3D printing has played a crucial role in the last decades as an innovative technology for tissue and organ fabrication, patient-specific orthoses, drug delivery, and surgical planning. However, biomedical materials used for 3D printing are usually static and unable to dynamically respond or transform within the internal environment of the body. These materials are fabricated ex situ, which involves first printing on a planar substrate and then deploying it to the target surface, thus resulting in a possible mismatch between the printed part and the target surfaces. The emergence of 4D printing addresses some of these drawbacks, opening an attractive path for the biomedical sector. By preprogramming smart materials, 4D printing is able to manufacture structures that dynamically respond to external stimuli. Despite these potentials, 4D printed dynamic materials are still in their infancy of development. The rise of artificial intelligence (AI) could push these technologies forward enlarging their applicability, boosting the design space of smart materials by selecting promising ones with desired architectures, properties, and functions, reducing the time to manufacturing, and allowing the in situ printing directly on target surfaces achieving high-fidelity of human body micro-structures.

1. Introduction

From its first appearance in 2013, 4D printing demonstrated a radical shift in

additive manufacturing (AM

) [1][2][3]. Tibbits defined 4D printing as multi-material printing with the capability to transform over time or a customized material system that can change shape, structure, or function directly off the print bed

[1]. The fourth dimension was described with the formula of “3D printing + time”, emphasizing that printed structures are no longer simply static or dead objects, but rather they are active and dynamic structures that can spontaneously transform.

With the evolution of this technology, the concept of 4D printing has been expanded by incorporating the product design into a flexible and intelligent material based on 3D printing

