Glucomannan (GM) is —a polysaccharide generally extracted from the tuber of Amorphophallus konjac—has Amorphophallus konjac. Igreat cponsists of mannose and glucose residues linked by β-(1-4) and exhibits hydrocolloid characteristics which can be applied as thickening and gelling agentstential as a filler–binder in direct compression, disintegrant in tablets, or gelling agent due to its strong hydrophilicity and extremely high viscosity. However, it has poor water resistance and low mechanical strength when used as an excipient in solid form. Several physical and chemical modifications have been carried out to improve these drawbacks. Chemical modification involveaffects the substitution of functional groups in GM’s structure including esterification and etherification. It causes a decrease in its high hydrophilic film behavior and produce water-resistant films. Pcharacteristics of GM based on the DS. Carboxymethylation improves GM functionality by modifying its solubility and viscosity, which in turn allows it to bind water more efficiently and thus improve its elongation and gel homogeneity. Meanwhile, physical modification involves mixing native GM enhances functionality through combination with other excipients through processes involving milling, moisture, temperature, pressure, radiation, etc. It causes variations to particle size, shape, surface properties, porosity, densityo improve mechanical properties and modify swelling ability and drug release from the matrix. This review discusses extraction of GM and its modification to enhance its applicability as an excipient in solid form. Modified GM is a novel excipient applicable in the pharmaceutical industry for direct compression, as a tablet disintegrant, a film-forming agent, and to functional properties such as swelling capacity and gelation abilityfor encapsulation of macromolecular compounds or drug carriers for controlled release.

- glucomannan

- chemical modification

- physical modification

- excipient

1. Introduction

2. Polysaccharides from Different Sources

2.1. Natural Polysaccharides

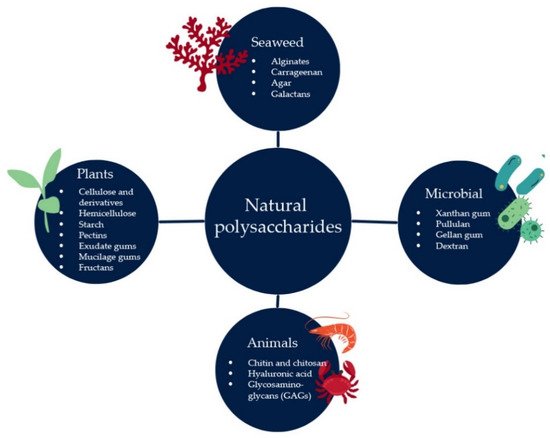

Natural polysaccharides can be derived from four main sources: algae, plants, animals, and microorganisms (Figure 2). Demand for polysaccharides from natural origins is tremendously because they provide several benefits, including natural abundance, ease of isolation, and ability to be chemically modified in order to fit technological demand. Furthermore, these polymers may be enzymatically hydrolyzed, and they produce a noncarcinogenic, degradable product [30,31].

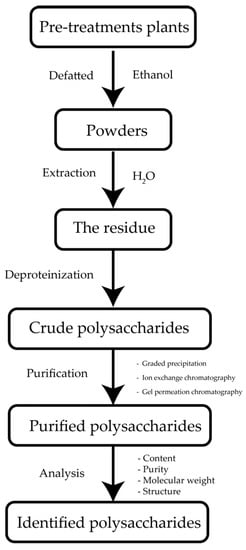

2. Structure and Physicochemical Properties of GM

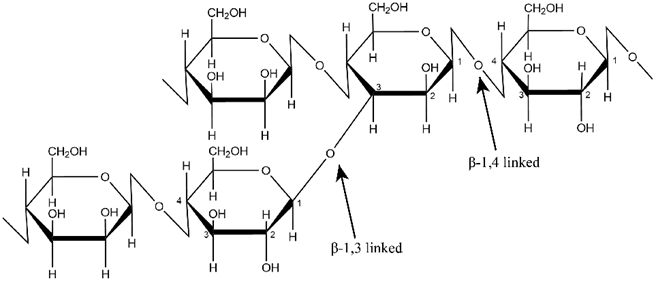

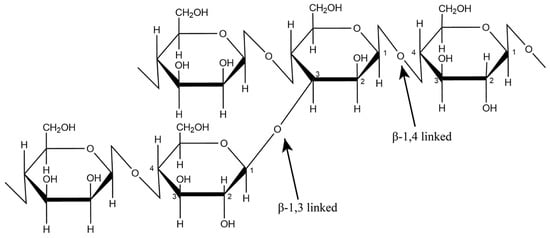

Natural polysaccharides consist of many monosaccharide residues joined by O-glycosidic bonds. When hydrolyzed, polysaccharides produce simple sugars such as glucose, galactose, mannose, arabinose, xylose, uronic acid, etc. Among numerous sources of naturally occurring substances, plants are considered a potentially renewable resource since they can provide a certain amount of natural polymers of plant origin [32,33]. Figure 3 shows some essential steps in the isolation and purification of polysaccharides from plants.GM is a natural heteropolysaccharide with a linear chain consisting of D-glucose and/or D-mannose in various proportions linked by β-1,4 glycosidic bonds. It also has multiple branching at β-1,3 glycosidic bonds to mannose units as shown in

Figure 1 [30].

2.2. Petrochemical Synthesis

Structurally, polysaccharides are composed of several monosaccharides joined together by O-glycosidic linkages. O-glycosidic linkages are formed by dehydration of the hemiacetal hydroxyl group of one sugar (a glycosyl donor) with a hydroxyl group on the anomeric carbon of another sugar (a glycosyl acceptor). Due to the presence of multiple hydroxyl groups, one glycosyl acceptor residue can be connected to more than one glycosyl donor via different O-glycosidic linkages. Consequently, polysaccharides may be linear or branched, and branching may occur at different positions of sugar units in the polysaccharide backbone with different branching densities [34,35]. Generally, three methods are used to synthesize polysaccharides: (1) stepwise glycosylation [36,37]; (2) condensation polymerization [38]; and (3) ring opening polymerization [39,40].The molecular weight varies from 200,000 to 2,000,000 Daltons, giving it incredibly higher viscosity than any known dietary fiber such as guar or locust bean gum [31][32]. When GM sol concentration is below 0.55%, it is only slightly affected by shear rate, indicating Newtonian fluid flow characteristics. However, at higher concentrations, shear rate can affect viscosity, leading to shear thinning and indicating non-Newtonian pseudoplasticity [33]. Based on previous reports, the viscosity of konjac glucomannan solution (1.0 g/100 g) can reach ~30,000 cps [34].

3. Structure and Physicochemical Properties of GM

Figure 14. Structure of glucomannan.

3. Chemical Modification

4. Extraction Optimization

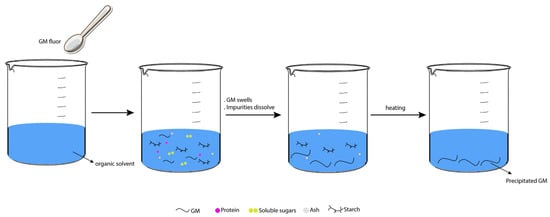

For extraction, the organic solvents usually used to obtain GM from flour are hot water [52], ethanol [7], or isopropanol sol [53]. As the majority of the glucomannan is present in the cell walls (intracellular polysaccharides) of higher plants, extraction begins with crushing plants to release intracellular polysaccharides. Furthermore, plant cell walls are mainly enclosed by lipids, which are removed by organic solvents, allowing extraction of glucomannan. An illustration of GM’s separation from impurities is depicted in Figure 5. The flour swells in organic solvents, and the aqueous part dissolves impurities trapped in the konjac particle, such as soluble sugars and partial proteins. During heating, gelatinization occurs, which irreversibly dissolves the starch in water, while ash is simultaneously removed with increasing temperature. Therefore, heat affects GM purity, while purified products are precipitated in the presence of an antisolvent [54].

