Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 2 by Sirius Huang and Version 1 by Zhengjun Qiu.

Aquaponics is an innovative, smart, and sustainable agricultural technology that integrates aquaculture (farming of fish) with hydroponics in growing vegetable crops symbiotically. The correct implementation of aquaponics helps in providing healthy organic foods with low consumption of water and chemical fertilizers. Numerous research attempts have been directed toward real implementations of this technology feasibly and reliably at large commercial scales and adopting it as a new precision technology. For better management of such technology, there is an urgent need to use the Internet of things (IoT) and smart sensing systems for monitoring and controlling all operations involved in the aquaponic systems.

- aquaponics

- Internet of Things (IoT)

- smart systems

1. Smart System-Based Aquaponics

The application of smart systems in agriculture is known as precision agriculture (PA), which aims to gather, process, and analyze temporal, spatial, and plant morphological features and combine them with other available information to support management decisions for optimizing growth inputs and preserving resources in terms of water and nutrients. Aquaponics includes this feature and can be adopted as a precision technology if it is monitored and controlled by modern technologies such as IoT and ICT. Integrating smart technologies into aquaponics systems helps mitigate production times, reduce the need for labor to manage systems, improve product quality, and provide more sustainability. The applications of artificial intelligence to predict various parameters in aquaponics systems are still under intensive investigation by researchers. In general, the main goal is usually to build a smart, self-regulating aquaponic system using a wireless sensor network (WSN). In the smart aquaponics system, real-time monitoring of the essential parameters (e.g., pH, DO, temperature, flow rate, nutritional levels, etc.) is performed, along with building different modeling approaches for predicting other future values of these aquaponics parameters to take smart proactive action [56,57][1][2]. Table 41 shows a summary of the different degrees of control over the aquaponics system, showing the development of the aquaponics system from early manual monitoring to the construction of a smart system to employ automatic control.

Table 41.

Summary of different control degrees implemented in traditional and modern aquaponic systems.

| System Control Degree | Technique or Method | Component | Ways of Data Acquisition | Data Acquisition | Control Unit | Effect | Advantages/Disadvantages | References |

|---|---|---|---|---|---|---|---|---|

| Manual control | Manual control | A fish-rearing tank, a solids-removal unit, two hydroponic tanks, and a reservoir | Experience | Sludge, DO, and pH |

Vertical-lift pump, drain valve, and add small amounts of base to regulate | Well suited for tropical regions where fresh water is scarce or level farmland is limited. | Low efficiency, inevitable mistakes, and more maintenance costs | [58][3] |

| Fish rearing, Solids removal, and hydroponic components | DO, water T, and pH | Chillers and evaporative cooling towers, pump, and feeders | Meet the need for more food fish and plant crop production in small Caribbean islands. | [59][4] | ||||

| Auto-Control | Control by using timers | Fish-holding tank, associated biofilter, and hydroponic growth bed | Meter and sonde probe, multiparameter meter, and various reagents. | Flow | Water pump, airlift, valve in the hydroponic bed drain line, and lighting unit | Managing the flow rate increases both biomass and yield. | Increased efficiency, automation control is realized, and higher management accuracy | [60][5] |

| Recirculating aquaculture system (RAS). |

YSI multi-probe meter (model YSI 550A) and pH cyber scan waterproof |

DO, water T, and pH | Adjust the gate valves, air stones, and connected to an air blower |

Effectively guarantee the flow rate of water, and stable operation of the system is guaranteed | [61][6] | |||

| Smart monitoring and control system | IoT | A fish-rearing tank, biofilter, Hydroponic growth bed | pH, EC, T, Level, Do, Air T, RH, Light sensors | pH, EC, water T, water level, Do, air T, RH, and light | Water heater, air pump, light-emitting diode grow lights, and exhaust fan |

Effective and efficient aquaponics system | Efficacy automated aquaponics, minimal costs, and human intervention | [25][7] |

| Microcontroller, sensor, web interface, display, pump, feeder, and emergency source |

pH and T sensors | pH and water T | Water pump and fish feeder | The ultrasonic sensor has a 99.94% success rate, pH sensor of 92.35%, and T sensor of 97.91%. | Autonomous monitoring | [62][8] | ||

| Source node, sink, database server, and visualization in mobile application | Level, T, pH, and TAN sensors | Water level, T, pH, and TAN | Water heater, coolant, fish feeder, and ammonia alarm | The plant growth was improved | [35][9] | |||

| Fish feeder and water supplier | T, water level, and moisture sensors | T, water level, and moisture content | Water pump, oxygen pump, fish feeder, and LED light | The climate has the least or no interference in the aquaponics, cost-effective, and less water consumption | [63][10] | |||

| IoT and deep learning | Recirculating aquaculture system, actuators, and sensors | DHT11, BH1750 light, soil moisture, HC-SR04 water level, and pH sensors | Air T, RH, soil moisture, light, water level, and pH | Water pump, and lamps, | Helped enhance the plant and fish growth. | [64][11] | ||

| Websocket | pH, water temperature monitoring system and controlling system |

DS18B20, DFROBOT analog pH, and water level sensors | Water T, water level, pH | Water pump, lights, fan, and lamp | Allows displaying multiple aquaponic parameter in specified delayed time |

Automatic early warning | [34][12] | |

| Raspberry Pi | Data acquisition, alarm, unit, web application, mobile application, and cloud server | T, pH, flow, light, and plant height sensors | T, pH, flow, light, plant height | Water heater, water pump, LED grow light, and fish feeder | Self-sustainable, cost-effective, and eco-friendly urban farming | Autonomous monitoring | [39][13] | |

| Fuzzy logic | Microcontroller, relay control, and fuzzy interface system | Water T, air T, pH, and luminance sensors | Water/air T, pH, light and intensity | Light, heater, and alarm | Accurate, low cost, and convenient | Continuous autonomous monitoring | [37][14] | |

| Open Wrt and WRT node | Data acquisition, mobile transfer, and smart application | Water T, water level, and RH sensors | Water T, light, water level, DO, and RH | Water pump, air pump, feeder, and lamps | Monitoring and controlling smart aquaponics remotely | Store data in cloud and analyzing data using smart technology | [33][15] | |

| Arduino microcontroller | controller, actuators, and sensors | Water T, and float sensors | Water T, water level, amount of food | Feeder, pump, and dimmer | Closed loop control system, and plant grow successfully | Continuous autonomous monitoring | [38][16] | |

| Hydroponics, aquaculture, and water reservoir | Water level and water T sensors | Water level and water T | DC motor, LED, an alarm | All functionality of the system were working as intended | [65][17] |

1.1. Microcontrollers Used in Smart Aquaponics

A microcontroller is an integrated circuit designed to control a specific operation in an integrated system. It includes a processor, memory, and input and output peripherals on a single board or chip. Such circuits could be circuits embedded in vehicles, robots, industrial machines, medical devices, mobile radio transceivers, vending machines, and household appliances. Most of these devices are rather compact compared to large computers. Microcontrollers, therefore, represent perfect tools for the control of smart aquaponics devices. Different technologies may differ in their computational capabilities, speed, and energy consumption. None of these criteria constitute critical parameters in smart aquaponics since the process of growth is relatively slow. Consequently, low-cost systems have been introduced for possible use in the literature, as shown in Table 3 wiith Arduino or Raspberry pi devices [38,39,65][13][16][17].

