The ability to measure and monitor the concentration of specific chemical and/or gaseous species (i.e., “analytes”) is the main requirement in many fields, including industrial processes, medical applications, and workplace safety management. As a consequence, several kinds of sensors have been developed in the modern era according to some practical guidelines that regard the characteristics of the active (sensing) materials on which the sensor devices are based. These characteristics include the cost-effectiveness of the materials’ manufacturing, the sensitivity to analytes, the material stability, and the possibility of exploiting them for low-cost and portable devices. Consequently, many gas sensors employ well-defined transduction methods, the most popular being the oxidation (or reduction) of the analyte in an electrochemical reactor, optical techniques, and chemiresistive responses to gas adsorption. In recent years, mMany of the efforts devoted to improving these methods have been directed towards the use of certain classes of specific materials.

- gas sensors

- ionic liquids

- metal–organic frameworks

- MOF-based composites

- optical sensors

- chemiresistors

- electrochemical sensors

- oxygen

- hydrogen

- chemical sensing

1. Introduction

| Sensor Type | Examples | Principle of Operation |

|---|---|---|

| Electrochemical | Amperometric, ChemFET |

Analyte molecules are involved in the redox reaction at the working electrode of an electrochemical cell, modulating the electrical current. |

| Analyte | Ionic Liquid | Electrode | Analyte Concentration | Ref. | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| O2 | ||||||||||

| Electrical | Chemoresistors | Adsorbed molecules of the target gas interact with oxygen species adsorbed on the surface of a nanoparticulated semiconductor, modifying its charge depletion regions and its electrical conductivity. | ||||||||

| [C4mpyrr][NTf2] | Clark-type sensor with polycrystalline Pt gauze | 1–20% | [83] | [36] | Gravimetric | Surface acoustic waves, piezoelectric |

A vibration resonance frequency is modified due to the adsorption of the target analyte. The shift in resonance frequency quantifies the analyte concentration. | |||

| [C2mim][NTf2] and [C4mpyrr][NTf2] |

Screen-printed (SP) electrodes | 10–100% and 0.1–5% | [84] | [37] | Thermochemical | Catalytic bead sensors | The target gas is burnt, causing a temperature rise that changes the resistance of the detecting element of the sensor proportional to the concentration of combusted gas. | |||

| Optical | Absorptive Reflective Fluorescence-based |

Adsorbed molecules of the target gas modify in several ways the optical properties of the sensing material (e.g., reflectivity, optical transmission, fluorescence spectrum and/or lifetime, etc.). | ||||||||

2. Ionic Liquids in Amperometric Gas Sensing—Recent Developments

| [N8,2,2,2][NTf2] | ||||||||||||

| Pt MATFE | ||||||||||||

| 10–100% | [ | 85 | ] | [38] | ||||||||

| [C2mim][NTf2] | Pt microdisk and Pt MATFE | 0.1–100% | [86] | [39] | ||||||||

| [MOmim][PF6] | Au microchannel electrode |

5000–25,000 ppm | [87] | [40] | ||||||||

| [Bmim][BF4] | Au interdigitated electrodes | 20–100% | [88] | [41] | ||||||||

| [C4mpyrr][NTf2] | Au on porous PTFE substrate | 5–20% | [89] | [42] | ||||||||

| [C2mim][NTf2] and [C4mim][PF6] |

SP electrodes (graphite) | 0.1–20% and 100% | [90] | [43] | ||||||||

| [C4mpyrr][NTf2] | Au microchannel electrode | 50–400 ppm and 2000–5000 ppm |

[91] | [44] | ||||||||

| [C4mpyrr][NTf2] | Clark-type sensor with polycrystalline Pt gauze | 5–20% | [92] | [45] | ||||||||

| [C4mpyrr][NTf2] | Interdigitated electrodes | 1400–4800 ppm | [93] | [46] | ||||||||

| [C4mim][PF6], [C2mim][PF6] and [C5mim][PF6] | Pt interdigitated electrodes | 0–100% | [94] | [47] | ||||||||

| [C4mim][BF4] | Planar electrodes | 20–100% | [95] | [48] | ||||||||

| [Bmim][BF6] | Pt planar electrodes modified by NiCo2O4/rGO/[Bmim][BF6] composite | 20–100% | [96] | [49] | ||||||||

| [C4mpn][Br] | Pt microelectrodes, 1% Ag-coated chitosan added to the IL | 20–100% | [97] | [50] | ||||||||

| [Bmim][BF4] | SPE, solid polymer electrolyte (PTFE/Carbon nanotubes/IL) | 2.1–12.6% | [98] | [51] | ||||||||

| [Emmim][TFSI] and [Bmim][TFSI] |

Pt electrodes, IL + reduced graphene (rGO) + α-Fe | 2 | O | 3 | electrolyte | 20–100% | [99] | [52] | ||||

| [C2mim][NTf2] | IL membrane on Au-TFE | 20–100% | [100] | [53] | ||||||||

| [C2mim][NTf2] added with Poly[DADMA][NTf2] |

IL/poly(IL) membrane on Au-TFE | 20–100% | [100] | [53] | ||||||||

| O2 | and | NH3 | [C2mim][BF4] and [C4mim][BF4] |

Gel polymer electrolyte (ILs in PVDF) between planar electrodes | 1–20% for O | 2 | ; 1–10 ppm for NH | 3 | [101] | [54] | ||

| O2 | and | H2 | [Bmpy][NTf2] | Planar Pt-Ni alloy electrodes | 500–5000 ppm for O | 2 | ; 500–6250 ppm for H | 2 | [102] | [55] | ||

| H2 | ||||||||||||

| [C4mim][NTf2] and [C4mpyrr][NTf2] |

Clark-type sensor with polycrystalline Pt gauze |

0.05–1.25% | [103] | [56] | ||||||||

| [C4mim]Cl | Pd deposited on carbon gas diffusion electrode | 1–5% | [104] | [57] | ||||||||

| [Bmpy][NTf2] | [Bmpy][NTf2] on Pt/C/Nafion screen-printed electrode | 2000–10,000 ppm | [105] | [58] | ||||||||

| [C2mim][NTf2] | Au microchannel electrodes with electrodeposited Pt nanoparticles | 0.1–10% | [106] | [59] | ||||||||

| NH3 | ||||||||||||

| [C2mim][NTf2] | Pt SPE, TFE, MATFE, and microdisk | 10–100 ppm | [107] | [60] | ||||||||

| [C2mim][NTf2] | SP electrode, thin-film electrode (TFE), microarray thin-film electrode (MATFE), and microdisk. | 10–100 ppm | [108] | [61] | ||||||||

| [C2mim][NTf2] | Pt MATFE | 10–100 ppm | [109] | [62] | ||||||||

| [C2mim][NTf2] | Pt-based MATFE (with different morphologies) | 1–2 ppm LODs (depending on the morphology) | [109] | [62] | ||||||||

| NH3 | and | HCl | [C2mim][NTf2] and [C4mpyrr][NTf2] | Au microchannel electrodes | 20–100 ppm | [110] | [63] | |||||

| VOC | (in air) | [C4mpyrr][NTf2] | Clark-type sensor with polycrystalline Pt gauze | 200–3000 ppm of acetaldehyde | [111] | [64] | ||||||