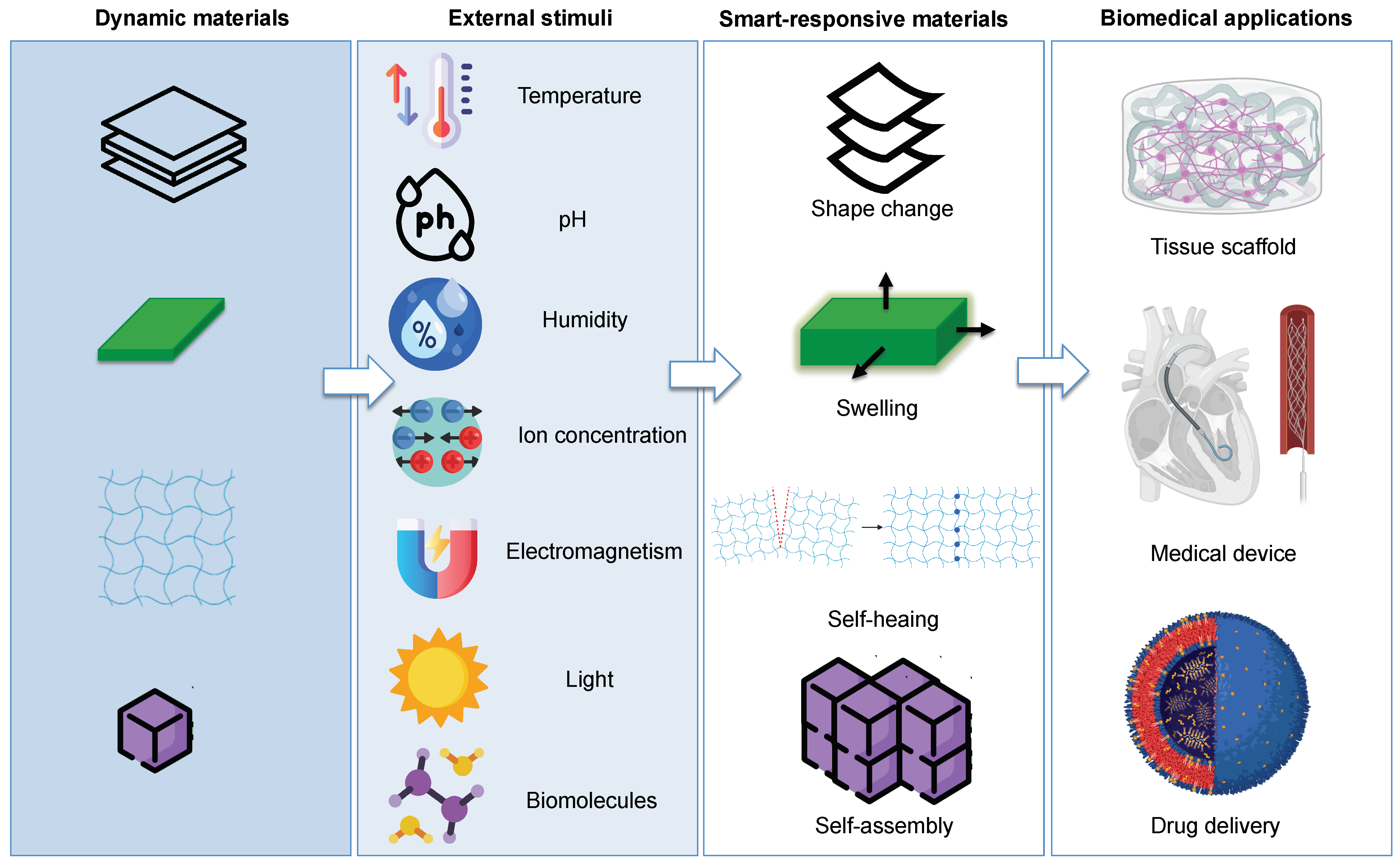

[4]. Therefore, the structures can deform, swell, self-assemble, or self-repair according to a pre-designed path under specific conditions of time and upon exposure to external stimuli. Such stimuli that are strictly connected with the changes in shape, properties, and functionality of 4D printed structures can be both physical (temperature, humidity, light, electromagnetism, and mechanical force) and chemical (pH, chemical reactions, ion concentration, cross-linking, redox state of metal ions) and can be applied sequentially or simultaneously to trigger a permanent or temporary change in the 4D printed objects (

Figure 1). In addition, such stimuli can also be of a biological nature (e.g., biomolecules, enzymes, and cell traction force), which are of particular interest for the fabrication of 4D-bioprinted engineered living scaffolds that allow tissue repair and regeneration or a replicating cell population of living organisms

[5][6][7].

Figure 1. Schematic representation of different types of stimuli, and responses observed in smart materials in terms of shape-shifting, swelling, self-assembly, self-repair, and their possible use in biomedical applications.

Hence, 4D printing represents a glimpse into the world of smart materials that can respond or adapt to environmental changes, biometric information, body temperature, pressure, or sweat, to name a few.

Therefore, it is clear that the stimuli-responsive materials must possess the following two key features to be used in 4D printing: (1) printability according to the guidelines of AM technologies and (2) sensitivity to a stimulus, achievable intrinsically from the polymer matrix or by incorporating additives or fillers into the polymer matrix

[8][9].

Below, the researchers elucidate some key aspects that distinguish 4D printing (self-repair, self-adaptability, shape-shifting, and self-assembly) as useful for creating the above-mentioned dynamic and controlled environments that are not exclusive to the biomedical field.

2. Self-Adaptability

Self-adaptive structures are fascinating applications of 4D printing. Through 4D printing, self-organizing structures can be obtained using materials that mimic DNA strands with complementarity sequences that couple under appropriate physical conditions. By doing so, the building blocks of specially programmable biomaterials can be induced to self-organize on multiple length scales to recapitulate the desired tissue architecture or to precisely control the composition and spatial distribution of cells in manufactured tissues that must mimic those natives

[10].

A prominent example of self-adaptive material has been reported by Zarek et al.

[11]. The authors fabricated 4D printed, customizable endoluminal cylindrical stents via SLA using methacrylated polycaprolactone (PCL-MA) as the stimuli-responsive material. This PCL-MA-based stent transits from a temporary closed state at room temperature (i.e., 20 °C) into a permanently open state at body temperature (i.e., 37 °C), enabling a minimally invasive insertion and better fitting of the stent at the damage site without the need for surgical traction.

In addition, using 4D printing, it is possible to embody self-sensing or self-actuation directly into a material so that external electromechanical systems are not necessary

[1], thus decreasing the number of printing parts, assembly time, material and energy costs, which is extremely useful for electromedical and electromechanical systems.

3. Self-Repair

The self-repair or error-correction capability is another key feature of 4D printing. As reported by Taylor et al.

[12], self-repair is defined as the property that enables a material to intrinsically and automatically heal damage, restoring itself to normality. Therefore, these materials are able to repair the damage themselves and regain the associated mechanical properties without human intervention or an external stimulus to promote the initiation or extent of self-repair but rather due to the molecular diffusion of ionic cross-links among the 4D printed polymer matrix. The self-repair requires rebonding a material to its original shape or condition, for example, by cutting a gel in half and then allowing it to bond back together

[13].

