Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 2 by Rita Xu and Version 1 by Hassane Naji.

Sharing renewable energies, reducing energy consumption and optimizing energy management in an attempt to limit environmental problems (air pollution, global warming, acid rain, etc.) has today become a genuine concern of scientific engineering research. Furthermore, with the drastic growth of requirements in building and industrial worldwide sectors, the need for proper techniques that allow enhancement in the thermal performance of systems is increasingly being addressed. It is worth noting that using sensible and latent heat storage materials (SHSMs and phase change materials (PCMs)) for thermal energy storage mechanisms can meet requirements such as thermal comfort in buildings when selected correctly.

- latent and sensible heat

- lattice Boltzmann method

1. Introduction

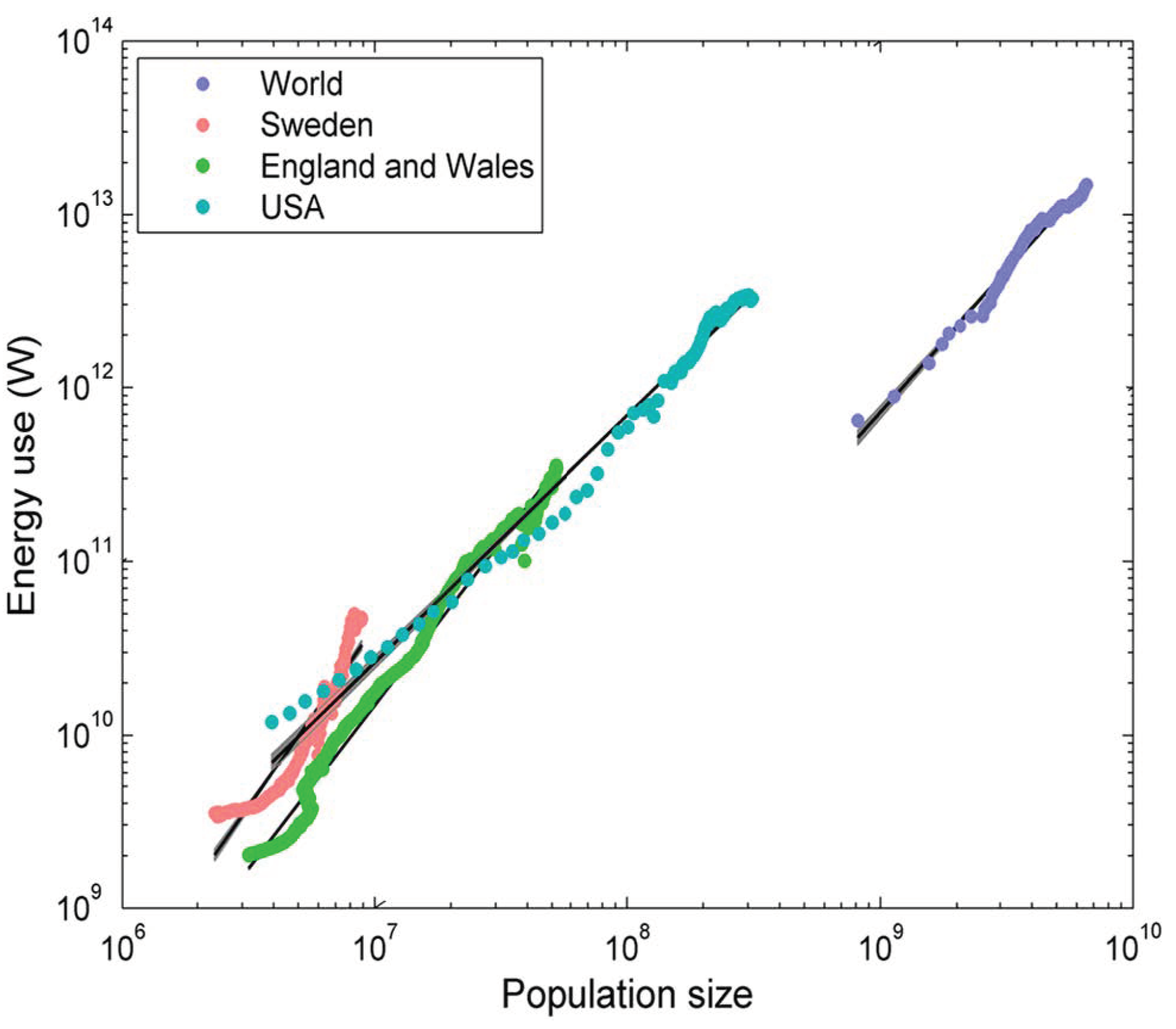

Nowadays, the energy storage sector figures as a fundamental technology facing the rapid development of industrialization and urbanization. Thereby, over the years, energy storage systems (ESSs) technology has been widely developed to ensure the renewable energy resources sustainability and to balance the gap between energy demand and supply [1]. Throughout history, along with the increase in human population, the global consumption of energy continues to increase, as shown clearly observed in Figure 1. Energy consumption is observed to increase faster than population size [2]. Yet, it is noteworthy to highlight the industrialization and welfare level as the main factors responsible for the tremendous increase in energy consumption.

Inevitably, it is crucial to implement ESS into energy systems not only to limit the intermittency of renewable energies but also to facilitate the flexibility of energy systems while increasing their efficiency. Generally, the use of ESSs is aimed at matching the energy demand and supply. As illustrated in Table 1, there are different ESSs approaches that can be used in various engineering applications [3].

Table 1. Energy storage (ES) methods, reprinted/adapted with permissionfrom Ref. [3], 2022, Springer Nature [3].

| Energy Storage Methods | ||||

|---|---|---|---|---|

| Thermal | Mechanical | Electromechanical | Electrical | Chemical |

| Sensible thermal | Pumped hydro | Electrochemical capacitors | Capacitors | Hydrogen storage |

| Latent thermal | Compressed air | Batteries | Super capacitors | Synthetic natural gas |

| Thermochemical | Flywheel | Fuel cells | Super conducting magnetic ES (SCMES) | |