| CO2 | [Bmpy][NTf2] | Au microchannel electrodes with electrodeposited Cu nanoparticles | 0.14–11% | [112] | [65] | |||||||

| Hexanaldehyde (HA) | [Bmim][OH] | Pt microelectrodes | 2–300 ppm (HA in squalene) | [113] | [66] | |||||||

| C6H6 | and | HCHO | [C2mim][EtSO | 4 | ] | IL and ionogel (IL in poly(N-isopropylacrylamide)) between interdigitated electrodes | 10–50 ppm | [114] | [67] | |||

| SO2 | [C4mpyrr][NTf2] | TFEs and MATFEs | 1–10 ppm | [115] | [68] | |||||||

| H2O (humidity) | [Bmim][DCA] | IL incorporated in gels on interdigitated electrodes | 30–70% RH | [116] | [69] | |||||||

| Ethanol | [Bmim][HSO4] | IL on Au screen-printed electrode | 1–10% | [117] | [70] | |||||||

| NO2 | [Bmim][NTf2] | Solid polymer electrolyte (PVDF + IL) on screen-printed electrodes | 1–10 ppm | [118] | [71] | |||||||

| [Bmim][BF4] | Solid polymer electrolyte (ionic liquid (IL), carbon nanotubes + polyaniline + IL) on SP electrodes | 0–700 ppm | [119] | [72] | ||||||||

| Ethylene (C2H4) | [Bmim][NTf2] | Solid polymer electrolyte (PVDF + IL) on SP electrodes | 100–500 ppm | [120] | [73] | |||||||

