Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 1 by Antreas Kantaros and Version 2 by Camila Xu.

A digital twin is a nonphysical model that has been designed in order to accurately reflect an artificial or physical system, where sensors are placed to acquire a variety of data regarding different aspects concerning the performance of the system.

- digital twin

- cyber-physical systems

- simulation

- vehicle

- automotive

1. Definition of a Digital Twin

A digital twin is a nonphysical model that has been designed in order to accurately reflect an artificial or physical system, where sensors are placed to acquire a variety of data regarding different aspects concerning the performance of the system. These data are then transmitted to a data-acquisition system and applied to the digital copy. When the digital copy is updated with the relevant data, the virtual model may be used for the implementation of various simulations, which can lead to potential improvements, by creating valuable information that can then be applied back to the original system existing in the physical world. In this way, physical processes and products together with their accompanying elements can be digitally transferred and described in a cyber-world context [1][2][3][4][1,2,3,4].

While digital twins have great potential, their use is not a necessity for every fabricated product. Not all objects can be considered as complicated enough in order to need the intense and tactic flow data sensors required by digital twins, neither is it always worth it from a financial point of view to invest important resources for the creation of a digital twin. Therefore, the industrial sectors that have a need to employ digital twins are those that develop and produce products of the niche sector. The rapidly growing digital twin market suggests that while digital twins are already used in many industries, their demand will continue to escalate in the immediate future [5][6][7][8][5,6,7,8].

The major benefits of a nonstatic and highly realistic digital model of a physical object are practically unlimited. Understanding individual aspects of real-life objects as well as designing new ones are endorsed and the competence to simulate and optimize is elevated. Via recording and digitally acquiring the operating data of the model (digital twin), in a real-time situation, the recording of behavioral patterns of the real-world system becomes more achievable. Therefore, users can predict them in a greater degree.

