Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 1 by Fuad Un-Noor and Version 4 by Sirius Huang.

Though the current wave of electric vehicles is transforming the on-road passenger and commercial vehicle fleets, similar attempts in the off-road equipment sector appear to be lacking. Because of the diverse equipment categories and varied applications, electrifying off-road equipment requires significant research and development.

- agricultural equipment

- construction equipment

- electric vehicle

- hybrid electric vehicle

1. Introduction

Electric vehicles (EVs) have become a symbol for emissions reduction in the on-road transportation sector. The superior torque and lower emissions of these vehicles as well as other advantages they offer have generated significant interest in them [1]. Though passenger EVs have faced challenges of limited driving range and insufficient charging infrastructure, those have been gradually overcome. To date, much work has been conducted on the electrification of on-road vehicles [1][2][3][1,2,3]—from light-duty passenger cars and sports utility vehicles (SUVs) to medium- and heavy-duty commercial trucks—many of which have become commercially available [4][5][6][7][4,5,6,7]. However, pieces of off-road equipment such as those used in construction and agricultural applications have not been given the same level of attention.

While many publications focus on specific equipment types (e.g., tractors, excavators) or categories (e.g., construction, agriculture), several others are geared toward general, multi-purpose off-road equipment. This section provides an overview of notable works conducted on construction and agricultural equipment electrification, with the additional inclusion of some general off-road equipment types. Each subsection covers different hybrid and battery electric powertrain configurations. A hybrid electric vehicle (HEV) uses electric motor(s) alongside an ICE, while a battery electric vehicle (BEV) employs electric motor(s) exclusively. A separate classification worth mentioning is fuel cell electric vehicle (FCEV), which uses fuel cells to generate electricity for running its electric powertrain. Partial or full electrification of equipment attachments, which conventionally is powered by ICE through PTO, is also discussed in the followings sections. In addition, the maturity level of technology development—software-based simulation or hardware implementation (either on test bench or in vehicle)—is also noted.

2. General Off-Road Equipment

A variety of EV architectures can be applied to electrify construction and agricultural equipment. Zhang et al. [8][27] showed the design of a battery management system (BMS) [9][28] for a light-duty off-road parallel plug-in hybrid (PHEV) vehicle, where they employed fuzzy programming to accomplish the task. Parsons et al. [10][18] showed the design of a heavy military vehicle employing a series hybrid configuration with hub-mounted electric motors utilizing a two-speed transmission. They stated that the design is scalable to vehicles requiring an individual motor capacity up to 400 kW, so it might be possible to adopt this design for heavy construction equipment. A concept similar to that proposed in Parsons et al. [10][18] was previously presented by Jackson et al. [11][29], and a two-speed transmission was also used for hybrid heavy off-road machinery by Sinkko et al. [12][30]. With sufficiently mature battery technology, the ICE might be discarded to move towards the BEV architecture, especially in applications where duty cycles do not demand power exceeding the battery capacity. Baronti et al. [13][31] proposed a BMS for lithium iron phosphate (LiFePO4) batteries intended for off-road BEV usage, considering battery modules with four cells. Their goal was to design a system that did not require any bespoke hardware, and could serve a wider range of applications. Employing hydrogen fuel cells to power an electric drivetrain represents another possibility for electrifying off-road construction and agricultural equipment. It would be faster to refuel FCEVs than BEVs in remote locations, provided that hydrogen fuel storage can be made available on or near those sites. An off-road FCEV configuration is presented by Saeks et al. [14][32], where a flywheel energy storage system [1] was used to recover energy and to aid in acceleration. The system had four motors in each of the four wheels to provide four-wheel drive, and employed adaptive controllers with interconnections to facilitate front- and rear-wheel steering as well as energy management and acceleration–deceleration. The works reviewed in this section are summarized in Table 1.

Table 1.

Academic literature overview of general off-road EV architecture.

Table 34.