3. Metal–Organic-Framework-Based Composites in Gas Sensing—Recent Developments

3.1. General Properties of Metal–Organic Frameworks

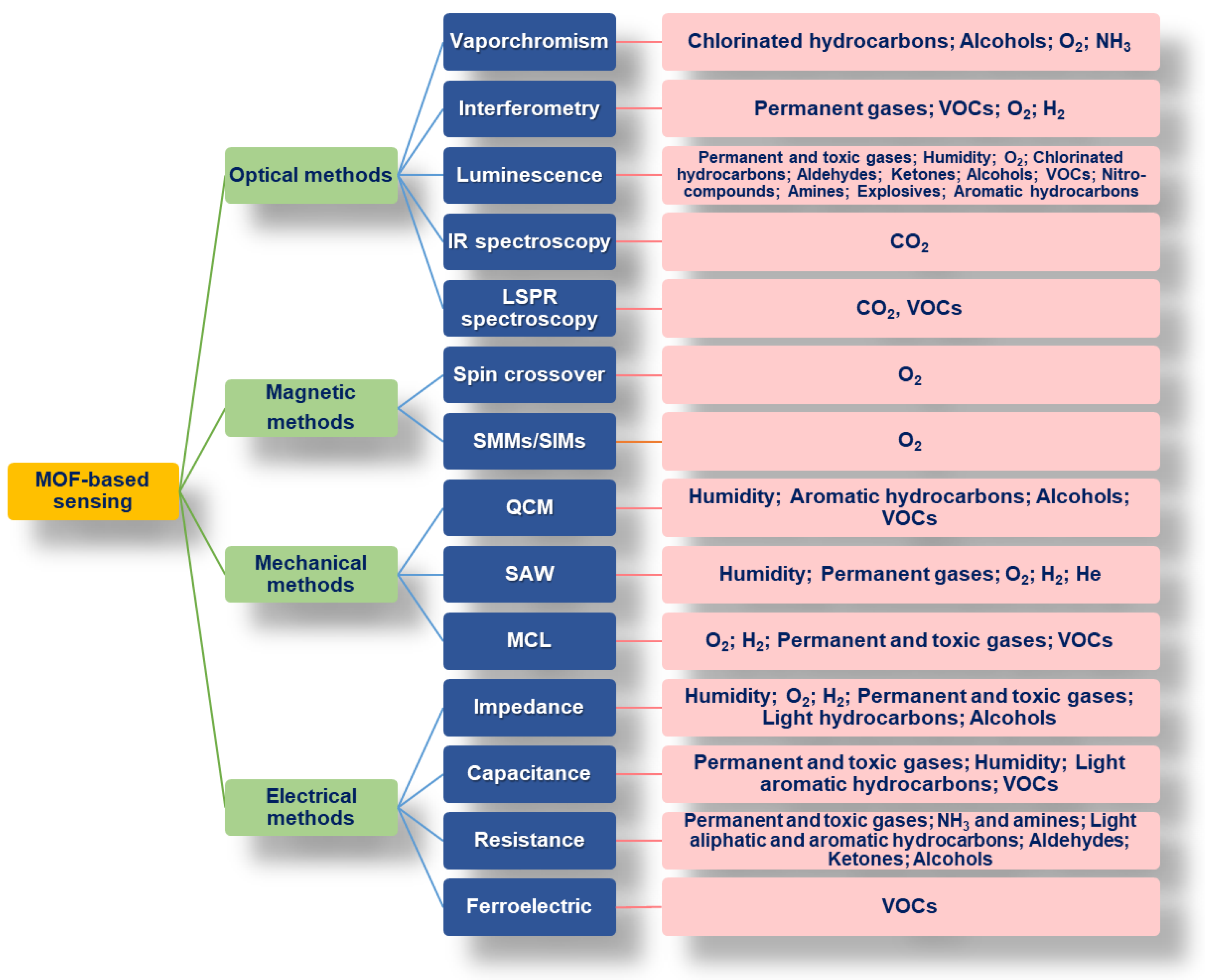

Metal–organic frameworks (MOFs) are solid porous materials which, according to the terminology officially adopted by IUPAC in 2013, are classified as a subclass of coordination networks which are a subclass of coordination polymers [123][76]. The MOF network (one-dimensional, two-dimensional, or three-dimensional) arises from the strong coordination bonds between metal nodes (metal ions, metal centers, or metal clusters [124][77]) and the organic linkers. Usually, transition metal ions, especially those of the first row, lanthanides, and some alkaline earth metals are used as metal nodes because of their variable coordination numbers, geometries, and oxidation states [123,125,126][76][78][79]. Organic molecules containing one or more N-donor or O-donor atoms are mostly used as organic linkers, especially carboxylates (either aliphatic or aromatic containing one or more condensed rings), pyridyl (e.g., pyridine, pyrazine and bipyridyl derivatives), cyano compounds, polyamines, and imidazole derivatives; in addition, oxalic acid, phosphonates, sulfonates, and crown ethers are other possible ligands [123,125][76][78]. The main distinctive structural features of MOFs are the high porosity, the large volume of the pores (up to 90% of the crystalline volume or more), the large specific surface area (above 5000 m2 g−1), and the good thermal stability (250–500 °C) due to the presence of strong bonds (e.g., C–C, C–H, C–O, and M–O) [123,125][76][78]. Many of these properties are determined by the mutual interaction between specific metal ions and linkers; as a consequence, MOFs’ characteristics can be tuned by judiciously selecting metal nodes and linkers to have the desired pore size, structure, and functionality for specific applications [127][80]. MOFs’ 3D structure displays cavities and inner surfaces, which are occupied by counterions, solvate molecules and/or guest molecules. The guest species can significantly extend the designed applications of MOFs [127][80]. MOF synthesis is performed mainly in the liquid phase by mixing solutions of the ligand and metal salts under solvothermal/hydrothermal conditions at a high temperature and pressure. Other alternative and consolidated synthetic strategies are based on mechanochemical, electrochemical (for large-scale synthesis), microwave, and sonochemical methods. The most recently proposed methods are: ionothermal synthesis [123[76][81],128], the slow evaporation method [123][76], the diffusion method [123[76][82],129], the use of a microfluidic device [128][81], dry-gel conversion (DGC) [128][81] and microemulsion [123][76]. MOFs are versatile materials which are attracting great interest for application in environmental and biomedical areas as catalysts, as absorbers for toxic gases and metal ions, as materials for electrochemical devices, as drug carriers, as bioimaging agents and also therapeutic agents [130,131][83][84]. Recently, MOFs have been used also as sacrificial templates for the production of metal oxides or metal oxide–carbon hybrids [132][85] with promising morphological and textural properties to be exploited in sensing and electrochemical applications [133,134][86][87]. MOFs also are emerging as novel sensing materials because of their high surface area which enhances detective sensitivity, their specific structural features (open metal sites, tunable pore sizes, etc.) which promote host–guest interactions and selectivity, and flexible porosity which enables the reversible release and uptake of small target molecules [131,135,136][84][88][89]. Presently, the exploitation of MOFs’ potentiality in gas sensing is affected by some limitations [135,137][88][90]: (1) Most pure MOFs are not stable under extreme conditions (high temperature and high humidity levels). (2) The types of gases detectable by MOFs are limited. (3) The inherent electrical conductivity of MOFs is low and this limits their use in the development of electronic sensors. (4) The interaction mechanism between MOFs and the analyte is poorly understood. (5) MOFs are generally produced as powders with a generally low mechanical strength and poor processability. This last limitation is particularly relevant since the sensitivity of gas sensors obtained from powders is low and poses the need for a post-process of MOFs as thin films or membranes. To ensure the potential use of MOFs in sensing applications, most of these concerns must be addressed and, to this aim, the development of new MOF–based materials which have better properties (including processability in harsh conditions) than pure MOFs is gaining a lot of attention [137,138][90][91]. Research efforts have been focused on different strategies, including: (i) post-synthetic modifications [139][92]; (ii) linker change or functionalization; (iii) ion exchange; (iv) active groups grafting; (v) impregnation with suitable active materials; (vi) production of MOF-based hybrids/composites [126,138,139,140][79][91][92][93]. Among the different possibilities, the common adapted solutions are post-synthetic modifications and the production of hybrids/composites integrating MOFs and functional materials. Post-synthetic modifications involve the introduction of desired functional groups into the MOFs after their synthesis [126,139][79][92]. The modification can involve: the heterogeneous exchange of ligands or metal ions by breaking and forming chemical bonds within the original MOF, solvent-assisted ligand exchange, and replacement of the nonbridging ligands and metal nodes [123,139,141][76][92][94]. Mixed-metal MOFs, containing at least two metal ions in their framework, can be prepared under post-synthetic methods and possess new properties and activities due to the presence of the second metal ion. This approach is frequently used to produce MOF-based materials exhibiting improved fluorescent/luminescent properties [139,141][92][94]. By combining MOFs with suitable materials, the functionality and the textural/thermal/magnetic/electric properties can be improved to meet specific requirements. In some cases, the hybrid/composite materials exhibit new properties that are superior to those of the individual components since they combine the advantages of both parent materials. Metal oxides [142][95], polymers [143][96], metal nanoparticles [144][97], silica [145][98], carbon nanotubes [146][99], graphene-related materials (GRMs) [140,147,148][93][100][101] and quantum dots [149][102] have been used for the production of MOF-based hybrids and composites [137,138][90][91]. A wide variety of methods have been applied for the preparation of MOF composites. The in situ growth approach involves the growth of MOF crystals under solvothermal/hydrothermal conditions in the presence of another functional material [138][91]. In this type of synthesis, the MOF structure is built from the precursors around and eventually inside the other composite component. This method has been mainly used for the preparation of MOF composites with carbon-based materials [140][93], metal oxides [150][103] or with metal nanoparticles [144,150][97][103]. During the synthesis, the second material can act also as a templating agent, leading to oriented growth of MOF crystals, and graphene is one such example [151][104]. In the encapsulation method, the MOF composite is formed starting from the second component precursors and the preformed MOF; namely, the second component forms inside the cages of the MOF and at the end of the synthesis, the particles stay stable inside the cages without directly bonding to the MOF structure [138][91]. This is the method primarily used for the production of MOF/polymer and MOF/NPs composites [138,143][91][96]. Solid grinding and impregnation are other strategies to incorporate NPs in MOFs [152,153][105][106]. The electrospinning and solution-blending methods are two possible approaches for the preparation of MOF/polymer membranes [150][103]. MOF composites for biomedical applications have been also produced by coating the MOF structure with silica or a specific polymer with the aim of reducing their cytotoxicity and intrinsic instability under physiological conditions [150][103]. The huge and wide variability in pore size distribution of MOFs allows different guest molecules with different characteristics (size, acid–base behavior, polarization, etc.) to easily access the cavity and interact with the pore surface due to the presence of unsaturated metal sites and Lewis acidic/basic sites [136,154][89][107]. In such a way, specific MOF properties can be influenced, and changes in optical, electrical, and mechanical MOF properties can occur [135,155][88][108]. On this basis, various MOFs have been developed for possible use as chemiresistive, magnetic, ferroelectric, colorimetric, as well as luminescent sensors [135,156,157][88][109][110]; many examples are reviewed in this section. The high porosity of MOFs and the easy reversibility of the interaction with the target guest molecule are valid prerequisites to achieve repeatability, regeneration and robust operability under repeated detection cycles. On the other side, signal transduction is a major challenge for the efficient utilization of MOFs in chemical sensing [136][89]. The sensitivity of MOF-based detection largely depends on the sensing method used for signal transduction. MOFs are generally coupled with such several signal transduction techniques and tools as chemiresistors, interferometry, quartz crystal microbalance (QCM), surface acoustic wave (SAW), and microcantilevers (MCLs). MOF-based thin-film techniques have hence been very recently suggested as a valid advantage for developing next-generation chemical sensors [157][110]. Moreover, recently, conductive MOFs have been synthesized by using proper organic ligands or doping with conductive materials to form hybrids and composites with the aim of generating detectable changes in resistance/capacitance upon guest-molecule exposure [158][111]. An overview of several different sensing mechanisms involving MOFs and the mainly detected gas types is provided in Figure 21 and detailed in the following sections.