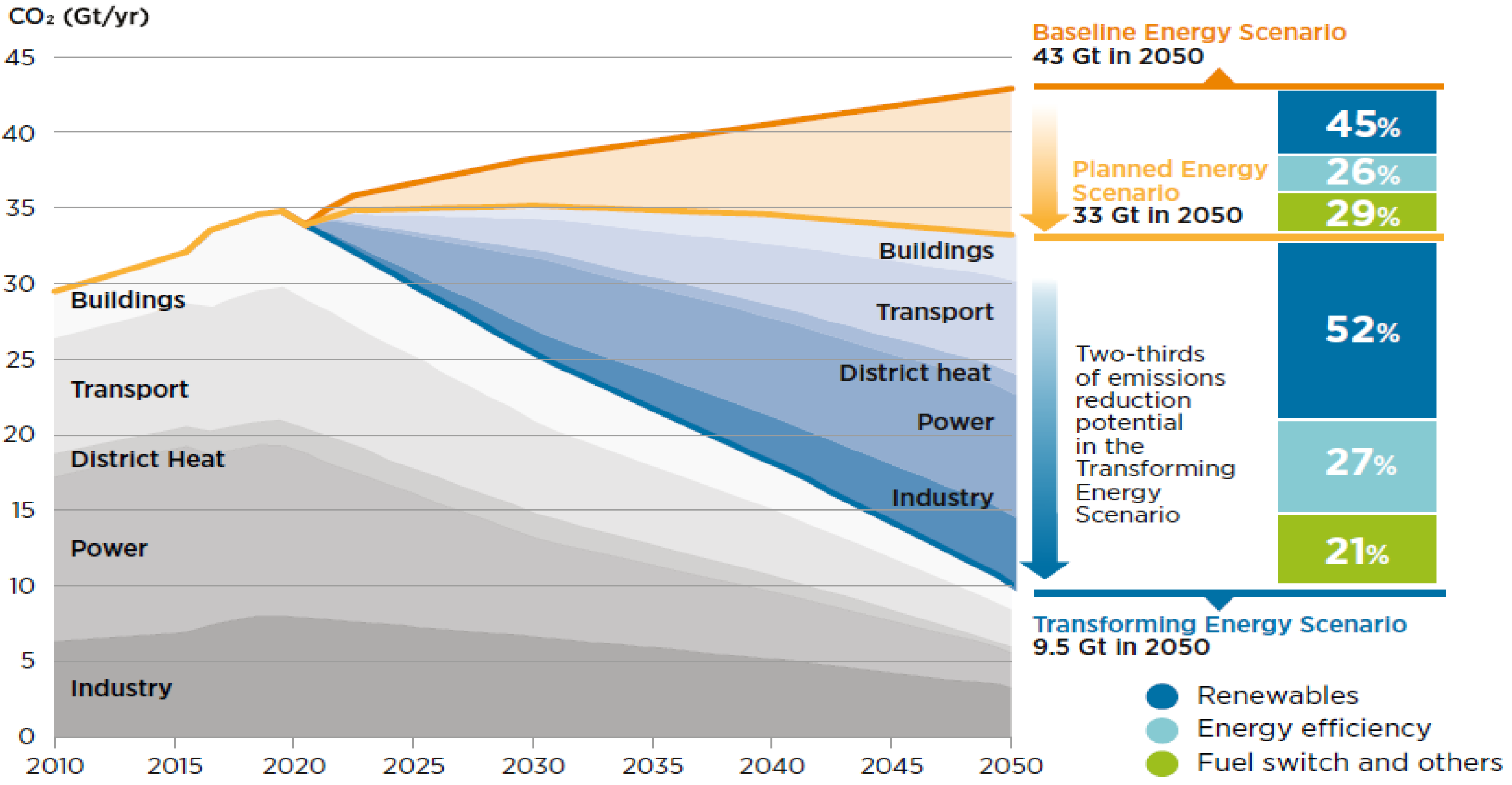

Among several ES methods, TES appears as one of the emerging technologies that can bridge the intermittency gap in renewables such as solar energy [4], energy saving and the promotion of environmental respect (greener world). TES systems consist of a thermal energy storage medium (heat and/or cold) kept for a defined period to use it when and where it is needed [4,5][4][5]. The applications of these systems (TES) are in the building sector (air conditioning, thermal comfort, domestic hot water, etc.) and industrial sector(chemical industry, food industry, etc.) [6]. It is worthy to emphasize that the estimated annual energy savings potential in the European Union (EU) is 7.5% thanks to the implementation of these technologies [7].In terms of environmental savings, the annual potential CO2 emissions were reduced by about 5.5% in the EU [7]. Later, 90% of the CO2 emissions mitigation is expected by 2050 (according to the international renewable energy agency (IRENA)) through the application of these systems (Figure 2) [8]. Since then, these systems have received particular attention through an economic and environmental analysis in several sectors (Figure 2).

According to Calderón et al. [9], more than 14,000 publications have been achieved over the last decade, showing that scientific research is increasingly productive in the TES field. However, the choice of an appropriate TES system depends on various factors, basically depending on the targeted field of application, technical conditions (volume, temperature span, etc.), storage time and economic aspect (marketing and cost-effectiveness) [10]. Considering the characteristics of the storage period, there are two concepts of TES systems called short-term storage systems and long-term storage systems. The first concept is a storage cycle of a few hours known as diurnal heat storage [11], while the second is known as storage seasonal heat [12]. In this context and by way of example, the seasonal TES (STES) stores the heat collected in the summer for up to more than three months (charging period) using thermal solar power plants to be used in winter (discharging period) [13]. It is worth noting that this reverse process can obviously be applied. Therefore, this second category of TES systems (STES) has a significant contribution to the efficient use of renewable in building applications such as decarbonization and district heating [14,15][14][15]. Note that such a category competes with others on a large scale such as natural gas storage, pumped storage hydroelectric system and heat generation methods. Yet, sector coupling remains as the most important challenge for future energy concepts. Furthermore, large-scale TES systems are needed for the conception of any other technology to ensure system stability and resilience. In addition, depending on the energy storage method deemed, TES solutions can be classified into three categories, viz., sensible heat storage (SHS), latent heat storage (LHS) using PCMs and thermochemical heat storage (TCHS). Moreover, these classes can be implemented in active or passive buildings [16,17][16][17]. In passive building technology, only the SHS and LHS methods are used, which allow improving thermal comfort through materials use with high thermal inertia [16,18][16][18]. As for the concept of active buildings, the TCHS method, which enables to attenuate the peak load, is the one that is rather used as it increases renewable energies contributions such as solar and aerothermal energies [17,18][17][18]. It improves the efficiency of systems by regulating the process range, for example using frequent starts/stops to reduce discontinuous inputs [17,18][17][18]. In this context, Ben Romdhane et al. [19] documented a review of passive building applications based on the LHS method while comparing it to the SHS approach. They reported that the LHS technique stores five to 14 times more heat than the SHS method. Otherwise, Rathore and Shukla [20] presented a review of the different types of TES used in construction while paying great attention to LHS materials. Furthermore, a description dealing with several LHS designs has been provided, which has indicated that a macro-encapsulated phase change material (MPCM) could be used for a period of time, helping to alleviate the reliance on heating and cooling devices and, thereby, saving energy.

Lizana et al. [18] reviewed the development and applications of thermal energy storage materials for zero energy buildings (ZEBs). Different properties, designs, and classifications of sensible, latent and thermochemical TES materials have been described and compared based on recent scientific research, well-known international projects, and commercial systems. They revealed that there exists a shortage of materials for TCHS solutions while noting that the thermochemical method requires well-maintained tanks and heat exchangers for small-scale processes. Thereby, further efforts are still needed to optimize the technical and economic concept of TCHS systems. In parallel, Navarro et al. [17] conducted a comprehensive review of TES technologies embedded into active buildings. It is worth noting that there are two types of active systems, viz direct and indirect systems where the storage medium is either the heat transfer fluid (HTF) or another medium. These authors stated that the active systems design requires proper maintenance to achieve suitable incorporation, taking into account various conditions and requirements that may be climatic, aesthetic and/or operational. Each type of TES has its advantages and disadvantages, the operating principle of which depends on the targeted application, such as capacity or power.

