produced from pressing copra of matured coconuts promotes the growth of common harmful bacteria. The content of the mesocarp itself influences the content of coconut milk

[29]. The variation in oil content and the yield of coconut milk directly relates to the mesocarp’s age

[30]. Apart from the coconut’s age and variety, the content of coconut milk is influenced by the method used to separate the milk from the coconut. Coconut oil is extracted from the mature fruit’s endosperm and subjected to chemical treatments, such as alkaline treatment and bleaching

[31]. VCO is extracted by either supercritical fluid carbon dioxide, enzymatic extraction, centrifugation, fermentation, freezing and thawing method, chilling, low-pressure extraction, hot extraction, and/or cold extraction

[32].

Coconut copra has a high quantity of potassium in comparison to other foods

[22]. A variety of phytochemicals—including saponins, alkaloids, tannins, glycosides, flavonoids, and phenols—have been discovered in studies on the Nigerian type of coconut. These phytochemicals significantly affect the anti-inflammatory, antioxidant, and reducing properties of the copra

[33]. The coconut is protected by a brown, thin outer layer of the endosperm called testa. It is a co-product and by-product of haustorium manufacture and coconut processing industry, respectively. Dehydrated coconut, coconut milk, and virgin coconut oil industry produce testa as a by-product, which is often neglected and utilized as feed for animals. Previously, Appaiah et al.

[22] and Marasinghe, Marikkar, Yalegama, Wimalasiri, Seneviratne, Weerasooriya and Liyanage

[24] discovered that the testa fraction was an important source of bioactive chemicals, including phenolics and flavonoid contents. Previous research discovered that the lignin content of coconut fiber in the husk and testa was high because of the characterization of the coconut fiber

[26][27][26,27]. The cellulose content of the coconut fibers was likewise high; however, this could be reduced by the pre-treatment with alkaline solution, NaOH

[26].

3. Functional Properties

Coconuts provide food, jobs, and business opportunities for millions of people. Because of its intrinsic rich macro and micronutrients profile for human health and nutrition, the fruit is known as ‘wonder fruit’. Commercially processed products include desiccated coconut, oil, raw kernels, milk, and coconut water. Coconut milk and oil production produces coconut cake or flour as a high-fiber, high-protein by-product, created from leftover coconut meal. In coconut meal, glutelin constitutes as the most abundant protein. According to Yalegama et al.

[34], dietary fiber can be isolated using the oil meal (poonac) and the coconut residue left over after coconut oil and coconut milk extraction, respectively. It can be utilized as an alternative material for food products, as well as a cheap material for animal feed. Large volumes of unused coconut residue, on the other hand, can be harmful to the environment since it usually ends up rotting. Providing protein and dietary fiber, coconut is included in many food products, for example its flour has been integrated into sweets, snacks, extruded products, and baked goods. It possesses anti-diabetic and anti-cancer properties, as well as the ability to boost immunity and to prevent cardiovascular diseases

[35][36][35,36]. It is interesting to note that while having a similar nutritional profile to wheat flour, coconut flour is gluten-free. Therefore, a viable and healthful option for the patients of celiac disease includes gluten-free foods utilizing coconut flour.

An ingredient’s functional properties describes its behavior during its preparation and cooking, and its effects to the finished food products with regards to the sensory feel, taste, and appearance. They impact the proteins’ behavior in food in the course of consumption, preparation, storage, and processing

[37]. It is crucial to understand the ingredients behavior throughout cooking and preparation, and its effects to the final food product’s flavor, appearance, and texture. Depending on the chemical and physical properties, and the protein size and molecular structure, the functional qualities impact the behavior of food systems throughout consumption, preparation, storage, processing, and manufacturing

[38].

Solubility, gelation, water and oil absorption capabilities, and emulsifying and foaming properties are all important functional properties of proteins

[39]. Nevertheless, how the protein is extracted, how the derived raw material is processed, including the stages and involved instruments, and the type of raw materials all influence the protein content and functional properties. A study investigating the functional and physicochemical aspects of a protein concentrate derived from a coconut by-product discovered that, at pH 4, coconut proteins were predominantly permeable in highly acidic and alkaline solutions

[40]. Extremely alkaline and acidic solutions can solubilize protein powders from coconut cakes. Determining the proteins’ properties will be beneficial in incorporating coconut protein powder into food systems.

3.1. Water and Oil Absorption Capacities

The protein powders from coconut oil cake reported lower water and oil absorption capacities than that of coconut milk cake

[40]. According to Dat and Phuong

[41], for the kernel flour, increasing the flour particles magnitude would reduce the oil absorption capacity; however, it increased the water absorption capacities and swelling.

3.2. Oil Holding Capacities

The oil holding capacity is related to the adsorption of organic compounds to the surface of the substrates and an important feature of polysaccharides. While oil holding is partly determined by the chemical composition, it is more determined by the fiber structure’s porosity than by the molecule’s affinity for oil

[42][43][42,43]. The coconut kernel residues obtained after extracting coconut milk and VCO can provide dietary fibers. Yalegama et al.

[34] reported that defatted VCO can be treated chemically to obtain coconut cell wall polysaccharides, exhibiting higher adsorption of oil and oil holding capacity compared to VCO and coconut milk. On the other hand, as opposed to coconut milk, virgin coconut oil has a compact structure with fat, sugar, protein, and minerals. As a result, the oil holding capacity of the virgin coconut oil is reduced by these non-cell-wall components. When compared to virgin coconut oil, coconut milk has more fat but less of the other components. As a result, coconut milk can draw more oil than virgin coconut oil, which has a lower fatty structure.