3.2. MOF-Based Sensors Using Gravimetric and Mechanical Methods

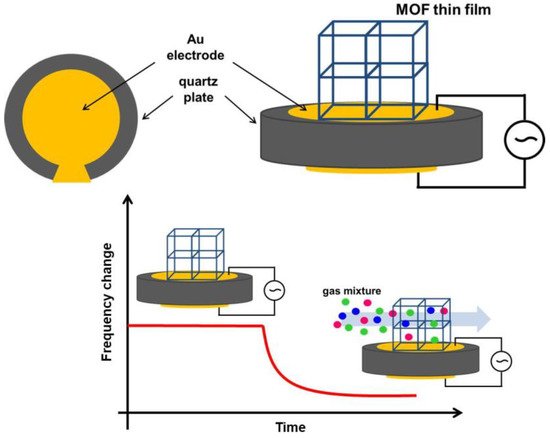

The easier approach for gas detection utilizing MOFs is the measurement of changes in MOF mass as the material selectively adsorbs the target analyte. This can be performed on a macroscale, bulk scale, or by using thin films deposited on a mechanical resonator. In this last case, the change in mass of the resonator due to gas adsorption is translated into an electrical signal [154][107]. In these mechanical methods, at first, an analyte is adsorbed into the pores of MOFs grown on electromechanical devices and then the mass changes are converted into an electrical signal through different transduction mechanisms (shifts in frequency or changes in the work function) [154][107]. In this framework, an important aspect is related to the characteristics of the MOF films: a tight contact between the MOF film and the electromechanical-device surface is strictly required to obtain the suitable sensitivity. The main gravimetric and mechanical methods involving MOFs for gas-sensing applications are based on the following electromechanical devices:3.2.1. Quartz Crystal Microbalance (QCM)-Based Sensors

In QCM-based sensing, a thin piezoelectric quartz crystal is the core component of a QCM transducer [170][112]. After being electroplated, the thin slice oscillates when an alternating current (AC) is applied. The mass increases upon the adsorption of analyzed gas molecules, and the resonant frequency decreases (Figure 52) [170][112].

3.3.2. Surface Acoustic Wave Sensors (SAWS)

In surface acoustic wave sensors (SAWS), the gas adsorption is detected by measuring the frequency shift of acoustic waves generated by a quartz oscillator vibrating and traveling parallel to the surface [173][115]. The response of this device is reproducible and faster as compared to the same coating on QCMs, but it is dependent on the film thickness: for each device, an optimal thickness can be estimated, above which the sensor response saturates [136][89]. Examples of MOF-based SAWS have been proposed by Paschke et al. (MOF@SAW sensor based on MFU-4 for the detection of H2, N2, CO2) [174][116], Devkota et al. (ZIF-8-coated SAW reflective-delay-line mass sensors for the sensitive detection of CO2 and CH4 at ambient conditions) [175][117] and by Vanotti et al. (SAW device functionalized with ZnTACN for CO2 detection) [176][118].3.2.3. Microcantilever-Based Sensors (MCLs)

Gas detection by microcantilever (MCLs) sensors are characterized by two transduction mechanisms: the changes in the cantilever oscillation frequency caused by mass uptake and the strain-induced bending [177][119]. In the former mode, changes in the sensor oscillation frequency are typically detected optically. In the latter mode, adsorption produces strain at the coating’s MCL interface, causing deflection of the cantilever beam that can be detected either optically or by using a built-in piezoresistive sensor. The structural flexibility of MOFs is an advantage for chemical detection using static MCL, because even small changes in the unit cell dimensions can result in large tensile or compressive stresses at the interface between the cantilever and the MOF thin film [160][120]. However, MCL-based sensors are scarce in practical applications, due to cross-sensitivity and poor selectivity; indeed, in the case of exposure to a gas mixture with multiple components, all constituents can be absorbed. Different kinds of MOFs have been proposed for the development of MCL-based gas sensors: UiO-66 for toxic organophosphorus molecules [178][121]; MIL-53 (Al) for CO2, N2, CO, and Ar [179][122]; and HKUST-1 for the detection of VOCs [180][123].References

- Gas and Particle Sensors–Technology and Market Trends 2021. Available online: https://www.i-micronews.com/products/gas-and-particle-sensors-technology-and-market-trends-2021/ (accessed on 9 April 2022).

- Fortune Business Insights Industrial Gas Sensors Market Size, Growth|Industry Report 2026. Available online: https://www.fortunebusinessinsights.com/industry-reports/industrial-gas-sensors-market-101064 (accessed on 9 April 2022).

- Barsan, N.; Koziej, D.; Weimar, U. Metal Oxide-Based Gas Sensor Research: How to? Sens. Actuators B Chem. 2007, 121, 18–35.

- Barsan, N.; Weimar, U. Conduction Model of Metal Oxide Gas Sensors. J. Electroceram. 2001, 7, 143–167.

- Korotcenkov, G. The Role of Morphology and Crystallographic Structure of Metal Oxides in Response of Conductometric-Type Gas Sensors. Mater. Sci. Eng. R Rep. 2008, 61, 1–39.

- Baron, R.; Saffell, J. Amperometric Gas Sensors as a Low Cost Emerging Technology Platform for Air Quality Monitoring Applications: A Review. ACS Sens. 2017, 2, 1553–1566.

- Lin, R.; Liu, S.; Ye, J.; Li, X.; Zhang, J. Photoluminescent Metal–Organic Frameworks for Gas Sensing. Adv. Sci. 2016, 3, 1500434.

- Wagner, T.; Haffer, S.; Weinberger, C.; Klaus, D.; Tiemann, M. Mesoporous Materials as Gas Sensors. Chem. Soc. Rev. 2013, 42, 4036–4053.

- Stetter, J.R.; Li, J. Amperometric Gas SensorsA Review. Chem. Rev. 2008, 108, 352–366.

- Malik, R.; Tomer, V.K.; Mishra, Y.K.; Lin, L. Functional Gas Sensing Nanomaterials: A Panoramic View. Appl. Phys. Rev. 2020, 7, 021301.

- Ghosh, R.; Gardner, J.W.; Guha, P.K. Air Pollution Monitoring Using Near Room Temperature Resistive Gas Sensors: A Review. IEEE Trans. Electron. Devices 2019, 66, 3254–3264.

- Halfaya, Y.; Bishop, C.; Soltani, A.; Sundaram, S.; Aubry, V.; Voss, P.L.; Salvestrini, J.-P.; Ougazzaden, A. Investigation of the Performance of HEMT-Based NO, NO2 and NH3 Exhaust Gas Sensors for Automotive Antipollution Systems. Sensors 2016, 16, 273.

- Wales, D.J.; Grand, J.; Ting, V.P.; Burke, R.D.; Edler, K.J.; Bowen, C.R.; Mintova, S.; Burrows, A.D. Gas Sensing Using Porous Materials for Automotive Applications. Chem. Soc. Rev. 2015, 44, 4290–4321.

- Kang, X.; Yip, S.; Meng, Y.; Wang, W.; Li, D.; Liu, C.; Ho, J.C. High-Performance Electrically Transduced Hazardous Gas Sensors Based on Low-Dimensional Nanomaterials. Nanoscale Adv. 2021, 3, 6254–6270.

- Horsfall, L.A.; Pugh, D.C.; Blackman, C.S.; Parkin, I.P. An Array of WO3 and CTO Heterojunction Semiconducting Metal Oxide Gas Sensors Used as a Tool for Explosive Detection. J. Mater. Chem. A 2017, 5, 2172–2179.

- Mirzaei, A.; Leonardi, S.G.; Neri, G. Detection of Hazardous Volatile Organic Compounds (VOCs) by Metal Oxide Nanostructures-Based Gas Sensors: A Review. Ceram. Int. 2016, 42, 15119–15141.

