Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 2 by Samuel Xin ren Ching and Version 1 by Jun Kit Chaw.

Specifically, a number of jobs were sorted together based on the material used and then consolidated for subsequent processes, i.e., assigned to the corresponding machines. To achieve the optimal sorting for the received orders, a combinatorial dispatch rule was proposed, which were Earliest Due Date (EDD), First In First Out (FIFO), and Shortest Processing Time (SPT).

- manufacturing industry

- dispatch rule

- Earliest Due Date (EDD)

- First In First Out (FIFO)

- Shortest Processing Time (SPT)

- Make-To-Order (MTO)

- Industry 4.0

1. Introduction

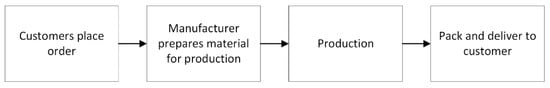

In the era of the Fourth Industrial Revolution, many countries aspire to embrace the digital transformation of manufacturing or production plants. However, many Small and Medium Industries (SMI) or Small and Medium Enterprises (SME) are not ready for the industrial revolution, especially in Malaysia [1]. In recent years, there are many Industry 4.0-related programs and incentives offered by the government, such as the Readiness Assessment, Intervention Fund, Domestic Investment Fund (DISF), and Automation Capital Allowance (Automation CA), with the aim of assisting the SMIs and SMEs to work towards Industry 4.0 [2]. Industry 4.0 growth is inevitable and may impact the traditional business manufacturing industry that is labor-intensive and cost-sensitive [3]. In fact, market demand is very dependent on the economic conditions, the rise of new markets, and product diversity [4]. The integration of planning and scheduling not only satisfies customers’ requirements but also optimizes the resources and achieves on-time delivery. Insufficient modal and lack of advanced technology are some of the main reasons that many old players in the industry resist the digital transformation [5]. First of all, when SMEs begin the transition to Industry 4.0, they refuse to start from scratch, and secondly, SMEs tend to become overwhelmed by the multitude of technologies that are currently available on the market [6]. Ultimately, most of the processes in the manufacturing industry are similar as in Figure 1.

Figure 1. The process from customer order to delivery. Adapted with permission from Ref. [7]. Copyright 2016 Łukasz Wiechetek.

Figure 1 shows a simple process of production. It shows that proper production planning is important because each step of the process affects the others. In conjunction with this, the main goal of production planning is to achieve high customer satisfaction with a low cost [8]. Production planning can be divided into the product structure, material requirement planning, and uncertainty management [9]. As the customer demand is increasing, the manufacturers realize that most of them are facing the same problem in the production stage. This resulted in the emergence of modern production planning tools and methods in the late 19th century.

In the past, traditional manufacturing systems focused on reducing cost and improving efficiency. However, they have not been able to follow the current trends, such as agile manufacturing, networked manufacture, mass customization, intelligent manufacture, and et cetera [10]. In fear of being eliminated by the competitors, a lot of SMIs and SMEs were forced to transform their business model. The transformation allowed them to cater to fluid customer demand. However, their demands may change often and dramatically in some cases [11].

Resource limitation is one of the common challenges. Hence, scheduling is essential to handle the allocation of resources based on the job sequence [12]. The output of the schedules is a production plan to estimate the start and end times for every job and machine. The jobs are planned according to certain optimization criteria while the scheduling performance is evaluated based on performance indicators such as costs, resource utilization, and adherence to deadlines. To strengthen the competitiveness of Malaysia as a production location, the manufacturing industry has to respond quickly and more flexibly according to the business models.

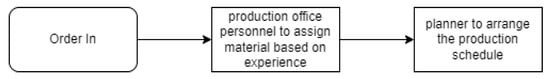

The objectives of production planning are to reduce inventory levels, increase machine utilization, and improve customer responsiveness [13]. Based on these objectives, many manufacturers are willing to provide customization services to improve customers’ satisfaction [14]. For example, Make-To-Order (MTO) is a business model that refers to a just-in-time philosophy due to the zero-inventory level between the stage of production and distribution [15]. This is to cater to personal customization, as shown in Figure 2.

Figure 2. Manual production planning.

Due to the different requirements of every customer, production has to produce products according to the needs of the customer. In this situation, productivity is restricted due to the maximum capacity of each machine. This is where material management plays an important role in production. When a manufacturing process has ended for one order, the next order may require another raw material. This may cause a long changing material lead time, as the operator has to request the raw material needed, and then perform material handling until the machine is set up.

Besides that, the complexity of sorting the orders at the stage of production planning will be higher due to the different order and delivery dates set by the customers. This may also affect the on-time delivery. It is difficult to achieve sorting optimization with so many different parameters in the production planning phase, such as time, product quality, and profit. Moreover, the performance of production planning will be inconsistent due to human involvement. Figure 2 shows the manual production planning:

Traditionally, once a customer makes an order, the order is submitted to the production office. The production office personnel manually assign the material according to the customer’s request based on experience. Then, those orders are sent to the planner to arrange the production schedule. However, each order is printed out as a hard copy. If there are any amendments, they are recorded on the hard copy, which is inconvenient. From the system layer point of view, the process of the data transfer still requires human involvement.

The optimization of production scheduling is viewed as a complicated task. Therefore, most of the schedulers prefer to employ simulation-based software or a manual decision-making process [16]. In this work, we integrated domain expert knowledge to generate the decisions. Priority dispatching rules were used for production planning, such as First-in-First Out (FIFO), Shortest Processing Time (SPT), and Earliest Due Date (EDD).

2. An Overview of SMIs and SMEs in Malaysia

According to the World Bank, approximately 98.5% of the business establishments in Malaysia are SMEs, which proves the importance of SMEs in Malaysia [18]. However, they are lacking resources in some respects, such as talent, funds, and technology. Table 1 shows the definition of SMEs in Malaysia.Table 1. Definition of SMEs in Malaysia. Adapted with permission from Ref. [19]. Copyright 2020 SME Corp. Malaysia Secretariat.

| Category | Manufacturing | Services and Other Sectors |

|---|---|---|

| Medium | Sales Turnover: RM15 mil to RM50 mil OR Employees: From 75 to 200 people |

Sales Turnover: RM3 mil to RM20 mil OR Employees: From 75 to 200 people |

| Small | Sales Turnover: RM300,000 to RM 15 mil OR Employees: From 5 to 75 people |

Sales Turnover: RM300,000 to RM3 mil OR Employees: From 5 to 30 people |

| Micro | Sales Turnover: Less than RM300,000 OR Employees: Less than 5 people |

Sales Turnover: Less than RM300,000 OR Employees: Less than 5 people |

3. Optimization Algorithm for Scheduling

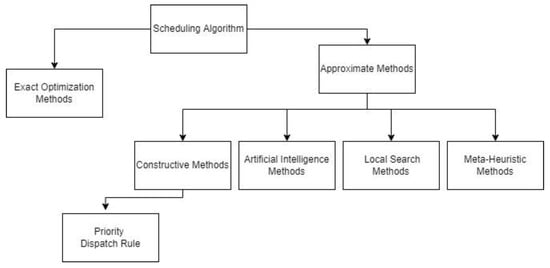

Production scheduling needs to send the information to the machine at the shop floor once the orders are scheduled and update the status once the order has been done. There are two major scheduling algorithms, which are the exact optimization methods and the approximate methods. Figure 3 shows an overview of the scheduling algorithms.

Figure 3. Types of scheduling algorithms. Adapted with permission from Ref. [20]. Copyright 2019 Yisheng Zou.