Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 2 by Sirius Huang and Version 3 by Sirius Huang.

The health of humans and the planet are the most vital contemporary issues and essential components of the Sustainable Development Goals (SDGs). The goals here are to implement sustainable and circular strategies as checking criteria for health through an example of an uncomplicated toolkit.

- healthy renewable resources

- timber construction technologies

- programmable sustainable materialisations

1. Introduction

Comprehensive strategies and thoughtful, immediate, and practical action plans are crucially required to make a difference in the challenges the building industry currently faces and to avoid future adverse outcomes. Objective plans should be taken into practice to lubricate the transition using appropriate supportive tools, such as indicators, checklists, toolkits, etc. The idea is to enhance the resulting strategies and plans in the construction processes and ensure they are harmlessly practicable, aiming to achieve healthy, sustainable concepts. Therefore, to provide example toolkits for the healthy selection of materials, the following section presents formulations of the previous statements in practical applications.

2. Tools for Materials Selection for the Planet and Its Occupants

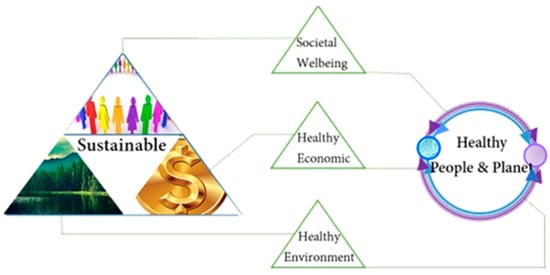

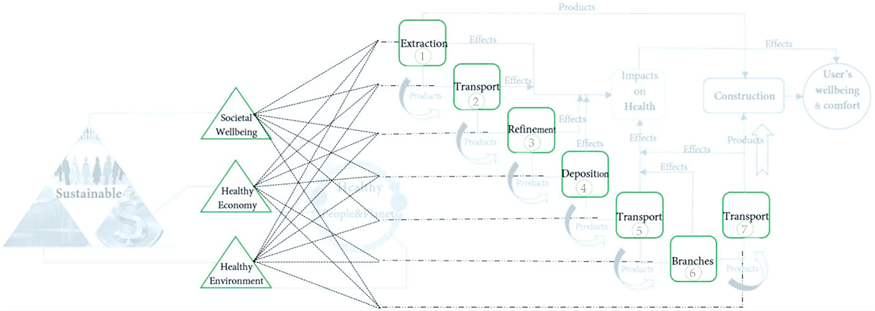

Based on previous practical and analytical discussions, and in line with the Paris Agreement (2015) and the SDGs [1], sustainable concepts of the building processes for objective systems, including construction parts, should incorporate and prioritise the users’ health. Thus, the target for this objective system here is a “programmable construction system” (PCS), dynamic CSs that are adjustable for health, biodiversity, economy, industrial ecology, etc., and safeguard a healthy forthcoming built environment. Similarly, Refs. [2][3] specified a long-term perspective as the only difference between liveability and sustainability. Thus, sustainability is a decent measure for the planet’s health and inhabitants. Figure 1 also shows that occupants’ health can be ensured by examining and checking the sustainability pillars.

Figure 1. Schematic demonstration of three famous pillars of sustainability for WB [4].

