After coal, petroleum, and natural gas, biomass is the world’s fourth-largest energy source, accounting for a considerable amount of global primary energy consumption

[1]. Biomass presently contributes roughly 14% of the world’s yearly energy consumption in all forms

[2]. As an alternative, biomasses, such as agricultural waste, forestry waste, municipal solid, and industrial waste, are renewable energy resources used for producing either solid or liquid fuels

[3][4][3,4]. There are different processes to produce biomass energy, such as thermochemical, biological, and physical conversion (oilseed extraction). Thermochemical conversions can be categorized into combustion, pyrolysis, and gasification. Biological conversion can be achieved by fermentation or anaerobic digestion

[5][6][7][8][5,6,7,8]. Moreover, there are some novel approaches to merging microbiology, electrochemistry, and electronics, such as microbial electrochemical technologies (METs)

[9]. Converting organic sources into electricity and treating organic waste stream in microbial fuel cells (MFCs)

[10], hydrogen or methane generation in microbial electrolysis cells (MEC)

[11], CO2 elongation to volatile fatty acids (VFAs) in microbial electro-synthesis (MES) cells

[12], low-cost desalination in microbial desalination cells (MDCs)

[13], and microbial reverse electrodialysis cells (MRCs) using a combination of MFC and reverse electro-dialysis (RED) stack

[14] are all examples of MET that may be used for wastewater treatment.

2. Gasification Technology

Biomass gasification for energy generation may appear to be a new technique, although it has been around for over a century

[19][33]. Even though gasification technology has been around for decades, it has yet to reach its full potential. The fundamental principles governing its operation, notably feedstock variability and the type of gasification system, are still ambiguous

[20][34]. Gasification technology is a thermochemical process used to convert organic substances into valuable gas (so-called syngas, a mixture of CO and H

2). Temperature, equivalent ratio, and pressure impact the syngas composition

[21][35]. The gasifier (reactor) and its configuration are the most critical factors affecting the reactions and products

[22][36]. Generally, gasifiers are classified based on their fluidization regime (gas–solid contacting mode) and gasifying medium

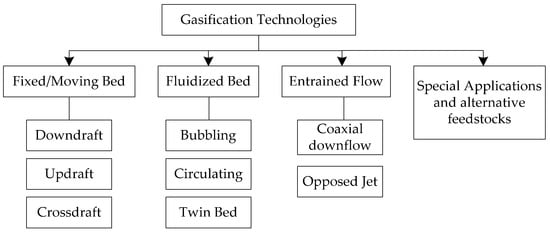

[23][24][37,38]. Based on the gas–solid contacting mode, fixed bed gasifiers (also known as the moving bed (a moving bed is also known as this type of gasifier since the fuel moves downward in the gasifier)), fluidized bed gasifiers, and entrained flow gasifiers are the three main types of gasifiers with commercial or near-commercial applications

[20][25][34,39]. However, there are some other uses that employ specific gasifier types or gasification processes.

These technologies are usually targeted at utilizing a wider variety of feedstock than only coal and demonstrate innovative applications of gasification

[26][40]. As illustrated in

Figure 1, each type can be further subdivided into specific commercial types. In all gasification processes, however, the phenomena of pyrolysis followed by partial oxidation of the residual carbon are prevalent

[27][41]. In general, due to the wide range of raw materials available, developing a valid theory to describe the entire gasification process is quite challenging

[28][42]. Over the years, different suppliers have developed gasifiers commercially.

Figure 1.

Gasification technologies.

2.1. Process Challenges

The gasification process still has to be optimized to reduce the energy loss caused by pretreatment of the biomass prior to the conversion process, optimizing the carbon conversion efficiency in the reactor, reducing tar production, and cleaning the syngas for further processing

[16].

Both the gasifier’s performance and the composition of syngas are affected by the moisture content of the biomass. Brammer and Bridgwater showed that high moisture content in the biomass has a negative impact on the quality of the produced syngas and the system’s overall performance

[29][50].

Although a high moisture content might not be a big problem in a fluidized bed due to using steam as the fluidizing agent, the entrained gasifier is more sensitive to the moisture. A downdraft gasifier’s maximum moisture content is typically 25%, whereas an updraft gasifier’s maximum moisture content is often 50%

[30][51]. Drying biomass before gasification might result in high capital and energy expenditures in small- and medium-scale gasification plants

[16].

The contaminants within the biomass might reduce the efficiency of the thermochemical conversion process

[31][52]. The most significant challenge for chemical production and energy generation using biomass gasification may be the high cost of auxiliary equipment required to produce clean contaminant-free syngas. Consequently, the overall cost of the process increases significantly, accounting for more than half of the ultimate price of biofuel produced

[32][53].

One of the most severe problems encountered throughout the various biomass gasification methods is tar formation

[33][54]. Condensable hydrocarbons, with or without additional oxygen-containing hydrocarbons, and more complex polycyclic aromatic hydrocarbons make up the tars formed during gasification

[34][55]. Tar formation results in the deactivation of catalysts, the halting of the downstream operations, and the generation of carcinogenic compounds

[35][56].