| TES Technique | Capacity (kWh/ton) | Power (MW) | Efficiency (%) | Storage Time | Cost (€/kWh) |

|---|---|---|---|---|---|

| Sensible heat | 10–50 | 0.001–10 | 50–90 | d/m | 0.1–10 |

| Latent heat | 50–150 | 0.001–1 | 75–90 | h/m | 10–50 |

| Thermochemical heat | 120–250 | 0.01–1 | 75–100 | h/d | 8–100 |

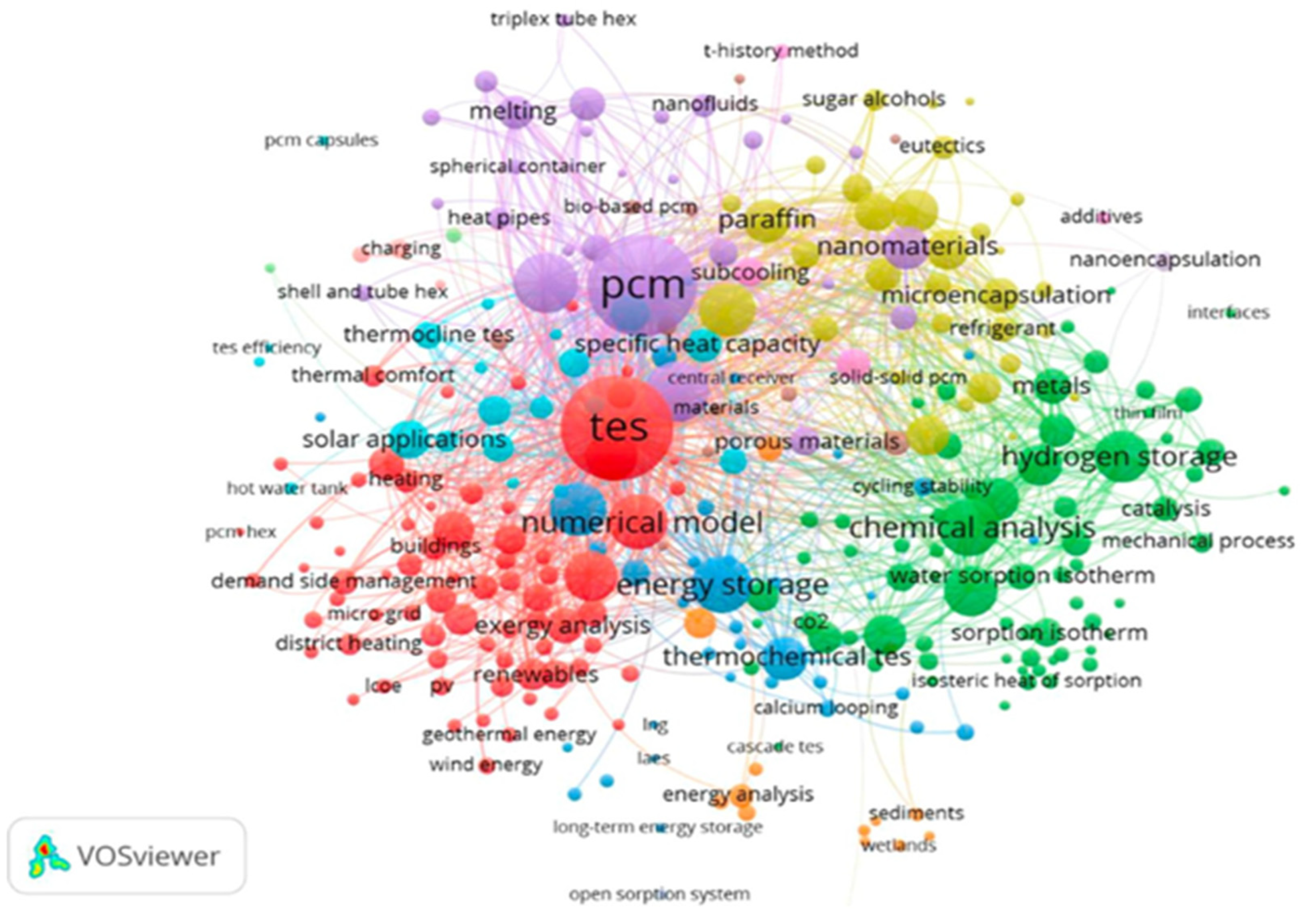

For some time now, various articles on energy storage have been published, pointing out research trends and drawing up the state of the art [9,22,23,24,25][9][22][23][24][25]. In this, Cabeza et al. [26] issued a bibliometric analysis using VOSviewer software to develop research related to TES categories and identify research gaps. For TES topics, the approach performed using the co-occurrence of the keywords found is illustrated in Figure 3. Through this diagram, it appears that terms relevance can be identified from the circles size. Simply stated, a larger circle identifies the subject with more studies. Furthermore, the research gaps are identified by smaller circles. As shown and indicated in Ref. [27], subjects TES (red circle) and LHS with PCMs (purple circle) indicate high relevance, meaning that they are the focus of intense investigation both experimentally and/or numerically. The benefit of this overview is to serve as a guide for any reader interested in the decision-making process in evolving TES solutions for different industries.

Figure 3. Keywords’ co-occurrence for the storage sector [26], reprinted/adapted with permission from Ref. [26], 2022, Elsevier.