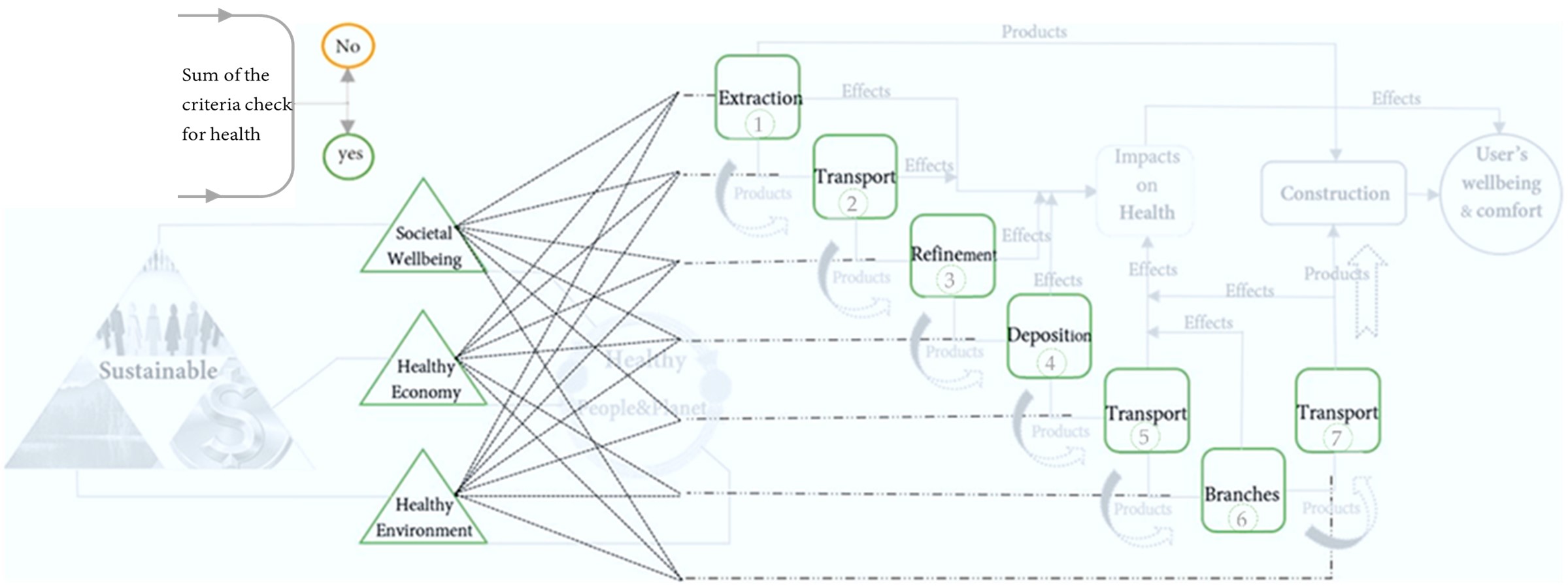

Regarding the pillars of sustainability, the economic situation of the users and the housing on a global scale are out of the scope of current research. However, the economic aspects predominantly related to the building industry incorporating the land use (i.e., indirectly), construction, materialisation, etc., that are relevant here can be checked concerning health within the scheme in Figure 1. Environmental health checks also focus on the built environment and housing, which targets CMs. Following the path of PCSs, the latter will be in the form of programmable construction materials (PCMs). Returning to the sustainability pillars, the social WB of the scheme only checks the health and desire regarding the construction of houses. The summary of the processes of providing materials for the construction is applicable for analysing housing stocks as a significant portion of the building industry. Therefore, to base the PCSs for health on a broad scale, checking the impacts of the materials’ production processes with the three well-known components of sustainability could be an example of, and a summarised indicator for, the selection of materials. Programming PCMs for health is a vital consideration; thus, the mentioned checking tool is the health-oriented selection of PCMs, or HS-PCMs, shown in Figure 2. This generative, simple, practical concept toolkit examines the health aspects of construction. It is easily developable into a sub-element.

Figure 2. Example toolkit for materials selection to check the health of each phase within processes of CMs with sustainability pillars.

The HS-PCMs is a general concept directly applicable to the mesoscale (i.e., construction). However, owing to its generative nature, it could also be further detailed for the application on the microscale (i.e., materials).