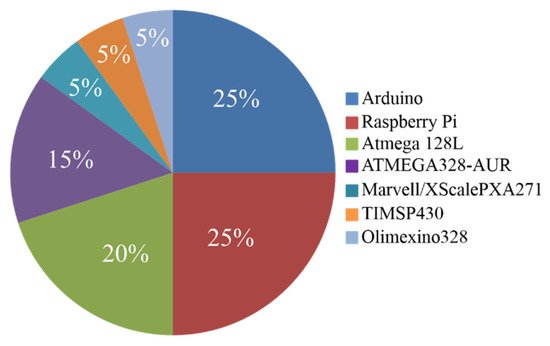

The microcontroller acts as a cornerstone in providing smart services as it enables devices to work together as a single system [66][18]. The information sensed by the sensors is used as an input to the microcontroller, then the microcontroller generates signals for the actuators and controls the system to reach the target state [67][19]. So, it is not possible to create a sensor system without using some kind of microcontroller. Many microcontrollers are available on the market, such as Arduino, Raspberry Pi, Atmega 128L, etc. The distribution of research papers based on the types of microcontrollers used is shown in Figure 51. The Arduino Mega microcontroller was used to feed the sensor outputs to the actuators and Raspberry Pi was used as the central control unit for the smart aquaponics system designed by Kyaw and Ng [39][13]. In the smart aquaponics system, Mahkeswaran and Ng [25][7] used an Arduino Mega 2560 microcontroller as the central processing unit. Pasha et al. used a Raspberry Pi microcontroller as the gateway to the sensor readings and control of those read by Arduino [34][12]. All microcontrollers integrated with the aforementioned aquaponics have been verified to be efficient and accurate in receiving signals from sensors and sending commands to actuators.

Figure 51.

Distribution of research papers based on the types of microcontrollers.

1.2. Neural Networks and Deep Learning Methods for Smart Aquaponics

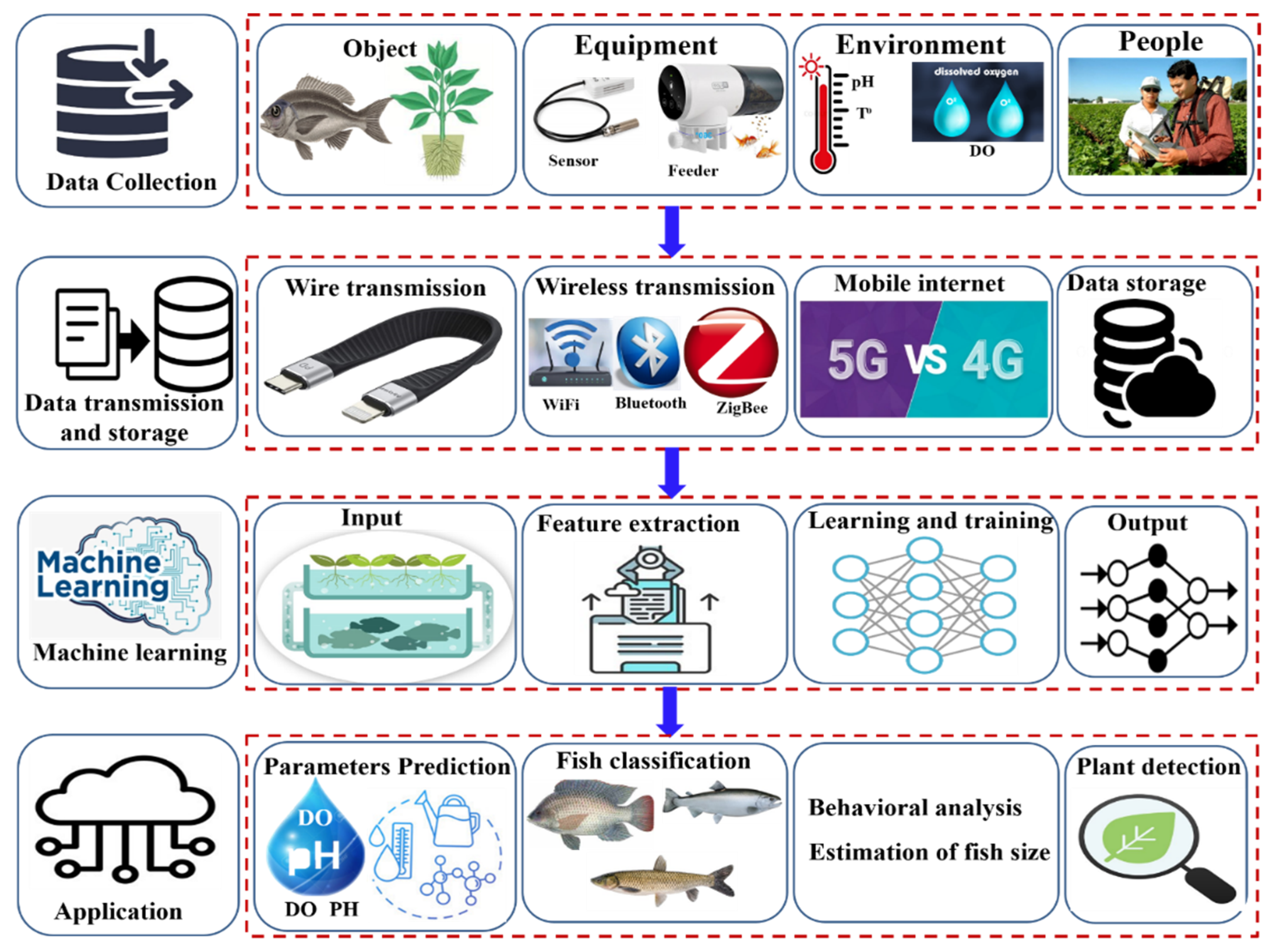

The development of computational systems, especially Graphical Processing Unit (GPU)-embedded processors, became a necessity in modern computer-integrated artificial intelligence applications. This has led to the emergence of new methodologies and models that now constitute a new category, namely deep learning [68][20]. Deep learning methods are based on networks of artificial neurons. When optimized, they have been demonstrated to be of high value for various tasks (classification, regression, image segmentation, object detection, etc.) where both feature extraction and decision making are trained end-to-end. Deep learning models have achieved remarkable success in many agricultural applications such as detecting and diagnosing plant disorders [69][21], predicting plant water content [70][22], and identifying plant species [71][23]. In addition to the contributions of deep learning in the field of aquaculture, such as fish detection and classification [72][24], estimating the age and size of fish [73][25], behavior analysis [74][26], and feeding decisions [75][27], there are dozens of other potential applications of this approach in smart aquaponics systems. Figure 6 2 shows deep-learning-enabled advanced applications for smart aquaponics.

Figure 62.

Neural networks and deep-learning-enabled advanced analytics applied for different tasks in smart aquaponics.

Deep neural networks consist of several deep layers (hidden layers), which means there are many layers between the input and output. The huge increase in both dataset size and the huge surge in computing power have led to the emergence of a new class of deep neural networks, Convolutional Neural Networks (CNNs), with huge potential in big data analysis. CNNs are very powerful in object recognition and image classification. CNNs are trained on the images to be analyzed, and during the training process, the network automatically recognizes the high-dimensional features of all the input images. Once the training process is completed, the trained networks are used to identify and classify the different images.

