Bioplastics have proven to be a viable substitute for plastics in some sectors, although their use in construction is still limited. The construction sector currently uses 23% of the world’s plastic production, both for the materials themselves and for their packaging and protection. A considerable part is not recycled and is dispersed into the environment or ends up in landfills. In response to the environmental problems caused by oil-based plastic pollution, the development of biocomposite materials such as bioplastics represents a paradigm shift. This entry aims to explain what bioplastics are, providing a classification and the description of the different properties and applications. It also lays out the most interesting uses of these materials in the construction field.

- bio-based material

- construction

- environment

- circular economy

- life cycle

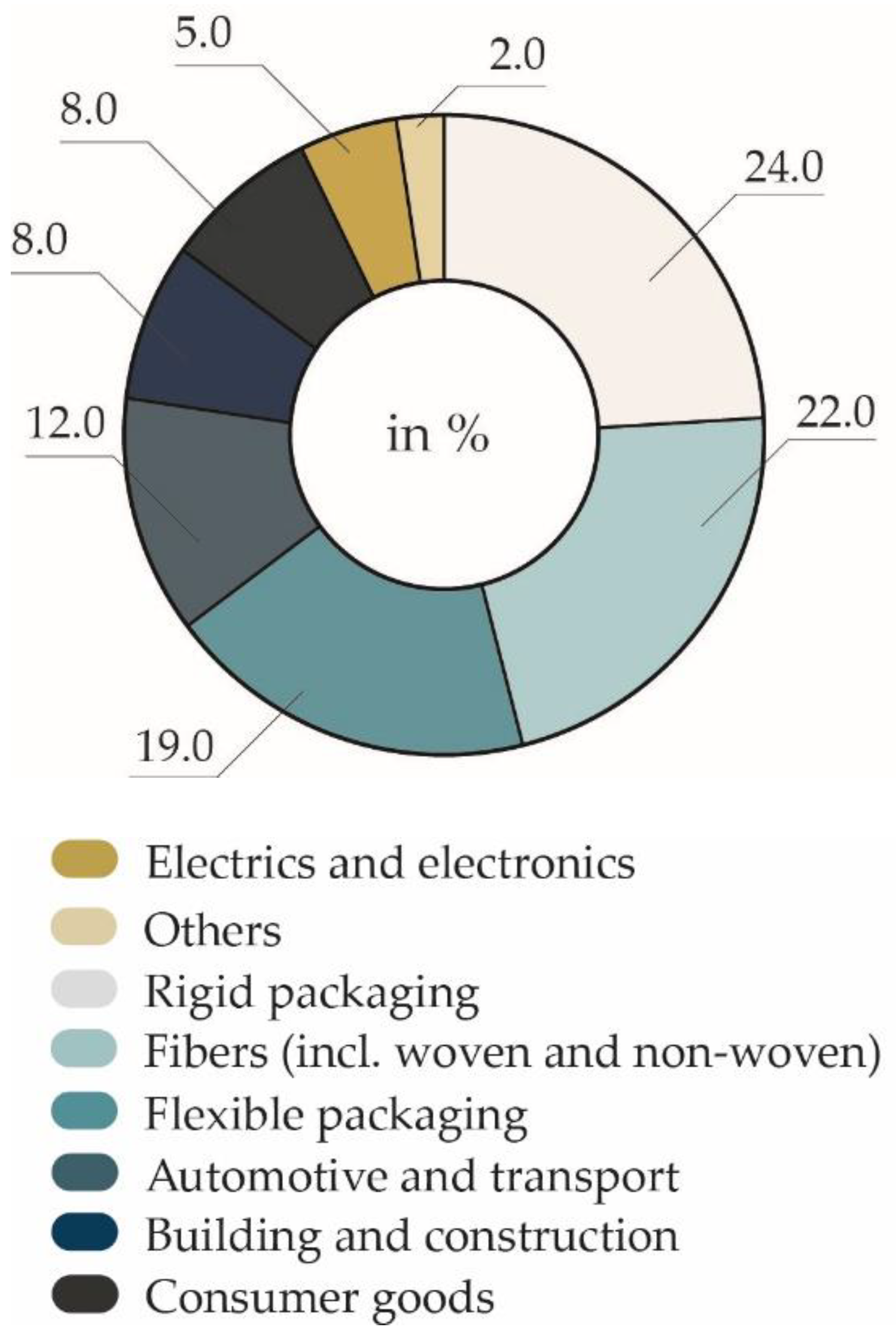

The problem of plastic pollution has become one of the most pressing global environmental issues. It is estimated that there are more than 269 thousand tons of plastic in the oceans, and if urgent prevention measures are not taken, there will be more plastic than fish by 2050 in terms of weight [1]. The immoderate production of plastics is growing year by year and is expected to grow by another 70% in the next 30 years [2]. The accumulation of plastics and microplastics in the oceans and on land over the decades is due to the reckless production and use of this material, which is particularly valued for its cheapness and variety of use. The causes of the plastic pollution problem can be summarized as follows: inordinate production, short use, polymer deterioration, inadequate waste management and disposal, and insufficient production chain for alternative materials. This is a great threat to the environment because already, millions of tons are dispersed in nature and end up amassing along shorelines or creating real garbage islands. This accumulation of products is also aggravated by the non-management or inadequate management of waste; in fact, it is often scattered in nature or abandoned in illegal dumps, polluting soil, fresh water, and oceans. Accumulation is also caused by the excessive use of single-use plastics: these are mainly polyethylene, found mostly in packaging and disposable products such as cutlery, glasses, or food containers. All these items have a very short life span, but a very long decomposition time that allows them to remain in the environment for years. For instance, a plastic bag has an average use of 12 min but takes 500 years to fully decompose [3]. Plastic pollution is aggravated by the deterioration of polymers, which produce a high amount of plastics/microplastics in the environment. Contributing to the waste management problem is the fact that only a small percentage of plastic is recycled. This is due to both the high economic cost of recycling processes and the low financial incentives for recycling. It is much cheaper to produce most types of plastic from scratch than to recycle old plastic. In addition, the complexity of recycling processes is an obstacle to achieving circular economy goals. Finally, the scarcity of production chains of more sustainable materials must be considered. Ecological alternatives are still limited and mainly related to products such as packaging, containers, and single-use plastic items, for which the raw materials used are plant-based polymers or polymers made from animal proteins. In most cases, the extraordinary properties of plastics mean that other, more environmentally friendly options are in short supply. However, a shift to more sustainable, non-petroleum-derived materials is the key step that production chains should take to reverse the trend of increasing plastic use and to transform the current linear economic model into a circular one. In fact, the circular economy is based on the different cycles of the production chain of discarded products to limit waste, minimize the use of totally new raw materials, maximize the potential of a material, and reduce the amount of waste that is dispersed into the environment. In this economic and production model, bioplastics assume high importance, particularly all those that are compostable since, after being used in different production cycles, they can be biodegraded, avoiding remaining in nature for years as opposed to fossil plastics. With this in mind, biopolymers, and biomaterials more generally, should be considered as a means for the ecological transformation of the economy and the construction sector. However, as Figure 1 shows, only 8% of the bioplastics produced are used in the buildings and construction sector, compared to 23% of the use, in the same sector, of plastic produced worldwide [4].