2. Sensible Heat Storage (SHS) Method

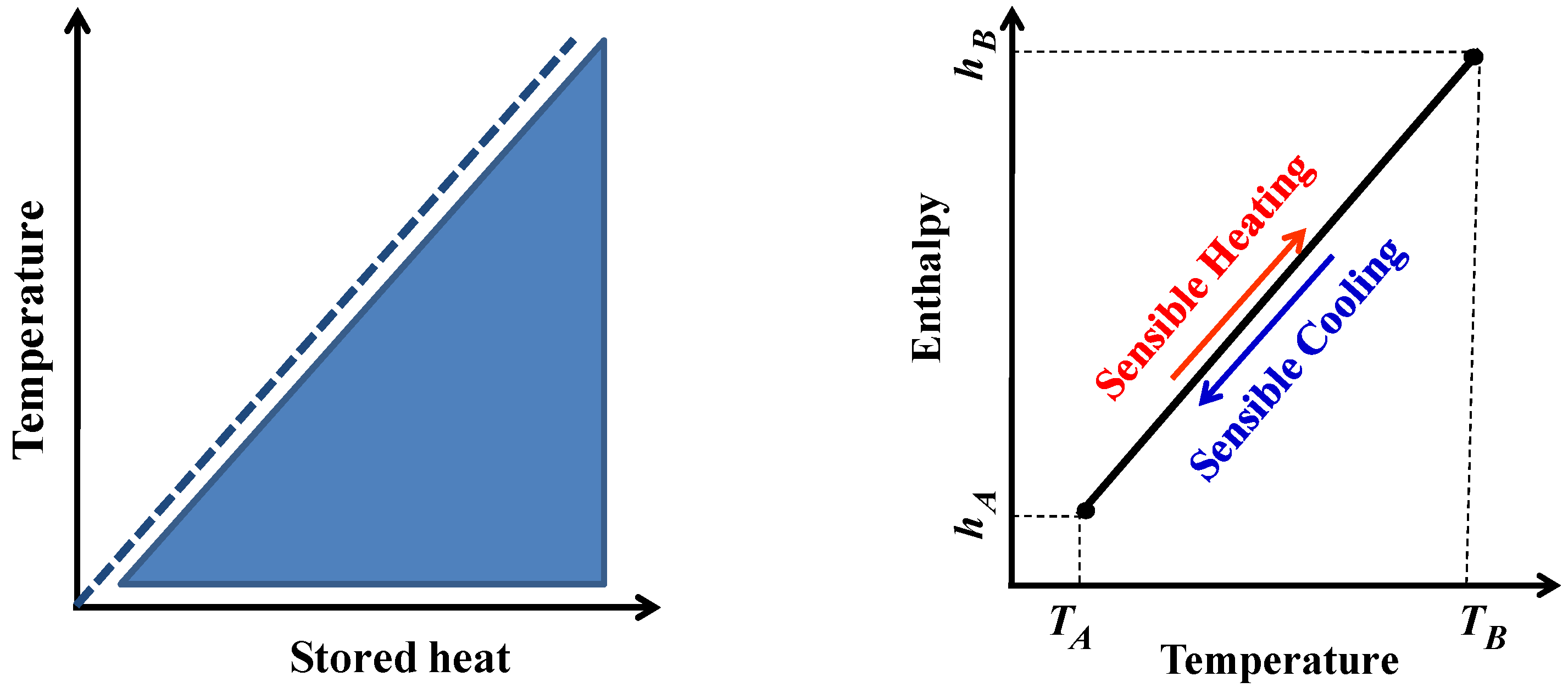

Sensible heat storage (SHS) is the most traditional, mature and widely applied TES solution due to its simple operation and reasonable cost. However, it suffers from the low-energy storage density achieved compared to the other two TES options, viz LHS and TCHS [27]. In this approach, the energy transfer (as heat) to and from the storage medium that can be liquid (water, oil, etc.) or solid (sand, rock beds, brick, etc.) results in the corresponding change (increase or decrease) of the medium’s temperature. Figure 4 depicts the SHS typical diagram during sensible heating or cooling with no phase transition during the process [3,28][3][28]. One of the advantages of this mode is that the storage and release of the accumulated heat (charging and discharging cycles) can be repeated without any problem while involving a large volume to meet the needs [29]. In addition, this method generally takes the advantage of certain properties of the storage material such as its high specific heat [30].

Figure 4. SHS typical diagram during sensible heating or cooling with no phase transition.

Since the quantity of sensible heat stored (Q) depends on the mass (m), the heat capacity ( ) [30], two main characteristics of SHS materials (SHSMs) should be pursued to increase the capacity storage volume (MJ·m−3) with high specific heat and density. Among the abundantly available materials, water has a comparably high specific heat and density, wherefore it is quite frequently used as a storage material in many practical applications. For example, the sensible heat storage capacity has been estimated at 250 MJ·m−3 for a thermal gradient of 60 °C in the case of water [18].

Fernández et al. [31] presented a bar chart where a certain property (e.g., specific heat capacity) is plotted for all families of engineering materials mostly used in SHSMs to better identify and classify them. On the other hand, thermal conductivity, thermal diffusivity and flow rate play a key role in charging/discharging cycles that ensure stratification ability.

It is worth noting that a high thermal stratification facilitates the release of heat, allowing a transfer of thermal energy at low temperature toward the colder zones during the charging period, and thereby, a higher exergy (quality energy) which is promptly obtained from the hottest zones during the discharge process [32]. The thermal effusivity parameter appears as the main variable influencing thermal inertia in passive construction applications [33]. This parameter characterizes the rate at which a material can release or absorb heat, where its raise augments the heat stored quantity and thereby mitigates energy consumption [18]. In addition, the availability, cost, toxicity and volume change are further criteria for the selection of sustainable SHSMs [18]. As mentioned before, the main disadvantages are their limited energy density and the device self-discharge [34]. To assess the SHS system performance, González-Roubaud et al. [35] pointed out that the relevant quantities are energy storage capacity, power, efficiency, time of charging/discharging cycles and cost.

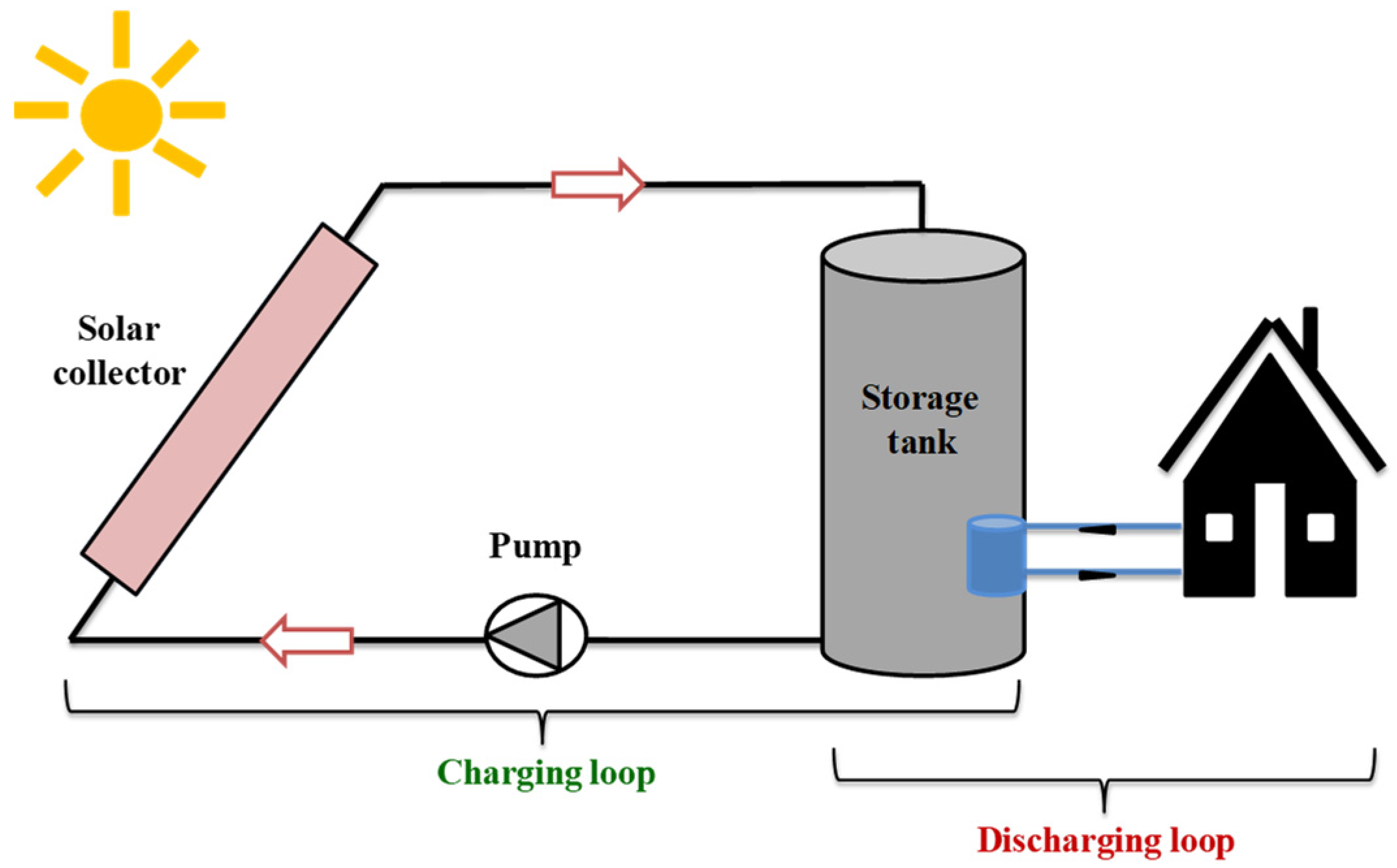

According to Cabeza et al. [26], the SHS approach has been widely used in solar applications such as concentrated solar power plants (CSP) [36] or desalination [37]. For example, the water-based SHS is one of the most widely used solar TES systems in residential applications (see sketch in Figure 5) [3], and besides, Koçak et al. [38] have published a comprehensive review article on SHS systems and materials available and applied in industrial solar heat applications. According to the temperature range, they pointed out that there are mainly three groups of solar industrial processes, viz low-temperature (<150 °C), medium-temperature (150 °C < T < 400 °C) and high-temperature (>400 °C) applications. They concluded that the fixed-bed thermocline technique is the most economical and widely used method for sustainable solar applications, regardless of the temperature range. SHS technologies are gathered in Table 3.