1.2.1. Prediction of Water Quality Parameters

Predicting changes in water quality parameters is critically important for better management of aquaponics systems, in order to take precautionary actions before harm occurs to the fish or the whole system. For instance, the concentration of dissolved oxygen in aquaponics was predicted based on both neural networks and genetic algorithms [76,77][28][29]. Furthermore, the water temperature, pH, salinity, water level, relative humidity, and light intensity were modeled by developing a smart IoT-based hydroponic system using deep neural networks and a Long-Short Term Memory (LSTM) algorithm. More importantly, the trained model was installed in a microcontroller (e.g., Raspberry Pi) to control the output and manage the operation of the whole system [78,79,80][30][31][32]. For the prediction of EC and pH, Pitakphongmetha et al. used an artificial neural network with temperature, light intensity, humidity, plant age, pH, and EC as inputs of the network. Then, the error between the expected values and the sensor output was used to monitor and control the factors [81][33].

1.2.2. Fish Detection and Species Classification

The availability of an accurate mechanism for automatic fish detection and species classification would support the sustainability of aquaponics systems, especially in large-scale commercial systems. For instance, an efficient framework for the automatic detection of fish in underwater videos was developed with an accuracy of 95.47% using ResNet-50 with the YOLO (You Only Look Once) deep neural network model [82][34]. Another approach to detecting moving live fish in open aquatic environments was suggested, using an area-based CNN with a detection accuracy of 87.44% [83][35]. The detection is also extended to include the detection of fish diseases, such as in the work of Hasan et al. who developed a CNN model for the detection of two fish diseases, namely red spot and white spot, with a detection accuracy of 94.44% [84][36]. A multi-procedure method for classifying tuna fish was also developed by integrating image processing with a network (Mask R-CNN), and then all segmented images were categorized by the ResNet50V2 network. The proposed method achieved a classification accuracy of 70% [72][24].

1.2.3. Estimation of Fish Size

Fish size estimation is one of the most key variables for both making short-term management decisions and modeling stock trends. In this regard, Region-based Deep Convolutional Neural Network (R-CNN) algorithms were the most widely used algorithms in the literature for the length measurement of fish [73,85,86][25][37][38] as detailed in Table 41. To estimate the length of pond fish, Lu and Ma used a multi-camera CNN, and their results proved that the model had a very good accuracy of 93.93% [87][39]. Junior et al. compared a set of convolutional neural networks (InceptionV3, Exception, VGG19, VGG16, and ResNet50) for the automatic estimation of the mass of Pintado Real fingerlings. ResNet50 achieved the highest accuracy of 67.08% [88][40].

1.2.4. Feeding Decisions

Apart from the loss of profits due to overfeeding, food waste accumulating from poor feeding strategies of aquaculture farms can harm the aquaponics environment. The integration of smart systems with the aquarium helps in evaluating the level of fish satiety, controlling the quantity of food, as well as making feeding decisions. Ubina et al. developed a smart system for assessing the feeding intensity of fish in aquaculture using convolutional neural networks, with an accuracy of 95% [75][27]. Måløy et al. developed a deep video classification model to identify salmon feeding behavior or non-feeding. The proposed Dual-Stream Recurrent Network captures the Spatio-temporal behavior of salmon species with a prediction accuracy of 80% [89][41]. Adegboye et al. evaluated feeding behavior predicated on Noda and Gleiss’s research sample dataset used in prior research. The results revealed that when the Fourier descriptor threshold was 0.5, the accuracy was 100%. Thus, the intelligent feeding of fish could be accurately achieved [90][42].

1.2.5. Plant Detection

In general, convolutional neural networks are extensively used to assess crop quality. In this vein, Mohanty et al. compared two well-established structures in identifying 26 plant diseases. Their results were very promising, with automatic recognition success rates reaching 99.35% [91][43]. Recently, convolutional neural networks were also applied to monitor the growth rate of lettuce in hydroponic systems [92][44]. Furthermore, a novel deep recurrent neural network (RNN) in combination with the long-term memory (LSTM) neuron model was used to predict the tomato yield and stem growth of Ficus Benjamina in a greenhouse. The proposed method performed well [93][45]. More recently, Taha et al. used a CNN (ResNet18 and Inceptionv3) to diagnose the nutrient deficiencies of lettuce grown in aquaponics. The results demonstrated that the proposed deep model (Inceptionv3) obtained an accuracy of 96.5 % [69][21]. Table 52 summarizes the results and outcomes obtained from these research endeavors in terms of the prediction of water quality parameters, detection and species classification, estimation of fish size, feeding decisions of fish, and plant detection using deep learning.

Table 52. Prediction of water quality parameters, detection and species classification, estimation of fish size, feeding decisions of fish, and plant detection using deep learning.

| Application | Models/Algorithm Technology |

Results/Accuracy | Reference |

|---|---|---|---|

| Predicting DO | DCNN and genetic algorithms | — | [76][28] |

| Predicting water temperature, pH, salinity, water level, relative humidity, and light intensity | DCNN | — | [78][30] |

| Monitoring and predicting temperature, DO, salinity, and pH of water using | DCNN and LSTM algorithm | — | [79][31] |

| Predicting dissolved oxygen | DCNN | — | [77][29] |

| Prediction of EC and pH | artificial neural network | — | [81][33] |

| Predicting the content of both chlorophyll (Chl-a) and DO using CNN-LSTM prediction model | Hybrid CNN–LSTM deep learning model | — | [80][32] |

| Detecting fish in underwater videos | ResNet-50 with YOLO (You Only Look Once) | 95.47% | [82][34] |

| Detecting moving live fish | DCNN | 87.44% | [83][35] |

| detection of fish disease | DCNN | 94.44% | [84][36] |

| Classifying tuna fish | R-CNN and ResNet50V2 | 70% | [72][24] |

| Estimating fish length | R-CNN | 99% | [73][25] |

| Fish length | R-CNN | 97.8% | [85][37] |

| Estimation of fishs length | Local gradient technique and Mask RCNN | 0.89 | [86][38] |

| Estimation the pond fish length | CNN | 93.93% | [87][39] |

| Estimation of fingerlings mass | InceptionV3, Exception, VGG19, VGG16, and ResNet50. | 67.08% | [88][40] |

| Assessing the feeding intensity of fish | Convolutional neural networks, | 95% | [75][27] |

| Identify salmon feeding behavior or non-feeding | Dual-Stream Recurrent Network | 80% | [89][41] |

| Prediction feeding behavior | Artificial neural networks | 100%. | [90][42] |

| Plant disease detection | CNN | 99.35% | [91][43] |

| Diagnose nutrient deficiencies of lettuce | ResNet18 and Inceptionv3 | 96.5% | [69][21] |

| Monitor the growth rate of lettuce | Mask R-CNN | 97.63% | [92][44] |

| Prediction tomato yield and stem growth | RNN with LSTM | Performed well | [93][45] |

1.3. Aquaponics and Industry 4.0

Industry 4.0 is an initiative that integrates many emerging technologies such as artificial intelligence (AI), the Internet of Things (IoT), big data and analytics (BDA), cyber-physical systems (CPS), wireless sensor networks (WSN), autonomous robot systems (ARS), interconnectivity, automation, machine learning, real-time data acquisition, and cloud computing [94,95][46][47]. Accordingly, the concept of a smart system is closely related to Industry 4.0 itself, involving algorithms and complex logical processes [50][48]. To implement the commercial aquaponics systems, enhance its capabilities, and increase its production efficiency, there is an urgent need to integrate Industry 4.0 technologies in such systems [96][49]. Hence, the term Aquaponics 4.0 emerged as a counterpart of Industry 4.0 as it is a digital agricultural ecosystem based on the use of the aforementioned technologies for operation, monitoring, autonomous control, and intelligent decision making in all aquaponics operations [96][49]. At the industry level, the realization of aquaponics 4.0 makes the aquaponics system more flexible and adaptable to ecosystems. The realization of aquaponics 4.0 requires the effective integration of data from different sources or from a whole web different sensing devices. These data are stored, classified, extracted, and processed to extract useful knowledge to solve real-world problems in real-time, not only to improve the system efficiency but also to revolutionize the way in which the system is operated and managed [96][49].