| Plant Sources | Part | Extraction Method | Principle | Extraction Solvent | Molecular Weight | % Yield | Ref |

|---|---|---|---|---|---|---|---|

| Aloe barbadensis M. | Leaves | Cold method (maceration for 24 h) | Maceration at room temperature with frequent agitation intended to soften and break the plant’s cell wall to release glucomannan | Ethanol precipitation | 1.2 MDa | 23.4% | [59] |

| Amorphophallus muelleri B. | Tubers | Cold method (maceration for 3 h) | Multilevel concentration of ethanol (40, 60, and 80%) | NA | 62.2% | [55] | |

| Amorphophallus konjac | Tubers | Cold method for 90 min | 50% ethanol | 9.5 × 105 g/mol | 91.4% | [60] | |

| Colocasia esculenta L. | Tubers | Cold method with centrifugal rotational | Separation of starch and glucomannan is done by adding electrolyte salts such as NaCl to break the bond between starch and glucomannan Maceration at room temperature with frequent agitation intended to soften and break the plant’s cell wall to release the soluble glucomannan. Centrifugal rotational promotes the starch precipitate faster. | Isopropyl alcohol precipitation. Crude extract was extracted with water for 2 h | NA | 4.08% | [61] |

| Amorphophallus campanulatus B.) | Tubers | Cold method with centrifugal rotational | Isopropyl alcohol precipitation. Crude extract was extracted with water for 2 h | NA | 5.64% | [61] | |

| Salacca edulis R. | Seeds | Hot water extraction (T = 95 °C for 2 h) | Glucomannan has greater solubility in hot water and is stable enough for minimum destruction with hot water extraction. | 95% isopropyl alcohol solvent in a ratio (1:17) | 2.057 × 104 g/mol | 40.19% | [62] |

| Durio zeibethinus M. | Seeds | Hot method (T = 95 °C for 2 h) | Isopropyl alcohol precipitation. Crude extract was washed with ethanol 95% | NA | 39.60% | [63] | |

| Dioscorea esculenta | Tubers | Hot method (T = 105 °C for 90 min) | Hot water extraction of the precipitate with isopropyl alcohol | 1.865 × 104 g/mol | 53.09% | [64] | |

| Bletilla striata | Tubers | Hot water extraction (T = 80 °C for 4 h) | 95% ethanol precipitation. Crude extract was purified with DEAE-52 cellulose column | 1.7 × 105 Da | 27.21% | [65] | |

| Amorphophallus oncophyllus | Tubers | Hot water extraction (T = 55 °C for 1.5 h) | Purified with 95% ethanol | NA | 93.84% | [6] | |

| Amorphophallus oncophyllus | Tubers | Ultrasonic | Ultrasonic breaking of plant cell wall significantly improves glucomannan extraction efficiency | 60% isopropanol | NA | 59.36% | [66] |

| Cibotium barometz | Rhizomes | Alkali extraction | Glucomannan, a higher molecular weight polysaccharide, has greater solubility in dilute alkaline solutions than in hot water. Generally, extraction of the polysaccharides is first carried out in hot water and thereafter a dilute alkaline solution is employed for the extraction of residual polysaccharides. | Sodium hydroxide ([NaOH] 0.3 mol/L) | 1445 Da | 8.25% | [67] |

5. Chemical Modification

3.1. Increased Solubility

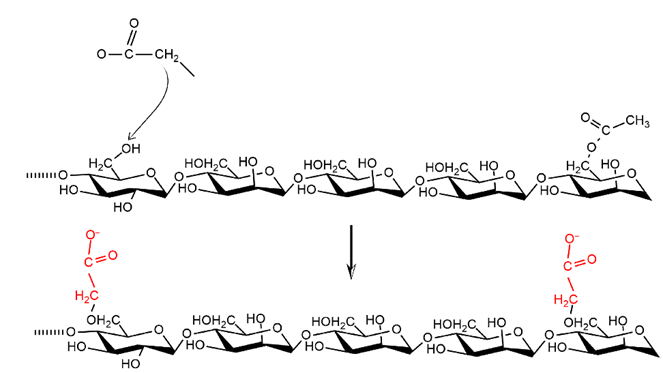

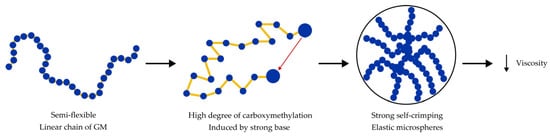

Chemical modification of CMGM affects solubility; carboxymethylation with NaOH catalyst substitutes chloroacetic acid with a hydroxyl group, which partially replaces hydroxyl and acetyl groups with carboxymethyl [2][48][49][58]. Incorporation of a carboxymethyl group appears as an extending chain structure that reduces hydrogen bonding between the polymer chains and increases the water-binding capacity, as shown in

5.1. Increased Solubility

Figure 2 below.

Figure 2 CMGM synthesis pathway.

3.2. Reduced Viscosity

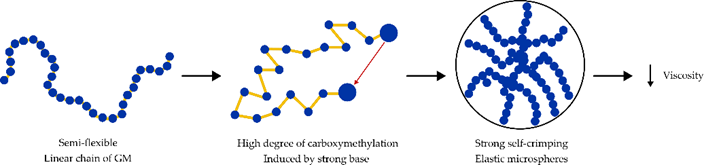

5.2. Reduced Viscosity

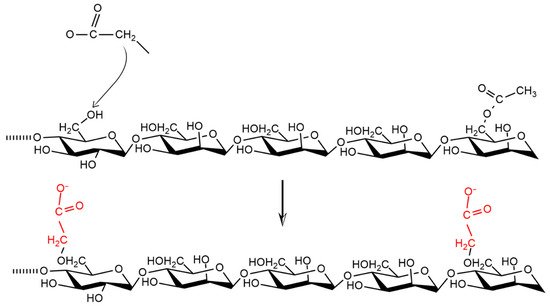

Figure 37. Effect of carboxymethylation on the structure of GM.

5.3. Increased Tensile Strength

5.4. Improved Thermal Stability

3.3. Increased Tensile Strength

6. Physical Modification

Generally, the presence of more -COO- groups due to carboxymethylation of the CMGM backbone improves gel strength by forming more crosslinks, while a high DS also increases mechanical strength [15]. The introduced COO− group can efficiently bind more water, which can act as a plasticizer to improve elongation of the film [68]. As the DS of CMGM increases, formed pore size decreases and the tissue structure becomes denser, indicating stronger interaction at higher DS [55]. This high density also increases tablet strength [3][24], but an excessive amount of CMGM causes charge repulsion, thereby weakening its mechanical properties [48].

3.4. Improved Thermal Stability

CMGM maintains the gel network through hydrogen bonding upon heating to 95 °C for 2 h, implying excellent thermal stability [15]. Carboxymethylation increases the thermal stability of GM in a DS-dependent manner. Based on thermogravimetric analysis (TGA), GM is degraded in three stages. TGA recorded a change in mass due to moisture removal from 60–200 °C. Meanwhile, from 200–300 °C, great weight loss was recorded in GM, CMGM (DS 0.28), and (DS 0.7), with values of 64.16%, 49.73%, and 43.17%, respectively. In the final stage of decomposition at a temperature of 300–500 °C, there was a greater decrease in mass change in GM than in CMGM due to thermal degradation [2].