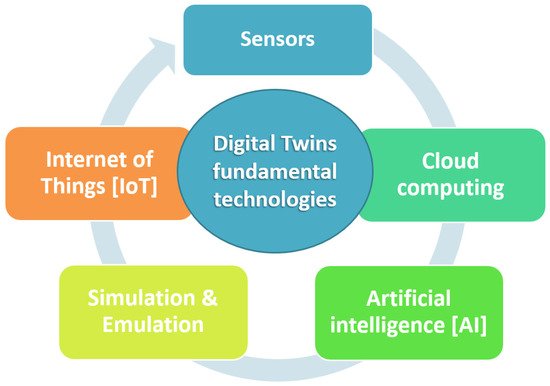

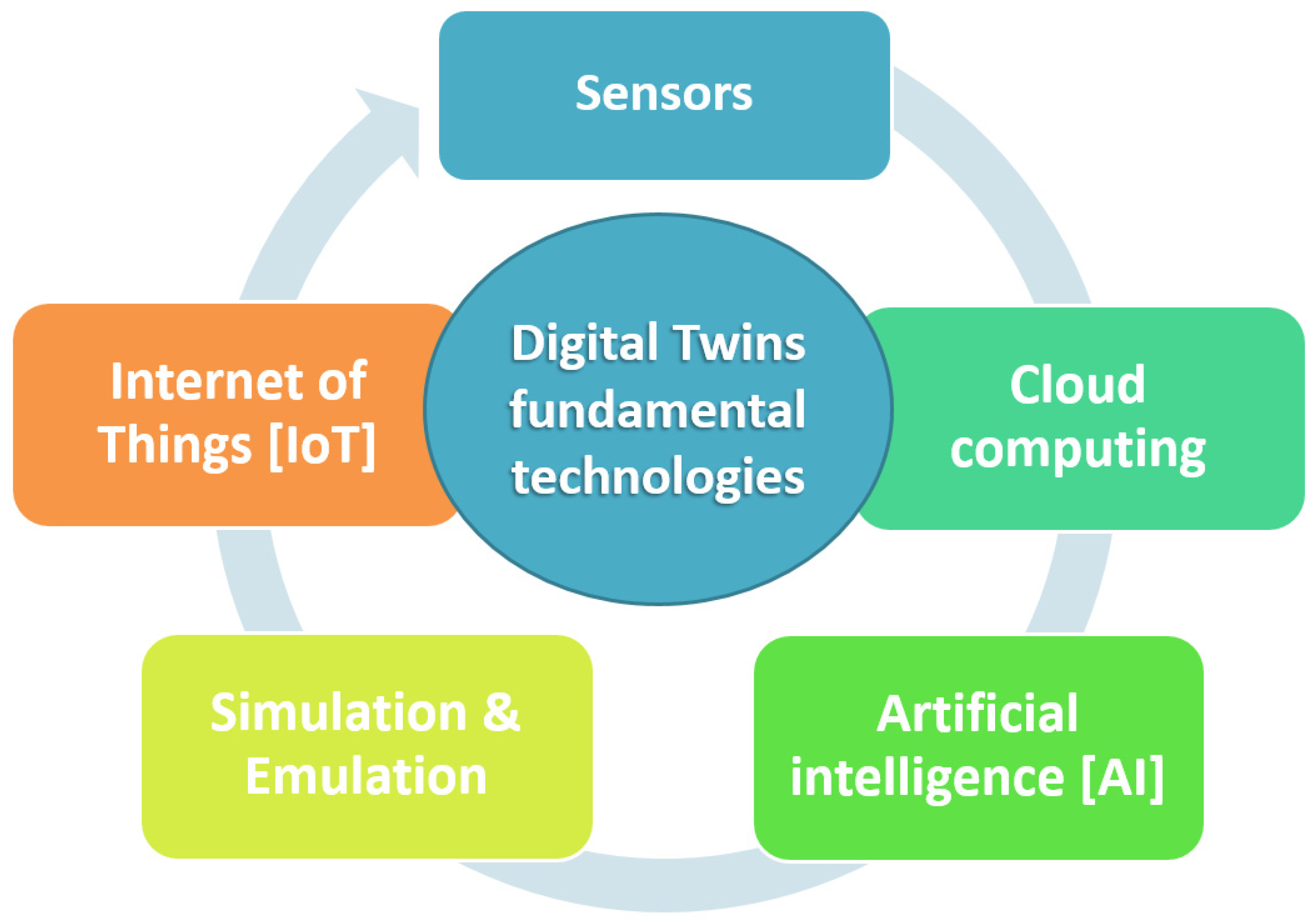

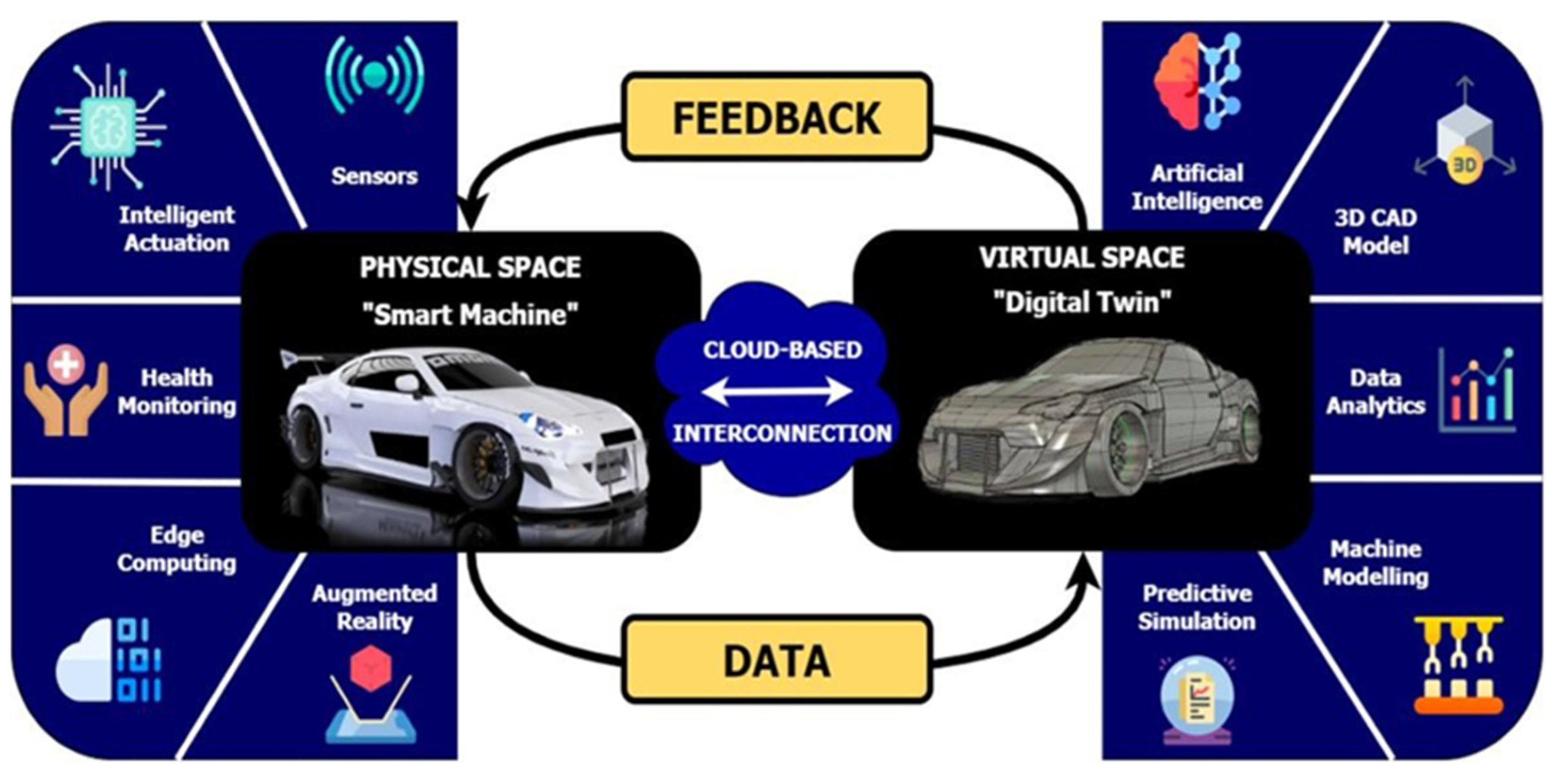

In order to utilize “digital twin” technology, three distinct steps are basically needed. At first, the digital twin prototype should be made, taking into account data along with processes carried out in the real-word system. After that stage, a digital twin of the properties of every object must be compiled. At the end, every relevant systemic property should be attributed, so that, via all the data acquired, a further understanding and prognosis can be achieved. In conclusion, the digital twin should be able to realistically represent its physical real-world twin and be able to show its condition in real-time. In order for this to be feasible, the employment of innovative technologies is requested, which are considered as the foundations of today’s industrial revolution context. These can be viewed in Figure 1.

Figure 1. Digital twin fundamental technologies.

2. The Historical Background of the Digital Twin Technology

The “Digital Twin” idea arose in 2002 when Challenge Advisory presented the idea from Michael Grieves from the University of Michigan regarding contemporary technological developments. The presentation had to do with the development lifecycle management center regarding products. This presentation included all the core details relevant with the “Digital Twin” technology such as physical space, virtual space, and the exchange of relevant data and information between physical and virtual worlds. Even though the used terms have been altered since then, the basic idea has remained the same. Even though it is generally believed that the concept was first been presented in 2002, it has been well-known since the 1960s. NASA has been using basic similar technology ever since, for space programming. What they actually did was fabricate physical twins at their facilities to simulate the physical mechanical assemblies operating outside of the Earth’s environment. A relevant case was setup in the case of Apollo 13 when it was placed in orbit [9].