Figure 5. Simple solar application: solar-based water heating device, reprinted/adapted with permission from Ref. [3], 2022, Springer Nature.

Table 3. SHS techniques and their classification, reprinted/adapted with permission from Ref. [38], 2022, Elsevier.

| SHS Techniques | Classification | |||

|---|---|---|---|---|

| Underground thermal energy storage | Aquifer thermal energy storage | Borehole thermal energy storage | Tank thermal energy storage | Pit thermal energy storage |

| Thermal energy storage in tanks | Vertical (thermocline) | Horizontal | ||

| Fluidized beds | ||||

| Thermal energy storage in building structures | ||||

It is noteworthy that numerical studies and experiments are increasingly performed to define optimal parameters to improve the system’s performance.

2.1. Sensible Heat Storage Materials (SHSMs)

There are different reviews on TES solutions dealing with the thermophysical characteristics of commonly used SHSMs and comparing the different parameters involved (such as physical, chemical, thermal, environmental, economic, etc.) to fulfill construction requirements and/or industrial applications. The SHSMs can be classified into solid and liquid storage materials [3,18][3][18]; regarding liquid heat storage materials, the most common materials are water, oils, and pure alcohol or its derivatives, while rocks, stones, bricks, concrete, dry and wet soils, wood, plasterboard and cork are the most commonly used as solid heat storage materials.

Fernández et al. [31] presented an overview of SHSMs in the temperature range of 150–200 °C leaning on Ashby’s method [39,40][39][40] for material selection to find suitable and potential materials for long and short-term cycles for the SHS method. According to these authors, solid SHSMs can be classified into metals and alloys, ceramics and glasses, polymers and elastomers, and hybrids. The thermophysical properties of some commonly used SHSMs are listed in Table 4 [3,18,19,41][3][18][19][41].

Table 4. Thermophysical properties of some commonly used SHSMs [3,18[3][18][19][41],19,41], reprinted/adapted with permission from Refs. [18[18][19],19], 2022, Elsevier.

| SHSM | Type | Density (kg·m−3) | Thermal Conductivity (W·m−1·K−1) | Specific Heat (kJ·m−1·K−1) |

|---|---|---|---|---|

| Water (80 °C) | Liquid | 970 | 0.67 | 4.19 |

| Water (40 °C) | Liquid | 990 | 0.63 | 4.19 |

| Thermal energy storage in packed bed | Stationary beds | |||

| Water (10 °C) | Liquid | 1000 | 0.6 | 4.19 |

| Oil | Liquid | 880 | 0.14 | 1.88 |

| Ethanol | Liquid | 790 | 0.171 | 2.4 |

| Propanol | Liquid | 800 | 0.161 | 2.5 |

| Butanol | Liquid | 809 | 0.167 | 2.4 |

| Ceramic brick | Solid | 1800 | 0.73 | 0.92 |

| Rock | Solid | 2800–1500 | 3.5–0.85 | 1 |

| Concrete | Solid | 2000 | 1.35 | 1 |

| Wood | Solid | 700–450 | 0.18–0.12 | 1.6 |

| Aluminum | Solid | 2707 | 204 | 0.896 |

| Copper | Solid | 8954 | 385 | 0.383 |

| Granite | Solid | 2640 | 4.0–1.7 | 0.82 |

| Sand and gravel | Solid | 2200–1700 | 2 | 1.18–0.91 |

| Clay or silt | Solid | 1800–1200 | 1.5 | 2.5–1.67 |

| Limestone | Solid | 2600–1600 | 2.3–0.85 | 1 |

| Cement mortar | Solid | 1800 | 1 | 1 |

| Brick | Solid | 1600 | 1.2 | 0.84 |

| Marble | Solid | 2500 | 2 | 0.88 |

| Plastic board | Solid | 1050 | 0.5 | 0.837 |

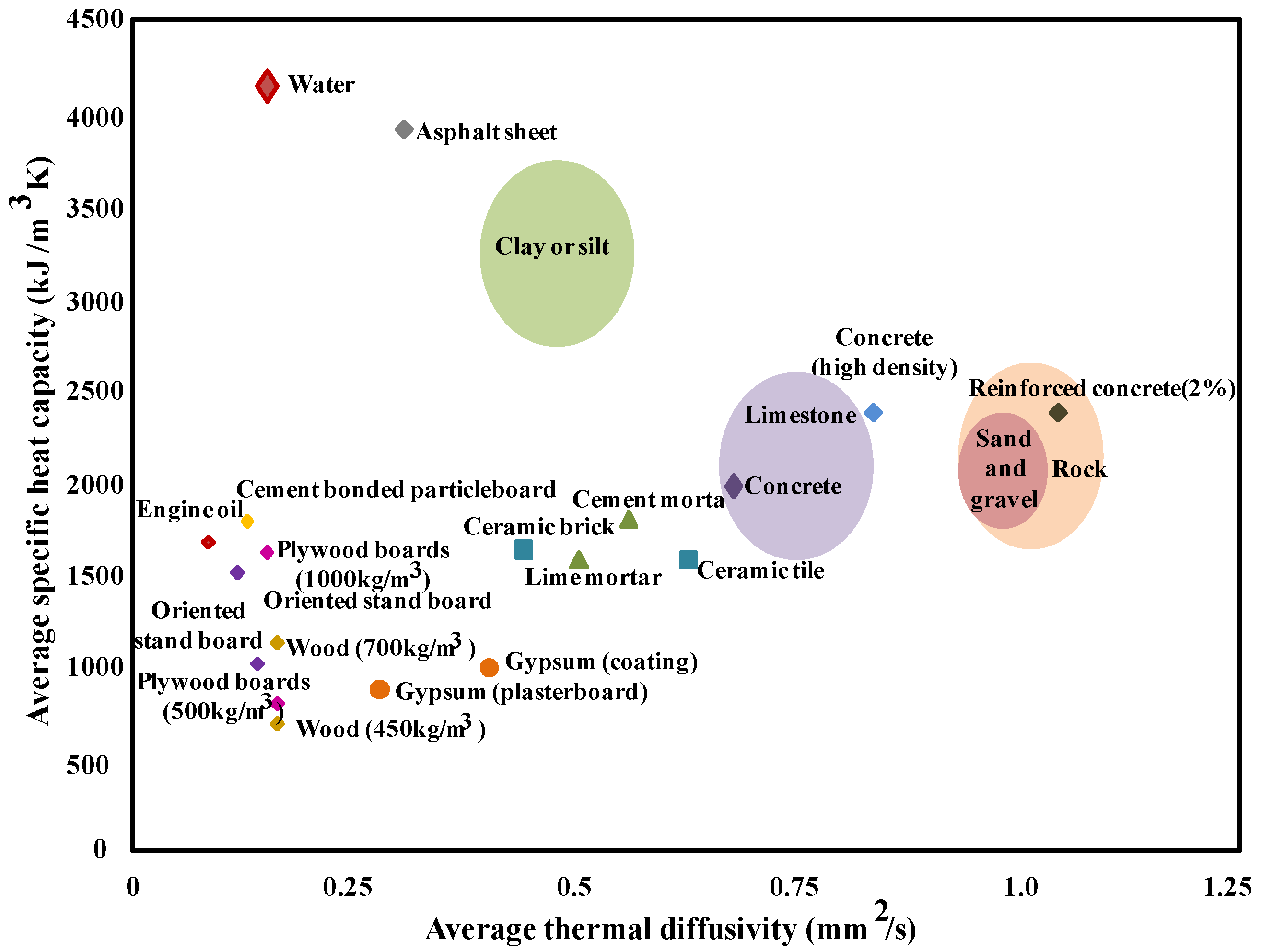

Note that many factors must be ensured to guarantee a long life of SHSMs such as thermal and chemical stability (constant thermal properties, no chemical decomposition and no degradation) at high temperature gradient regardless of the number of cycles (charge/discharge). According to Klein et al. [42], storage substances should conduct heat better, have higher specific heat and density, be able to operate in a suitable temperature range and be easily accessible in terms of cost. Figure 6 displays the average volumetric specific heat capacity vs. average thermal diffusivity for the most available SHSMs [18].