2.2. Gasification’s Environmental Impacts

The environmental impact of biomass gasification is related to input and output values of material flows, energy flows, emissions to air and water, and by-products. The input material composition depends on the type of biomass used and its origin. The gasification process is robust, and mixtures of biomasses can be used, which challenges the evaluation of the biomass feed. The contaminants in the material will vary and affect the environmental impact assessment. Other input flows related to water resources, the energy sources for heating the reactor, and catalytic compounds used in the reactor must be considered in the assessment. The output of emissions to air and water needs to be carefully monitored. Fly ash generation, dust, gaseous emissions, and water pollution are significant adverse environmental impacts

[36][57]. Moreover, combustible gases, vapors, dust, fire risks, carbon monoxide poisoning, and gas leaks are the primary hazards of gasifier operation

[37][58].

Dust is created during storage, handling, feeding, feedstock preparation, and fly ash removal

[38][59]. Because of the acidic conditions in landfills, the ash that remains after gasification is hazardous and poses particular problems

[39][60]. The gasification process produces many tiny solid particles, mostly fly ash and char (unburned carbons). These cause a similar issue as dust and biomass ash. Ash may also constitute a fire hazard, demonstrating the need to keep it wet and sealed

[40][22]. During the cooling and cleaning of produced syngas, wastewater is produced as an effluent

[41][61]. The disposal of some contaminants in effluents, such as phenolic and terry components, reveals severe environmental problems and requires adequate pretreatment before discharging into the environment

[42][26].

3. Current Work

The results indicated that, environmentally, agave bagasse combustion is the best option, followed by agave bagasse gasification, sugarcane bagasse gasification, and sugarcane bagasse combustion. A comprehensive LCA was conducted by Sun et al.

[43][77] to compare the environmental performance of converting corn stover to biofuels in fermentation, pyrolysis, and gasification processes. They conclude that the total environmental performance of the system for producing high-grade jet fuel from maize stover by gasification synthesis is optimum. Moreover, fermentation scores poorly in almost all environmental effect categories for 1 GJ of biofuel, whereas pyrolysis has the greatest comparable CO2 emission. Similarly, Tang et al.

[44][91] found that, in comparison with incineration, although gasification-based systems were excellent in mitigating environmental impacts, they had a greater impact on global warming. Muthudineshkumar and Anand

[45][97] reported that for biofuel production from biomass, between gasification and syngas fermentation, gasification reduced pollution emissions and was an ecologically friendly method of fuel use. Nevertheless, in contrast, due to economic and societal problems, Valente et al.

[46][47][103,104] found that hydrogen from biomass gasification cannot currently be regarded as a viable alternative to conventional hydrogen. On the other hand, considering economic and economic performances separately, environmentally, hydrogen from biomass gasification performs substantially better than hydrogen from steam methane reforming, although the opposite result was reached in economics. Zang et al.

[48][80] examined the technological alternatives of biomass gasification, syngas combustion, and CO

2 emission control in the LCA of eight biomass-integrated gasification combined cycles (BIGCCs). Results showed that the GWP of BIGCC systems is less than 240 kg CO

2-equivalent/MWh, which is negative when BIGCC systems are integrated with CO

2 capture and storage technology. In addition, the exterior syngas combustion technique has a lower GWP, human toxicity potential, and ozone depletion potential than the internal syngas combustion technology, and the Selexol CO

2 capture

[49][112] method is more environmentally friendly than the MEA CO

2 capture

[50][113] method.

In another approach, two studies addressed by Ouedraogo et al.

[51][90] compared LCA of gasification and landfilling for the disposal of MSW. The LCA found that, in comparison with gasification, landfilling is a significant contributor to global warming, ecotoxicity, eutrophication, acidification, smog formation, and cancer and non-cancer human health outcomes. Finally, Demetrious and Crossin

[52][99] assessed the environmental performance of mixed paper and mixed plastic waste management in landfills, incineration, and combined gasification–pyrolysis using LCA for impacts. According to the data, mixed paper handled with incineration or gasification–pyrolysis created fewer greenhouse gas emissions than mixed plastic managed in the landfill. The studies above confirm that it is impossible to make conclusions about the gasification process because the studies could have opposite results under different methodology, boundaries, or assumptions.

Six studies have investigated a combined process (gasification combined with one or more processes). Through LCA, Reaño et al.

[53][74] evaluated the environmental performance and energy efficiency of rice straw power generation utilizing a combination of gasification and an internal combustion engine (G/ICE). The results showed that the GWP of this process was 27% lower than the GWP of rice straw on-site burning and that biogenic methane emissions from flooded rice fields may be mitigated to lower the system’s GWP by 34%. Using energy generated by the G/ICE system to supply farm and plant activities might reduce the environmental impact and increase the effectiveness of the process. Iannotta et al.

[54][78] investigated the environmental performance of a novel integrated process based on supercritical water gasification and oxidation for treating carbon black and used oil as model wastes. It is demonstrated that this process decreases effects in several categories and results in a positive energy balance during the life cycle, ensuring good environmental performance. Moretti et al.

[55][72] offered the LCA of novel high-efficiency bio-based power technology that combines biomass gasification with a 199 kW solid oxide fuel cell to generate heat and electricity.

It demonstrated superior environmental performance compared to natural gas and the German/European grid. The other two studies were also discussed above

[48][52][80,99].

In another approach, Li et al.

[56][107] performed a multi-criteria optimization model (TOPSIS) based on LCA for a biomass gasification-integrated combined cooling, heating, and power system to study the overall performance criterion, the primary energy saving ratio, the total cost saving ratio, and the CO

2 emission reduction ratio. It is concluded that the system fueled by biomass greatly differs from that fueled by fossil fuels in energetic, economic, and environmental aspects. Consequently, exclusive assessments and optimizations are required.