3.3. Protein Solubility

The profile of protein solubility can determine the kinds of beverage or food that can be incorporated with the protein

[44]. Coconut protein solubility is normally low—between pH 4 and 5—but it increases if the pH is above or below this range. The range between pH 4 and 5 is the minimum solubility of major protein components from coconut including the extracts from endosperm, coconut skim milk, and coconut protein isolate; this range is also known as the isoelectric point

[27][45][46][27,45,46]. The highest solubility was demonstrated at pH 10.3

[45]. When the pH is outside the isoelectric range (pH 3–5), the proteins have net negative or positive charges, causing electrostatic repulsion, ionic hydration, and protein solubilization

[46]. Balachandran et al.

[47] reported that the solubility of proteins from coconut endosperm also depends on different regions, associated with different amino acid profiles.

3.4. Foaming Properties

According to Wani et al.

[48], the ability of a protein to generate an interfacial skin to keep air bubbles suspended and prevent them from collapsing when the protein unfolds is called the foaming properties. The denaturation of protein yields more unfolding structures during oil extraction, increasing the interactions at the air–water interface. Furthermore, reducing the surface tension enhances the high foaming capacity, increasing the capacity of a protein to yield good foam. The protein from coconut milk cake has a lower foaming capacity than that from coconut oil cake

[49]. pH impacts the foaming capacity of coconut protein isolate. Gonzaliz and Tanchuco

[50] showed that the foam expansion was greatest at pH 2 and 11 while the foam stability was low. A thick cohesive layer forms around the air bubble, affecting the foaming stability. Damodaran

[49] reported that the foaming stability of protein powders in coconut oil cake and coconut milk cake showed no differences. Wu et al.

[38] have reported that peanut and coconut proteins have similar foaming capacity and properties. Foaming properties are important to apply the proteins in food products, such as in whipped toppings, mousses, and beverages.

3.5. Emulsifying Properties

According to Senphan and Benjakul

[51], proteins are emulsifiers, stabilizing the oil droplets in coconut milk. They stabilize emulsion in two ways: preventing coalescence by generating a cohesive interfacial layer around the oil droplets and reducing the interfacial tension between the water and oil phases. The emulsifying properties of proteinaceous emulsifiers are a measure of their effectiveness based on the emulsifying stability, activity, and capacity

[52]. To obtain the emulsifying activity index, the stabilized interface area per unit weight of protein is calculated. Meanwhile, the emulsifying stability index measures an emulsion’s capacity to withstand structural change over a specified time period

[53]. The properties are related to the molecular flexibility, surface hydrophobicity, surface charge, and protein solubility. Due to the partial unfolding and dissociation of globular proteins, the hydrophobic groups interact with the denatured proteins, increasing the adsorption at the oil–water interface and surface activity

[54]. As a consequence, protein from coconut oil cake had higher emulsifying stability index values and emulsifying activity than that of the protein from coconut milk cake

[55].

Proteins in coconut milk affect emulsion stability. A comparative study gauged the emulsion stability and physicochemical parameters of coconut milk derived from three distinct coconut maturation stages

[29]. Intrinsic parameters, mainly pH and protein concentration, influenced the stability of coconut milk emulsion. According to Onsaard, et al.

[56], proteins extracted from coconut skim milk efficiently stabilized viscous emulsions. However, when compared to whey protein isolate, the proteins extracted from coconut cream had a lesser efficacy due to either the homogenizer’s avoiding droplet aggregation or producing small oil droplets to achieve a stable emulsion

[56].

Generally, the coconut proteins’ emulsifying properties are significantly affected by temperature, pH, and ionic strength

[17][56][17,56]. The emulsion that has 1.2% coconut milk protein and is applied with ultrasound is very stable

[57]. Patil and Benjakul

[29] investigated the emulsifying properties of fractionated globulin and albumin from defatted coconut meat. When compared to albumin, the globulin fraction performed better as an emulsifier. The coconut proteins showed discrepancies in the emulsifying properties due to amino acid composition changes. The ratios of the protein surface’s polar and nonpolar amino acids, and the changes in the amino acids’ distribution impact emulsifying property. According to the Patil and Benjakul

[29], in general, emulsifying properties are higher in hydrophobic proteins with nonpolar side chains. In other words, coconut milk is essentially comprised of emulsion stabilized by proteins in the aqueous phase. Maximizing the emulsifier through protein functionality can improve the coconut milk stability. Nonetheless, destabilizing the emulsion causes its collapse, yielding virgin coconut oil. The procedures used to destabilize coconut milk determine the yield, properties, and qualities of virgin coconut oil.

3.6. Thermal Properties

Coconut proteins are very sensitive to heat. Heating them to 80 °C causes denaturation and coagulation

[17]. In the high temperature ranging from 80 °C to 120 °C, the raw undiluted coconut milk shows many endothermic transitions through the differential scanning calorimetric measurements. This result reflects the diverse protein composition of coconut proteins as well as their varying heat denaturation behavior

[17][58][17,58]. The denaturation and precipitation of proteins in coconut milk occur when it is exposed to high temperatures for a long time. Heat enhances the denaturation of coconut protein in both basic and acidic pH regions

[56].