4. Physical Modification

Co-processing is a technique for mixing two or more excipients at the sub-particle level to synergistically enhance functionality and mask undesired properties without undergoing chemical changes [69][95]. This method can change fundamental characteristics such as particle size and shape, morphology, porosity, density, and surface area, which affects flowability, compressibility, compactibility, and ultimately influences the disintegration and mechanical properties of tablets [70][96]. Some examples of GM processed together with other excipients are shown in Table 2 for various applications, especially controlling drug release through crosslinking and/or formation of dense hydrogen bonds.Table 12.

| Combination of Excipients | Co-Processed | Application | Mechanism | Ref. |

|---|---|---|---|---|

| GM and HPMC K 100 LV | Microwave on level 5 (350 W) for 30 min | Matrix for gastro-retentive tablets forming a porous channel that allows the polymer mixture to absorb more water and expand, followed by prolonged drug release | Hydrogen bonds in single polymers have low energy, but the simultaneous formation of interlinked hydrogen bonds between polymer components provides significant interaction strength, resulting in a matrix that floats quickly and maintains the integrity of the polymer mixture under acidic conditions. | [97] |

| GM and lactose | Wet granulation | Filler–binder for direct compression of effervescent tablets | GM has a high viscosity and strong adhesive properties, thus providing good tablet binding effectiveness. GM has poor solubility in water, so it is combined with lactose as a water-soluble ingredient and to improve the poor flowability of lactose. | [98] |

| GM, sodium alginate (SA), and graphene oxide (GO) | Freeze dried | Microsphere-making polymers that enhance targeted delivery of drugs or nutrients to the colon | GM interacts with SA via hydrogen bonding and physical entanglement, and GO enhances these interactions in the microspheres. In addition, GO can greatly improve the loading efficiency of ciprofloxacin (CPFX) of microspheres, and achieve the sustained release effect of CPFX. | [26] |

| Oxidized GM, cassava starch, and sucrose esters | Dry heated | The OGM–CS combination exhibits low solubility and swellability, which makes it a possible excipient for the formulation of sustained-release drugs. However, the addition of SE significantly decreased porosity and swelling of the tablets, which inhibited immediate drug release. | Heating OGM and CS to high temperatures causes structural damage that limits the solubility and swelling ability of the polymer. The addition of SE with HLB 5 decreased porosity and slowed drug release because the more closed structure inhibited free movement of the drug out of the matrix. In addition, more hydroxyl groups in SE form hydrogen bonds, increasing intergranular bonding. |

[84] |

| CMGM and 2-hydroxypropyl trimethyl ammonium chloride chitosan (HACC) | Complex coacervation and freeze dried | The coaservation complex formed can encapsulate and control the release of the molecular model for the vaccine, namely ovalbumin (OVA). | The anionic carboxyl group of CMGM and the cationic quaternary amine group of HACC cause intramolecular electrostatic attraction that causes the HACC and CMGM macromolecular chains to aggress and coil, forming the CMGM/HACC composite nanosphere. | [23] |

7. GM application as an Excipient for Solid Dosage Forms

7.1. Direct Compression Excipient

Direct compression is the most preferred tablet manufacturing method because it is effective and efficient for industrial use. The excipient used in this process plays an important role, especially in the formulation of low-dose, active pharmaceutical ingredients (APIs), and is affected by the overall properties of the mixture. Excipients must have good flowability, compressibility, and compactibility. GM is a candidate for a direct compression excipient because it has good flowability, as demonstrated by an angle of repose of <35°, and the particle size of CMGM (130 µm) [24,99]. Moreover, co-processing with other excipients such as HPMC [97], lactose, and starch [84] creates products that meet these criteria. This is because co-processing combines excipients, thereby increasing particle size, which also affects compressibility. Smaller particles tend to have larger air gaps, which cannot be compressed. Co-processed excipients with larger particle sizes provide more-compact structures because less air is captured in the tablet, reducing the release of elastic energy [5,76]. Based on X-ray results, deacetylated CMGM has an orthorhombic unit cell pattern with spatial plane a = 9.01 Å, b = 16.73 Å, and c (fiber axis) = 10.40, and a possible space group of I222. Given that orthorhombic crystals are not capped at higher compression pressures, this increased compressibility is due to high-level densification or decreased relaxation stress [10,100].7.2. Tablet Disintegrants

A disintegrant is a substance or mixture of substances added to a drug formulation that helps disintegrate tablets into smaller particles, making them dissolve more quickly. Various natural polysaccharides, such as modified starch, agar gum, and guar gum, have been used as disintegrants [101]. Carboxymethylation of polysaccharides increases water absorption and causes faster disintegration. As a comparison, sodium carboxymethyl cellulose (Na CMC) with a DS of 1.0 tends to make CMC easily disaggregated in water, making it more hydrophilic compared to water-insoluble cellulose [102,103]. A similar property was also observed in carboxymethylation of xanthan, where an increase in the degree of substitution exhibits greater hydrophilicity and lower molecular weight [104]. GM is a hydrophilic natural polymer, but its solubility in water can be reduced by the formation of strong hydrogen bonds during purification and drying. Several chemical modifications, such as CMGM, have been carried out to obtain derivatives with better solubility. The increase in solubility occurs due to the incorporation of water-soluble carboxylic groups. Changes to water-binding properties are caused by reduction and/or loss of crystal structure in the granules, making them mostly amorphous and more hygroscopic [76]. Furthermore, water absorption is influenced by DS, where high (>0.5) carboxymethylation increases absorption [9]. CMGM with high-water absorption capacity causes rapid disintegration; hence, it has great potential as a tablet disintegrant. In contrast, low DS values (ranging from 0.2–0.4) obtained with sodium acetate catalyst reportedly reduced water absorption [76]. Ma et al. reported super-disintegration and rapid drug release by the combination of GM–superporous hydrogel composite (SPHC) on an artificial gastric fluid medium, where drug release reached >90%, with GM accounting for 80% in the first 3 min. These results support the potential application of modified GM as a disintegrant for tablet dosage forms containing drugs needing rapid disintegration [105].7.3. Film-Forming Agent

One property of GM solutions is their extremely high viscosity, which needs to be modified either chemically or physically. With lower viscosity, this material is easier to apply as a film. Xie et al. revealed that the combination of CMGM and crosslinked chitosan can be used in wound dressing due to good swelling ability and moisture permeability, which effectively protect the wound from excessive dehydration and accumulation of exudate. Moreover, the produced film had excellent thermal stability and biocompatibility, which can accelerate tissue regeneration [77]. Apart from wound dressing, the combination of CMGM with other polymers, such as gelatin, is used as packaging films with increased thermal stability. Single application of CMGM showed continuous thermal degradation, whereas the onset temperature increased when it was combined with gelatin. Cross-linkage with gelatin through free amino and carboxyl groups also exhibited electrostatic interactions that improved the mechanical properties of the nanocomposite films [106].7.4. Sustained Release Agent

The advantages of sustained-release tablets include increased plasma drug level stability and patient compliance, leading to optimum therapy [3,23,81,84,99]. One method to control drug release is through a polyelectrolyte complex reaction, which improves and increases gel strength. Mixture of two oppositely charged polysaccharides produces polyelectrolyte complexes (PECs) through electrostatic complex coacervation (FigureCo-processed GM with other excipients.

8) and hydrogen bonding. Coacervation can be achieved even without the use of chemical covalent crosslinking [85,107,108].