Industrial research on electric off-road construction equipment.

| Reference | Manufacturer | Model | EV Type | Components of Interest | Control Strategy | Equipment Type | Implementation Level | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| FCEV |

| |||||||||||

| [19][36[53],66] |

| John Deere |

|

644K Hybrid Wheel Loader |

|

HEV |

|

Simulation | ||||

| Zhang et al. [8][27] | 2008 | Parallel PHEV |

|

|

|

Simulation | ||||||

| Baronti et al. [13][31] | 2013 | General |

|

- |

|

Simulation |

Wang et al. [36][21] also conducted a comparative study of hybrid excavator configurations, and identified the parallel system to be the best based on cost and performance considerations. Although they did not explicitly consider a compound system, the compound hybrid configuration in Kwon et al. [35][20] can be considered as a part of the parallel configuration set in Wang et al. [36][21], thus supporting the argument about the superiority of this configuration. A similar conclusion was made by Lin et al. [37][51] as well. Lee et al. [38][52] simulated a plug-in hybrid excavator in series, parallel, and compound modes, and the model showed that the compound mode could exploit the benefits of both series and parallel configurations but with higher cost and complexity. Yoo et al. [39][53] developed a hybrid control system with SC to operate in series, parallel, and compound modes, and then implemented the control system in a mid-sized excavator successfully. Xiao et al. [40][54] presented a control strategy for a parallel hybrid excavator employing ICE and SC to dynamically control the ICE’s operating region for better overall system operation with little effect on performance. Ge et al. [41][55] used a variable speed electric motor to drive a variable displacement pump to meet the dynamic energy demand of excavators, which resulted in 1.35 kW less power consumption during idling and around 30% energy savings as compared to a pure displacement variable design.

Off-highway trucks (Figure 6) are also known as mining haul trucks [42][56]. Many them use diesel-electric drivetrains (electric drivetrains without high-voltage storage, powered by diesel engines [43][23]) with dynamic braking that employs AC wheel motors [42][44][45][56,57,58]. Efforts have been made to recover the braking energy, which is generally sent to brake resistors to be dissipated as heat (hence, the term dynamic braking) by adding ESS. This essentially transforms the diesel-electric architecture into a series hybrid one. Such an attempt was made by Richter et al. [42][56], where they successfully implemented a Sodium-Nickle-Chloride (NaNiCl2) battery ESS in a Komatsu 830E [41][55]. Mazumdar [46][59] presented a truck trolley system where the trucks were provided with electricity from a dedicated substation through an overhead line to make the vehicles all-electric, thus reducing the fuel consumption even more by transferring the ICE’s power generation operation to a more efficient system (the electrical grid). In this work, the use of supercapacitors was also proposed to capture regenerated energy for use in stretches of track where overhead lines could not be placed. Esfahanian et al. [44][57] proposed the use of road-grade data to dynamically control the energy management system (EMS) of a hybrid mining haul truck with ESS. This approach allowed the battery level to drop below safe state of charge (SoC) limits if there were downhill slopes within reach, which could replenish the battery and bring the SoC level back within the safe operating window through regenerative braking. The use of an AC–AC converter to run the AC motors in off-highway trucks without an intermediate DC converter was proposed by Kwak et al. [47][60], where they presented a matrix converter architecture with phase redundancy that came with fault detection capabilities. There have also been pilot projects demonstrating battery electric mining haul trucks. An example is a Komatsu 605-7 truck retrofitted with a 700 kWh Lithium Nickel Manganese Cobalt Oxide (LiNiMnCo) (called NMC in industry-standard nomenclature) battery pack and a synchronous motor [48][61]. Additionally, Mirzaei et al. [49][62] presented software and hardware solutions for improved electric braking in such trucks, where the hardware solution was proved to be more reliable but more costly than the software one. From the review of literature, it is evident that the diesel-electric powertrain has been widely used in off-highway trucks. Recent research in this area has focused on technologies to further electrify these trucks, such as integrating ESS for capturing energy from regenerative braking, and employing overhead power lines for full-electric operation.

