Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 3 by Conner Chen and Version 2 by Conner Chen.

One of the emerging techniques of chemical warfare agents (CWA) detection is based on acoustic wave sensors, among which surface acoustic wave (SAW) devices and quartz crystal microbalances (QCM) are of particular importance. These devices allow for the construction of undemanding and affordable gas sensors whose selectivity, sensitivity, and other metrological parameters can be tailored by application of particular coating material.

- SAW

- QCM

- sulfur mustard

- blister agent detection

1. Introduction

Sensors using various analytical techniques are used for on-site chemical warfare agents (CWAs) detection. Among them are devices using well-established techniques such as ion mobility spectrometry (IMS) [1] and flame photometry (FP) [2] but also analytical techniques based on simple and undemanding sensors. Recently, semiconductor [3][4], colorimetric, and fluorescent [5][6] sensors have also attracted a lot of interest.

In addition to the above-mentioned techniques, acoustic wave sensors are used for on-site CWA detection [7]. As acoustic wave gas sensors meet all requirements for mobility (light weight, low energy consumption) and affordability (low cost, ease of use) well, they are seen as a potential technique for detecting CWA and other hazardous substances. Despite the fact that acoustic wave chemical gas sensors are not a very new issue (the first work on gas sensors with quartz crystal microbalance (QCM) dates from 1964 [8] while the first sensor with a surface acoustic wave (SAW) device was described in 1979 [9]), work on these devices is still very intensive as evidenced by the number of publications in scientific journals in recent years.

In 2017, a comprehensive review was published on the detection of volatile organic compounds (VOCs) and other gases with SAW sensors [10]. Another review from 2022 [11] presents achievements in the field of gas sensors based on different types of acoustic wave devices, including QCM. The works cited summarize the achievements in the field of acoustic wave gas sensors for the detection of vapors of various organic compounds and gases. The available scientific literature also includes studies focused solely on the detection of nerve CWAs [12].