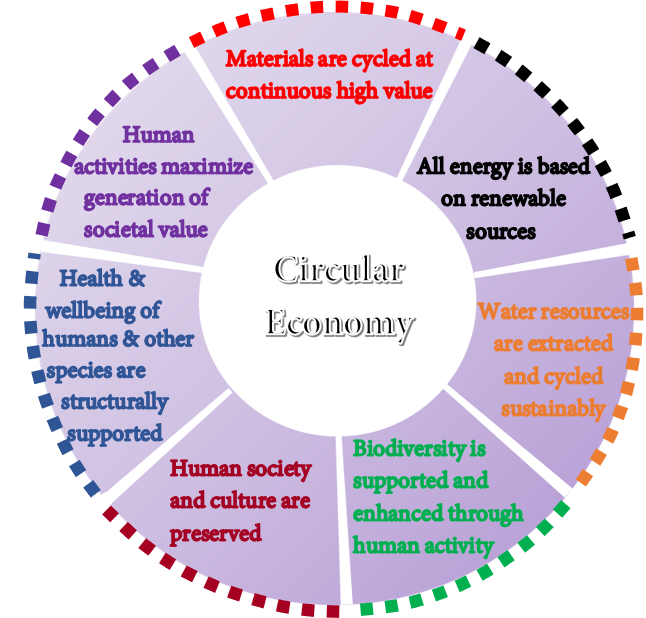

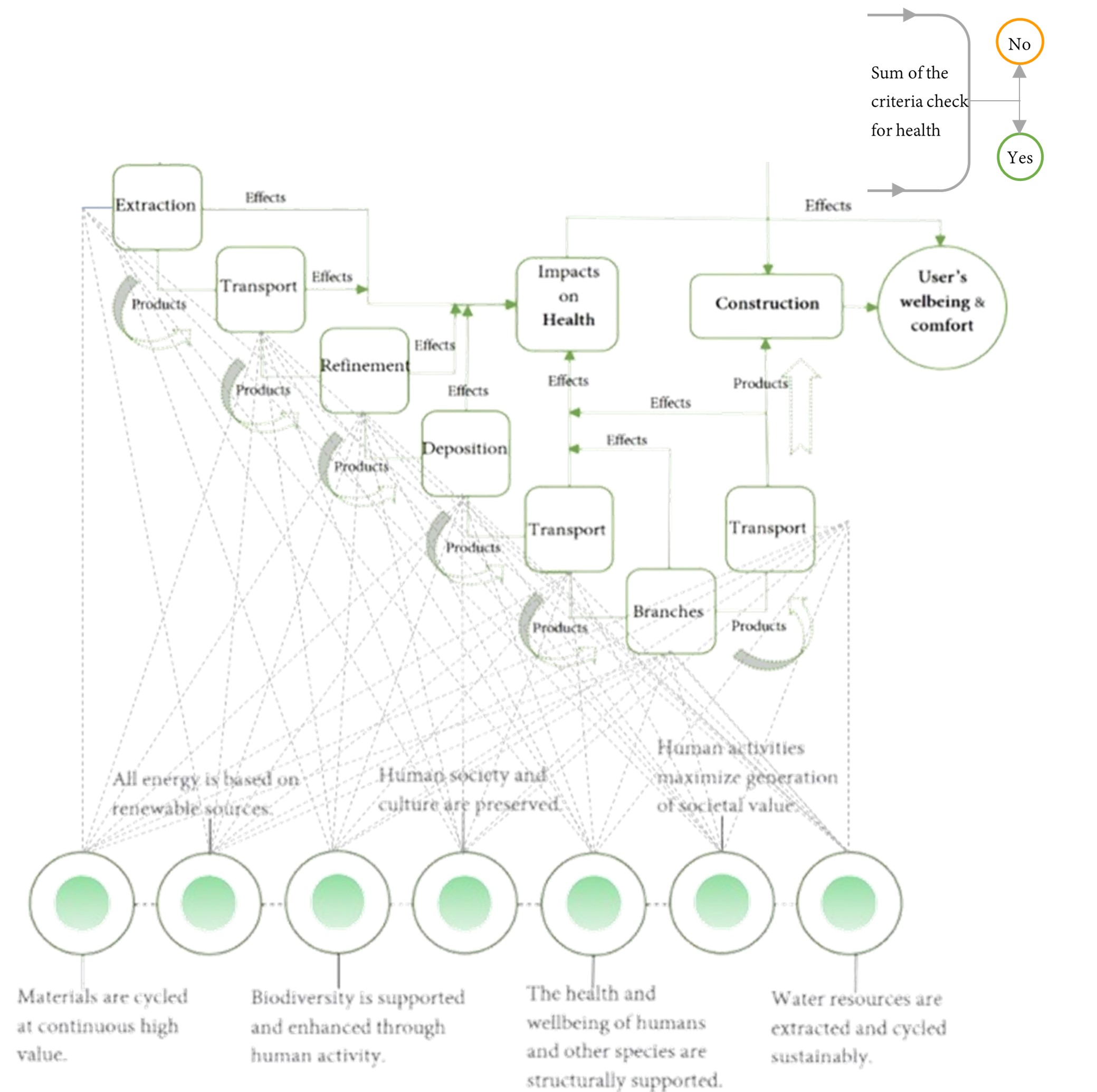

To ensure the concept’s viability, it will also be tuned to circularity. Choosing the circular economy as the best way to battle climate change and take the strategies into action means it is the only way to make modern life healthy (see the pillars of the circular economy in Figure 3). Julie Hirigoyen (2016), CEO of the UK Green Building Council, states that transferring the circular economy to the building industry will decrease resource consumption and adapt various applications while providing healthier living and workspaces. Similarly, Cheshire [5] emphasises the healthy built environment as an advantage of the circular economy, resulting in significant economic returns for ownership costs. Examples are provided here, depending on the sustainable solutions and support for transitions into a circular framework. The same method that health issues are previously checked with sustainability pillars in a sample case (e.g., scheme in Figure 2) is also applicable to inspect them with the circular economy pillars (Figure 3). A concept (to demonstrate the simplicity and effectiveness of practical applications) to make a toolkit out of a collection of these checking criteria is shown in the scheme of Figure 4, which is similar to the HS-PCMS, which can be used with the circular economy.

Figure 3. Schematic demonstration of 7 pillars of CE.

Figure 4. Principles of checking health. Similar to HCMS but based on circular economy pillars.

Thriving emerging solutions include alternative CMs, evaluation criteria capable of public applications, and high-tech solutions for healthier PCMs based on renewable and sustainable sources.

3. Healthy Alternatives for the PCMs

This section concentrates on an appropriate compatible alternative that could be used as the third target material after steel and concrete (i.e., those currently dominant in the market) to facilitate transitions towards healthy PCMs. The alternative must be suitable for replacing CCMs on a vast scale. Bio-based materials have been implemented for use in sheltering humankind for our entire history [6]. It is the source of environmentally friendly CMs that are primarily harmless [7] and harvestable, only consuming a minor amount of energy [8]. The platform of bio-based materials contains two main categories: biodegradable and bio-sourced materials.

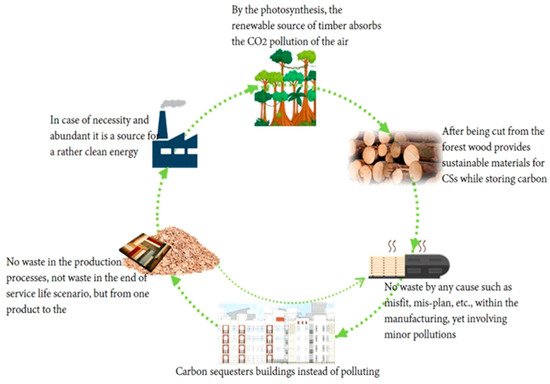

Because of the sustainability aspects of these low-impact healthy materials, their bio-based applications in the building industry are advancing considerably. Examples include Eindhoven’s growing Pavillion, 2019; Hy-Fi tower of “The Living” in New York, 2014; HempHouse in Nashville, 2010; etc. Hence, their variety is also enlarging, going beyond the scope of this research. Therefore, only wood belonging to the second bio-based category is discussed here as an alternative replacement for abiotic materials on a public scale. Wood, in general applications, is the most widely used material [9]. In addition to being the most sought after by humans [10], this material comes from the most renewable resource on the planet [11][12][13][14][15]. Therefore, it belongs to the very sustainable group of natural sources (e.g., Figure 5) due to its carbon sequestering and low energy consumption; compared with CCSs, it is very quickly renewable [16]. The new generations of timber are lightweight, robust, durable [13][14], and applicable in prefabricated buildings. However, due to historical issues (e.g., centennial large city fires) [17][18][19], timber was gradually removed from the modern construction market as a result of the disadvantages in its technical characteristics, as well as its other limitations [20]. Nevertheless, new advancements in timber technology caused drastic developments, creating innovative high-tech timber [21], which is also compatible with the cutting-edge technologies transferable for PCSs. However, applications in new houses are not equally growing with these advances (e.g., only 25% of the UK’s newly built houses are timber-based).

Figure 5. Cycle that makes mass timbers sustainable and circular PCMs.