- Leidinger, M.; Sauerwald, T.; Reimringer, W.; Ventura, G.; Schütze, A. Selective Detection of Hazardous VOCs for Indoor Air Quality Applications Using a Virtual Gas Sensor Array. J. Sens. Sens. Syst. 2014, 3, 253–263.

- Chaisiwamongkhol, K.; Batchelor-McAuley, C.; Compton, R.G. Optimising Amperometric PH Sensing in Blood Samples: An Iridium Oxide Electrode for Blood PH Sensing. Analyst 2019, 144, 1386–1393.

- Landini, N.; Anania, G.; Fabbri, B.; Gaiardo, A.; Gherardi, S.; Guidi, V.; Rispoli, G.; Scagliarini, L.; Zonta, G.; Malagù, C. Neoplasms and Metastasis Detection in Human Blood Exhalations with a Device Composed by Nanostructured Sensors. Sens. Actuators B Chem. 2018, 271, 203–214.

- Galstyan, V.; Bhandari, M.P.; Sberveglieri, V.; Sberveglieri, G.; Comini, E. Metal Oxide Nanostructures in Food Applications: Quality Control and Packaging. Chemosensors 2018, 6, 16.

- Pallotti, D.; Orabona, E.; Amoruso, S.; Maddalena, P.; Lettieri, S. Modulation of Mixed-Phase Titania Photoluminescence by Oxygen Adsorption. Appl. Phys. Lett. 2014, 105, 031903.

- Gaiardo, A.; Fabbri, B.; Guidi, V.; Bellutti, P.; Giberti, A.; Gherardi, S.; Vanzetti, L.; Malagù, C.; Zonta, G. Metal Sulfides as Sensing Materials for Chemoresistive Gas Sensors. Sensors 2016, 16, 296.

- Ambrosone, G.; Coscia, U.; Lettieri, S.; Maddalena, P.; Privato, C.; Ferrero, S. Hydrogenated Amorphous Silicon Carbon Alloys for Solar Cells. Thin Solid Film. 2002, 403, 349–353.

- Comini, E. Metal Oxide Nano-Crystals for Gas Sensing. Anal. Chim. Acta 2006, 568, 28–40.

- Setaro, A.; Bismuto, A.; Lettieri, S.; Maddalena, P.; Comini, E.; Bianchi, S.; Baratto, C.; Sberveglieri, G. Optical Sensing of NO2 in Tin Oxide Nanowires at Sub-Ppm Level. Sens. Actuators B Chem. 2008, 130, 391–395.

- Setaro, A.; Lettieri, S.; Diamare, D.; Maddalena, P.; Malagù, C.; Carotta, M.C.; Martinelli, G. Nanograined Anatase Titania-Based Optochemical Gas Detection. New J. Phys. 2008, 10, 053030.

- Bittig, H.C.; Körtzinger, A.; Neill, C.; van Ooijen, E.; Plant, J.N.; Hahn, J.; Johnson, K.S.; Yang, B.; Emerson, S.R. Oxygen Optode Sensors: Principle, Characterization, Calibration, and Application in the Ocean. Front. Mar. Sci. 2018, 4, 429.

- Wang, X.; Wolfbeis, O.S. Optical Methods for Sensing and Imaging Oxygen: Materials, Spectroscopies and Applications. Chem. Soc. Rev. 2014, 43, 3666–3761.

- Quaranta, M.; Borisov, S.M.; Klimant, I. Indicators for Optical Oxygen Sensors. Bioanal. Rev. 2012, 4, 115–157.

- Zhuang, W.; Hachem, K.; Bokov, D.; Javed Ansari, M.; Taghvaie Nakhjiri, A. Ionic Liquids in Pharmaceutical Industry: A Systematic Review on Applications and Future Perspectives. J. Mol. Liq. 2022, 349, 118145.

- Tanner, E.E.L. Ionic Liquids Charge Ahead. Nat. Chem. 2022, 14, 842.

- Buettner, C.S.; Cognigni, A.; Schröder, C.; Bica-Schröder, K. Surface-Active Ionic Liquids: A Review. J. Mol. Liq. 2022, 347, 118160.

- Plechkova, N.V.; Seddon, K.R. Applications of Ionic Liquids in the Chemical Industry. Chem. Soc. Rev. 2008, 37, 123–150.

- Schreiner, C.; Zugmann, S.; Hartl, R.; Gores, H.J. Fractional Walden Rule for Ionic Liquids: Examples from Recent Measurements and a Critique of the So-Called Ideal KCl Line for the Walden Plot. J. Chem. Eng. Data 2010, 55, 1784–1788.

- Ignat’ev, N.V.; Welz-Biermann, U.; Kucheryna, A.; Bissky, G.; Willner, H. New Ionic Liquids with Tris(Perfluoroalkyl)Trifluorophosphate (FAP) Anions. J. Fluor. Chem. 2005, 126, 1150–1159.

- Tang, Y.; Zeng, X. Electrochemical Oxidation of Hydrogen in Bis(Trifluoromethylsulfonyl)Imide Ionic Liquids under Anaerobic and Aerobic Conditions. J. Phys. Chem. C 2016, 120, 23542–23551.

- Lee, J.; Arrigan, D.W.M.; Silvester, D.S. Achievement of Prolonged Oxygen Detection in Room-Temperature Ionic Liquids on Mechanically Polished Platinum Screen-Printed Electrodes. Anal. Chem. 2016, 88, 5104–5111.

- Hussain, G.; O’Mullane, A.P.; Silvester, D.S. Modification of Microelectrode Arrays with High Surface Area Dendritic Platinum 3D Structures: Enhanced Sensitivity for Oxygen Detection in Ionic Liquids. Nanomaterials 2018, 8, 735.

- Lee, J.; Silvester, D.S. Low-Cost Microarray Thin-Film Electrodes with Ionic Liquid Gel-Polymer Electrolytes for Miniaturised Oxygen Sensing. Analyst 2016, 141, 3705–3713.

- Gondosiswanto, R.; Gunawan, C.A.; Hibbert, D.B.; Harper, J.B.; Zhao, C. Microcontact Printing of Thiol-Functionalized Ionic Liquid Microarrays for “Membrane-Less” and “Spill-Less” Gas Sensors. ACS Appl. Mater. Interfaces 2016, 8, 31368–31374.

- Liu, X.; Chen, X.; Xu, Y.; Chen, T.; Zeng, X. Effects of Water on Ionic Liquid Electrochemical Microsensor for Oxygen Sensing. Sens. Actuators B Chem. 2019, 285, 350–357.

- Wan, H.; Yin, H.; Mason, A.J. Rapid Measurement of Room Temperature Ionic Liquid Electrochemical Gas Sensor Using Transient Double Potential Amperometry. Sens. Actuators B Chem. 2017, 242, 658–666.

- Lee, J.; Hussain, G.; Banks, C.E.; Silvester, D.S. Screen-Printed Graphite Electrodes as Low-Cost Devices for Oxygen Gas Detection in Room-Temperature Ionic Liquids. Sensors 2017, 17, 2734.