8. Discussion

Among numerous naturally occurring polysaccharides, GM has considerable potential, warranting further exploration. These polymers are abundantly available from natural sources. However, Amorphophallus contains considerable amounts of GM, up to 93% of dry weight, and is the main plant genus used for commercial production of GM [6]. This also indicates that individual species are the main factor that determines GM content and the quality of GM flour. Some other factors that affect the amount of glucomannan extracted are age of tuber, method of extraction, processing temperature, and solvent concentration for purification. GM, which is abundantly available, shows potential as an excipient for solid dosing. GM has an orthorhombic unit cell pattern—its physical structure contains possible sliding planes, which may be responsible for increased crystal plasticity [10,110,111]. This is why it exhibits good compressibility, and it is not capped at higher compression pressures during decompression due to decreased relaxation stress. In addition, GM is free-flowing, as demonstrated by an angle of repose < 35° [99,112,113], making it suitable for use as a direct-compression excipient in tablet manufacturing. Several studies have reported some of the physicochemical properties of GM. GM shows very high-water solubility, yet it forms a very viscous solution at pH 5–7 even at low concentrations. The reason for this is high water sorption by GM. However, water sorption is affected by the degree of acetylation of GM chains. Chemical and physical modifications have been made to obtain GM with desired properties. Structurally, the simplest GM molecules consist of repeating monosaccharide units, such as glucose and/or mannose, with hydroxyl groups, which act as the main site of chemical modification. The hydroxyl groups can be changed through chemical reactions such as substitution, grafting, oxidation, and deacetylation, or by disrupting the original structure. In its application as an excipient in solid preparations, chemical modification of GM is usually aimed at modifying the viscosity, solubility, and tensile strength. However, the resulting change in properties depends on the DS. Higher DS results in lower viscosity because substitution of hydroxyl for carboxymethyl reduces interactions (intermolecular hydrogen bonds) between GMs, so it can be assumed that less water is entangled, which decreases GM viscosity. Then, the hydrogen bonds that have been disrupted cause a high decrease in crystallinity, thereby increasing the solubility of GM in water. On the other hand, low DS only increases hydrophobicity [6]. Regarding the tensile index, addition of 0.9% CMGM increased inter-fiber binding, which is attributed to increased tensile index and folding endurance [74]. As a direct-compression excipient, GM has the potential to be used as a filler–binder if it is co-processed both thermally and hydrothermally. Besides having good flowability and compressibility, native GM has high viscosity, so binding capacity is very strong, meaning it can be co-processed with another excipient that has good wetting properties and high porosity in order to increase water intake, which will aid tablet disintegration [105]. However, if GM is to be applied in a sustained-release tablet formulation, then GM can be combined with sodium alginate or HPMC in order to form intermolecular hydrogen bonds and physical entanglement between the two polymers, making an efficient membrane to inhibit water penetration, delaying drug release from the matrix [26,84].9. Future Recommendations

GM is a polysaccharide that has promise as an excipient for solid dosage forms, especially for direct compression due to its free-flowing nature and compressibility. Some applications of chemically or physically modified GM have been reported. Chemical modification is suggested to modify the solubility, viscosity, and mechanical properties of GM, while physical modification of GM is suggested to modify swelling ability and drug release from the matrix. Although chemical and physical modifications of GM have been studied, compared to other polysaccharides such as chitosan or alginate, the studies are not wide or deep enough. The mechanisms behind the effects of modifications on pharmaceutical characteristics, such as the relationship between structure and functionality/application of modified GM, are not clearly understood. Thus, the study of mechanisms of modified GM is necessary for its development as a potential pharmaceutical excipient. In recent years, a wide variety of innovative approaches to modify GM have been developed through non-contaminating physical modification methods (green methods) such as microwave heating, ultrasound-assisted and hydrothermal processes, and ball milling. In addition, exploration of other plants as sources of GM may also be conducted to create a wider range of functionalities, which also may expand applicability.10. Conclusions

| Combination of Excipients | Co-Processed | Application | Mechanism | Ref. |

|---|---|---|---|---|

| GM and HPMC K 100 LV | Microwave on level 5 (350 W) for 30 min | Matrix for gastro-retentive tablets forming a porous channel that allows the polymer mixture to absorb more water and expand, followed by prolonged drug release | Hydrogen bonds in single polymers have low energy, but the simultaneous formation of interlinked hydrogen bonds between polymer components provides significant interaction strength, resulting in a matrix that floats quickly and maintains the integrity of the polymer mixture under acidic conditions. | [71] |

| GM and lactose | Wet granulation | Filler–binder for direct compression of effervescent tablets | GM has a high viscosity and strong adhesive properties, thus providing good tablet binding effectiveness. GM has poor solubility in water, so it is combined with lactose as a water-soluble ingredient and to improve the poor flowability of lactose. | [72] |

| GM, sodium alginate (SA), and graphene oxide (GO) | Freeze dried | Microsphere-making polymers that enhance targeted delivery of drugs or nutrients to the colon | GM interacts with SA via hydrogen bonding and physical entanglement, and GO enhances these interactions in the microspheres. In addition, GO can greatly improve the loading efficiency of ciprofloxacin (CPFX) of microspheres, and achieve the sustained release effect of CPFX. | [26] |

| Oxidized GM, cassava starch, and sucrose esters | Dry heated | The OGM–CS combination exhibits low solubility and swellability, which makes it a possible excipient for the formulation of sustained-release drugs. However, the addition of SE significantly decreased porosity and swelling of the tablets, which inhibited immediate drug release. | Heating OGM and CS to high temperatures causes structural damage that limits the solubility and swelling ability of the polymer. The addition of SE with HLB 5 decreased porosity and slowed drug release because the more closed structure inhibited free movement of the drug out of the matrix. In addition, more hydroxyl groups in SE form hydrogen bonds, increasing intergranular bonding. |

[58] |

| CMGM and 2-hydroxypropyl trimethyl ammonium chloride chitosan (HACC) | Complex coacervation and freeze dried | The coaservation complex formed can encapsulate and control the release of the molecular model for the vaccine, namely ovalbumin (OVA). | The anionic carboxyl group of CMGM and the cationic quaternary amine group of HACC cause intramolecular electrostatic attraction that causes the HACC and CMGM macromolecular chains to aggress and coil, forming the CMGM/HACC composite nanosphere. | [23] |

5.Author FutContributions

Conceptualization, A.Y.C., Y.W.W. and A.B.; methodology, N.A.; validation, A.Y.C., Y.W.W. and A.B.; formal analysis, N.A.; resources, N.A., A.Y.C. and Y.W.W.; data curation, N.A.; writing—original draft preparation, N.A.; writing—review and editing, N.A., Y.W.W. and A.B.; visualization, N.A.; supervision, A.Y.C., Y.W.W. and A.B.; project administration, A.Y.C. and Y.W.W.; funding acquisition, A.Y.C., Y.W.W. and A.B. All authors have read and agreed to the published version of the manuscript.Institutional Review Boared Statement

Not applicable.Informed RConsent Statement

Not applicable.Data Availability Statement

Not applicable.Acknommendatwledgments

The authors thank the Academic Leadership Grant of Universitas Padjadjaran for the Year 2022 and Lembaga Pengelola Dana Pendidikan (LPDP) for supporting the project.Conflicts onf Interest

GM is a polysaccharide that has promise as an excipient for solid dosage forms, especially for direct compression due to its free-flowing nature and compressibility. Some applications of chemically or physically modified GM have been reported. Chemical modification is suggested to modify the solubility, viscosity, and mechanical properties of GM, while physical modification of GM is suggested to modify swelling ability and drug release from the matrix. Although chemical and physical modifications of GM have been studied, compared to other polysaccharides such as chitosan or alginate, the studies are not wide or deep enough. The mechanisms behind the effects of modifications on pharmaceutical characteristics, such as the relationship between structure and functionality/application of modified GM, are not clearly understood. Thus, the study of mechanisms of modified GM is necessary for its development as a potential pharmaceutical excipient.

The authors declare no conflict of interest.In recent years, a wide variety of innovative approaches to modify GM have been developed through non-contaminating physical modification methods (green methods) such as microwave heating, ultrasound-assisted and hydrothermal processes, and ball milling. In addition, exploration of other plants as sources of GM may also be conducted to create a wider range of functionalities, which also may expand applicability.