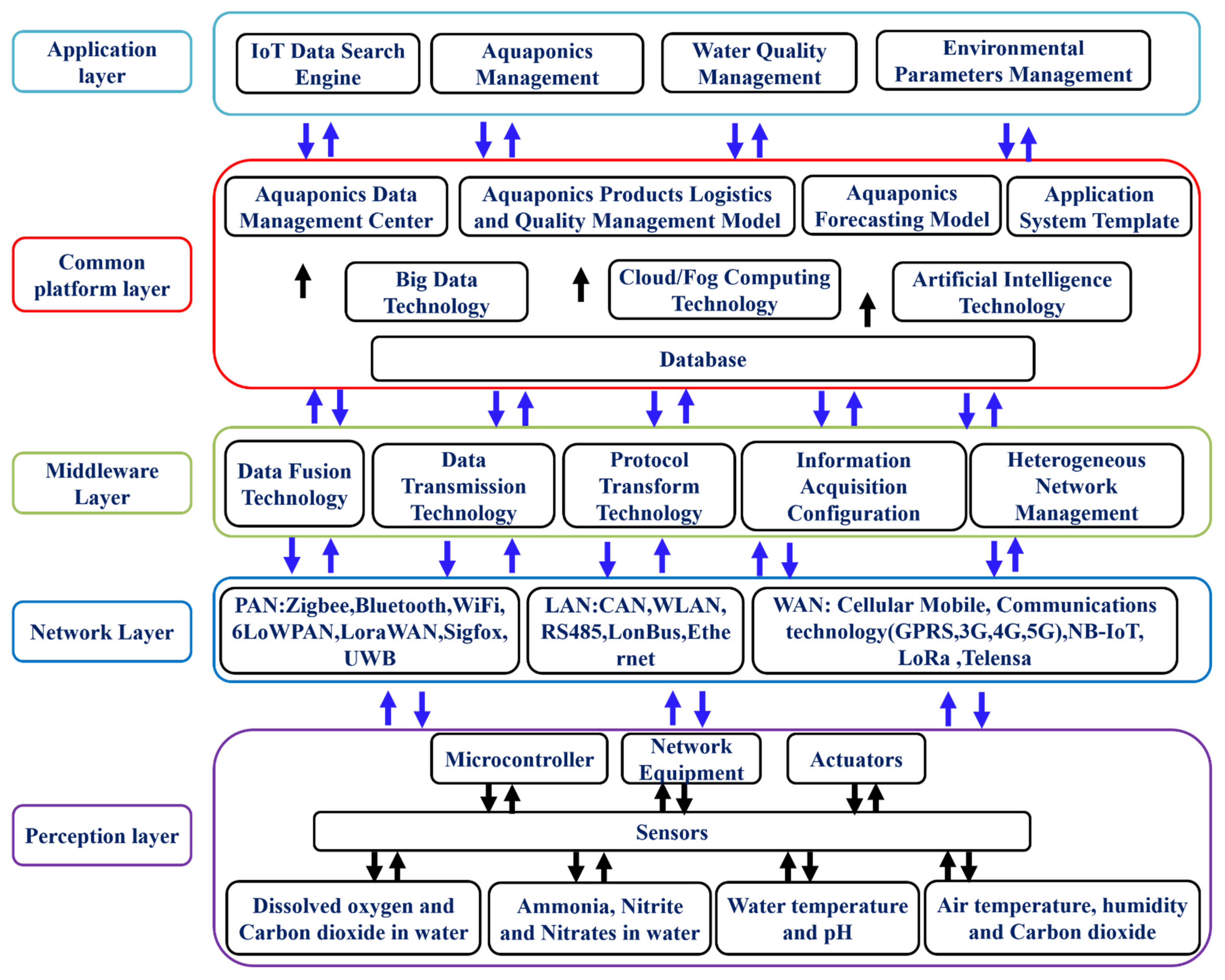

2. IoT-Based Aquaponics

As shown in Figure 73, the structure of the IoT applied in aquaponics systems and protected agriculture scenarios consists of five layers [97][50]:

Figure 73.

Structure of IoT in aquaponics.

-

Perception Layer: This layer consists of various sensors for acquiring aquaponics parameters (such as DO, T, pH, and EC), various actuators and microcontrollers, a wireless sensor network (WSN), Radio-frequency identification (RFID) tags, readers, and so on.

-

Network layer: This is the infrastructure of an IoT system, which includes a group of different wired (CAN bus and RS485 bus) and wireless (Zigbee, Bluetooth, and LoRa) communication networks. This network transmits the information collected by the perception layer to the upper layer and sends control commands from the application layer to the perception layer to take appropriate action in devices related to the sensing layer.

-

Middleware Layer: This layer collects data and procedures received from IoT devices to provide developers with a more versatile tool for building their applications. There are different types of middleware such as HYDRA, UBIWARE, UBIROAD, SMEPP, SOCRADES, GSN, and SIRENA.

-

Common platform layer: This layer consists of common processing technologies such as fog computing, cloud computing, machine, and deep learning algorithms, as well as their establishment models. This layer is responsible for storing, making decisions, statistics, and creating intelligence algorithms such as control, decision making, forecasting, and early warning.

-

Application layer: This is the highest level of the IoT structure and the position in which the importance and value of IoT is more clearly visible to the final users. This layer includes many smart platforms and systems for monitoring, real-time environmental control, and early warning of various diseases and disorders. All of these measures can contribute to improving the final product and saving effort, time, and costs.

In brief, if IoT in agriculture was applied correctly, it can bring a new green revolution. The capacity of networks can be enhanced by using 4G and 5G technologies, which makes the use of IoT technologies more feasible, in addition to creating new communication technologies. In the modern era of artificial intelligence of things (AIoT) and 5G, early warning and remote monitoring based on an autonomous wireless sensing system are critical. IoT has been used in three axes: Monitoring interfaces, remote applications, and Wireless Sensor Networks (WSN).