2. Surface Acoustic Wave and Quartz Crystal Microbalance Devices Used in Gas Sensing

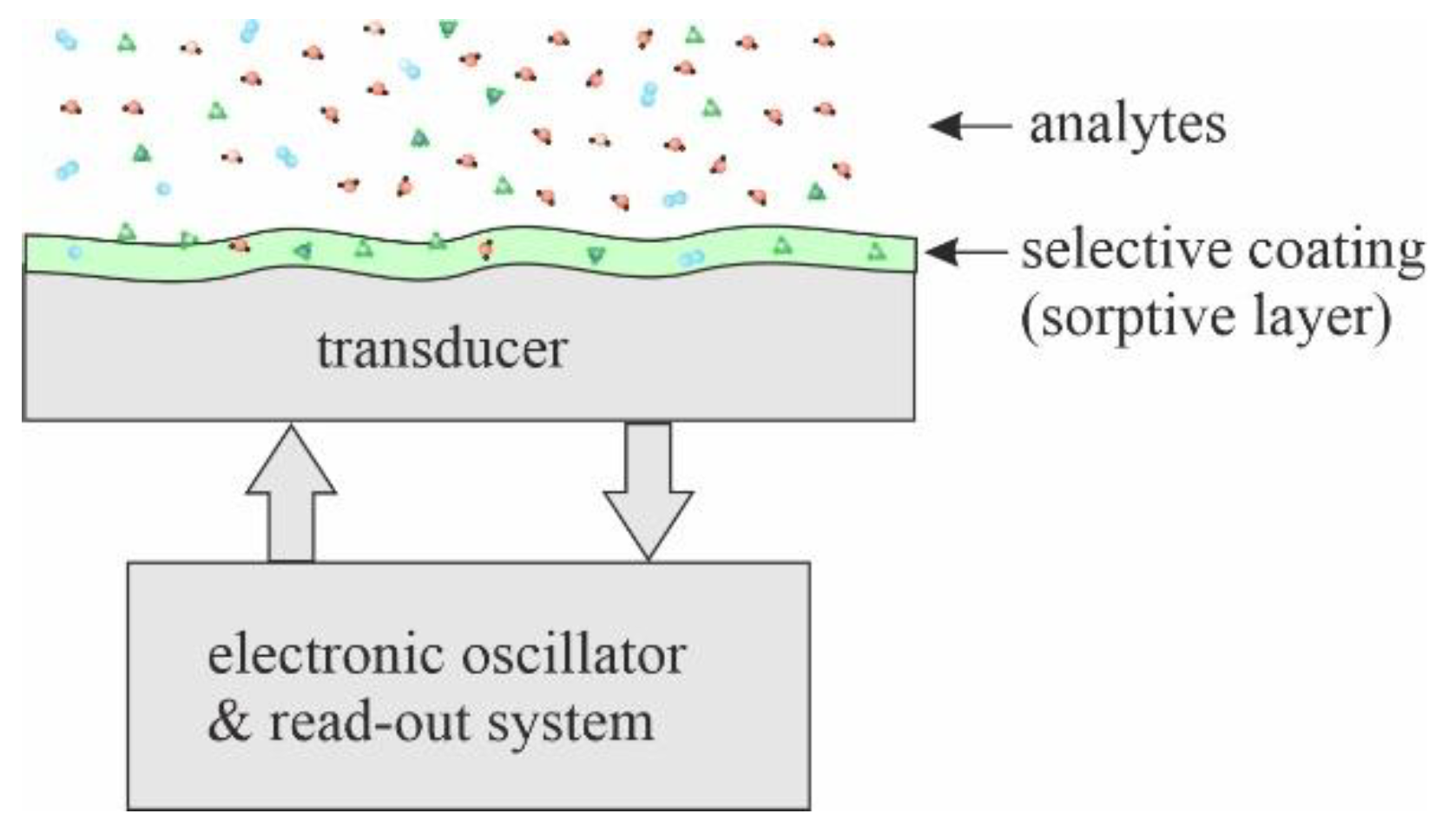

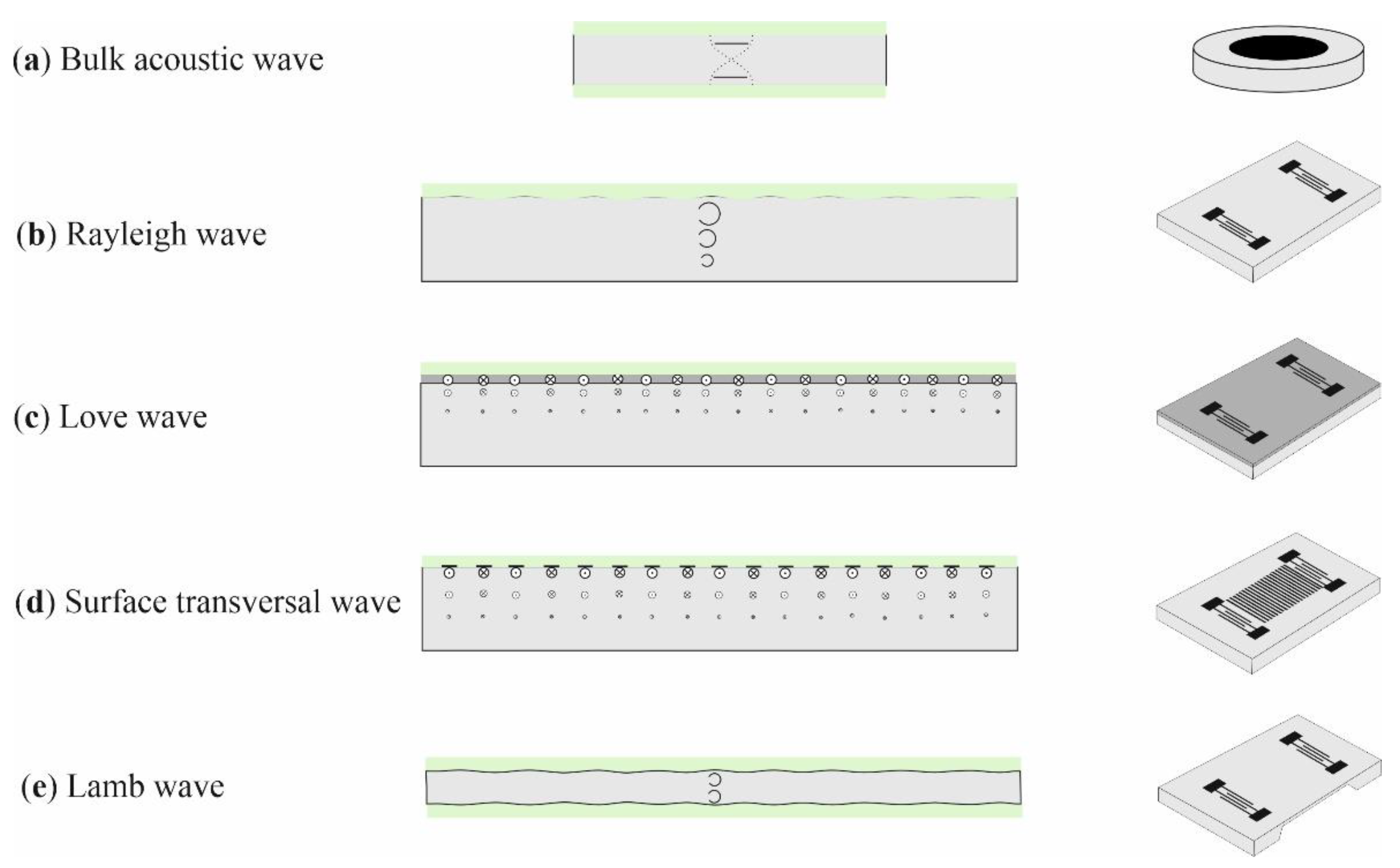

The group of acoustic wave sensors includes several types of piezoelectric devices, among which ware can list quartz crystal microbalances, a variety of surface acoustic wave sensors, and other sensors such as polymorphic sensors with different geometries (cantilever, fork, disk-shaped etc.) [13][14]. Sensors of this type are characterized by a very small size, uncomplicated structure, low power consumption, and simple electronic systems, which makes them an ideal candidate for use in portable instruments, in particular for the detection of CWAs and toxic industrial chemicals (TICs) in the field. Regardless of the type of piezoelectric device used, each sensor consists of a transducer with an acoustic wave and a selective coating that interacts with the analyte present in the environment. As a result of this interaction, the parameters of the coating, such as mass, density, stiffness, and electrical conductivity, change. These changes affect the propagation of the acoustic wave in the transducer material to which the sorption layer adheres, changing its speed and attenuation. An ordinary piezoelectric transducer is equipped with a resonant system, which vibrates with a strictly defined frequency depending on the parameters of the acoustic wave. Associated electronic systems convert acoustic wave parameters into electrical quantities. As a result, changes in wave parameters caused by analyte sorption are observed as changes in the resonant frequency, phase, and attenuation in the resonance system. A general diagram of the operation of an acoustic wave chemical gas sensor is shown in Figure 1.

Figure 1. The basic principle of operation of an acoustic wave chemical gas sensor.

Figure 2. Wave propagation modes and acoustic wave transducers used in chemical gas sensors.

References

- Puton, J.; Namieśnik, J. Ion mobility spectrometry: Current status and application for chemical warfare agents detection. Trends Anal. Chem. 2016, 85, 10–20.

- Choi, N.; Kwak, J.; Lim, Y.; Bahn, T.; Yun, K.; Kim, J.; Huh, J.; Lee, D. Classification of chemical warfare agents using thick film gas sensor array. Sens. Actuators B Chem. 2005, 108, 298–304.