References

- Lajoinie, A.; Henin, E.; Kassai, B.; Terry, D. Solid oral forms availability in children: A cost saving investigation. Br. J. Clin. Pharmacol. 2014, 78, 1080–1089. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.H.; Huang, G.Q.; Xu, T.C.; Xiao, J.X. Characterization of carboxymethylated konjac glucomannan for potential application in colon-targeted delivery. Food Hydrocoll. 2019, 94, 354–362. [Google Scholar] [CrossRef]

- Wu, C.; Sun, J.; Jiang, H.; Li, Y.; Pang, J. Construction of carboxymethyl konjac glucomannan/chitosan complex nanogels as potential delivery vehicles for curcumin. Food Chem. 2021, 362, 130242. [Google Scholar] [CrossRef] [PubMed]

- Zhu, W.; Li, J.; Lei, J.; Li, Y.; Chen, T.; Duan, T.; Yao, W.; Zhou, J.; Yu, Y.; Liu, Y. Silver nanoparticles incorporated konjac glucomannan-montmorillonite nacre-like composite films for antibacterial applications. Carbohydr. Polym. 2018, 197, 253–259. [Google Scholar] [CrossRef]

- Xiao, C.; Weng, L.; Zhang, L. Improvement of physical properties of crosslinked alginate and carboxymethyl konjac glucomannan blend films. J. Appl. Polym. Sci. 2002, 84, 2554–2560. [Google Scholar] [CrossRef]

- Harmayani, E.; Aprilia, V.; Marsono, Y. Characterization of glucomannan from Amorphophallus oncophyllus and its prebiotic activity in vivo. Carbohydr. Polym. 2014, 112, 475–479. [Google Scholar] [CrossRef]

- Yanuriati, A.; Marseno, D.W.; Rochmadi Harmayani, E. Characteristics of glucomannan isolated from fresh tuber of Porang (Amorphophallus muelleri Blume). Carbohydr. Polym. 2017, 156, 56–63. [Google Scholar] [CrossRef]

- Septiawan, A.R.; Darma, G.C.; Aryani, R. Preparation and Characterization of Glucomannan from Porang Bulbs (Amorphophallus muelleri Blume.) as a tablet binder. Pros. Farm. 2021, 7, 508–515. [Google Scholar] [CrossRef]

- Cui, T.; Liu, R.; Wu, T.; Sui, W.; Zhang, M. Influence of konjac glucomannan and frozen storage on rheological and tensile properties of frozen dough. Polymers 2019, 11, 794. [Google Scholar] [CrossRef]

- Du, X.; Li, J.; Chen, J.; Li, B. Effect of degree of deacetylation on physicochemical and gelation properties of konjac glucomannan. Food Res. Int. 2012, 46, 270–278. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, J.; Lindström, M.E.; Stepan, A.; Gatenholm, P. Spruce glucomannan: Preparation, structural characteristics and basic film forming ability. Nord. Pulp Pap. Res. J. 2013, 28, 323–330. [Google Scholar] [CrossRef]

- Wang, K.; Fan, J.; Liu, Y.; He, Z. Konjac glucomannan and xanthan gum as compression coat for colonic drug delivery: Experimental and theoretical evaluations. Front. Chem. Eng. China 2010, 4, 102–108. [Google Scholar] [CrossRef]

- Long, X.Y.; Luo, X.G.; Zou, N.W.; Ma, Y.H. Preparation and in vitro evaluation of Carboxymethyl konjac glucomannan coated 5-aminosalicylic acid tablets for colonic delivery. Adv. Mater. Res. 2011, 152–153, 1712–1715. [Google Scholar] [CrossRef]

- Wu, K.; Zhu, Q.; Qian, H.; Xiao, M.; Corke, H.; Nishinari, K.; Jiang, F. Controllable hydrophilicity-hydrophobicity and related properties of konjac glucomannan and ethyl cellulose composite films. Food Hydrocoll. 2018, 79, 301–309. [Google Scholar] [CrossRef]

- Guo, Y.; Wu, M.; Li, R.; Cai, Z.; Zhang, H. Thermostable physically crosslinked cryogel from carboxymethylated konjac glucomannan fabricated by freeze-thawing. Food Hydrocoll. 2022, 122, 107103. [Google Scholar] [CrossRef]

- Ai, T.; Shang, L.; He, C.; Teng, Y.; Ren, C.; Zhou, P.; Wang, L.; Li, J.; Li, B. Development of multi-layered gastric floating tablets based on konjac glucomannan: A modified calcium supplement with enhanced bioavailability. Food Funct. 2019, 10, 6429–6437. [Google Scholar] [CrossRef]

- Zhu, G.-Q.; Zhang, Y.; Liu, J.-H. Studies on drug release from aminophylline konjac glucomannan matrix tablet. China J. Chin. Mater. Med. 2007, 32, 2236–2239. [Google Scholar]

- Liu, J.; Zhang, L.; Wang, C.; Yuan, P.; Xin, Y. Study on novel colon position pulsatile capsule and its release in vitro. China J. Chin. Mater. Med. 2010, 35, 3127–3130. [Google Scholar]

- Cuña, M.; Alonso-Sande, M.; Remunãn-López, C.; Pivel, J.P.; Alonso-Lebrero, J.L.; Alonso, M.J. Development of phosphorylated glucomannan-coated Chitosan nanoparticles as nanocarriers for protein delivery. J. Nanosci. Nanotechnol. 2006, 6, 2887–2895. [Google Scholar] [CrossRef]

- Deshpande, G.G.; Borate, H.P.; Wangikar, S.S. Fabrication and Characterization of Composite Material Connecting Rod. Techno-Societal 2021, 2, 87–95. [Google Scholar]

- Patria, D.G.; Sutrisno, A.; Sukamto, S.; Lin, J. Process optimization in the development of porang glucomannan (Amorphophallus mulleri B.) incorporated into the restructured rice using a pasta extruder: Physicochemical properties, cooking characteristics, and an estimated glycemic index. Food Sci. Technol. 2021, 42, 1–9. [Google Scholar] [CrossRef]

- Xie, W.; Du, Y.; Yuan, S.; Pang, J. Dihydromyricetin incorporated active films based on konjac glucomannan and gellan gum. Int. J. Biol. Macromol. 2021, 180, 385–391. [Google Scholar] [CrossRef] [PubMed]

- Shi, C.; Zhu, P.; Chen, N.; Ye, X.; Wang, Y.; Xiao, S. Preparation and sustainable release of modified konjac glucomannan/chitosan nanospheres. Int. J. Biol. Macromol. 2016, 91, 609–614. [Google Scholar] [CrossRef] [PubMed]

- Liang, H.; Ye, T.; Zhou, B.; Li, J.; He, L.; Li, Y.; Liu, S.; Chen, Y.; Li, B. Fabrication of gastric floating controlled release tablet based on konjac glucomannan. Food Res. Int. 2015, 72, 47–53. [Google Scholar] [CrossRef]

- Chéret, R.; Chapleau, N.; Delbarre-Ladrat, C.; Verrez-Bagnis, V.; Lamballerie, M.D. Effects of High Pressure on Texture and Microstructure of Sea Bass (Dicentrarchus labrax L.) Fillets. Science 2005, 70, 477–483. [Google Scholar] [CrossRef]

- Yuan, Y.; Xu, X.; Gong, J.; Mu, R.; Li, Y.; Wu, C.; Pang, J. Fabrication of chitosan-coated konjac glucomannan/sodium alginate/graphene oxide microspheres with enhanced colon-targeted delivery. Int. J. Biol. Macromol. 2019, 131, 209–217. [Google Scholar] [CrossRef]

- Li, Z.; Wang, J.; Zheng, B.; Guo, Z. Effects of high pressure processing on gelation properties and molecular forces of myosin containing deacetylated konjac glucomannan. Food Chem. 2019, 291, 117–125. [Google Scholar] [CrossRef]

- Li, B.; Li, J.; Xia, J.; Kennedy, J.F.; Yie, X.; Liu, T.G. Effect of gamma irradiation on the condensed state structure and mechanical properties of konjac glucomannan/chitosan blend films. Carbohydr. Polym. 2011, 83, 44–51. [Google Scholar] [CrossRef]

- Fan, L.; Yang, J.; Wu, H.; Hu, Z.; Yi, J.; Tong, J.; Zhu, X. Preparation and characterization of quaternary ammonium chitosan hydrogel with significant antibacterial activity. Int. J. Biol. Macromol. 2015, 79, 830–836. [Google Scholar] [CrossRef]

- Al-Ghazzewi, F.H.; Tester, R.F. Efficacy of cellulase and mannanase hydrolysates of konjac glucomannan to promote the growth of lactic acid bacteria. J. Sci. Food Agric. 2012, 92, 2394–2396. [Google Scholar] [CrossRef]

- Mikkelson, A.; Maaheimo, H.; Hakala, T.K. Hydrolysis of konjac glucomannan by Trichoderma reesei mannanase and endoglucanases Cel7B and Cel5A for the production of glucomannooligosaccharides. Carbohydr. Res. 2013, 372, 60–68. [Google Scholar] [CrossRef] [PubMed]