Indeed, hydrogels are the most promising materials for self-healing due to their tunable physical and chemical properties

[14]. In the case of self-healing hydrogels, non-covalent interactions (such as an ionic bond, hydrogen bond, hydrophobic interaction, Van der Waals interactions, electrostatic attractions, and ππ stacking) are generally utilized, separately or in combination, to self-mend damage or to restore their original properties

[15][16]. The 4D printed self-healing hydrogels show enormous advantages as they not only have the ability to extend their half-life but also lead to an increase in the durability, reliability, reusability of the material and, in some specific applications such as wound dressings, contact lenses, scaffolding for meniscus or cartilage, increase safety by avoiding sagging caused by the accumulation of cracks or breaks

[15].

4. Shape-Shifting

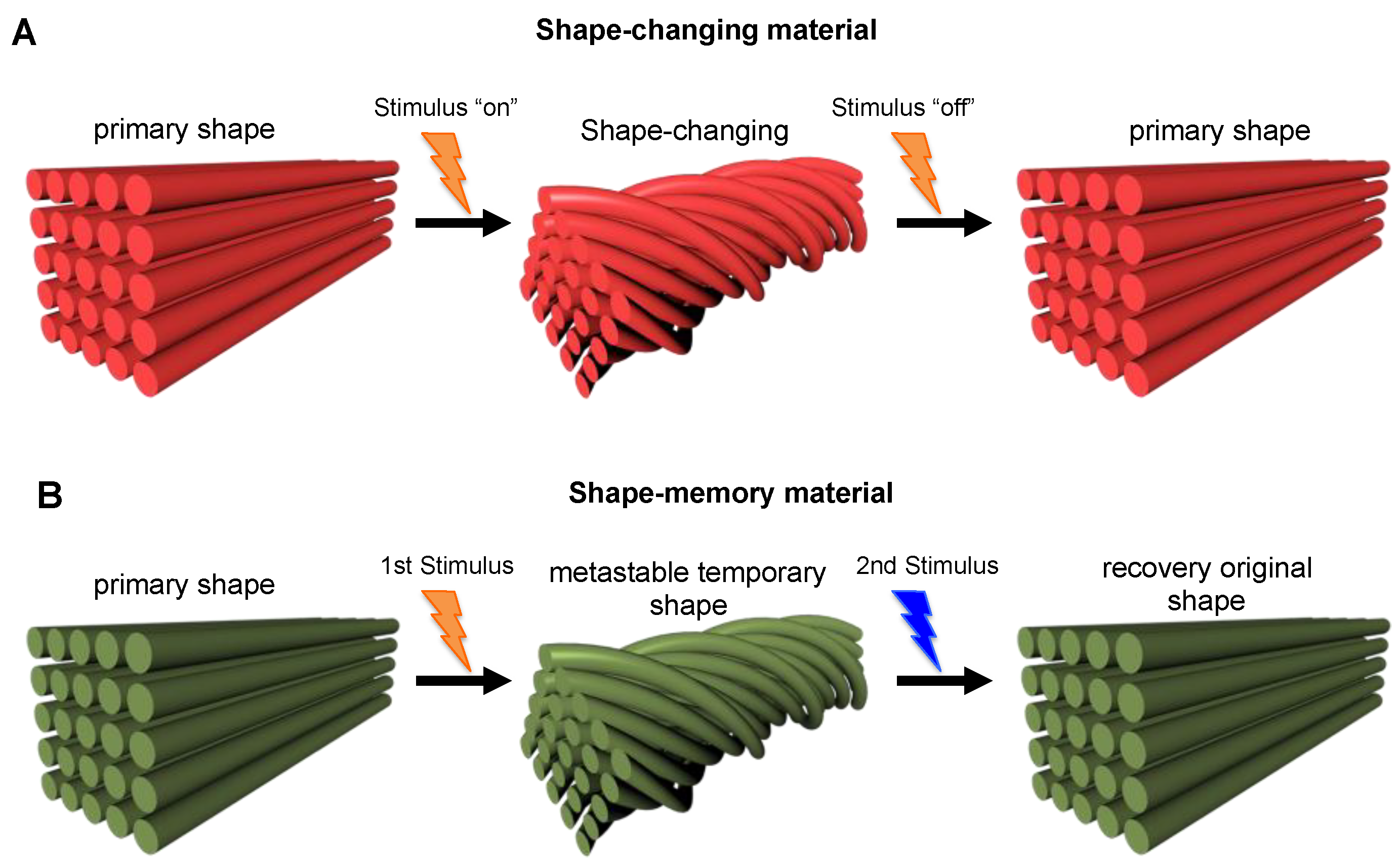

The shape-shifting materials can take and hold any possible shape, or folding, bending, or twisting following applied stimuli, thus paving the way for a new type of multifunctional material that could be used in a wide range of applications, from medicine and biotechnology to robotics. As reported by Momeni et al.