2.1. Remote Monitoring Interfaces

Remote monitoring interfaces are often the medium that humans use to interact with computers or machines. Currently, IoT is applied in many monitoring activities for agricultural environments such as hydroponics and aquaponics. IoT technologies allow us to improve the quality of aquaponics products (plants and fish), increase their sustainability, and support the decision-making of aquaponic systems managers. Recently, the wireless monitoring system that integrates monitoring interfaces, wireless networks, multiple types of electronic devices, and sensors with connectivity capability is widely distributed in multiple scenarios such as smart farming, smart city, and environmental detection. IoT technology enables monitoring interfaces to display values sensed by wireless networks in real-time. In this context, aquaponics parameter-monitoring systems were designed using IoT in combination with microcontrollers. The sensed parameter data are sent to a web-based platform to be stored and displayed on a graphical user interface (GUI) in real-time [19,98,99,100][51][52][53][54]. Recently, Elsokah and Sakah developed an iOS app that allows for real-time and continuous monitoring of an aquaponics ecosystem through data obtained directly from sensors and microcontrollers [101][55]. These collaborations are heading towards information reliability and real-time mobility (through mobile applications, not only on the web). More recently, a remote monitoring system was designed using IoT combined with Convolutional Neural Networks (CNN) to monitor the greenhouse environment using an A6 GSM module to develop an android mobile application for notifying operators of any changes that occurred in the system by sending an alert in case of an anomaly [32][56]. Continuous monitoring of these parameters will provide a healthy environment for fish and plants while saving approximately 90% of the water used in traditional farming systems [98][52].

2.2. Remote Control Applications and Strategies

Remote control refers to the ability to send certain signals to system operators to interact or change the state of a certain environmental parameter. The potential of these applications does not stop at mere monitoring, but also extends to control systems and actuators. Using remote control applications, operators can control pumps, artificial lights, fans, ventilation pumps, and other different actuators.

Wang et al. developed an Intelligent Voice Control System (IVCS) combined with IoT to monitor and control aquaponic parameters [102][57].

Many applications of remote control were found in the literature using various communication technologies and microcontrollers. To design an IoT-based monitoring and control system for aquaponics environmental parameters, a NodeMCU microcontroller with a Wi-Fi module was used to connect to the Internet. The data are sent to the Blynk–IoT (a multi-language platform that enables remote control of different microcontrollers), and finally, the local server receives the measurements and sends them to the mobile phone. In these systems, the operators control the different actuators in real-time by sending a message to the receptor [24,25,81][7][33][58]. A simple GSM Arduino-based monitoring and control system was developed to notify farmers when aquaponics parameter measurements are outside the specified ranges where the measurements were displayed on a GUI. This system enables operators to control various parameters in real-time [31,63][10][59]. An IoT-based monitored and controlled aquaponics system using a microcontroller (Raspberry Pi and Arduino) was also applied to monitor water quality parameters in aquaponics systems. System information was displayed to enable operators to control different actuators [18,103][60][61]. Using the Modbus TCP protocol, another IoT-based remote monitoring and control system for aquaponics was created to extract data from sensing nodes [104][62]. Lastly, an IoT system was utilized to monitor and control the parameters of the aquaponics system using a microcontroller connected to the web via Ubuntu IoT Cloud [62][8].

The monitoring and control framework of the aquaponics system consists of three basic stages, as shown in Figure 84. The first stage is data acquisition using various sensing devices. In aquaponics, there are two main components from which data are sensed: Water and the environment. There are many methods of sensing water, from the traditional methods (e.g., the floating method, the volumetric method) to modern methods using different sensors [105][63]. Then the data are stored and processed using different algorithms and processing tools [106][64]. At the end, the processing commands are sent to different actuators, and the operation and control are then performed automatically.

Figure 84.

Schematic diagram of detection and control system for aquaponics system.

Generally, three different types/levels of monitoring and control strategies were observed. The main control strategies are to monitor the various quality and operation parameters using various sensors and control them using microcontrollers, such as the contribution of Murad et al., who used sensors controlled by an Arduino microcontroller and connected to the GSM interface to send alarms/notifications to the operator as a proactive action based on the defined levels of the sensors [107][65]. The next level involves wireless data collection and analysis using a cloud server. In the contribution of Wang et al., Arduino, OpenWrt, and WRTnode were used to connect field monitoring and remote monitoring centers for collecting information and managing the aquaponics system. The information was collected and sent wirelessly to the management and control center for storage, processing, and transmission to a remote server. The data stored in the server are analyzed and decisions are made regarding the different actuators, such as artificial lights, water, and air pumps [33][15]. Finally, the control systems found in the contributions listed in this paper aim to implement autonomous systems by using a variety of techniques that shift from traditional linear regression to complex prediction approaches such as convolutional neural networks (CNN). In Kumar et al.’s system, WSN (6LoWPAN PROTOCOL) was included to monitor and control the nitrate level, pH, and temperature [56][1]. Their network conceived a 10 m communications range and a transfer rate of 250 kbit/s. Moreover, in this system, the IBM Mote Runner (run-time platform) is used as a sensor network. In addition, to collect and store information from the set of sensors, a cloud data storage system was used. Then the time-series values of different variables were predicted with the help of trend analysis. To predict the levels of pH and nitrates, linear regression was implemented to create an automated aquaponics system concerning these two parameters.