Figure 6.

Off-highway truck.

According to the literature, a significant amount of effort has already been made in hybridizing excavators, as evidenced by a large body of research work mrentioned hereinviewed in Section 2.2. The reason behind there being this much interest in hybrid excavators is comprehensible. Hydraulic excavators are one of the most used pieces of construction equipment [50][63]. Their energy consumption is vast, yet the efficiency of converting that energy to useful work is quite low—less than 30% if fuel-to-actuator efficiency is calculated. Pollutant emissions including particulate matter (PM) and nitrogen oxides (NOx) from this type of equipment is very high as well. The primary reason behind these is that the ICE is often operated near its rated speed, as opposed to in the high-efficiency region, so that the hydraulic pressure stays at a sufficient level to facilitate smooth transition from light to heavy load [35][20]. Moreover, the hydraulic system itself has an average efficiency of around 54% [41][55]. Thus, hybridization can significantly improve fuel efficiency and reduce the emission of hydraulic excavators, as the electric motor can help supply the instantaneous power required, letting the ICE operate in its most efficient region. In addition, the electric motor coupled with ESS can capture and store regenerative power, which is wasted as heat in excavators with ICE [35][51][20,64]. A similar observation can be made for off-highway trucks where the diesel-electric system has become mainstream, and series hybrid as well as battery electric options are being considered. On the other hand, the electrification of other major types of construction equipment, such as tractor–loader–backhoes, rubber-tired loaders, and scrapers, has not received the same level of attention. As they are major emitters of CO2, PM, and NOx, increased research and development effort to electrify these types of construction equipment is warranted. The academic and industrial works reviewed are summarized in Table 23 and Table 34, respectively.

Table 23.

Academic literature on electric off-road construction equipment.

| Reference | Year | EV Type | Components of Interest | Control Algorithm | Implementation Level | Equipment Type | |

|---|---|---|---|---|---|---|---|

| Kwon et al. [35][20] | 2010 | HEV |

|

Balancing power demand between a supercapacitor and the engine at each instance. | Simulation | Excavator | |

| ICE powered electric drivetrain, electricity driven PTO. | Yao et al. [34][50] | 2013 | HEV |

|

Combination of proportional (P) controller and mixed sensitivity controller. | Simulation and Hardware implementation |

Excavator |

| Xiao et al. [40][54] | 2008 | Parallel HEV |

| ||||

| Parsons et al. [10][18] | 2014 | Series HEV |

|

- |

|

Simulation andHardware implementation | |

| Sinkko et al. [12][30] | 2014 | HEV |

|

- |

|

Simulation |

3. Construction Equipment

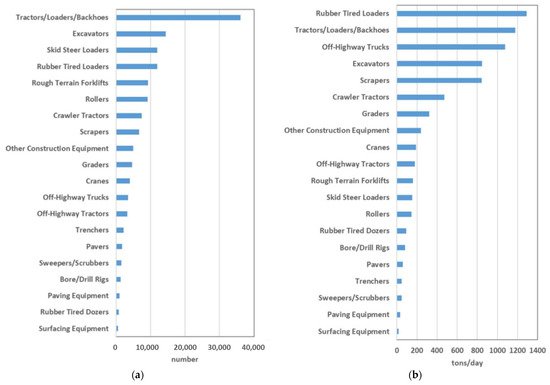

This section is focused on electrification efforts on construction equipment. Special attention is paid to construction equipment with higher population or carbon dioxide (CO2) emission contribution in California, USA, according to data from the California Air Resources Board (CARB) [15][24]. The lists of construction equipment types in 2018 as sorted by population and CO2 emission are shown in Figure 1. These two lists are not necessarily the same, as some types of equipment tend to have larger engine sizes, which produce more CO2 emission per hour. Moreover, some equipment types are used more than others. It is notable that off-highway trucks had a small population (ranked 12th) but were the third largest contributors of CO2 emission among all the construction equipment types. Thus, efforts to electrify this type of construction equipment could yield significant CO2 emission reduction. In this section, the dreviscussionew will concentrate on the top equipment types in terms of CO2 emission contribution, namely, loader, tractor–loader–backhoe, excavator, off-highway truck, and scraper.