- Gondosiswanto, R.; Hibbert, D.B.; Fang, Y.; Zhao, C. Ionic Liquid Microstrips Impregnated with Magnetic Nanostirrers for Sensitive Gas Sensors. ACS Appl. Mater. Interfaces 2017, 9, 43377–43385.

- Lin, L.; Zeng, X. Toward Continuous Amperometric Gas Sensing in Ionic Liquids: Rationalization of Signal Drift Nature and Calibration Methods. Anal. Bioanal. Chem. 2018, 410, 4587–4596.

- Gondosiswanto, R.; Hibbert, D.B.; Fang, Y.; Zhao, C. Redox Recycling Amplification Using an Interdigitated Microelectrode Array for Ionic Liquid-Based Oxygen Sensors. Anal. Chem. 2018, 90, 3950–3957.

- Liu, Y.; Liu, J.; Liu, Q.; Zhang, H.; Li, Z.; Jing, X.; Yuan, Y.; Zhang, H.; Liu, P.; Wang, J. Ionic Liquids Combined with Pt-Modified Ordered Mesoporous Carbons as Electrolytes for the Oxygen Sensing. Sens. Actuators B Chem. 2018, 254, 490–501.

- Zhang, H.; Liu, J.; Liu, Q.; Chen, R.; Zhang, H.; Yu, J.; Song, D.; Jing, X.; Zhang, M.; Wang, J. Electrochemical Oxygen Sensor Based on the Interaction of Double-Layer Ionic Liquid Film (DLILF). J. Electrochem. Soc. 2018, 165, B779.

- Yu, L.; Liu, J.; Yin, W.; Yu, J.; Chen, R.; Song, D.; Liu, Q.; Li, R.; Wang, J. Ionic Liquid Combined with NiCo2O4/RGO Enhances Electrochemical Oxygen Sensing. Talanta 2020, 209, 120515.

- Yin, W.; Liu, J.; Liu, Q.; Chen, R.; Yu, J.; Zhang, H.; Song, D.; Fan, M.; Zhang, M.; Wang, J. Ag-CS Enhanced Performance of Pyrrolidone-Based Ionic Liquid Oxygen Sensor. J. Electrochem. Soc. 2020, 167, 067522.

- Wan, H.; Liu, X.; Wang, X.; Chen, Y.; Wang, P.P. Facile Screen-Printed Carbon Nanotube Electrode on Porous Substrate with Gold Nanoparticle Modification for Rapid Electrochemical Gas Sensing. J. Electrochem. Soc. 2021, 168, 067514.

- Yin, W.; Alali, K.T.; Zhang, M.; Liu, J.; Song, D.; Liu, Q.; Yu, J.; Chen, R.; Zhang, H.; Wang, J. A−Fe2O3/RGO Cooperated with Tri-Alkyl-Substituted-Imidazolium Ionic Liquids for Enhancing Oxygen Sensing. Sens. Actuators B Chem. 2021, 341, 130029.

- Doblinger, S.; Hay, C.E.; Tomé, L.C.; Mecerreyes, D.; Silvester, D.S. Ionic Liquid/Poly(Ionic Liquid) Membranes as Non-Flowing, Conductive Materials for Electrochemical Gas Sensing. Anal. Chim. Acta 2022, 1195, 339414.

- Lee, J.; Hussain, G.; López-Salas, N.; MacFarlane, D.R.; Silvester, D.S. Thin Films of Poly(Vinylidene Fluoride-Co-Hexafluoropropylene)-Ionic Liquid Mixtures as Amperometric Gas Sensing Materials for Oxygen and Ammonia. Analyst 2020, 145, 1915–1924.

- Liu, X.; Chen, X.; Ju, J.; Wang, X.; Mei, Z.; Qu, H.; Xu, Y.; Zeng, X. Platinum–Nickel Bimetallic Nanosphere–Ionic Liquid Interface for Electrochemical Oxygen and Hydrogen Sensing. ACS Appl. Nano Mater. 2019, 2, 2958–2968.

- Tang, Y.; He, J.; Gao, X.; Yang, T.; Zeng, X. Continuous Amperometric Hydrogen Gas Sensing in Ionic Liquids. Analyst 2018, 143, 4136–4146.

- Jayanthi, E.; Murugesan, N.; Suneesh, A.S.; Ramesh, C.; Anthonysamy, S. Sensing Behavior of Room Temperature Amperometric H2 Sensor with Pd Electrodeposited from Ionic Liquid Electrolyte as Sensing Electrode. J. Electrochem. Soc. 2017, 164, H5210.

- Zhi, Z.; Gao, W.; Yang, J.; Geng, C.; Yang, B.; Tian, C.; Fan, S.; Li, H.; Li, J.; Hua, Z. Amperometric Hydrogen Gas Sensor Based on Pt/C/Nafion Electrode and Ionic Electrolyte. Sens. Actuators B Chem. 2022, 367, 132137.

- Hussain, G.; Ge, M.; Zhao, C.; Silvester, D.S. Fast Responding Hydrogen Gas Sensors Using Platinum Nanoparticle Modified Microchannels and Ionic Liquids. Anal. Chim. Acta 2019, 1072, 35–45.

- Hussain, G.; Silvester, D.S. Comparison of Voltammetric Techniques for Ammonia Sensing in Ionic Liquids. Electroanalysis 2018, 30, 75–83.

- Hussain, G.; Silvester, D.S. Detection of Sub-Ppm Concentrations of Ammonia in an Ionic Liquid: Enhanced Current Density Using “Filled” Recessed Microarrays. Anal. Chem. 2016, 88, 12453–12460.

- Hussain, G.; Aldous, L.; Silvester, D.S. Preparation of Platinum-Based ‘cauliflower Microarrays’ for Enhanced Ammonia Gas Sensing. Anal. Chim. Acta 2019, 1048, 12–21.

- Ge, M.; Hussain, G.; Hibbert, D.B.; Silvester, D.S.; Zhao, C. Ionic Liquid-Based Microchannels for Highly Sensitive and Fast Amperometric Detection of Toxic Gases. Electroanalysis 2019, 31, 66–74.

- Chi, X.; Tang, Y.; Zeng, X. Electrode Reactions Coupled with Chemical Reactions of Oxygen, Water and Acetaldehyde in an Ionic Liquid: New Approaches for Sensing Volatile Organic Compounds. Electrochim. Acta 2016, 216, 171–180.

- Ge, M.; Gondosiswanto, R.; Zhao, C. Electrodeposited Copper Nanoparticles in Ionic Liquid Microchannels Electrode for Carbon Dioxide Sensor. Inorg. Chem. Commun. 2019, 107, 107458.

- Toniolo, R.; Dossi, N.; Bortolomeazzi, R.; Bonazza, G.; Daniele, S. Volatile Aldehydes Sensing in Headspace Using a Room Temperature Ionic Liquid-Modified Electrochemical Microprobe. Talanta 2019, 197, 522–529.

- Gil-González, N.; Benito-Lopez, F.; Castaño, E.; Morant-Miñana, M.C. Imidazole-Based Ionogel as Room Temperature Benzene and Formaldehyde Sensor. Microchim. Acta 2020, 187, 638.