Figure 6. Most available and common SHSMs, reprinted/adapted with permission from Ref. [18], 2022, Elsevier.

Today, the number of the available SHSMs (either liquids or solids) for engineering purposes exceeds 150,000 [28,31][28][31]. Among them, water is the most mature material due to its availability, non-toxicity, low cost and high specific heat capacity [28].

Almendros-Ibáñez et al. [43] performed a synthesis study on different techniques for storing solar energy in particle beds, emphasizing the different particle methods called packed beds and fluidized beds. They stated that liquid SHSMs have a higher specific heat capacity than solids (e.g., rock). Unfortunately, some issues such as liquid storage infrastructure, high cost of heat exchangers, risk of leaks and large storage tanks (hot and cold) limit their use [18,44,45,46][18][44][45][46]. On the other hand, concerning solids SHSMs, their main disadvantages are the low density, the high investment cost and the risk of self-discharge (in the long term).

2.2. Sensible Heat Storage in Porous Media

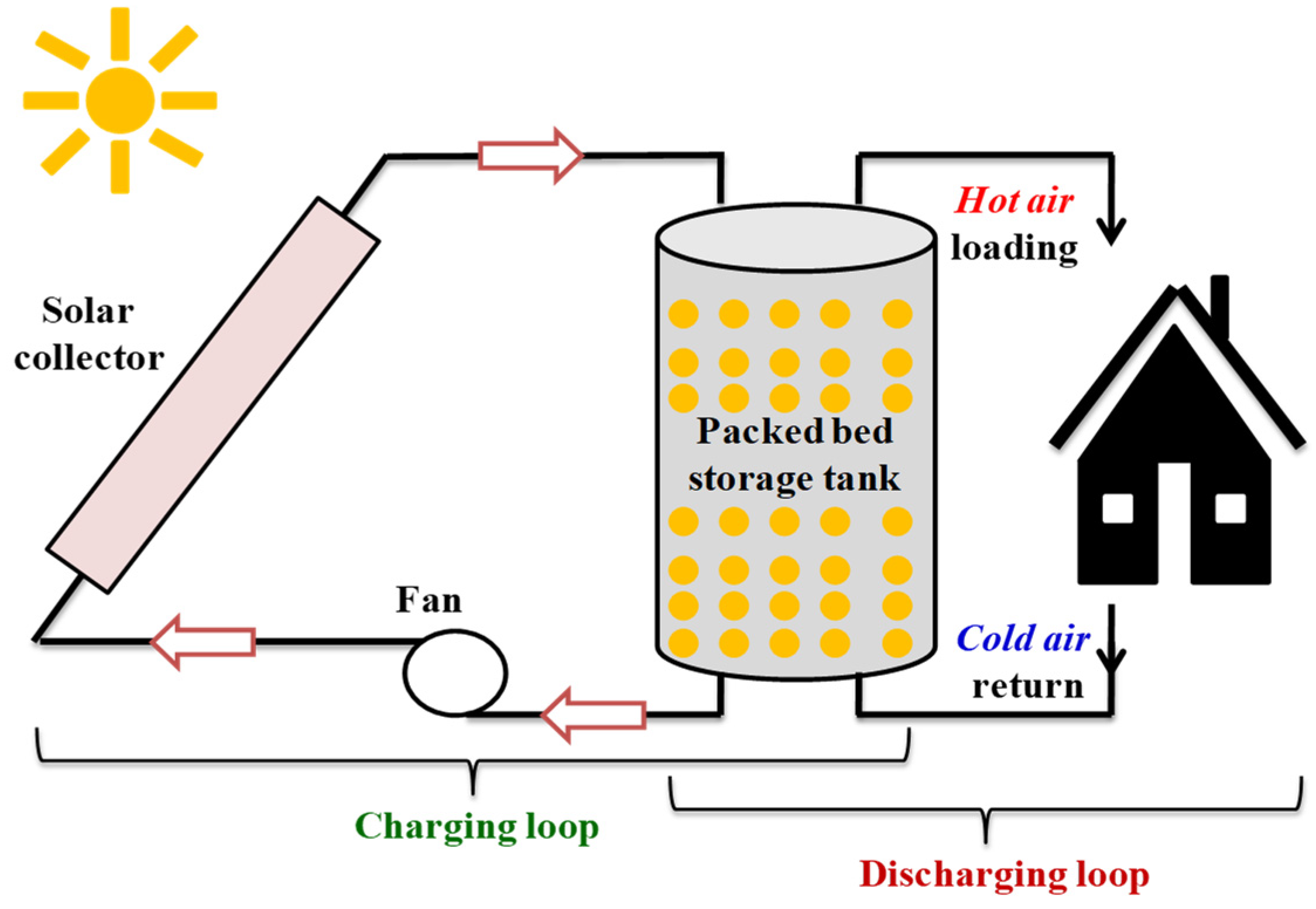

Without detailing, the SHS mode consists of a sensible heat storage material (SHSM), an SHSM container (e.g., tank) to prevent leakage and heat losses and input/output devices [47].Among the tools used in this storage mode, SHS in a porous medium is the most preferred solution. Out of the available case studies in the literature in this field, a few representative ones are reviewed in the present section. Saturated tanks of porous solid SHSMs are used in many industrial and building applications such as power generation and heating [3]. Figure 7 exemplifies a residential heating application using a porous fixed bed storage tank. In general, a fixed bed storage tank is used for the TES of solar air heaters and represents a volume of porous medium formed by packing particles of selected SHSM into a container. In this system, the working fluid (e.g., air) advects heat from the collector to the reservoir. Hot fluid passes through spaces between solid SHSMs (e.g., rock or sand), causing the particles to rise in temperature during the day (charging loop), and the quantity of sensible heat stored inside the tank is recovered during the night (discharging loop).

Figure 7. Heating application: porous packed bed SHS system, reprinted/adapted with permission from Ref. [3], 2022, Springer Nature.

Let us pHoint out, however, that the main parameters that influence the SHS system performance are the working fluid type, the flow rate and the porosity [3,47][3][47].

A huge range of investigations in the literature have dealt with SHS in various porous units. Among the different characteristics of a sensible storage medium, the porosity effect, which turned out to be a crucial characteristic, is sketched herein. To address this topic, Mabrouk et al. [48] developed a numerical model to study the effect of pore density parameter (PPI) on an SHS unit. The system deemed was subjected to forced convection and compared to an LHS unit. They advised a porous metal foam to optimize energy and exergy efficiencies while indicating that increasing the PPI for high porosity value mitigates energy losses for sensible heat systems and thereby increases the quality of stored energy. In another study, Amami et al. [49] explored the charging and discharging process enhancement in a porous SHS duct held under a forced pulsating flow. They examined several porosities of the porous support while estimating its thermal performance. They found that with increasing porosity, the sensible energy amount stored is improved, and the exergy efficiency (quality) is significantly raised. As an example, the energy efficiency increased from 31% to 68.2% when the porosity increased from 0.6 to 0.8, respectively, for a given flow pulsation amplitude. The same shall apply to exergy efficiency, which goes from 32.4% (for ε=0.6) to 67% (for ε=0.8).