Figure 1.

(

a

) Population and (

b

) CO

Tractor–loader–backhoe (also known as backhoe–loader) is a tractor with a loader at the front and a backhoe at the back (Figure 2). Escorts [16][33] proposed a concept of an electric backhoe–loader, but details are currently limited [17][34]. Skid steer loaders are generally small, and can be tracked or wheeled. On the other hand, rubber-tired loaders are typically larger, and have articulate frames to allow the front wheels to pivot relative to the rear. Hybrid rubber-tired loaders are already available commercially [18][19][20][21][35,36,37,38], while BEV versions of skid steer loaders have also been introduced [21][38]. An example of hybrid rubber-tired loaders is the Caterpillar® 988K XE [22][23][39,40], which combines a switched reluctance electric drive with a Tier 4 diesel engine [24][41] for increased efficiency and convenience. It utilizes the switched reluctance machines as a generator and pump drive. Additional hybrid loader designs were reported in Achten et al. [25][42]. In addition, there has been development of BEV loaders, such as the Caterpillar R1300G LHD [26][43], which uses electric motors and lithium ion batteries to run the mechanical drivetrain with gears. Caterpillar also developed a commercial product, the R1700 XE LHD, which is shown in Figure 3.

Figure 2.

Tractor–loader–backhoes are tractors with a front-mounted loader and a back-mounted backhoe as attachments.