- Bigiani, L.; Zappam, D.; Barreca, D.; Gasparotto, A.; Sada, C.; Tabacchi, G.; Fois, E.; Comini, E.; Maccato, C. Sensing Nitrogen Mustard Gas Simulant at the ppb Scale via Selective Dual-Site Activation at Au/Mn3O4 Interfaces. ACS Appl. Mater. Interfaces 2019, 11, 23692–23700.

- Davidson, C.; Dixon, M.; Williams, B.; Kilper, G.; Lim, S.; Martino, R.; Rhodes, P.; Hulet, M.; Miles, R.; Samuels, A.; et al. Detection of Chemical Warfare Agents by Colorimetric Sensor Arrays. ACS Sens. 2020, 5, 1102–1109.

- Burnworth, M.; Rowan, S.; Weder, C. Fluorescent Sensors for the Detection of Chemical Warfare Agents. Chem. Eur. J. 2007, 13, 7828–7836.

- Umapathi, R.; Sonwal, S.; Lee, J.; Rani, G.; Lee, E.-S.; Jeon, T.-J.; Kang, S.-M.; Oh, M.-H.; Huh, Y. Colorimetric based on-site sensing strategies for the rapid detection of pesticides in agricultural foods: New horizons, perspectives, and challenges. Coord. Chem. Rev. 2021, 446, 214061.

- Giannoukos, S.; Brkić, B.; Taylor, S.; Marshall, A.; Verbeck, G. Chemical Sniffing Instrumentation for Security Applications. Chem. Rev. 2016, 116, 8146–8172.

- King, W., Jr. Piezoelectric sorption detector. Anal. Chem. 1964, 36, 1735–1739.

- Wohltjen, H.; Dessy, R. Surface acoustic wave probes for chemical analysis. Anal. Chem. 1979, 51, 1458–1470.

- Devkota, J.; Ohodnicki, P.; Greve, D. SAW sensors for chemical vapors and gases. Sensors 2017, 17, 801.

- Kumar, A.; Prajesh, R. The potential of acoustic wave devices for gas sensing applications. Sens. Actuators A Phys. 2022, 339, 113498.

- Bielecki, M.; Witkiewicz, Z.; Rogala, K. Sensors to detect sarin simulant. Crit. Rev. Anal. Chem. 2021, 51, 299–311.

- Pasternak, M. Acoustic Sensors; Military University of Technology: Warsaw, Poland, 2018.

- Ballantine, D., Jr.; White, R.; Martin, S.; Ricco, A.; Frye, G.; Zellers, E.; Wohltjen, H. Acoustic Wave Sensors: Theory, Design, and Physico-Chemical Applications in Applications of Modern Acoustics; Academic Press: Cambridge, MA, USA, 1996.

- David, J.; Cheeke, N. Acoustic Sensors. In Fundamentals and Applications of Ultrasonic Waves; CRC Press: Boca Raton, FL, USA, 2002.

- Mandal, D.; Banerjee, S. Surface Acoustic Wave (SAW) Sensors: Physics, Materials, and Applications. Sensors 2022, 22, 820.

- Go, D.; Atashbar, M.; Ramshani, Z.; Chang, H. Surface acoustic wave devices for chemical sensing and microfluidics: A review and perspective. Anal. Methods 2017, 9, 4112–4134.

More