Health-Related Parameters for the Alternative PCMs

This study attempts to benefit from the effects of nature on mental and physical health, conducting research in construction-related directions. The connectivity of WB with the natural environment is a proven fact [22][23][24][25][26][27][28][29][30]. In the built environment, biophilic, -mimetic, and other bio-inspired concepts that were first designed for the recovery of patients [29], are famous examples of nature’s effectiveness on WB. Researchers at Michigan University observed that the productivity of office workers increased by 20% after spending one hour in nature [28]. Hence, the U-M’s researchers also examined students’ test results and found that 20% of the students improved their scores after walking through nature [28].

Further studies show similar effects on improving the memory of people diagnosed with depression, etc. Therefore, logically, as a part of nature, according to Dematte et al. [19], timber is much closer to human feelings and sensations than any synthetics. Users’ emotions directly influence their mental states [31]. In addition, the link between happiness and health has been excessively studied and proven (e.g., Refs. [32][33][34][35][36][37]). Similarly, Nyrud et al. [38] and Nyrud et al. [39] studied the influences of wood on patients’ health; they observed positive impacts. Hence, Cronhjort et al. [40] examined the effect of timber on the interior of buildings; in blind testing, positive influences on participants’ feelings were the primary outcome.

The effectiveness of wood on people’s psychological health has also been investigated by Burnard et al. [41] and Dematte et al. [19]. Surprisingly, many researchers confirm that wood surfaces, compared with other CCSs, more effectively confine microbial growth and minimise microbial transmission [42][43][44][45][46]. The study regarding the effects of exposed surfaces on hospital patients performed by Munir et al. [46] proved that using wood in such applications reduces the requirements for chemicals and antimicrobic agents for daily cleaning. Based on the analysis of Alpert [47], microbes on timber will face desiccation due to wood’s absorption properties. Hence, unhealthy and damaging microorganisms are withdrawn or even killed by the extractive components of wood’s tissue [48]. Although the study of Munir et al. [46] focuses on natural and untreated wood, it proves its effectiveness. They argue that due to wood’s hygroscopicity properties, microbes are stuck in this material and thus cannot contaminate food or other contacts. Hence, the absorption characteristics of timber trap microbes and prevent reproduction and colonisation [49].

According to Munir et al. [46], the porosity of wood, which was always discussed as a negative parameter in timber, is favourable for its hygroscopicity that causes unfavourable living conditions for microbes and even for some typical bacteria. Each of these natural materials resembles humankind’s affinity with uniqueness. However, inherent beauty features, cleanliness, and reactions towards microorganisms in different wood species vary [46]. However, all timber embodies a certain level of hygroscopicity and antimicrobial chemicals to engage positively in users’ health. Therefore, if the properties and capacities of the emerging technologies allow for a massive market, this restorative material is an effective option for the transitions.

4. An Overview of the Qualities as Principles for an Alternative Healthy Materialisation

The effectiveness of wood in the modern CSs has been proven (e.g., Refs. [40][50][51][52][53][54]). For example, Jayalath et al. [55], by conducting experimentations and analyses in three major cities in Australia on midrise buildings, approved the environmental efficiency of advanced mass timber over the CCSs. In principle, high-tech timber has provided two essential opportunities for the housing sector (and most other sectors).

Mass timber (MT): these are production techniques that can be applied on an extensive scale; they are crucial solutions for housing units, for example, for the demanding housing market of the Netherlands (see Ref. [4] for analysis). The category of mass timber, which was primarily established as a framing style, currently uses large, dense wood panels for walls, floors, and roofs, and even in column construction. Additionally, employing a combination of digital design, CNC processing, and other modern techniques, such as 3D printing and lasers, the market for mass timber is further enlarging and encompassing almost all types of buildings.

The engineering of mass timber (e.g., see examples of some high-tech mass timbers in Table 1), in addition to the old systems, such as modular concepts developing in the novel and emerging techniques [56], creates a new wave of advantages for the PCSs based on high-tech mass timber.

Table 1. Some examples of readily available high-tech mass timber.

| Advanced Tech Mass Timber (MT) Products | ||||||||

|---|---|---|---|---|---|---|---|---|

| MT categories | Cross-Laminated Timber | Glued-Laminated Timber | ||||||

| PSL | ||||||||

Healthy PCMs also require certain properties. Therefore, a summary of some technical characteristics and practical features for the new, high-tech mass timber, compared with conventional materials, is provided in Table 2.

Table 2. A comparison of technical characteristics of present days’ BI market materials.

| Characteristics | Concrete | Steel | Timber | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Nail-Laminated Timber | Dowel-Laminated Timber | ||||||||

| Weight per CM | 2400–3200 | Laminated Veneer Lumber | Laminated Strand Lumber | Oriented Strand Lumber | Parallel-Strand Lumber | ||||

| 7500–8050 | 400–700 | Acronyms | CLT | GluLam, GLT | NaiLam, NLT | DowelLam, DLT | LVL | LSL | OSL |