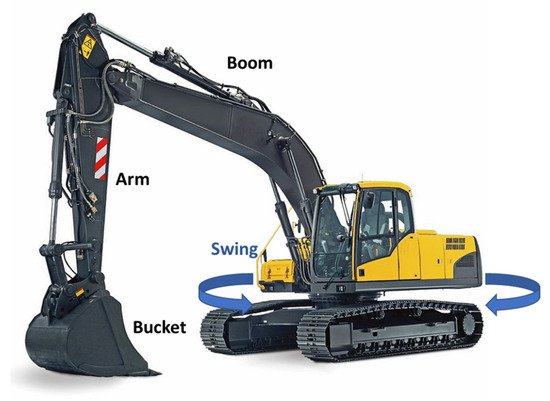

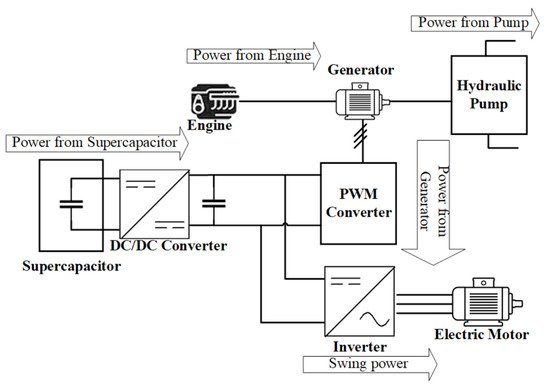

Excavators are fitted with digging equipment using a boom, and can be wheeled or tracked. Figure 4 shows an excavator. In [28][29][45,46], electric systems were successfully integrated into excavator booms for energy recovery, resulting in less energy consumption, and hence lower CO2 emissions. Wang et al. [30][16] studied different drivetrain configurations for hybrid excavators. They found that a combination of electric motor with battery was most frequently used for small hybrid excavators, whereas medium hybrid excavators favored supercapacitors (SC) (also known as ultracapacitors) instead of battery as the ESS. The superior power density of SC and its faster power transfer in larger amounts as compared to battery might have driven this choice. The use of battery in hybrid excavators was also documented in Xiao et al. [31][47], while the use of hybrid ESS comprised both battery and SC was also proposed [30][32][33][16,48,49]. Yao and Wand [34][50] proposed a hybrid excavator using a supercapacitor to power its electric swing system. Kwon et al. [35][20] classified hybrid excavators in three configurations: series (electric motor controls all movements, powered by ICE), parallel (both ICE and motor powers the system), and compound (electric motor replaces the hydraulic swing motor facilitating energy recovery). They determined the compound system to be superior because of its greater reliability and shorter anticipated payback period. They also proposed a power control algorithm for compound hybrid excavators, which was claimed to reduce fuel consumption by 24% as compared to conventional excavators. This algorithm works by balancing power demand between the supercapacitor and the engine at each instance. In this hybrid configuration, the supercapacitor, the swing motor, and the generator (powered by the engine) are all connected to a pulse width modulation (PWM) converter (Figure 5). The power balance is attained by controlling this converter’s DC-link voltage. The generator maintains a constant DC-link voltage utilizing a feedback mechanism, and the supercapacitor voltage is kept in a certain range through a feed-forward mechanism while the engine speed is kept almost constant. The hydraulic pump is driven by the generator, which is run by the engine. According to some operational set points, the system power is supplied or absorbed (during swing regeneration) by either the generator or the supercapacitor. When the supercapacitor voltage is within its rated operational range, it is used to power the swing, and the generator charges the supercapacitor. In such a scenario, the supercapacitor also absorbs any regeneration from the swing. If the supercapacitor voltage is higher than the rated value (indicating that it cannot absorb any more energy), regeneration from the swing is used to run the generator in motoring mode, thus sharing the hydraulic load with the engine. In cases of zero swing power with a high supercapacitor voltage, the supercapacitor is discharged to share the hydraulic load with the engine by running the generator in motoring mode.

Figure 4. A wheeled excavator shown with its major components. The swing motion allows this equipment to rotate 360 degrees without engaging the drivetrain.

|

|

No reverse gear as electric motor can perform this shift in direction, brake resistor consumes and dissipates excess energy generated during regenerative braking. | Skid steer loader/rubber-tired loader | Hardware implementation | |||||||||||||

| Tractor | Pre-production versions produced | [20][21][37,38] | John Deere | 318E 320E 326E 328E 332E |

HEV |

| |||||||||||

| [65][77] |

|

New Holland | NH2 | FCEV | - | Skid steer loader/rubber-tired loader | Hardware implementation | Dynamic work point. | Simulation | Excavator | |||||||

|

|

Traction and PTO operation handled by separate motors. | Tractor | Hardware implementation | [22][39] | Tobroco-Giant | GIANT E-skid steer | BEV |

|

- | Skid steer loader/rubber-tired loader | Hardware implementation | Lin et al. [37][51] | ||||

| [27] | 2008 | [44]Parallel HEV, Series HEV |

|

Caterpillar | Dynamic multi work point controller comprising of direct torque control, and closed loop proportional-integral (PI) control. | R1300G LHD | BEV |

| Simulation |

| Excavator | ||||||

| Electric motor used to run mechanical drivetrain through electric motor. | Rubber-tired loader | Hardware implementation | Lee et al. [38][52] | 2013 | Parallel, series, and dual mode power split PHEV |

| |||||||||||

| [23][24][40,41] |

|

|

Electric motor drives hydraulic pump, powered by battery; battery is charged by the generator run by ICE. | Simulation | Excavator | ||||||||||||

| Caterpillar | 988K XE | HEV |

|

- | Rubber-tired loader | Hardware implementation | Yoo et al. [39][53] | 2009 | Parallel, series, and compound HEV | ||||||||

| [30][16] |

|

Electric swing system, electric power assistance of ICE, regenerated energy stored in SC. | Kobelco (modified) | 70SR | HEVSimulation and hardware implementation |

| Excavator | ||||||||||

|

|

Energy supplied to the electrical load from the battery when needed, and absorbed during braking. | Excavator | - | Ge et al. [41][55] | 2017 | HEV | ||||||||||