Elouali et al. [44] achieved four physical models through numerical simulations to describe the thermal behavior of a packed bed for sensible heat storage. They particularly discussed the porosity influence on the packed bed during charging and discharging periods. They demonstrated that a decrease in porosity improves the thermal storage capacity of the packed bed and increases the interstitial heat transfer between the coolant and the solid particles. Furthermore, they noted that high porosity slows down the charging process.

Kasaeian et al. [50] presented a review of numerous models to simulate nanofluid flow physics in a porous medium. They gathered details on the main features of a porous structure embedded in thermal systems such as heat exchangers and ducts. They stated that the use of a porous matrix extends the specific interface area between the porous structure and the working fluid, which results in a higher rate of heat transfer and, thereby, significantly improves the system thermal efficiency.

Sheremet et al. [51] conducted a numerical analysis of natural convection in a concentric horizontal annulus filled with a porous structure saturated by Cu-water nanofluid. It turned out that a low porosity (ε<0.5) increases the thermal conductivity of the medium, and it has no effect on the flow of the fluid nor on the heat transfer. On the other hand, they found out that a large porosity (ε>0.5) intensifies the convective flow. In 2015, Sheremet et al. [52] numerically examined the thermal behavior of a square cavity composed of solid porous medium (aluminum foam and glass beads). They targeted the effects of pore morphological parameters such as porosity. The authors noted that the local and mean Nusselt numbers are minimum at high porosity, and the latter significantly affects the heat transfer rate.

In 2014, Amami et al. [53] proposed a porous unit designed to store sensible heat. They demonstrated that the use of a porous medium with high permeability and low thermophysical properties improves the performance of the considered TES unit and raises temperature and the stored sensible energy amount.

Heap et al. [54] discussed the influence of volcanic rock porosity and magma (SHSM). They indicated that an increase in porosity decreases the density and compressive strength of rocks while increasing their deformability. Thereby, they advised adopting a low porosity. Dhifaoui et al. [55] conducted an experimental study of SHS performance of a vertical porous bed composed of glass beads and air which is heated with a constant heat flow.

References

- Xu, H.; Wang, N.; Zhang, C.; Qu, Z.; Cao, M. Optimization on the melting performance of triplex-layer PCMs in a horizontal finned shell and tube thermal energy storage unit. Appl. Therm. Eng. 2020, 176, 115409.

- DeLong, J.P.; Burger, O. Socio-economic instability and the scaling of energy use with population size. PLoS ONE 2015, 10, e0130547.

- Dincer, I.; Ezan, M.A. Heat Storage: A Unique Solution for Energy Systems; Springer: Cham, Switzerland, 2018.

- Sarbu, I.; Sebarchievici, C. Solar Heating and Cooling Systems: Fundamentals, Experimentsand Applications; Elsevier: Oxford, UK, 2016.

- Cabeza, L.F. Advances in Thermal Energy Storage Systems; Woodhead Publishing Series in Energy; Elsevier Science: Amsterdam, The Netherlands, 2015.

- Stutz, B.; Le Pierres, N.; Kuznik, F.; Johannes, K.; Del Barrio, E.P.; Bédécarrats, J.-P.; Gibout, S.; Marty, P.; Zalewski, L.; Soto, J.; et al. Storage of thermal solar energy. Comptes Rendus Phys. 2017, 18, 401–414.

- Arce, P.; Medrano, M.; Gil, A.; Oró, E.; Cabeza, L.F. Overview of thermal energy storage (TES) potential energy savings and climate change mitigation in Spain and Europe. Appl. Energy 2011, 88, 2764–2774.

- IRENA. Innovation Outlook: Thermal Energy Storage; International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2020.

- Calderón, A.; Barreneche, C.; Hernández-Valle, K.; Galindo, E.; Segarra, M.; Fernández, A.I. Where is Thermal Energy Storage (TES) research going?—A bibliometric analysis. Sol. Energy 2020, 200, 37–50.

- Ibrahim, H.; Ilinca, A.; Perron, J. Energy storage systems-Characteristics and comparisons. Renew. Sustain. Energy Rev. 2008, 12, 1221–1250.

- Dahash, A.; Ochs, F.; Janetti, M.B.; Streicher, W. Advances in seasonal thermal energy storage for solar district heating applications: A critical review on large-scale hot-water tank and pit thermal energy storage systems. Appl. Energy 2019, 239, 296–315.

- Guo, F.; Yang, X.; Xu, L.; Torrens, I.; Hensen, J. A central solar-industrial waste heat heating system with large scale borehole thermal storage. Procedia Eng. 2017, 205, 1584–1591.

- Persson, J.; Westermark, M. Low-energy buildings and seasonal thermal energy storages from a behavioral economics perspective. Appl. Energy 2013, 112, 975–980.

- Reed, A.L.; Novelli, A.P.; Doran, K.L.; Ge, S.; Lu, N.; McCartney, J.S. Solar district heating with underground thermal energy storage: Pathways to commercial viability in North America. Renew. Energy 2018, 126, 1–13.

- International Renewable Energy Agency (IRENA). The Energy Technology Systems Analysis Program (ETSAP): Technology Brief E17; International Energy Agency (IEA): Paris, France, 2013; Available online: https://www.irena.org/-/media/Files/IRENA/Agency/Publication/2013/IRENA-ETSAP-Tech-Brief-E17-Thermal-Energy-Storage.pdf (accessed on 1 January 2013).

- Navarro, L.; de Gracia, A.; Niall, D.; Castell, A.; Browne, M.; McCormack, S.J.; Griffiths, P.; Cabeza, L.F. Thermal energy storage in building integrated thermal systems: A review. Part 2. Integration as passive system. Renew. Energy 2015, 85, 1334–1356.

- Navarro, L.; De Gracia, A.; Niall, D.; Castell, A.; Browne, M.; Mccormack, S.J.; Griffiths, P.; Cabeza, L.F. Thermal energy storage in building integrated thermal systems: A review. Part 1. Active storage systems readable. Renew. Energy 2016, 88, 526–547.

- Lizana, J.; Chacartegui, R.; Barrios-Padura, A.; Valverde, J.M. Advances in thermal energy storage materials and their applications towards zero energy buildings: A critical review. Appl. Energy 2017, 203, 219–239.

- Romdhane, S.B.; Amamou, A.; Khalifa, R.B.; Said, N.M.; Younsi, Z.; Jemni, A. A review on thermal energy storage using phase change materials in passive building applications. J. Build. Eng. 2020, 32, 101563.

- Rathore, P.K.S.; Shukla, S.K. Potential of macroencapsulated PCM for thermal energy storage in buildings: A comprehensive review. Constr. Build. Mater. 2019, 225, 723–744.

- Hauer, A.; Bayern, Z. Storage Technology Issues and Opportunities. In Proceedings of the Strategic and Cross-Cutting Workshop “Energy Storage—Issues and Opportunities”, France, Paris, 15 February 2011.