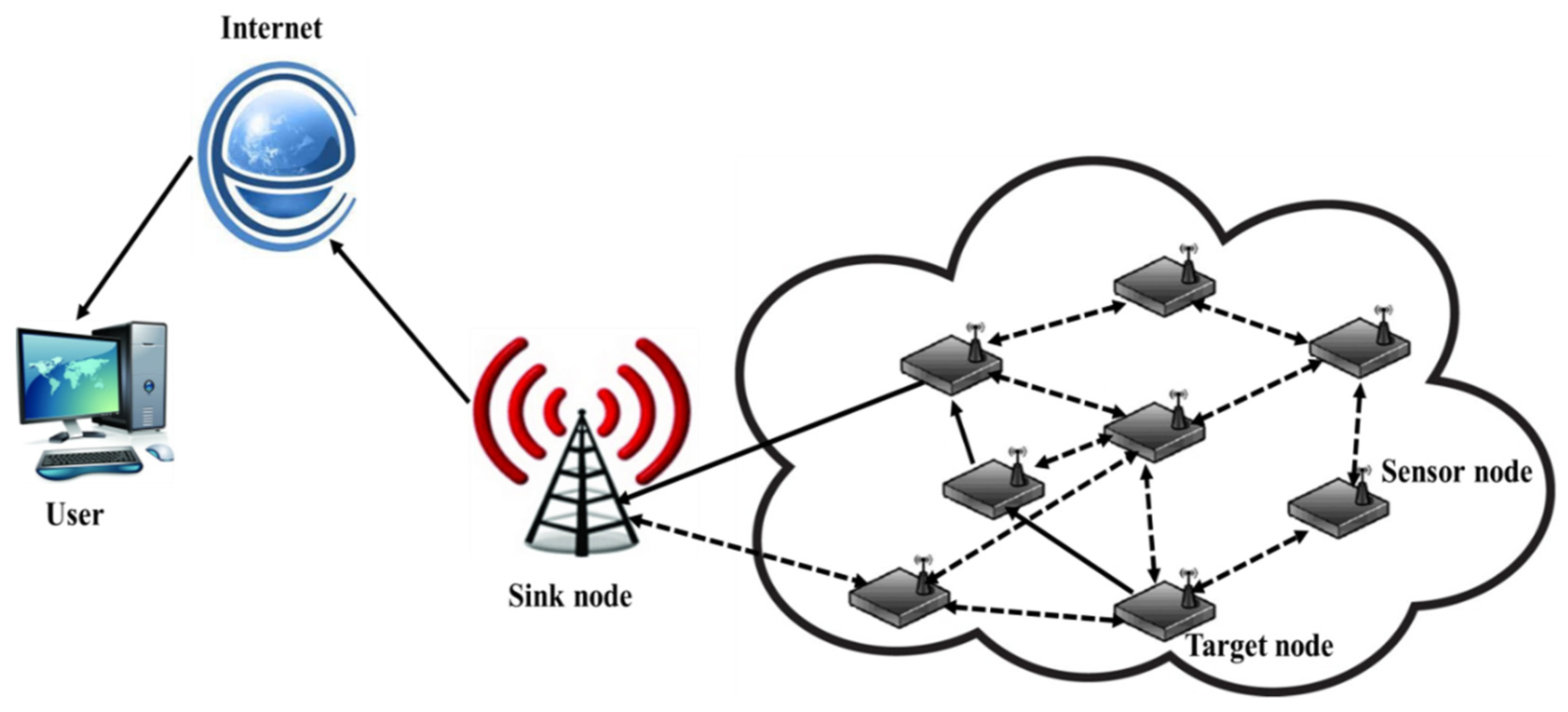

2.3. Wireless Sensor Network (WSN)

WSN consists of a group of smart devices used to collect application-oriented data requirements called “nodes”, as shown in Figure 95. Sensing, communication, and computation using software and algorithms are the main functions of sensor networks. There are two types of nodes based on the function the node performs. The nodes that collect basic information from the field are called the source node and they also act as routing nodes due to the multiplicity of routing hops. Meanwhile, the node that collects information from the source nodes is called the sink node or the gate node. Applications of wireless technologies are often not presented alone and are mostly associated with remote monitoring or control interfaces. However, contributions focused on the application of wireless networking techniques to develop connectivity in aquaponics were found. Wang et al. designed a smart system to monitor and control aquaponics using wireless sensor network (WSN) technologies and an Arduino microcontroller with a Wi-Fi module. The data are stored on the WRT nodes and then transmitted via Wi-Fi to the OpenWrt server [33][15]. Kumar et al. Used the 6LOWPAN protocol and WSN to design a monitored and controlled aquaponics system [56][1]. To monitor the temperature and pH of the water in the aquaponics system, GSM technology was used to send an alert message to the operator if the values were outside the specified range [107][65]. To collect and store data from the aquaponics system, Mamatha and Namratha used the ThingSpeak data logging platform [108][66]. Sreelekshmi and Madhusoodanan monitored aquaponics using the ThingSpeak IoT platform combined with an Arduino Uno microcontroller and a transceiver (ESP8266-01 Wi-Fi) [27][67]. To design an IoT-monitored and -controlled aquaponics system, Jacob used a Raspberry Pi microcontroller equipped with a Wi-Fi module. Cloud-based platforms integrating an IoT dashboard and Freeboard were used to collect, store, and control target parameters [51][68]. The application of wireless technologies for transmitting data and integrating them with sensors is a promising field in the development and improvement of monitoring and control techniques. Table 63 lists current wireless communication technologies.

Figure 95.

Wireless Sensor Network (WSN).

Table 63.

Wireless communication technologies.

| Parameters | Standard | Frequency Band | Data Rate | Transmission Range | Consumption | Cost |

|---|---|---|---|---|---|---|

| WiFi | IEEE 802.11a/c/b/d/g/n | 5–60 GHz | 1 Mb/s–7 Gb/s | 20–100 m | High | High |

| ZigBee | IEEE 802.15.4 | 2.4 GHz | 20–250 kb/s | 10–20 m | Low | Low |

| LoRa | LoRaWAN R1.0 | 868/900 MHz | 0.3–50 kb/s | <30 Km | Very low | High |

| RFID | ISO 18000-6C | 860–960 MHz | 40 to 160 kb/s | 1–5 m | Low | Low |

| Mobile communication | 2G-GSM, CDMA 3G-UMTS, CDMA2000, 4G-LTE, GPRS | 865 MHz, 2.4 GHz | 2G: 50–100 kb/s 3G: 200 kb/s 4G: 0.1–1 Gb/s |

Entire Celluar Area | Low | Low |

| Bluetooth | IEEE 802.15.1 | 24 GHz | 1–24 Mb/s | 8–10 m | Very low | Low |

References

- Kumar, N.H.; Baskaran, S.; Hariraj, S.; Krishnan, V. An autonomous aquaponics system using 6lowpan based wsn. In Proceedings of the IEEE 4th International Conference on Future Internet of Things and Cloud Workshops (FiCloudW), Vienna, Austria, 22–24 August 2016.

- Da Silva, L.F.; Yang, Z.; Pires, N.M.; Dong, T.; Teien, H.-C.; Storebakken, T.; Salbu, B. Monitoring aquaculture water quality: Design of an early warning sensor with Aliivibrio fischeri and predictive models. Sensors 2018, 18, 2848.

- Rakocy, J.E. Aquaponics-integrating fish and plant culture. In Book Aquaculture Production Systems, 1st ed.; James, H., Tidwell, A., Eds.; John Wiley & Sons, Ltd.: Oxford, UK, 2012; pp. 344–386.

- Rakocy, J.E.; Shultz, R.C.; Bailey, D.S. Commercial aquaponics for the Caribbean. In Proceedings of the 51st Gulf and Caribbean Fisheries Institute (GCFI). 2000. Available online: http://hdl.handle.net/1834/29306 (accessed on 15 July 2022).

- Lennard, W.A.; Leonard, B.V. A comparison of reciprocating flow versus constant flow in an integrated, gravel bed, aquaponic test system. Aquac. Int. 2004, 12, 539–553.

- Endut, A.; Jusoh, A.; Ali, N.; Nik, W.W.; Hassan, A. A study on the optimal hydraulic loading rate and plant ratios in recirculation aquaponic system. Bioresour. Technol. 2010, 101, 1511–1517.

- Mahkeswaran, R.; Ng, A.K. Smart and Sustainable Home Aquaponics System with Feature-Rich Internet of Things Mobile Application. In Proceedings of the 6th International Conference on Control, Automation and Robotics (ICCAR), Singapore, 20–23 April 2020.

- Haryanto, M.U.; Ibadillah, A.; Alfita, R.; Aji, K.; Rizkyandi, R. Smart aquaponic system-based Internet of Things (IoT). In Proceedings of the Journal of Physics: Conference Series, Medan, Indonesia, 19–20 July 2019.

- Zaini, A.; Kurniawan, A.; Herdhiyanto, A. Internet of Things for monitoring and controlling nutrient film technique (NFT) aquaponic. In Proceedings of the International Conference on Computer Engineering, Network and Intelligent Multimedia (CENIM), Surabaya, Indonesia, 26–27 November 2018.

- Aishwarya, K.; Harish, M.; Prathibhashree, S.; Panimozhi, K. Survey on automated aquaponics based gardening approaches. In Proceedings of the 2018 Second International Conference on Inventive Communication and Computational Technologies (ICICCT), Coimbatore, India, 20–21 April 2018.