- Doblinger, S.; Lee, J.; Gurnah, Z.; Silvester, D.S. Detection of Sulfur Dioxide at Low Parts-per-Million Concentrations Using Low-Cost Planar Electrodes with Ionic Liquid Electrolytes. Anal. Chim. Acta 2020, 1124, 156–165.

- Esteves, C.; Palma, S.I.C.J.; Costa, H.M.A.; Alves, C.; Santos, G.M.C.; Ramou, E.; Carvalho, A.L.; Alves, V.; Roque, A.C.A. Tackling Humidity with Designer Ionic Liquid-Based Gas Sensing Soft Materials. Adv. Mater. 2022, 34, 2107205.

- Zuliani, I.; Fattori, A.; Svigelj, R.; Dossi, N.; Grazioli, C.; Bontempelli, G.; Toniolo, R. Amperometric Detection of Ethanol Vapors by Screen Printed Electrodes Modified by Paper Crowns Soaked with Room Temperature Ionic Liquids. Electroanalysis 2022, 34, 1–11.

- Gao, J.; Hua, Z.; Xu, S.; Wan, H.; Zhi, Z.; Chen, X.; Fan, S. Amperometric Gas Sensors Based on Screen Printed Electrodes with Porous Ceramic Substrates. Sens. Actuators B Chem. 2021, 342, 130045.

- Luo, R.; Wu, Y.; Li, Q.; Du, B.; Zhou, S.; Li, H. Rational Synthesis and Characterization of IL-CNTs-PANI Microporous Polymer Electrolyte Film. Synth. Met. 2021, 274, 116720.

- Kuberský, P.; Navrátil, J.; Syrový, T.; Sedlák, P.; Nešpůrek, S.; Hamáček, A. An Electrochemical Amperometric Ethylene Sensor with Solid Polymer Electrolyte Based on Ionic Liquid. Sensors 2021, 21, 711.

- Zhang, S.-Y.; Zhuang, Q.; Zhang, M.; Wang, H.; Gao, Z.; Sun, J.-K.; Yuan, J. Poly(Ionic Liquid) Composites. Chem. Soc. Rev. 2020, 49, 1726–1755.

- Silvester, D.S. New Innovations in Ionic Liquid–Based Miniaturised Amperometric Gas Sensors. Curr. Opin. Electrochem. 2019, 15, 7–17.

- Raptopoulou, C.P. Metal-Organic Frameworks: Synthetic Methods and Potential Applications. Materials 2021, 14, 310.

- Andirova, D.; Cogswell, C.F.; Lei, Y.; Choi, S. Effect of the Structural Constituents of Metal Organic Frameworks on Carbon Dioxide Capture. Microporous Mesoporous Mater. 2016, 219, 276–305.

- Yulia, F.; Nasruddin; Zulys, A.; Ruliandini, R. Metal-Organic Framework Based Chromium Terephthalate (MIL-101 Cr) Growth for Carbon Dioxide Capture: A Review. J. Adv. Res. Fluid Mech. Therm. Sci. 2019, 57, 158–174.

- Ding, M.; Cai, X.; Jiang, H.-L. Improving MOF Stability: Approaches and Applications. Chem. Sci. 2019, 10, 10209–10230.

- Jiao, L.; Seow, J.Y.R.; Skinner, W.S.; Wang, Z.U.; Jiang, H.-L. Metal–Organic Frameworks: Structures and Functional Applications. Mater. Today 2019, 27, 43–68.

- Lee, Y.-R.; Kim, J.; Ahn, W.-S. Synthesis of Metal-Organic Frameworks: A Mini Review. Korean J. Chem. Eng. 2013, 30, 1667–1680.

- Silva, P.; Vilela, S.M.F.; Tomé, J.P.C.; Almeida Paz, F.A. Multifunctional Metal–Organic Frameworks: From Academia to Industrial Applications. Chem. Soc. Rev. 2015, 44, 6774–6803.

- Safaei, M.; Foroughi, M.M.; Ebrahimpoor, N.; Jahani, S.; Omidi, A.; Khatami, M. A Review on Metal-Organic Frameworks: Synthesis and Applications. TrAC Trends Anal. Chem. 2019, 118, 401–425.

- Freund, R.; Zaremba, O.; Arnauts, G.; Ameloot, R.; Skorupskii, G.; Dincă, M.; Bavykina, A.; Gascon, J.; Ejsmont, A.; Goscianska, J.; et al. The Current Status of MOF and COF Applications. Angew. Chem. Int. Ed. 2021, 60, 23975–24001.

- Song, Y.; Li, X.; Sun, L.; Wang, L. Metal/Metal Oxide Nanostructures Derived from Metal–Organic Frameworks. RSC Adv. 2015, 5, 7267–7279.

- Alfè, M.; Gargiulo, V.; Amati, M.; Maraloiu, V.-A.; Maddalena, P.; Lettieri, S. Mesoporous TiO2 from Metal-Organic Frameworks for Photoluminescence-Based Optical Sensing of Oxygen. Catalysts 2021, 11, 795.

- Tan, X.; Wu, Y.; Lin, X.; Zeb, A.; Xu, X.; Luo, Y.; Liu, J. Application of MOF-Derived Transition Metal Oxides and Composites as Anodes for Lithium-Ion Batteries. Inorg. Chem. Front. 2020, 7, 4939–4955.

- Li, H.-Y.; Zhao, S.-N.; Zang, S.-Q.; Li, J. Functional Metal–Organic Frameworks as Effective Sensors of Gases and Volatile Compounds. Chem. Soc. Rev. 2020, 49, 6364–6401.

- Li, Y.; Xiao, A.-S.; Zou, B.; Zhang, H.-X.; Yan, K.-L.; Lin, Y. Advances of Metal–Organic Frameworks for Gas Sensing. Polyhedron 2018, 154, 83–97.

- Huang, B.; Li, Y.; Zeng, W. Application of Metal-Organic Framework-Based Composites for Gas Sensing and Effects of Synthesis Strategies on Gas-Sensitive Performance. Chemosensors 2021, 9, 226.

- Sosa, J.; Bennett, T.; Nelms, K.; Liu, B.; Tovar, R.; Liu, Y. Metal–Organic Framework Hybrid Materials and Their Applications. Crystals 2018, 8, 325.

- Mandal, S.; Natarajan, S.; Mani, P.; Pankajakshan, A. Post-Synthetic Modification of Metal–Organic Frameworks Toward Applications. Adv. Funct. Mater. 2021, 31, 2006291.

- Alfe, M.; Policicchio, A.; Lisi, L.; Gargiulo, V. Solid Sorbents for CO2 and CH4 Adsorption: The Effect of Metal Organic Framework Hybridization with Graphene-like Layers on the Gas Sorption Capacities at High Pressure. Renew. Sustain. Energy Rev. 2021, 141, 110816.

- Lei, J.; Qian, R.; Ling, P.; Cui, L.; Ju, H. Design and Sensing Applications of Metal–Organic Framework Composites. TrAC Trends Anal. Chem. 2014, 58, 71–78.

- Zhu, Q.-L.; Xu, Q. Metal–Organic Framework Composites. Chem. Soc. Rev. 2014, 43, 5468–5512.