- Tong, X.; Pan, W.; Su, T.; Zhang, M.; Dong, W.; Qi, X. Recent advances in natural polymer-based drug delivery systems. React. Funct. Polym. 2020, 148, 104501. [Google Scholar] [CrossRef]

- Ogaji, I.J.; Nep, E.I.; Audu-Peter, J.D. Advances in Natural Polymers as Pharmaceutical Excipients. Pharm. Anal. Acta 2012, 3, 146. [Google Scholar] [CrossRef]

- Thakur, V.K.; Thakur, M.K.; Gupta, R.K. Graft copolymers from cellulose: Synthesis, characterization and evaluation. Carbohydr. Polym. 2013, 97, 18–25. [Google Scholar] [CrossRef]

- Ciric, J.; Loos, K. Synthesis of branched polysaccharides with tunable degree of branching. Carbohydr. Polym. 2013, 93, 31–37. [Google Scholar] [CrossRef]

- Chaudhury, A.; Maity, S.K.; Ghosh, R. Efficient routes toward the synthesis of the D-rhamno-trisaccharide related to the A-band polysaccharide of Pseudomonas aeruginosa. Beilstein J. Org. Chem. 2014, 10, 1488–1494. [Google Scholar] [CrossRef]

- Sarkar, V.; Mukhopadhyay, B. Chemical synthesis of the tetrasaccharide repeating unit of the O-polysaccharide isolated from Azospirillum brasilense SR80. Carbohydr. Res. 2015, 406, 65–70. [Google Scholar] [CrossRef]

- Kobayashi, S.; Kashiwa, K.; Shimada, J.; Kawasaki, T.; Shoda, S. Enzymatic polymerization: The first in Vitro Sínthesis of Cellulose Via Nonbiosynthetic Path Catalyzed by Cellulase. Makromol. Chem. Macromol. Symp. 1992, 54–55, 509–518. [Google Scholar] [CrossRef]

- Uryu, T.; Yamanaka, M.; Date, M.; Ogawa, M.; Hatanaka, K. Selective synthesis of polysaccharide macromers by ring-opening polymerization of anhydro sugar. Macromolecules 1988, 21, 1916–1920. [Google Scholar] [CrossRef]

- Yagura, T.; Ikegami, W.; Kamitakahara, H.; Takano, T. Synthesis of an enantiomer of cellulose via cationic ring-opening polymerization. Cellulose 2020, 27, 9755–9766. [Google Scholar] [CrossRef]

- Shi, X.D.; Yin, J.Y.; Zhang, L.J.; Huang, X.J.; Nie, S.P. Studies on O-acetyl-glucomannans from Amorphophallus species: Comparison of physicochemical properties and primary structures. Food Hydrocoll. 2019, 89, 503–511. [Google Scholar] [CrossRef]

- Wu, W.T.; Cheng, H.C.; Chen, H.L. Ameliorative effects of konjac glucomannan on human faecal -glucuronidase activity, secondary bile acid levels and faecal water toxicity towards Caco-2 cells. Br. J. Nutr. 2011, 105, 593–600. [Google Scholar] [CrossRef] [PubMed]

- Luan, J.; Wu, K.; Li, C.; Liu, J.; Ni, X.; Xiao, M.; Xu, Y.; Kuang, Y.; Jiang, F. pH-Sensitive drug delivery system based on hydrophobic modified konjac glucomannan. Carbohydr. Polym. 2017, 171, 9–17. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Xu, M.; Lv, W.; Qiu, P.; Gong, Y.; Li, D. Study on Rheological Behavior of Konjac Glucomannan. Phys. Procedia 2012, 33, 25–30. [Google Scholar] [CrossRef]

- Tatirat, O.; Charoenrein, S. Physicochemical properties of konjac glucomannan extracted from konjac flour by a simple centrifugation process. LWT Food Sci. Technol. 2011, 44, 2059–2063. [Google Scholar] [CrossRef]

- Koroskenyi, B.; McCarthy, S.P. Synthesis of acetylated konjac glucomannan and effect of degree of acetylation on water absorbency. Biomacromolecules 2001, 2, 824–826. [Google Scholar] [CrossRef]

- Guo, L.; Yokoyama, W.; Chen, L.; Liu, F.; Chen, M.; Zhong, F. Characterization and physicochemical properties analysis of konjac glucomannan: Implications for structure-properties relationships. Food Hydrocoll. 2021, 120, 106818. [Google Scholar] [CrossRef]

- Alves, A.; Miguel, S.P.; Araujo, A.R.T.S.; Jes, D. Xanthan Gum–Konjac Glucomannan Blend Hydrogel for Wound Dressings. Polymers 2020, 12, 99. [Google Scholar] [CrossRef]

- Hu, Y.; Tian, J.; Zou, J.; Yuan, X.; Li, J.; Liang, H.; Zhan, F.; Li, B. Partial removal of acetyl groups in konjac glucomannan significantly improved the rheological properties and texture of konjac glucomannan and κ-carrageenan blends. Int. J. Biol. Macromol. 2019, 123, 1165–1171. [Google Scholar] [CrossRef]

- Gong, J.; Wang, L.; Wu, J.; Yuan, Y.; Mu, R.J.; Du, Y.; Wu, C.; Pang, J. The rheological and physicochemical properties of a novel thermosensitive hydrogel based on konjac glucomannan/gum tragacanth. LWT 2019, 100, 271–277. [Google Scholar] [CrossRef]

- Kurt, A.; Kahyaoglu, T. Characterization of a new biodegradable edible film made from salep glucomannan. Carbohydr. Polym. 2014, 104, 50–58. [Google Scholar] [CrossRef] [PubMed]

- Blumentritt, M.; Gardner, D.J.; Cole, B.J.W.; Shaler, S.M. Influence of hot-water extraction on ultrastructure and distribution of glucomannans and xylans in poplar xylem as detected by gold immunolabeling. Holzforschung 2016, 70, 243–252. [Google Scholar] [CrossRef]

- Wardhani, D.H.; Nugroho, F.; Muslihudin, M.; Aryanti, N. Application of response surface method on purification of glucomannan from amorphophallus oncophyllus by using 2-propanol. Sci Study Res. Chem. Chem. Eng. Biotechnol. Food Ind. 2016, 17, 63–74. [Google Scholar]

- Xu, W.; Wang, S.; Ye, T.; Jin, W.; Liu, J.; Lei, J.; Li, B.; Wang, C. A simple and feasible approach to purify konjac glucomannan from konjac flour–Temperature effect. Food Chem. 2014, 158, 171–176. [Google Scholar] [CrossRef]

- Nurlela Andriani, D.; Arizal, R. Extraction of Glucomannan from porang (Amorphophallus muelleri Blume) flour using Ethanol. J. Sains. Dan Terap. Kim. 2020, 14, 88–98. [Google Scholar] [CrossRef]

- Widjanarko, S.B.; Sutrisno, A.; Faridah, A. Effect of hydrogen peroxide on physicochemical properties of Common Konjac (Amorphophallus oncophyllus) flour by maceration and ultrasonic methods. J. Teknol. Pertan. 2011, 12, 143–152. [Google Scholar]

- Faridah, A.; Widjanarko, S.B. Optimization of Multilevel Ethanol Leaching Process of Porang Flour (Amorphophallus muelleri) Using Response Surface Methodology. Int. J. Adv. Sci. Eng. Inf. Technol. 2013, 3, 74–80. [Google Scholar] [CrossRef]

- Ariesta, N.; Santosa, E.; Muhandri, T. Effect of harvest timing and length of storage time on glucomannan content in porang tubers. IOP Conf. Ser. Earth Environ. Sci. 2019, 299, 012012. [Google Scholar]

- Campestrini, L.H.; Silveira, J.L.M.; Duarte, M.E.R.; Koop, H.S.; Noseda, M.D. NMR and rheological study of Aloe barbadensis partially acetylated glucomannan. Carbohydr. Polym. 2013, 94, 511–519. [Google Scholar] [CrossRef]