| Specific gravity (kn/m3) | 2 | 7.66 | 0.4 | ||||||

| Thermal conductivity | 1–10 W/mK | 55.50% | 0.14–0.17 | ||||||

| Embodied energy | 450–750 KWh/tone | 5000 + indirect | |||||||

| Sum | 100 |

6. An Extreme Case of Application of the Proposed Alternative as a Demonstrative Example

Advanced mass timber techniques, such as the CLT (Cross Laminated Timber), GLM (Glue Laminated), LVL (Laminated Veneer Lumber), etc., demonstrate higher qualities than the CCMs. However, qualities are relative and should be comparatively evaluated. Hence, the advances in mass timber technologies are progressive and at a rather rapid pace. They come from renewable sources [74]. Their carbon footprint is at least 50% lower than CCMs. Their life-cycle assessment and end-of-life scenario confirm their healthy advantages [75][76][77][78]. As an appropriate case of applied, sustainable, and healthy CMs, the Sara Cultural Centre is partly evaluated according to the PCMs (see Table 4). The 76 m 20-story building is currently one of the world’s tallest timber buildings (i.e., the fourth tallest), containing GLM columns and CLT walls, and it is located in Skelleftea, Sweden. Constructed from 12,200 cubic meters of wood, it also uses carbon-neutral energy via solar panels, batteries, and a heat pump that works with electrical, water, and district heating. The fire compartment system (i.e., the charring capacity of wood) is also powered by renewable energy (White Arkitekter, 2021). Thanks to the wood structure, the carbon emissions for lighting and thermal comfort are less than 50% of the carbon sequestering in the construction. With more than 100 years of service life span, the building will continue sequestering carbon for more than 50 years (GCR, 2021). Similar cases, such as the 85.4 m tall Mjøstårnet in Brumunddal, 100 km north of Oslo, or the Treet Tower in Bergen (Damgårdsveien 99), are increasingly being developed across the globe.

Table 4. Streamlining brief evaluation of CMs of Sara Cultural Centre with general items of PCMs.

|

||||||

|---|---|---|---|---|---|---|

| 1. Extract: +++ | 2. Transport: +++ | 3. Refine: +++ | 4. Depose: +++ | 5. Product Transport: +++ | 6. Branches: +++ | 7. Site Services: +++ |

| The raw materials come from Swedish sustainable forests. | Sustainable harvesting is performed in regional boreal forests, so no significant production-related transportation is needed. | Not complicated. The mills are located close to the Swedish local wood sources. | Direct-use and modular systems, etc., prevent depositions, yet, wood is natural and harmless. | The manufacturing for processing in a sawmill is about 50 km from the construction site. | ||

| Technical life span | ||||||

| 100+ | 100+ | 10–30 | ||||

| Renewability of the resource | - | - | 100% | |||

| End-of-life scenario | Waste/landfill/downcycle | Waste/recycle/downcycle | Biodegrade with min energy | |||

Some of the abovementioned mass timber technologies have already confirmed their unique qualities. For example, GluLam and CLT have been implemented even in large-volume construction and high-rise buildings (e.g., Dalston Lane in London, Forté in Melbourne, Brock Common in Vancouver, HoHo in Vienna, T3 in Minneapolis, the Kajstaden in Västerås Sweden, etc.). Therefore, mass timber can sustainably fulfil the current scale of demands for housing at a rapid pace with agility, sustainability, and resilience, which are crucial for a successful transition [57]. Although mass production after the Industrial Revolution [58] caused most of the adverse effects on the environment [2][59][60][61][62][63], mass timber is based on relatively quick renewable sources [21][64][65][66]. The historic obstacles were fire and decay. Fire has a long history regarding buildings [20]. Naturally, wood decays in various ways, including through weathering, insect infestation [67], and fungal decay [68]. However, modern timbers have overcome the old complications [69][70].

Nevertheless, in addition to the study of Igarashi [71] and Feldhoff [72], which recognised the lobby in Japan’s construction market against sustainable products, Kaiser [70] identifies the poor regulations that relate to the returning of wood into the building industry on a global scale. He emphasises the high qualities and potential of new generations of CLT that meet the building requirements [70]. Studying the Swedish construction sector, Hemstrom et al. [73] also show the necessity for some governmental regulation and intervention to accomplish successful innovative transitions. Similarly, in the Netherlands, new policies such as BENG 1, 2, and 3 with the TOjuli, functioning from 01.01.2021, tighten the advanced CS regulations to provide more room for the CCSs. Thus, the technical and social characteristics of the innovative renewable alternatives for CMs, such as timber for public use, do not seem to be adequately appreciated.

5. Practical Checking: A Sample to Examine the Societal Preferences

In addition to the interconnectivity of health and occupants’ satisfaction, the users’ desire is a critical priority for the PCSs concerning WB and the economy. Addressing health ensures the durability of a specific construction system (CS) or construction material (CM) in the market. Therefore, social preferences are considered a significant component of the objective PCMs’ establishment. In this regard, brief, abstract results from comprehensive research (see the subsequent investigation in Shahnoori et al. (2022)) are presented here. The PCMs are tools under a comprehensive strategy for healthy evolving CSs. To examine the method in various aspects, extensive questionnaires and interviews were conducted. Gradually, more than 750 users submitted their reactions; however, around 500 results were incorporated in this article due to time constraints. In the first phase of the field research, the questionnaires about the people’s interests in three materials (CMs), namely steel, concrete, and timber, were delivered without providing extra information about the characteristics of the CSs. However, some critical features of advanced mass timber were presented to the interviewees in the second round. The results towards timber dramatically and positively changed. The other noticeable difference between the two research rounds was the age classification. In the first round, older adults were the most common group, while all age groups were equal in the second round. Discussing the societal-related study in detail and its analytical arguments is beyond the current article’s scope. Therefore, only the summary of outcomes of the research on social interests is shown in Table 3. A comparison of the male and female participants’ preferences for the same case is demonstrated in the chart in Figure 6.

Figure 6. Social aspects for PCMs: preference towards CMs’ selection between 500 participant samples.

Table 3. Percentage of level of social trends towards CMs (i.e., with 500 participants).

| Construction Type | Sum | ||||

|---|---|---|---|---|---|

| Steel | 7.14% | ||||

| No complications between the sources and use preventing storage, transport, etc. | Sequesters more than twice all the emissions by the entire related carbon—at least 9000 tons of CO | 2 | . | Concrete | 37.40% |

| Wood |

Yet, with identical performance characteristics of the CLT compared with CSs, such as concrete, it is 80% lighter, affecting transportation, energy use, time and velocity, safety, etc. Hence, the mentioned CO2 reduction is natural and does not incorporate extra MAC (marginal abatement costs). In addition to the seismic performance and ductility of the joints, CLT and GLT do not transmit heat and cold, which disturb the indoor thermal balances.