- Kalaj, M.; Bentz, K.C.; Ayala, S.; Palomba, J.M.; Barcus, K.S.; Katayama, Y.; Cohen, S.M. MOF-Polymer Hybrid Materials: From Simple Composites to Tailored Architectures. Chem. Rev. 2020, 120, 8267–8302.

- Wang, X.; Wang, Y.; Ying, Y. Recent Advances in Sensing Applications of Metal Nanoparticle/Metal–Organic Framework Composites. TrAC Trends Anal. Chem. 2021, 143, 116395.

- Chen, C.; Li, B.; Zhou, L.; Xia, Z.; Feng, N.; Ding, J.; Wang, L.; Wan, H.; Guan, G. Synthesis of Hierarchically Structured Hybrid Materials by Controlled Self-Assembly of Metal–Organic Framework with Mesoporous Silica for CO2 Adsorption. ACS Appl. Mater. Interfaces 2017, 9, 23060–23071.

- Chronopoulos, D.D.; Saini, H.; Tantis, I.; Zbořil, R.; Jayaramulu, K.; Otyepka, M. Carbon Nanotube Based Metal–Organic Framework Hybrids From Fundamentals Toward Applications. Small 2022, 18, 2104628.

- Zheng, Y.; Zheng, S.; Xue, H.; Pang, H. Metal-Organic Frameworks/Graphene-Based Materials: Preparations and Applications. Adv. Funct. Mater. 2018, 28, 1804950.

- Alfè, M.; Gargiulo, V.; Lisi, L.; Di Capua, R. Synthesis and Characterization of Conductive Copper-Based Metal-Organic Framework/Graphene-like Composites. Mater. Chem. Phys. 2014, 147, 744–750.

- Aguilera-Sigalat, J.; Bradshaw, D. Synthesis and Applications of Metal-Organic Framework–Quantum Dot () Composites. Coord. Chem. Rev. 2016, 307, 267–291.

- Li, S.; Huo, F. Metal–Organic Framework Composites: From Fundamentals to Applications. Nanoscale 2015, 7, 7482–7501.

- Jahan, M.; Bao, Q.; Yang, J.-X.; Loh, K.P. Structure-Directing Role of Graphene in the Synthesis of Metal–Organic Framework Nanowire. J. Am. Chem. Soc. 2010, 132, 14487–14495.

- Li, X.; Zhang, Z.; Xiao, W.; Deng, S.; Chen, C.; Zhang, N. Mechanochemistry-Assisted Encapsulation of Metal Nanoparticles in MOF Matrices via a Sacrificial Strategy. J. Mater. Chem. A 2019, 7, 14504–14509.

- Chen, L.; Chen, H.; Luque, R.; Li, Y. Metal−organic Framework Encapsulated Pd Nanoparticles: Towards Advanced Heterogeneous Catalysts. Chem. Sci. 2014, 5, 3708–3714.

- Hu, M.-L.; Razavi, S.A.A.; Piroozzadeh, M.; Morsali, A. Sensing Organic Analytes by Metal–Organic Frameworks: A New Way of Considering the Topic. Inorg. Chem. Front. 2020, 7, 1598–1632.

- Small, L.J.; Schindelholz, M.E.; Nenoff, T.M. Hold on Tight: MOF-Based Irreversible Gas Sensors. Ind. Eng. Chem. Res. 2021, 60, 7998–8006.

- Zhang, R.; Lu, L.; Chang, Y.; Liu, M. Gas Sensing Based on Metal-Organic Frameworks: Concepts, Functions, and Developments. J. Hazard. Mater. 2022, 429, 128321.

- Kumar, P.; Deep, A.; Kim, K.-H. Metal Organic Frameworks for Sensing Applications. TrAC Trends Anal. Chem. 2015, 73, 39–53.

- Bhardwaj, S.K.; Bhardwaj, N.; Kaur, R.; Mehta, J.; Sharma, A.L.; Kim, K.-H.; Deep, A. An Overview of Different Strategies to Introduce Conductivity in Metal–Organic Frameworks and Miscellaneous Applications Thereof. J. Mater. Chem. A 2018, 6, 14992–15009.

- Na Songkhla, S.; Nakamoto, T. Overview of Quartz Crystal Microbalance Behavior Analysis and Measurement. Chemosensors 2021, 9, 350.

- Wang, L. Metal-Organic Frameworks for QCM-Based Gas Sensors: A Review. Sens. Actuators A Phys. 2020, 307, 111984.

- Ma, Z.; Yuan, T.; Fan, Y.; Wang, L.; Duan, Z.; Du, W.; Zhang, D.; Xu, J. A Benzene Vapor Sensor Based on a Metal-Organic Framework-Modified Quartz Crystal Microbalance. Sens. Actuators B Chem. 2020, 311, 127365.

- Mandal, D.; Banerjee, S. Surface Acoustic Wave (SAW) Sensors: Physics, Materials, and Applications. Sensors 2022, 22, 820.

- Paschke, B.; Wixforth, A.; Denysenko, D.; Volkmer, D. Fast Surface Acoustic Wave-Based Sensors to Investigate the Kinetics of Gas Uptake in Ultra-Microporous Frameworks. ACS Sens. 2017, 2, 740–747.

- Devkota, J.; Greve, D.W.; Hong, T.; Kim, K.-J.; Ohodnicki, P.R. An 860 MHz Wireless Surface Acoustic Wave Sensor with a Metal-Organic Framework Sensing Layer for CO2 and CH4. IEEE Sens. J. 2020, 20, 9740–9747.

- Vanotti, M.; Poisson, S.; Blondeau-Patissier, V.; André, L.; Brandès, S.; Desbois, N.; Gros, C.P. SAW Based CO2 Sensor: Influence of Functionalizing MOF Crystal Size on the Sensor’s Selectivity. In Proceedings of the International Conference on Advances in Sensors, Actuators, Metering and Sensing, Nice, France, 18–22 July 2021.

- Vashist, D.S.K.; Tewari, R.; Bajpai, D.R.P.; Bharadwaj, D.L.M.; Raiteri, R. A Review of Microcantilevers for Sensing Applications. J. Nanotechnol. 2007, 3, 15.

- Wang, H.; Lustig, W.P.; Li, J. Sensing and Capture of Toxic and Hazardous Gases and Vapors by Metal–Organic Frameworks. Chem. Soc. Rev. 2018, 47, 4729–4756.

- Cai, S.; Li, W.; Xu, P.; Xia, X.; Yu, H.; Zhang, S.; Li, X. In Situ Construction of Metal–Organic Framework (MOF) UiO-66 Film on Parylene-Patterned Resonant Microcantilever for Trace Organophosphorus Molecules Detection. Analyst 2019, 144, 3729–3735.

- Yim, C.; Lee, M.; Yun, M.; Kim, G.-H.; Kim, K.T.; Jeon, S. CO2-Selective Nanoporous Metal-Organic Framework Microcantilevers. Sci. Rep. 2015, 5, 10674.

- Ellern, I.; Venkatasubramanian, A.; Lee, J.H.; Hesketh, P.J.; Stavilla, V.; Allendorf, M.D.; Robinson, A.L. Characterization of Piezoresistive Microcantilever Sensors with Metal Organic Frameworks for the Detection of Volatile Organic Compounds. ECS Trans. 2013, 50, 469–476.