- Chua, M.; Chan, K.; Hocking, T.J.; Williams, P.A.; Perry, C.J.; Baldwin, T.C. Methodologies for the extraction and analysis of konjac glucomannan from corms of Amorphophallus konjac K. Koch. Carbohydr. Polym. 2012, 87, 2202–2210. [Google Scholar] [CrossRef]

- Chairul, C.; Chairul, S.M. Isolasi Glukomanan dari Dua Jenis Araceae: Talas {Colocasia esculenta (L.) Schott} dan Iles-iles (Amorphophallus campanulatus Blumei) [Isolation of Glucomannan from Two Species of Araceae: Talas {Colocasia esculenta (L.) Schott} and Iles-iles. Ber. Biol. 2006, 8, 171–178. [Google Scholar]

- Anindita, F.; Bahri, S.; Hardi, J. Extraction and Characterization of Glucomannan From Salak (Salacca Edulis Reinw.) Seed Flours. KOVALEN J. Ris. Kim. 2016, 2, 1–10. [Google Scholar]

- Darmawati, D.; Bahri, S.; Sosidi, H. Analysis of glucomannan content from durian seeds (Durio zeibethinus Murr) by spectrophotometric method at various times and hydrolysis temperatures. KOVALEN J. Ris. Kim. 2020, 6, 158–164. [Google Scholar] [CrossRef]

- Sareu, P.L.; Ridhay, A.; Mirzan, M. Extraction of Glucomannan from Gembili Bulbs (Dioscorea esculenta L.). KOVALEN J. Ris. Kim. 2021, 7, 51–58. [Google Scholar] [CrossRef]

- Wang, B.; Zhang, H.; Chen, L.; Mi, Z.; Xu, Y.; Zhao, G.; Liu, S.; Lei, H.; Wang, Z.; Niu, J. Extraction, purification, and determination of the gastroprotective activity of glucomannan from Bletilla striata. Carbohydr. Polym. 2020, 246, 116620. [Google Scholar] [CrossRef] [PubMed]

- Fatmawati, S.; Nurgraheni, B.; Setyani, D.K. Ekstraksi Berbantu Ultrasonik dan Penetapan Kadar Glukomanan Dalam Umbi Porang (Amorphophallus oncophyllus). Media Farm. 2013, 11, 1075–1083. [Google Scholar]

- Huang, D.; Zhang, M.; Yi, P.; Yan, C. Structural characterization and osteoprotective effects of a novel oligo-glucomannan obtained from the rhizome of Cibotium barometz by alkali extraction. Ind. Crops Prod. 2018, 113, 202–209. [Google Scholar] [CrossRef]

- Jin, W.; Mei, T.; Wang, Y.; Xu, W.; Li, J.; Zhou, B.; Li, B. Synergistic degradation of konjac glucomannan by alkaline and thermal method. Carbohydr. Polym. 2014, 99, 270–277. [Google Scholar] [CrossRef]

- Su, L.; Ji, W.K.; Lan, W.Z.; Dong, X.Q. Chemical modification of xanthan gum to increase dissolution rate. Carbohydr. Polym. 2003, 53, 497–499. [Google Scholar] [CrossRef]

- Yu, H.; Xiao, C. Synthesis and properties of novel hydrogels from oxidized konjac glucomannan crosslinked gelatin for in vitro drug delivery. Carbohydr. Polym. 2008, 72, 479–489. [Google Scholar] [CrossRef]

- Lu, M.; Li, Z.; Liang, H.; Shi, M.; Zhao, L.; Li, W.; Chen, Y.; Wu, J.; Wang, S.; Chen, X.; et al. Controlled release of anthocyanins from oxidized konjac glucomannan microspheres stabilized by chitosan oligosaccharides. Food Hydrocoll. 2015, 51, 476–485. [Google Scholar] [CrossRef]

- Hongbo, T.; Lan, W.; Yanping, L.; Siqing, D. Effect of acidolysis and oxidation on structure and properties of konjac glucomannan. Int. J. Biol. Macromol. 2019, 130, 378–387. [Google Scholar] [CrossRef] [PubMed]

- Lin, X.; Wu, Q.; Luo, X.; Liu, F.; Luo, X.; He, P. Effect of degree of acetylation on thermoplastic and melt rheological properties of acetylated konjac glucomannan. Carbohydr. Polym. 2010, 82, 167–172. [Google Scholar] [CrossRef]

- Wang, M.; He, W.; Wang, S.; Song, X. Carboxymethylated glucomannan as paper strengthening agent. Carbohydr. Polym. 2015, 125, 334–339. [Google Scholar] [CrossRef]

- Kobayashi, S.; Tsujihata, S.; Hibi, N.; Tsukamoto, Y. Preparation and rheological characterization of carboxymethyl konjac glucomannan. Food Hydrocoll. 2002, 16, 289–294. [Google Scholar] [CrossRef]

- Xiao, M.; Dai, S.; Wang, L.; Ni, X.; Yan, W.; Fang, Y.; Corke, H.; Jiang, F. Carboxymethyl modification of konjac glucomannan affects water binding properties. Carbohydr. Polym. 2015, 130, 1–8. [Google Scholar] [CrossRef]

- Xie, Y.; Yi, Z.X.; Wang, J.X.; Hou, T.G.; Jiang, Q. Carboxymethyl konjac glucomannan-crosslinked chitosan sponges for wound dressing. Int. J. Biol. Macromol. 2018, 112, 1225–1233. [Google Scholar] [CrossRef]

- Fadilah Distantina, S.; Kaavessina, M.; Wijayanti, S.T.; Andayani, R. Study on the carboxymethylation of glucomannan from porang. AIP Conf. Proc. 2018, 1931, 030005. [Google Scholar]

- Wang, L.; Xiao, M.; Dai, S.; Song, J.; Ni, X.; Fang, Y.; Corke, H.; Jiang, F. Interactions between carboxymethyl konjac glucomannan and soy protein isolate in blended films. Carbohydr. Polym. 2014, 101, 136–145. [Google Scholar] [CrossRef]

- Xiao, J.X.; Wang, L.H.; Xu, T.C.; Huang, G.Q. Complex coacervation of carboxymethyl konjac glucomannan and chitosan and coacervate characterization. Int. J. Biol. Macromol. 2019, 123, 436–445. [Google Scholar] [CrossRef]

- Wang, C.; Li, B.; Chen, T.; Mei, N.; Wang, X.; Tang, S. Preparation and bioactivity of acetylated konjac glucomannan fibrous membrane and its application for wound dressing. Carbohydr. Polym. 2020, 229, 115404. [Google Scholar] [CrossRef] [PubMed]

- Korkiatithaweechai, S.; Umsarika, P.; Praphairaksit, N.; Muangsin, N. Controlled release of diclofenac from matrix polymer of chitosan and oxidized konjac glucomannan. Mar. Drugs 2011, 9, 1649–1663. [Google Scholar] [CrossRef]

- Liu, C.; Li, J.; Li, K.; Xie, C.; Liu, J. Oxidized konjac glucomannan-cassava starch and sucrose esters as novel excipients for sustained-release matrix tablets. Int. J. Biol. Macromol. 2020, 156, 1045–1052. [Google Scholar] [CrossRef] [PubMed]

- Feng, X.; Pelton, R.; Leduc, M. Mechanical properties of polyelectrolyte complex films based on polyvinylamine and carboxymethyl cellulose. Ind. Eng. Chem. Res. 2006, 45, 6665–6671. [Google Scholar] [CrossRef]

- Rashid, S.; Dutta, H. Physicochemical characterization of carboxymethyl cellulose from differently sized rice husks and application as cake additive. LWT 2022, 154, 112630. [Google Scholar] [CrossRef]