As also shown in Table 4, although the HS-PCM toolkit is at the concept level and early development stage, it is already applicable for a general evaluation of the health aspects of various phases of a construction case based on sustainability pillars.

References

- United Nations. Sustainable Development Gols Report 2016. Department of Economic and Social Affairs; United Nations: New York, NY, USA, 2016.

- Shahnoori, S. Sustainable Reconstruction of Houses in Seismic Desert Areas. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 2012.

- Knox, P.; Mayer, H. Small Town Sustainability; Birkhäuser: Basel, Switzerland, 2013.

- Shahnoori, S.; Mohammadi, M. Green systems for a Grey Society. J. Trends Civ. Eng. Its Archit. 2021, 4, 2637–4668.

- Cheshire, D. Building Revolutions; RIBA Publishing: London, UK, 2016.

- Shahnoori, S. Problem Statement and Research insights in Circular Systems for Older Adults’ Housing. In Discussing Circularity; presented at the ICSBE1-2020; Eindhoven University of Technology: Eindhoven, The Netherlands, 2020; pp. 1–8. ISBN 978-90-386-5317-4.

- Peñaloza, D.; Erlandsson, M.; Falk, A. Exploring the climate impact effects of increased use of bio-based materials in buildings. Constr. Build. Mater. 2016, 125, 219–226.

- Ramesh, M.; Palanikumar, K.; Reddy, K.H. Plant fibre based bio-composites: Sustainable and renewable green materials. Renew. Sustain. Energy Rev. 2017, 79, 558–584.

- Ross, R.J. Wood Handbook: Wood as an Engineering Material; US Department of Agriculture: The Bronx, NY, USA, 2010; p. 190.

- Horx-Strathern, O.; Varga, C.; Guntsching, G. The Future of Timber Construction CLT—Cross Laminated Timber, A Study about Changes, Trends, and Technologies of Tomorrow. A Study in Collaboration with Stora Enso; Zukunftsinstitut Osterreich GmbH: Vienna, Austria, 2017.

- Falk, R.H. Wood as a Sustainable Building Material. Wood Handbook: Wood as an Engineering Material: Chapter 1; Centennial ed. General Technical Report FPL.; GTR-190; US Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 2010; pp. 1.1–1.6, 190, 1–1.1.

- Lowden, L.A.; Hull, T.R. Flammability behaviour of wood and a review of the methods for its reduction. Fire Sci. Rev. 2013, 2, 4.

- McMorrough, J. The Architecture Reference & Specification Book: Everything Architects Need to Know Every Day; Rockport Publishers: Beverly, MA, USA, 2013.

- Moore, J.R.; Cown, D.J. Processing of wood for wood composites. In Wood Composites; Elsevier: Amsterdam, The Netherlands, 2015; pp. 27–45.

- Green, M. Why we should build wooden skyscrapers. TED Conferences. February 2013.

- Hetemäki, L.; Nasi, R.; Palahi, M.; Cerutti, P.; Mausch, K. The Future of Wood—Towards Circular Bioeconomy; SocArXiv Papers; European Forest Institute: Joensuu, Finland, 2021.

- Tardini, C. Experimental values of wood strength in bending between the 17th and the 18th century. In Advanced Materials Research; Trans Tech Publications Ltd.: Bach, Switzerland, 2013; Volume 778, pp. 3–10.

- Grewe, B.S. The Decline of Wood as an Economic Force with the Rise of the Industrial Revolution. Brewminate. Available online: www.brewminate.com (accessed on 16 February 2018).

- Demattè, M.L.; Zucco, G.M.; Roncato, S.; Gatto, P.; Paulon, E.; Cavalli, R.; Zanetti, M. New insights into the psychological dimension of wood–human interaction. Holz Roh Werkst. 2018, 76, 1093–1100.

- Kuzman, M.K.; Sandberg, D. Development of Multi-Storey Timber Buildings and Future Trends . In Proceedings of the CLEM-CIMAD 2017, Buenos Aires, Argentina, 17–19 May 2017.

- Ramage, M.H.; Burridge, H.; Busse-Wicher, M.; Fereday, G.; Reynolds, T.; Shah, D.U.; Wu, G.; Yu, L.; Fleming, P.; Dens-ley-Tingley, D.; et al. The wood from the trees: The use of timber in construction. Renew. Sustain. Energy Rev. 2017, 68, 333–359.

- Pretty, J.; Peacock, J.; Sellens, M.; Griffin, M. The mental and physical health outcomes of green exercise. Int. J. Environ. Health Res. 2005, 15, 319–337.

- Han, K.-T. Influence of Limitedly Visible Leafy Indoor Plants on the Psychology, Behavior, and Health of Students at a Junior High School in Taiwan. Environ. Behav. 2009, 41, 658–692.

- Hanie, O.; Aryan, A.; Mohammadreza, L.; Elham, L. Understanding the Importance of Sustainable Buildings in Occupants Environmental Health and Comfort. J. Sustain. Dev. 2010, 3, 194.

- Ghodrati, N.; Samari, M.; Shafiei, M.W.M. Green buildings impacts on occupants’ health and productivity. J. Appl. Sci. Res. 2012, 8, 4235–4241.

- Gray, T.; Birrell, C. Are Biophilic-Designed Site Office Buildings Linked to Health Benefits and High Performing Occupants? Int. J. Environ. Res. Public Health 2014, 11, 12204–12222.

- Kellert, S.R. Nature in buildings and health design. Sci. Adv. 2016, 5, 247–251.