| [30][54][16,67] |

|

Kobelco | SK80H |

|

Variable speed electric motor drives a variable displacement pump to meet the dynamic energy demand. | HEV | Simulation and hardware implementation |

| Excavator | ||||||||

| Battery charging and discharging limit set according to concurrent state-of-charge to ensure maximum efficiency and lifetime. | Excavator | Simulation | Wang et al. [52][65] | |||||||||||||

| [30] | 2013 | [HEV |

|

Energy regeneration from swing system and boom. | Simulation | Excavator | |||||||||||

| 16] | Caterpillar | - | Parallel HEV |

|

Operating mode and torque set according to load variation and SOC. | Excavator | - | Mazumdar [46][59] | 2013 | ||||||||

| [ | BEV | 30][16] |

|

Driven by overhead power supply. Regenerated energy stored in ESS to use in short driving distances. | Komatsu | - | HEVSimulation |

| Off-highway truck | ||||||||

|

|

Separate use of hydraulic motor and generator. | Excavator | - | Esfahanian et al. [44][57] | 2013 | |||||||||||

| [ | HEV | 30][54][16,67] |

|

Hitachi |

|

- |

|

Parallel HEV |

|

Control system comprised of master and slave controllers where the slave is used to monitor and govern the SC charge-discharge. | Excavator | - | |||||

| [30][16] | Doosan | - | HEV |

|

- | Excavator | - | ||||||||||

| [30][32][33][16,48,49] | Kobelco | - | Series HEV |

|

ESS assists during heavy load and stores surplus energy under light loads. Engine works in high efficiency region all the time, even stops when ESS energy is sufficient to drive loads. |

Excavator | - | ||||||||||

| [30][16] | Sumitomo | - | HEV |

|

SC SoC set to a higher value to drive load at higher voltage with better efficiency. | Excavator | - | ||||||||||

| [42][56] | Komatsu | 830E (modified) | Series HEV |

|

Battery used to recover braking energy to be deployed for power boost or enhanced engine efficiency. | Off-highway truck | Simulation and hardware implementation | ||||||||||

| [45][58] | Komatsu | 830E-1AC | Series HEV |

|

- | Off-highway truck | Commercially available | ||||||||||

| [55][68] | Komatsu | 930E-4 | Diesel-electric with dynamic braking |

|

- | Off-highway truck | Commercially available | ||||||||||

| [56][69] | Caterpillar | 795F AC Mining Truck | Diesel-electric with dynamic braking |

|

- | Off-highway truck | Commercially available | ||||||||||

| [47][60] | Komatsu | 605-7 (modified) | BEV |

|

The battery powers the motor and stores regenerative energy. | Off-highway truck | Hardware implementation |

4. Agricultural Equipment

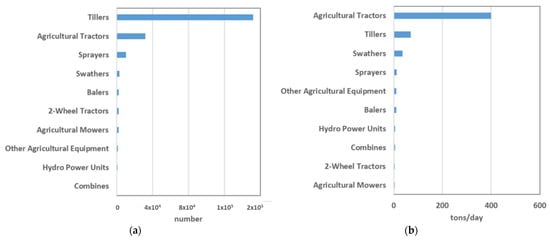

This subsection focuses on electrification attempts on agricultural equipment. Similar to construction equipment, special attention is paid to equipment with higher population or carbon dioxide (CO2) emission contribution in California, USA, according to data available from the California Air Resources Board (CARB) [15][24]. Agricultural equipment types recorded in the CARB database are shown in Figure 7, sorted by population and CO2 emission in 2018. As mentioned in the previous subsection, these two lists showing population and emission are not necessarily the same, because of larger engine sizes and/or higher use of some equipment types—which led to greater CO2 emission per hour despite their lower population. It can be seen from Figure 7 that agricultural tractors have much smaller population than tillers, but supersede them in terms of CO2 emission. Tractors are also identified as the most fuel-consuming mobile agricultural equipment [57][70], which provides some explanation of their higher CO2 emission. Thus, electrifying the agricultural tractors could yield significant CO2 emission reduction, and this subsection will concentrate on this single agricultural equipment type. Figure 8 shows an agricultural tractor.