- Arvind, C.; Jyothi, R.; Kaushal, K.; Girish, G.; Saurav, R.; Chetankumar, G. Edge Computing Based Smart Aquaponics Monitoring System Using Deep Learning in IoT Environment. In Proceedings of the 2020 IEEE Symposium Series on Computational Intelligence (SSCI), Canberra, Australia, 1–4 December 2020.

- Pasha, A.K.; Mulyana, E.; Hidayat, C.; Ramdhani, M.A.; Kurahman, O.T.; Adhipradana, M. System design of controlling and monitoring on aquaponic based on Internet of Things. In Proceedings of the 2018 4th International Conference on Wireless and Telematics (ICWT), Nusa Dua, Indonesia, 12–13 July 2018.

- Kyaw, T.Y.; Ng, A.K. Smart aquaponics system for urban farming. Energy Procedia 2017, 143, 342–347.

- Shaout, A.; Scott, S.G. IoT fuzzy logic aquaponics monitoring and control hardware real-time system. In Proceedings of the International Arab Conference on Information Technology, Giza, Egypt, 28–30 November 2020.

- Wang, D.; Zhao, J.; Huang, L.; Xu, D. Design of a smart monitoring and control system for aquaponics based on OpenWrt. In Proceedings of the 5th International Conference on Information Engineering for Mechanics and Materials, Huhhot, Inner Mongolia, 25–26 July 2015.

- Saaid, M.; Fadhil, N.; Ali, M.M.; Noor, M. Automated indoor Aquaponic cultivation technique. In Proceedings of the IEEE 3rd international conference on system engineering and technology, Shah Alam, Malaysia, 19–20 August 2013.

- Cheong, C.; Iskandar, A.; Azhar, A.; Othman, W.J. Smart Aquaponics System: Design and Implementation using Arduino Microcontroller. Int. J. Res. 2018, 2348–6848.

- Wu, Z.; Qiu, K.; Zhang, J. Smart microcontroller architecture for the Internet of Things. Sensors 2020, 20, 1821.

- Verma, S.; Bhatia, A.; Chug, A.; Singh, A.P. Recent advancements in multimedia big data computing for IoT applications in precision agriculture: Opportunities, issues, and challenges. In Multimedia Big Data Computing for IoT Applications; Springer: Berlin/Heidelberg, Germany, 2020; pp. 391–416.

- LeCun, Y.; Bengio, Y.; Hinton, G. Deep learning. Nature 2015, 521, 436–444.

- Taha, M.F.; Abdalla, A.; ElMasry, G.; Gouda, M.; Zhou, L.; Zhao, N.; Liang, N.; Niu, Z.; Hassanein, A.; Al-Rejaie, S. Using Deep Convolutional Neural Network for Image-Based Diagnosis of Nutrient Deficiencies in Plants Grown in Aquaponics. Chemosensors 2022, 10, 45.

- Zhou, L.; Zhang, C.; Taha, M.; Qiu, Z.; He, L. Determination of Leaf Water Content with a Portable NIRS System Based on Deep Learning and Information Fusion Analysis. Trans. ASABE 2021, 64, 127–135.

- Zhou, L.; Zhang, C.; Taha, M.F.; Wei, X.; He, Y.; Qiu, Z.; Liu, Y. Wheat Kernel Variety Identification Based on a Large Near-Infrared Spectral Dataset and a Novel Deep Learning-Based Feature Selection Method. Front. Plant Sci. 2020, 11, 575810.

- Lekunberri, X.; Ruiz, J.; Quincoces, I.; Dornaika, F.; Arganda-Carreras, I.; Fernandes, J.A. Identification and measurement of tropical tuna species in purse seiner catches using computer vision and deep learning. Ecol. Inform. 2022, 67, 101495.

- Álvarez-Ellacuría, A.; Palmer, M.; Catalán, I.A.; Lisani, J. Image-based, unsupervised estimation of fish size from commercial landings using deep learning. ICES J. Mar. Sci. 2020, 77, 1330–1339.

- Han, F.; Zhu, J.; Liu, B.; Zhang, B.; Xie, F. Fish shoals behavior detection based on convolutional neural network and spatiotemporal information. IEEE Access 2020, 8, 126907–126926.

- Ubina, N.; Cheng, S.-C.; Chang, C.-C.; Chen, H.-Y. Evaluating fish feeding intensity in aquaculture with convolutional neural networks. Aquac. Eng. 2021, 94, 102178.

- Ren, Q.; Zhang, L.; Wei, Y.; Li, D. A method for predicting dissolved oxygen in aquaculture water in an aquaponics system. Comput. Electron. Agric. 2018, 151, 384–391.

- Ta, X.; Wei, Y. Research on a dissolved oxygen prediction method for recirculating aquaculture systems based on a convolution neural network. Comput. Electron. Agric. 2018, 145, 302–310.

- Mehra, M.; Saxena, S.; Sankaranarayanan, S.; Tom, R.J.; Veeramanikandan, M. IoT based hydroponics system using Deep Neural Networks. Comput. Electron. Agric. 2018, 155, 473–486.

- Thai-Nghe, N.; Thanh-Hai, N.; Chi Ngon, N.J. Deep learning approach for forecasting water quality in IoT systems. Int. J. Adv. Comput. Sci. Appl. 2020, 11, 686–693.

- Barzegar, R.; Aalami, M.T.; Adamowski, J. Short-term water quality variable prediction using a hybrid CNN–LSTM deep learning model. Stoch. Environ. Res. Risk Assess. 2020, 34, 415–433.

- Pitakphongmetha, J.; Boonnam, N.; Wongkoon, S.; Horanont, T.; Somkiadcharoen, D.; Prapakornpilai, J. Internet of things for planting in smart farm hydroponics style. In Proceedings of the 2016 International Computer Science and Engineering Conference (ICSEC), Chiang Mai, Thailand, 14–17 December 2016.

- Jalal, A.; Salman, A.; Mian, A.; Shortis, M.; Shafait, F. Fish detection and species classification in underwater environments using deep learning with temporal information. Ecol. Inform. 2020, 57, 101088.

- Salman, A.; Siddiqui, S.A.; Shafait, F.; Mian, A.; Shortis, M.R.; Khurshid, K.; Ulges, A.; Schwanecke, U. Automatic fish detection in underwater videos by a deep neural network-based hybrid motion learning system. ICES J. Mar. Sci. 2020, 77, 1295–1307.

- Hasan, N.; Ibrahim, S.; Aqilah Azlan, A.J. Fish diseases detection using convolutional neural network (CNN). Int. J. Nonlinear Anal. Appl. 2022, 13, 1977–1984.

- Monkman, G.G.; Hyder, K.; Kaiser, M.J.; Vidal, F.P. Using machine vision to estimate fish length from images using regional convolutional neural networks. Methods Ecol. Evol. 2019, 10, 2045–2056.

- Garcia, R.; Prados, R.; Quintana, J.; Tempelaar, A.; Gracias, N.; Rosen, S.; Vågstøl, H.; Løvall, K.J. Automatic segmentation of fish using deep learning with application to fish size measurement. ICES J. Mar. Sci. 2020, 77, 1354–1366.

- Lu, H.; Ma, X. Hybrid decision tree-based machine learning models for short-term water quality prediction. Chemosphere 2020, 249, 126169.