- Borri, E.; Tafone, A.; Zsembinszki, G.; Comodi, G.; Romagnoli, A.; Cabeza, L.F. Recent trends on liquid air energy storage: A bibliometric analysis. Appl. Sci. 2020, 10, 2773.

- Tarragona, J.; de Gracia, A.; Cabeza, L.F. Bibliometric analysis of smart control applications in thermal energy storage systems. A model predictive control approach. J. Energy Storage 2020, 32, 101704.

- Cardenas-Ramírez, C.; Jaramillo, F.; Gomez, M. Systematic review of encapsulation and shape-stabilization of phase change materials. J. Energy Storage 2020, 30, 101495.

- Mustapha, A.N.; Onyeaka, H.; Omoregbe, O.; Ding, Y.; Li, Y. Latent heat thermal energy storage: A bibliometric analysis explicating the paradigm from 2000–2019. J. Energy Storage 2020, 33, 102027.

- Cabeza, L.F.; de Gracia, A.; Zsembinszki, G.; Borri, E. Perspectives on thermal energy storage research. Energy 2021, 231, 120943.

- Zhao, Y.; Zhao, C.Y.; Markides, C.N.; Wang, H.; Li, W. Medium-and high-temperature latent and thermochemical heat storage using metals and metallic compounds as heat storage media: A technical review. Appl. Energy 2020, 280, 115950.

- De Gracia, A.; Cabeza, L.F. Phase change materials and thermal energy storage for buildings. Energy Build. 2015, 103, 414–419.

- Chandel, S.S.; Agarwal, T. Review of current state of research on energy storage, toxicity, health hazards and commercialization of phase changing materials. Renew. Sustain. Energy Rev. 2017, 67, 581–596.

- Lin, Y.; Alva, G.; Fang, G. Review on thermal performances and applications of thermal energy storage systems with inorganic phase change materials. Energy 2018, 165, 685–708.

- Fernández, A.; Martínez, M.; Segarra, M.; Martorell, I.; Cabeza, L.F. Selection of materials with potential in sensible thermal energy storage. Sol. Energy Mater. Sol. Cells 2010, 94, 1723–1729.

- Kalaiselvam, S.; Parameshwaran, R. Thermal Energy Storage Technologies. In Thermal Energy Storage Technologies for Sustainability: Systems Design, Assessment, and Applications, 1st ed.; Academic Press: Cambridge, MA, USA, 2014; pp. 57–64.

- Ståhl, F. Influence of Thermal Mass on the Heating and Cooling Demands of a Building Unit. Ph.D. Thesis, Chalmers University of Technology, Gothenburg, Sweden, 2009.

- Tatsidjodoung, P.; Le Pierrès, N.; Luo, L. A review of potential materials for thermal energy storage in building applications. Renew. Sustain. Energy Rev. 2013, 18, 327–349.

- González-Roubaud, E.; Pérez-Osorio, D.; Prieto, C. Review of commercial thermal energy storage in concentrated solar power plants: Steam vs. molten salts. Renew. Sustain. Energy Rev. 2017, 80, 133–148.

- Myers, P.D., Jr.; Goswami, D.Y. Thermal energy storage using chloride salts and their eutectics. Appl. Therm. Eng. 2016, 109, 889–900.

- Elashmawy, M. Improving the performance of a parabolic concentrator solar tracking-tubular solar still (PCST-TSS) using gravel as a sensible heat storage material. Desalination 2020, 47, 114182.

- Koçak, B.; Fernandez, A.I.; Paksoy, H. Review on sensible thermal energy storage for industrial solar applications and sustainability aspects. Sol. Energy 2020, 209, 135–169.

- Ashby, M.F. Materials Selection in Mechanical Design, 3rd ed.; Elsevier: Oxford, UK, 2005.

- Ashby, M.F.; Shercliff, H.; Cebon, D. Materials Engineering, Science, Processing and Design, 4th ed.; Butterworth-Heinemann: Oxford, UK, 2007.

- Ayyappan, S.; Mayilsamy, K.; Sreenarayanan, V.V. Performance improvement studies in a solar greenhouse drier using sensible heat storage materials. Heat Mass Transf. 2016, 52, 459–467.

- Klein, P.; Roos, T.H.; Sheer, T.J. Experimental investigation into a packed bed thermal storage solution for solar gas turbine systems. Energy Procedia 2014, 49, 840–849.

- Almendros-Ibanez, J.A.; Fernandez-Torrijos, M.; Díaz-Heras, M.; Belmonte, J.F.; Sobrino, C.A. Review of solar thermal energy storage in beds of particles: Packed and fluidized beds. Sol. Energy 2018, 192, 193–237.

- Elouali, A.; Kousksou, T.; El Rhafiki, T.; Hamdaoui, S.; Mahdaoui, M.; Allouhi, A.; Zeraouli, Y. Physical models for packed bed: Sensible heat storage systems. J. Energy Storage 2019, 23, 69–78.

- Pelay, U.; Luo, L.; Fan, Y.; Stitou, D.; Rood, M. Thermal energy storage systems for concentrated solar power plants. Renew. Sustain. Energy Rev. 2017, 79, 82–100.

- Kumar, A.; Kim, M.H. Solar air-heating system with packed-bed energy-storage systems. Renew. Sustain. Energy Rev. 2017, 72, 215–227.

- Gil, A.; Medrano, M.; Martorell, I.; Lázaro, A.; Dolado, P.; Zalba, B.; Cabeza, L.F. State of the art on high temperature thermal energy storage for power generation. Part 1-Concepts, materials and modellization. Renew. Sustain. Energy Rev. 2010, 14, 31–55.

- Mabrouk, R.; Naji, H.; Dhahri, H. Numerical Investigation of Metal Foam Pore Density Effect on Sensible and Latent Heats Storage through an Enthalpy-Based REV-Scale lattice Boltzmann Method. Processes 2021, 9, 1165.

- Amami, B.; Rabhi, R.; Dhahri, H.; Mhimid, A. Numerical thermodynamic analysis of heat storage porous duct under pulsating flow using lattice Boltzmann method. Int. J. Exergy 2017, 22, 376–395.

- Kasaeian, A.; Daneshazarian, R.; Mahian, O.; Kolsi, L.; Chamkha, A.J.; Wongwises, S.; Pop, I. Nanofluid flow and heat transfer in porous media: A review of the latest developments. Int. J. Heat Mass Transf. 2017, 107, 778–791.

- Sheremet, M.A.; Pop, I. Natural convection in a horizontal cylindrical annulus filled with a porous medium saturated by a nanofluid using Tiwari and Das’ nanofluid model. Eur. Phys. J. Plus 2015, 130, 107.

- Sheremet, M.A.; Grosan, T.; Pop, I. Free convection in a square cavity filled with a porous medium saturated by nanofluid using Tiwari and Das’ nanofluid model. Transp. Porous Media 2015, 106, 595–610.

- Amami, B.; Dhahri, H.; Mhimid, A. Viscous dissipation effects on heat transfer, energy storage, and entropy generation for fluid flow in a porous channel submitted to a uniform magnetic field. J. Porous Media 2014, 17, 841–859.

- Heap, M.J.; Xu, T.; Chen, C.F. The influence of porosity and vesicle size on the brittle strength of volcanic rocks and magma. Bull. Volcanol. 2014, 76, 859.

- Dhifaoui, B.; Jabrallah, S.B.; Belghith, A.; Corriou, J.P. Experimental study of the dynamic behaviour of a porous medium submitted to a wall heat flux in view of thermal energy storage by sensible heat. Int. J. Therm. Sci. 2007, 46, 1056–1063.

More