Figure 7.

(

a

) Population and (

b

) CO

Figure 8. Agricultural tractor. Series hybrid concept for this type of equipment was presented in [58] with electric drivetrain and PTO.

Agricultural tractor. Series hybrid concept for this type of equipment was presented in [71] with electric drivetrain and PTO.

Previously, Usinin et al. presented a series hybrid electric drivetrain for tractors, having an engine, generator, two traction motors, and required power electronics [59][72]. Gas turbine and diesel engines were proposed as the engine choices; while electric machines and power electronics were designed to reduce cost [59][72]. Mousazadeh et al.’s design employed two solar panels on their tractor, which was capable of meeting 18% of the energy demand, and the rest was obtained from the grid to charge its valve-regulated lead acid (VRLA) battery pack [60][73]. This tractor successfully carried out several common light agricultural tasks, including plowing, mowing, and towing. This equipment was mentioned as a PHEV, but based on the definitions used in thereis paper, it was a BEV because of its sole use of electric drivetrain and absence of ICE. It is categorized accordingly in Table 45. Mousazadeh et al. conducted a comparative study on different battery technologies best suited for their solar-assisted tractor in [61][74]. They concluded that the VRLA technology was the best considering the regional manufacturing capabilities. Ueka et al.’s design used an electric motor to drive a rotary tiller and employed four wheel drive in a battery electric tractor [57][70]. An electronically controlled continuously variable transmission (e-CVT) with PTO capabilities was designed and implemented by Rossi et al. for a parallel hybrid agricultural tractor [62][75]. Florentsev et al. presented a pre-production version of a series hybrid tractor. It used an asynchronous traction motor and electricity-driven PTO [58][71]. A similar work was shown by Puhovoy et al. in [63][76]. To enable high-voltage PTO capabilities, Moreda et al. proposed installing a PTO-dedicated high voltage generator on tractors [43][23]. Gonzalez-de-Soto et al. presented a hydrogen-fuel-cell-powered PTO system for an ICE-driven tractor [64][25]. Their system comprised a fuel cell stack and a solar photovoltaic (PV) system for power generation, and batteries for storage. A fuel cell electric tractor was also demonstrated previously [65][77]. Additionally, Zhitkova et al. designed an electric motor for agricultural tractor use. This motor was suited for both low speed off-road operation and higher speed produce-transportation work [66][78].

Table 45.

Academic literature on electric off-road agricultural equipment.

The academic and industrial works reviewed are summarized in Table 45 and Table 56, respectively.

Table 56.

Industrial research on electric off-road agricultural equipment.

| Reference | Manufacturer | Model | EV Type | Components of Interest | Control Strategy | Equipment Type | Implementation Level | |||

|---|---|---|---|---|---|---|---|---|---|---|

| Separate excitation for generator and motor, motor torque control by controlling armature current and magnetic flux. | Simulation | Tractor | ||||||||

| [58][71] | Ruselprom | Belarus-3023 | Series HEV |

| ||||||

| Mousazadeh et al. [60][73] | 2010 | BEV |

|

Solar panel supplied 18% of required power, rest taken from grid. | Simulation and hardware implementation | Tractor | ||||

| Ueka et al. [57][70] | 2013 | BEV |

|

A rotary tiller along with the four wheels driven by the motor through reduction gear. | Tractor | |||||

| Simulation and hardware implementation | Rossi et al. [62][75] | 2014 | Parallel HEV |

|

Set up for using ICE’s maximum torque operating region. | Simulation and hardware implementation | Tractor | ||

| Gonzalez-de-Soto et al. [64][25] | 2016 | ICE vehicle with fuel cell-powered PTO |

|

The fuel cell system powers the PTO, while ICE runs the drivetrain. Battery stores excess energy. | Simulation and hardware implementation | Tractor |