- Yeager, D.S.; Hanselman, P.; Walton, G.M.; Murray, J.S.; Crosnoe, R.; Muller, C.; Tipton, E.; Schneider, B.; Hulleman, C.S.; Hinojosa, C.P.; et al. A national experiment reveals where a growth mindset improves achievement. Nature 2019, 573, 364–369.

- Makram, A.; Abou Ouf, T. Biomimetic and Biophilic Design as an Approach to Innovative Sustainable Architectural Design. Architecture & Urbanism. A Smart Outlook. In Proceedings of the Third International Conference of Architecture and Urban PlanningAt: Department Faculty of Engineering, Ain Shams University, Cairo, Egypt, 14–16 October 2019.

- Chowdhury, S.; Noguchi, M.; Doloi, H. Defining Domestic Environmental Experience for Occupants’ Mental Health and Wellbeing. Designs 2020, 4, 26.

- Steptoe, A.; Deaton, A.; Stone, A.A. Subjective wellbeing, health, and ageing. Lancet 2015, 385, 640–648.

- O’Brien, C.; Tranter, P.J. Planning for and with children and youth: Insights from children about happiness, well-being and walking. In Proceedings of the 7th International Conference on Walking and Liveable Communities, Melbourne, VIC, Australia, 23–25 October 2006.

- Oswald, A.J. Emotional Prosperity and the Stiglitz Commission. Br. J. Ind. Relat. 2010, 48, 651–669.

- Helliwell, J.; Layard, R.; Sachs, J. World Happiness Report; The Earth Institute, Columbia University: New York, NY, USA, 2012.

- Gilbert, P.; McEwan, K.; Catarino, F.; Baião, R. Fears of Negative Emotions in Relation to Fears of Happiness, Compassion, Alexithymia and Psychopathology in a Depressed Population: A Preliminary Study; Human Sciences Research Centre: Derby, UK, 2014; Available online: https://derby.openrepository.com/handle/10545/621736 (accessed on 16 February 2018).

- Jongbloed, J.; Andres, L. Elucidating the constructs happiness and wellbeing: A mixed-methods approach. Int. J. Wellbeing 2015, 5, 1–20.

- Steptoe, A. Happiness and health. Annu. Rev. Public Health 2019, 40, 339–359.

- Nyrud, A.; Bysheim, K.; Bringslimark, T. Health benefits from wood interior in a hospital room. In Proceedings of the International Convention of Society of Wood Science and Technology and United Nations Economic Commission for Europe, Geneva, Switzerland, 11–14 October 2010; Volume 1114.

- Nyrud, A.Q.; Bringslimark, T. Is interior wood use psychologically beneficial? A review of psychological re-sponses toward wood. Wood Fiber Sci. 2010, 42, 202–218.

- Cronhjort, Y.; Tulamo, T.; Verma, I.; Zubillaga, L. Interior Design and Care Environments End—User Perceptions of Wood Material. In Wood2New Competitive Wood-Based Interior Materials and Systems for Wood Construction; Aalto University: Espoo, Finland, 2017.

- Burnard, M.D.; Kutnar, A. Wood and human stress in the built indoor environment: A review. Wood Sci. Technol. 2015, 49, 969–986.

- Laireiter, C.M.; Schnabel, T.; Köck, A.; Stalzer, P.; Petutschnigg, A.; Oostingh, G.J.; Hell, M. Active Anti-Microbial Effects of Larch and Pine Wood on Four Bacterial Strains. BioResources 2014, 9, 273–281.

- Montibus, M.; Ismaïl, R.; Michel, V.; Federighi, M.; Aviat, F.; Le Bayon, I. Assessment of Penicillium expansum and Escherichia coli transfer from poplar crates to apples. Food Control 2016, 60, 95–102.

- Pailhoriès, H.; Munir, M.T.; Aviat, F.; Federighi, M.; Belloncle, C.; Eveillard, M. Oak in Hospitals, the Worst Enemy of Staphylococcus aureus? Infect. Control Hosp. Epidemiol. 2017, 38, 382–384.

- Ismail, R.; Aviat, F.; Gay-Perret, P.; Le Bayon, I.; Federighi, M.; Michel, V. An assessment of L. monocytogenes transfer from wooden ripening shelves to cheeses: Comparison with glass and plastic surfaces. Food Control 2017, 73, 273–280.

- Munir, M.T.; Pailhories, H.; Eveillard, M.; Aviat, F.; Lepelletier, D.; Belloncle, C.; Federighi, M. Antimicrobial Characteristics of Untreated Wood: Towards a Hygienic Environment. Health 2019, 11, 152–170.

- Alpert, P. Constraints of tolerance: Why are desiccation-tolerant organisms so small or rare? J. Exp. Biol. 2006, 209, 1575–1584.

- Milling, A.; Kehr, R.; Wulf, A.; Smalla, K. Survival of bacteria on wood and plastic particles: Dependence on wood species and environmental conditions. Holzforschung 2005, 59, 72–81.

- Vainio-Kaila, T.; Kyyhkynen, A.; Viitaniemi, P.; Siitonen, A. Pine heartwood and glass surfaces: Easy method to test the fate of bacterial contamination. Holz Roh Werkst. 2011, 69, 391–395.

- Hameury, S. The Hygrothermal Inertia of Massive Timber Construction. Ph.D. Thesis, Centre Scientifique et Technique du Bâtiment, Paris, France, 2006.

- Li, M.; Lam, F.; Foschi, R.O.; Nakajima, S.; Nakagawa, T. Seismic performance of post-and-beam timber buildings II: Reliability evaluations. J. Wood Sci. 2012, 58, 135–143.

- Takano, A. Wood in Sustainable Construction-A Material Perspective: Learning from Vernacular Architecture. Ph.D. Thesis, Department of Forest Products Technology, Aalto University, Finland, 2015.