[17] and Zhou et al.

[18], the shape-shifting materials could be divided into the following two categories: shape-changing materials and shape-memory materials. A shape-changing material changes its shape immediately upon the application of a stimulus and returns to its original shape immediately after the stimulus has been removed (

Figure 2A). Therefore, this type of material works with an “on-off” mechanism, which is usually limited to changes in expansion swelling, twisting, or volume shrinkage

[18]. Instead, the shape-memory behavior involves a two-step process (

Figure 2B). In step one, the material is deformed from its primary shape following the application of a stimulus, thus reaching a temporary metastable shape, which is maintained until a second appropriate stimulus (which may be different from the previous one) is applied to allow the material to recover its original shape (step 2). Therefore, such shape-memory materials possess the capability to “memorize” and maintain a temporary shape until an appropriate stimulus is applied, while shape-changing materials cannot, thus immediately return to their original conformation as soon as the stimulus is removed.

Figure 2. Illustration of (A) a shape-changing material with the “on-off” mechanism, and of (B) a shape-memory material with the two programming steps in which the structure of the material is deformed from its primary shape following the application of a stimulus and then kept in a temporary metastable shape until a second stimulus is applied allowing the recovery of the original shape.

The difference between shape-changing and shape-memory may seem nuanced, but in reality, it has important implications for biomedical applications. For instance, with a similar approach to that reported by Zarek et al.

[11] for the 4D-printed self-adaptive endoluminal tracheal stent, Wan et al. exploited the shape-changing properties of poly(D,L-lactide-co-trimethylene carbonate) to 4D-print shape-changing patient-specific flower-shaped intravascular stents via DIW

[19]. The authors showed that the stents could rapidly self-expand from a closed deformed shape when warmed to 37 °C and return to their original shape when they are cooled (so when the warm temperature stimulus is removed). Instead, Kim et al. fabricated a kirigami-inspired 4D-printed polyurethane-based bifurcated stent using FDM

[20]. This bifurcated stent possesses shape-memory properties; when heated to its glass temperature of 55 °C, the stent deforms from its open “Y”-shaped configuration to an “I”-shaped temporary metastable closed configuration, in which the branching of the tube bends into a single tube of smaller diameter. The 4D-printed stent, in the temporary metastable configuration, can thus travel through the main vessel and, upon reaching the bifurcation of the target vessel, the original “Y”-shaped configuration can be recovered by applying a second specific stimulus, which is to increase the temperature to 60 °C. In this way, using this innovative shape-memory method, it will be possible to easily implant a stent at the bifurcation of the target site (even if it is difficult to reach) because, thanks to its temporary metastable configuration, it will be able to pass through the main vessels in a minimally invasive way.

5. Self-Assembly

The concept of self-assembly is not new and it is increasingly used in many application fields such as nanomedicine, biotechnology, architecture, infrastructure and other industry scenarios

[21]. By definition, self-assembly is the process in which the components of a system, be they atoms, molecules, particles, or polymers, organize themselves autonomously and with free energy into ordered and/or functional structures as a consequence of specific interactions or stimuli

[22].

Self-assembly processes are ubiquitous in nature (e.g., minerals, shells, pearls, corals, bones, teeth, wood, silk). Indeed, as reported by Shuguang Zhang

[23], nature has found a fascinating way of using the self-assembly phenomenon, allowing molecules or structures to organize themselves hierarchically from the nano- to the mesoscale level, thus leading to exceptional properties. Just think of the formation of complex biological machines such as ribosomes, ATP synthase, membrane channels, and hemoglobin.

In 4D printing, the concept of self-assembly is very attractive not only for the fabrication of responsive tissue engineering scaffolds to mimic the complex structure of the extracellular matrix (ECM) of damaged tissues

[24], but also for the transfer of parts of equipment within the human body

[25]. Certainly, the future development of 4D printing will focus on a variety of self-assembly capabilities and properties of free energy that must be functionally incorporated into the material for developing single parts that can be 4D printed with small printers and then self-assembled into larger structures, such as space antennas, satellites, or international space stations as envisaged by Tibbits and colleagues

[26]. Further attractive applications of 4D-self-assembly include self-assembling buildings, especially in non-industrialized zones or war zones where elements can come together to produce a finished building with minimal human involvement

[27], and reconfigurable robotic systems with different degrees of freedom (DOFs)

[28] in order to serve different and complex mechanical (i.e., locomotion), and/or “programming matter” that encodes structural and functional information of biological-inspired assembly systems

[29].