- Junior, A.D.; Sant’Ana, D.A.; Pache, M.C.B.; Garcia, V.; de Moares Weber, V.A.; Astolfi, G.; de Lima Weber, F.; Menezes, G.V.; Menezes, G.K.; Albuquerque, P.L. Fingerlings mass estimation: A comparison between deep and shallow learning algorithms. Smart Agric. Technol. 2021, 1, 100020.

- Måløy, H.; Aamodt, A.; Misimi, E. A spatio-temporal recurrent network for salmon feeding action recognition from underwater videos in aquaculture. Comput. Electron. Agric. 2019, 167, 105087.

- Adegboye, M.A.; Aibinu, A.M.; Kolo, J.G.; Aliyu, I.; Folorunso, T.A.; Lee, S. Incorporating intelligence in fish feeding system for dispensing feed based on fish feeding intensity. IEEE Access 2020, 8, 91948–91960.

- Mohanty, S.P.; Hughes, D.P.; Salathé, M. Using deep learning for image-based plant disease detection. Front. Plant Sci. 2016, 7, 1419.

- Lu, J.Y.; Chang, C.L.; Kuo, Y.F. Monitoring growth rate of lettuce using deep convolutional neural networks. In Proceedings of the ASABE Annual International Meeting, Boston, MA, USA, 7–10 July 2019.

- Alhnaity, B.; Pearson, S.; Leontidis, G.; Kollias, S. Using deep learning to predict plant growth and yield in greenhouse environments. In Proceedings of the International Symposium on Advanced Technologies and Management for Innovative Greenhouses, Angers, France, 16–20 June 2019.

- Hazra, A.; Adhikari, M.; Amgoth, T.; Srirama, S.N. A comprehensive survey on interoperability for IIoT: Taxonomy, standards, and future directions. ACM Comput. Surv. 2021, 55, 1–35.

- Lelli, F. Interoperability of the Time of Industry 4.0 and the Internet of Things. Future Internet 2019, 11, 36.

- Yanes, A.R.; Martinez, P.; Ahmad, R.J. Towards automated aquaponics: A review on monitoring, IoT, and smart systems. J. Clean. Prod. 2020, 263, 121571.

- Rabiya, A.; Martinez, P.; Ahmad, R. An ontology model to represent aquaponics 4.0 system’s knowledge. Inf. Process. Agric. 2021, 100, 55–60.

- Ge, W.; Zhao, C. State-of-the-art and developing strategies of agricultural internet of things. Nongye Jixie Xuebao Trans. Chin. Soc. Agric. Mach. 2014, 45, 222–277.

- Manju, M.; Karthik, V.; Hariharan, S.; Sreekar, B. Real time monitoring of the environmental parameters of an aquaponic system based on Internet of Things. In Proceedings of the International Conference on Science Technology Engineering & Management (ICONSTEM), Chennai, India, 23–24 March 2017.

- Abraham, S.; Shahbazian, A.; Dao, K.; Tran, H.; Thompson, P. An Internet of Things (IoT)-based aquaponics facility. In Proceedings of the 2017 IEEE Global Humanitarian Technology Conference (GHTC), San Jose, CA, USA, 19–22 October 2017.

- Dutta, A.; Dahal, P.; Prajapati, R.; Tamang, P.; Kumar, E.S. IOT based aquaponics monitoring system. In Proceedings of the 1st Kantipur Engineering College (KEC) Conference Proceedings, Dhapakhel, Nepal, 27 September 2018.

- Raju, K.R.S.R.; Varma, G.H.K. Knowledge based real time monitoring system for aquaculture using IoT. In Proceedings of the IEEE 7th International Advance Computing Conference (IACC), Hyderabad, India, 5–7 January 2017.

- Elsokah, M.M.; Sakah, M. Next generation of smart aquaponics with internet of things solutions. In Proceedings of the 19th International Conference on Sciences and Techniques of Automatic Control and Computer Engineering (STA), Sousse, Tunisia, 24–26 March 2019.

- Mellit, A.; Benghanem, M.; Herrak, O.; Messalaoui, A. Design of a Novel Remote Monitoring System for Smart Greenhouses Using the Internet of Things and Deep Convolutional Neural Networks. Energies 2021, 14, 5045.

- Wang, S.S.C.; Lin, W.L.; Hsieh, C. To improve the production of agricultural using IoT-based aquaponics system. Int. J. Appl. Sci. Eng. 2020, 17, 207–222.

- Khaoula, T.; Abdelouahid, R.A.; Ezzahoui, I.; Marzak, A. Architecture design of monitoring and controlling of IoT-based aquaponics system powered by solar energy. Procedia Comput. Sci. 2021, 191, 493–498.

- Nagayo, A.M.; Mendoza, C.; Vega, E.; Al Izki, R.K.; Jamisola, R.S. An automated solar-powered aquaponics system towards agricultural sustainability in the Sultanate of Oman. In Proceedings of the IEEE International Conference on Smart Grid and Smart Cities (ICSGSC), Singapore, 23–26 July 2017.

- Mandap, J.P.; Sze, D.; Reyes, G.N.; Dumlao, S.M.; Reyes, R.; Chung, W.Y.D. Aquaponics ph level, temperature, and dissolved oxygen monitoring and control system using raspberry pi as network backbone. In Proceedings of the TENCON IEEE Region 10 Conference, Jeju, Korea, 28–31 October 2018.

- Vernandhes, W.; Salahuddin, N.S.; Kowanda, A.; Sari, S.P. Smart aquaponic with monitoring and control system based on IoT. In Proceedings of the Second International Conference on Informatics and Computing (ICIC), Jayapura, Indonesia, 1–3 November 2017.

- Odema, M.; Adly, I.; Wahba, A.; Ragai, H. Smart aquaponics system for industrial Internet of Things (IIoT). In Proceedings of the International Conference on Advanced Intelligent Systems and Informatics, Cairo, Egypt, 9–11 September 2017.

- Llaban, A.; Ella, V. Conventional and sensor-based streamflow data acquisition system for sustainable water resources management and agricultural applications: An extensive review of literature. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Bogor, Indonesia, 11–13 October 2021.

- Lelli, F.; Frizziero, E.; Gulmini, M.; Maron, G.; Orlando, S.; Petrucci, A.; Squizzato, S. The many faces of the integration of instruments and the grid. Int. J. Web Grid Serv. 2007, 3, 239–266.

- Murad, S.; Harun, A.; Mohyar, S.; Sapawi, R.; Ten, S. Design of aquaponics water monitoring system using Arduino microcontroller. In Proceedings of the AIP Conference Proceedings, Bydgoszcz, Poland, 30 September 2017.

- Mamatha, M.; Namratha, S. Design & implementation of indoor farming using automated aquaponics system. In Proceedings of the IEEE International Conference on Smart Technologies and Management for Computing, Communication, Controls, Energy and Materials (ICSTM), Chennai, India, 2–4 August 2017.

- Sreelekshmi, B.; Madhusoodanan, K. Automated aquaponics system. In Emerging Trends in Engineering, Science and Technology for Society, Energy and Environment; CRC Press: Boca Raton, FL, USA, 2018; pp. 719–724.

- Jacob, N.K. IoT powered portable aquaponics system. In Proceedings of the Second International Conference on Internet of things, Data and Cloud Computing, Cambridge, UK, 22–23 March 2017.

More