- Bysheim, K.; Nyrud, A.Q.; Strobel, K. Building Materials and Well-Being in Indoor Environments A Focus Group Study Byggematerialer Och Velvære I Innendørs Miljø; Norsk Treteknisk Institutt: Oslo, Norway, 2016; Available online: https://www.wood2new.org (accessed on 4 December 2020).

- Teischinger, A. Opportunities and limits of timber in construction. In Proceedings of the World Conference on Timber Engineering WCTE 2016, Vienna, Austria, 22–25 August 2016.

- Jayalath, A.; Navaratnam, S.; Ngo, T.; Mendis, P.; Hewson, N.; Aye, L. Life cycle performance of Cross Laminated Timber mid-rise residential buildings in Australia. Energy Build. 2020, 223, 110091.

- Ostrowska-Wawryniuk, K. Prefabrication 4.0: BIM-aided design of sustainable DIY-oriented houses. Int. J. Arch. Comput. 2021, 19, 142–156.

- Williams, J. The role of spatial planning in transitioning to circular urban development. Urban Geogr. 2020, 41, 915–919.

- Giglio, A. Towards an Advanced Acoustic Ecology. In Material Balance; Springer: Berlin, Germany, 2021; pp. 115–127.

- Jovane, F.; Yoshikawa, H.; Alting, L.; Boër, C.; Westkamper, E.; Williams, D.; Tseng, M.; Seliger, G.; Paci, A. The incoming global technological and industrial revolution towards competitive sustainable manufacturing. CIRP Ann. 2008, 57, 641–659.

- Jänicke, M.; Jacob, K.A. Third Industrial Revolution? Solutions to the Crisis of Resource-Intensive Growth. 2009. FFU Report, Forthcoming. Available online: https://ssrn-com.dianus.libr.tue.nl/abstract=2023121 (accessed on 21 February 2021).

- Janicke, M.; Jacob, K. A Third Industrial Revolution? In Long-Term Governance for Social-Ecological Change; Siebenhüner, B., Arnold, M., Eisenack, K., Jacob, K.H., Eds.; Routledge: Oxfordshire, UK, 2013; ISBN 978-0-415-63352-9.

- Moavenzadeh, J. The 4th Industrial Revolution: Reshaping the Future of Production. In Proceedings of the DHL Global Engineering & Manufacturing Summit, Amsterdam, The Netherlands, 7 October 2015.

- Chou, S.Y. The fourth industrial revolution. J. Int. Aff. 2018, 72, 107–120.

- De Flander, K.; Rovers, R. One laminated bamboo-frame house per hectare per year. Constr. Build. Mater. 2009, 23, 210–218.

- Riala, M.; Ilola, L. Multi-storey timber construction and bioeconomy–barriers and opportunities. Scand. J. For. Res. 2014, 29, 367–377.

- Hospodarova, V.; Singovszka, E.; Stevulova, N. Characterization of cellulosic fibres by FTIR spectroscopy for their further implementation to building materials. Am. J. Anal. Chem. 2018, 9, 303–310.

- Shupe, T.; Lebow, S.; Ring, D. Causes and Control of Wood Decay, Degradation and Stain (Pub. 2703); Louisiana Cooperative Extension Service: Baton Rouge, LA, USA, 2008.

- Cruz, H.; Jones, D.; Nunes, L. Chapter 12-wood. Materials for construction and civil engineering. In Science, Processing and Design; Clara, G.M., Margarido, F., Eds.; Springer: Berlin/Heidelberg, Germany, 2015; pp. 557–583.

- Green, M. The ‘Mass Timber Revolution’ is Coming. Renewable Carbon News. Available online: https://renewable-carbon.eu/news/the-mass-timber-revolution-is-coming/ (accessed on 31 July 2018).

- Kaiser, B. A Sustainable Timber Skyline: The Future of Design. In Proceedings of the TED Conferences, Portland, OR, USA, 17 July 2017.

- Igarashi, T. Public works at a crossroads. Soc. Sci. Jpn. 1999, 17, 3–5.

- Feldhoff, T. Japan’s construction lobby activities–Systemic stability and sustainable regional development. Asien 2002, 84, 34–42.

- Hemström, K.; Mahapatra, K.; Gustavsson, L. Architects’ Perception of the Innovativeness of the Swedish Con-Struction Industry; Construction Innovation: Bingley, UK, 2017.

- Leskinen, P.; Cardellini, G.; González-García, S.; Hurmekoski, E.; Sathre, R.; Seppälä, J.; Smyth, C.; Stern, T.; Verkerk, P.J. Substitution effects of wood-based products in climate change mitigation. In From Science to Policy; European Forest Institute: Joensuu, Finland, 2018.

- Dodoo, A.; Gustavsson, L.; Sathre, R. Carbon implications of end-of-life management of building materials. Resour. Conserv. Recycl. 2009, 53, 276–286.

- Dodoo, A.; Gustavsson, L.; Sathre, R. Effect of thermal mass on life cycle primary energy balances of a concrete- and a wood-frame building. Appl. Energy 2012, 92, 462–472.

- Coelho, A.C.; Lopes, A.; Branco, J.M.; Gervásio, H. Comparative Life-cycle assessment of a single-family house: Light steel frame and timber frame. In Towards Forest Products and Processes with Lower Environmental Impact; University Fernando Pessoa: Porto and Ponte de Lima, Portugal, 2014; p. 31.

- Dodoo, A.; Gustavsson, L.; Sathre, R. Recycling of Lumber. In Handbook of Recycling; Elsevier: Amsterdam, The Netherlands, 2014; pp. 151–163.

More