- Ohya, Y.; Ihara, K.; Murata, J.; Sugitou, T.; Ouchi, T. Preparation and biological properties of dicarboxy-glucomannan: Enzymatic degradation and stimulating activity against cultured macrophages. Carbohydr. Polym. 1994, 25, 123–130. [Google Scholar] [CrossRef]

- Sa, B.; Mukherjee, S.; Roy, S.K. Effect of polymer concentration and solution pH on viscosity affecting integrity of a polysaccharide coat of compression coated tablets. Int. J. Biol. Macromol. 2019, 125, 922–930. [Google Scholar] [CrossRef]

- Chen, Y.; Chen, B.Z.; Wang, Q.L.; Jin, X.; Guo, X.D. Fabrication of coated polymer microneedles for transdermal drug delivery. J. Control. Release 2017, 265, 14–21. [Google Scholar] [CrossRef]

- Fowler, P.D.; Ruscher, C.; McGraw, J.D.; Forrest, J.A.; Dalnoki-Veress, K. Controlling Marangoni-induced instabilities in spin-cast polymer films: How to prepare uniform films. Eur. Phys. J. E 2016, 39, 90. [Google Scholar] [CrossRef]

- Nair, S.B.; Jyothi, A.N.; Sajeev, M.S.; Misra, R. Rheological, mechanical and moisture sorption characteristics of cassava starch-konjac glucomannan blend films. Starch-Staerke 2011, 63, 728–739. [Google Scholar] [CrossRef]

- Xu, M.; Li, D.S.; Li, B.; Wang, C.; Zhu, Y.P.; Lv, W.P.; Xie, B.J. Comparative study on molecular weight of konjac glucomannan by gel permeation chromatography-laser light scattering-refractive index and laser light-scattering methods. J. Spectrosc. 2013, 2013, 685698. [Google Scholar] [CrossRef]

- Jacon, S.A.; Rao, M.A.; Cooley, H.J.; Walter, R.H. The isolation and characterization of a water extract of konjac flour gum. Carbohydr. Polym. 1993, 20, 35–41. [Google Scholar] [CrossRef]

- He, Y.; Wang, S.; Li, J.; Liang, H.; Wei, X.; Peng, D.; Jiang, Z.; Li, B. Interaction between konjac glucomannan and tannic acid: Effect of molecular weight, pH and temperature. Food Hydrocoll. 2019, 94, 451–458. [Google Scholar] [CrossRef]

- Chen, Y.; Zhao, H.; Liu, X.; Li, Z.; Liu, B.; Wu, J.; Shi, M.; Norde, W.; Li, Y. TEMPO-oxidized Konjac glucomannan as appliance for the preparation of hard capsules. Carbohydr. Polym. 2016, 143, 262–269. [Google Scholar] [CrossRef]

- Bin, L.K.; Mohammed Helaluddin, A.B.; Islam Sarker, M.Z.; Mandal, U.K.; Gaurav, A. Effect of processing methods on xylitol-starch base co-processed adjuvant for orally disintegrating tablet application. Pak. J. Pharm. Sci. 2020, 33, 551–559. [Google Scholar]

- Narang, A.S.; Boddu, S.H. Excipient applications in formulation design and drug delivery. In Excipient Applications in Formulation Design and Drug Delivery; Springer: Cham, Switzerland, 2015; pp. 1–681. [Google Scholar]

- Hardikar, S.; Bhosale, A. Formulation and evaluation of gastro retentive tablets of clarithromycin prepared by using novel polymer blend. Bull. Fac. Pharm. Cairo Univ. 2018, 56, 147–157. [Google Scholar] [CrossRef]

- Ermawati, D.E.; Andini, B.P.; Prihapsara, F.; Farida, Y.; Rohmani, S.; Kundarto, W.; Nugraheni, E.R. Optimization of Suweg starch (Amorphophallus paeoniifolius (Dennst.) Nicolson) and lactose as co-processed excipient of Ibuprofen-PEG 6000 solid dispersion of effervescent tablet. AIP Conf. Proc. 2020, 2237, 020061. [Google Scholar]

- Shevkar, B.; Ahirrao, S.; Bhavsar, G.; Patel, A.; Rajurkar, V.; Amale, P. Konjac Glucomannan Matrix Tablet for Extended Release of Diclofenac Sodium. Int. J. Adv. Pharm. Sci. 2014, 5, 2098–2108. [Google Scholar]

- Wang, S.; Zhou, B.; Wang, Y.; Li, B. Preparation and characterization of konjac glucomannan microcrystals through acid hydrolysis. Food Res. Int. 2015, 67, 111–116. [Google Scholar] [CrossRef]

- Pawar Harshal, A.; Jadhav Surekha, M.; Jadhav Pravin, T.; Rachel, G. Development and Evaluation of Mucoadhesive Patch Using a Natural Polysaccharide Isolated from Cordia dichotoma Fruit. J. Mol Pharm. Org. Process Res. 2014, 2, 91–98. [Google Scholar]

- Bisht, S.S.; Pandey, K.K.; Joshi, G.; Naithani, S. New route for carboxymethylation of cellulose: Synthesis, structural analysis and properties. Cellul. Chem. Technol. 2017, 51, 609–619. [Google Scholar]

- Mansouri, S.; Khiari, R.; Bettaieb, F.; El-Gendy, A.A.; Mhenni, F. Synthesis and Characterization of Carboxymethyl Cellulose from Tunisian Vine Stem: Study of Water Absorption and Retention Capacities. J. Polym. Environ. 2015, 23, 190–198. [Google Scholar] [CrossRef]

- Yahoum, M.M.; Moulai-Mostefa, N.; Le Cerf, D. Synthesis, physicochemical, structural and rheological characterizations of carboxymethyl xanthan derivatives. Carbohydr. Polym. 2016, 154, 267–275. [Google Scholar] [CrossRef] [PubMed]

- Ma, Y.; Lei, Y.; Zhang, X.; Liu, Y.; Sui, H.; Feng, J.; Wang, W. Konjac Glucomannan and Its Modifications as Tablet Disintegrants. Acta Pol. Pharm. Drug Res. 2017, 74, 1841–1849. [Google Scholar]

- Wang, L.; Lin, L.; Pang, J. A novel glucomannan incorporated functionalized carbon nanotube films: Synthesis, characterization and antimicrobial activity. Carbohydr. Polym. 2020, 245, 116619. [Google Scholar] [CrossRef]

- Sow, L.C.; Toh, N.Z.Y.; Wong, C.W.; Yang, H. Combination of sodium alginate with tilapia fish gelatin for improved texture properties and nanostructure modification. Food Hydrocoll. 2019, 94, 459–467. [Google Scholar] [CrossRef]

- Liu, R.; Saunders, J.M.; Freemont, T.J.; Saunders, B.R. Doubly crosslinked microgel–polyelectrolyte complexes: Three simple methods to tune and improve gel mechanical properties. Soft Matter. 2012, 8, 10932–10940. [Google Scholar] [CrossRef]

- Zhang, Y.; Bai, Y.; Chen, H.; Huang, Y.; Yuan, P.; Zhang, L. Preparation of a colon-specific sustained-release capsule with curcumin-loaded SMEDDS alginate beads. RSC Adv. 2017, 7, 22280–22285. [Google Scholar] [CrossRef]

- Yui, T.; Ogawa, K.; Sarko, A. Molecular and crystal structure of konjac glucomannan in the mannan II polymorphic form. Carbohydr. Res. 1992, 229, 41–55. [Google Scholar] [CrossRef]

- Ogawa, K.; Yui, T.; Mizuno, T. X-ray diffraction study of glucomannans and their acetates. Agric. Biol. Chem. 1991, 55, 2105–2111. [Google Scholar]

- Ainurofiq, A.; Choiri, S. Model and release pattern of water soluble drug from natural-polymer based sustained release tablet dosage form. Int. J. Pharm. Pharm. Sci. 2014, 6, 179–182. [Google Scholar]

- Ainurofiq, A.; Choiri, S. Drug release model and kinetics of naturl polymers-based sustained release tablet. Lat. Am. J. Pharm. 2015, 34, 1328–1337. [Google Scholar]