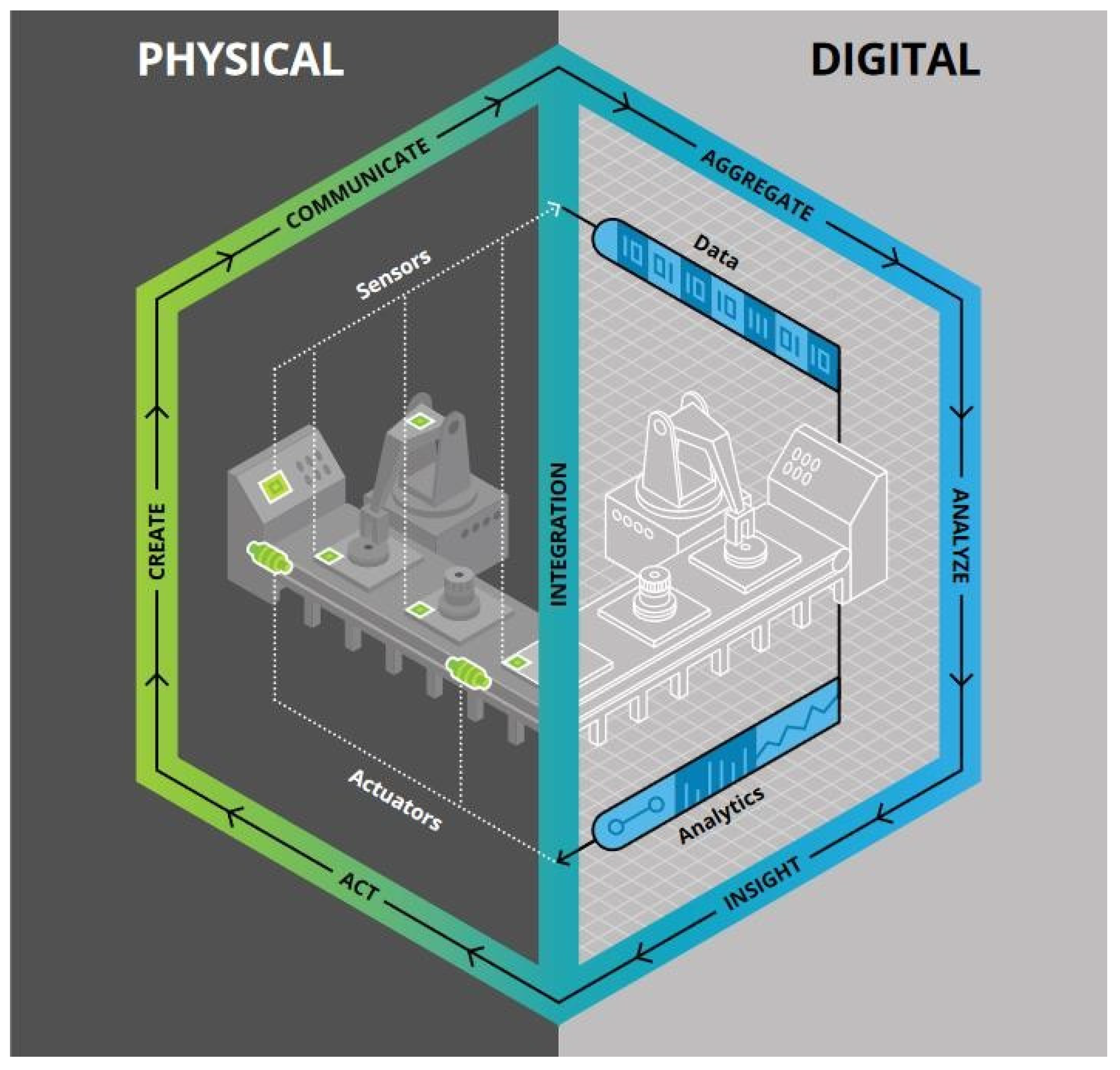

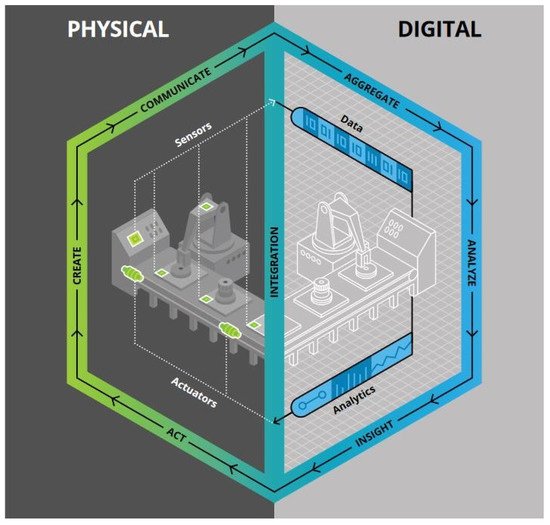

When Apollo 13 was launched in April 1970, it was statistically unthinkable that the crew would fight for their own survival when oxygen tanks malfunctioned midflight. It is one of the most well-known rescue missions attempted, while technicians on Earth tried to come up with a solution while being on the Earth. What turned the rescue mission into a success, however, was the fact a digital twin of the spaceship was set-up on Earth, which enabled ground crews and scientists to come-up with a rescue plan. However, nowadays, such system layouts have apparently become virtual rather than physical. Figure 2 depicts a characteristic systemic layout of a digital twin [10][11][10,11].

Figure 2. Characteristic systemic layout of a digital twin.

3. Digital Twins in Automotive Industry

The automotive industry has changed dramatically over time as consumer needs grow and new technologies are constantly entering the field. The industry retains some of its traditional infrastructure while being constantly enriched with emerging digital services based on sensors and devices utilizing artificial intelligence, which operate mainly after the product enters the market. The involvement and importance of Digital Twins in the improvement of the vehicle aid in its life cycle-added value and also in the optimized design of future vehicles [12][13][49,50]. Figure 3 depicts a typical Digital Twin arrangement applied in the automotive industry.

Figure 3. A typical Digital Twin arrangement applied in the automotive industry.

In order for a vehicle to enter the market, it should undergo a number of obligatory design and control stages. The first stage concerns the initial design of the vehicle’s exterior surface in a relevant CAD design software package. At that point, designers start with a simple exterior and interior modeling and then proceed with the design of the vehicle’s individual components. Physical prototyping has also evolved nowadays with the introduction of 3D printing technology that allows designers to fabricate physical prototypes of their designs rapidly for testing operations [13][14][15][16][17][18][50,51,52,53,54,55]. However, while physical prototyping is essential, the simultaneous presence of a Digital Twin is of paramount importance for the automotive companies. In the initial stages of product development, the Digital Twin can collect the vehicle’s behavioral information in performance terms, thus providing valuable information to the designers and system engineers.

Upon the vehicle’s market introduction, in the case of test conduction or a potential recall campaign, via a Digital Twin, vehicle test data can be simulated to determine their quality and performance, such as the use of a new component under various conditions to implement design improvements and to experiment with substantially different elements that may lead to its optimization. Product performance may be predicted along with changes made in real time, determining the optimal configuration. By tracking key components, no recall is required for tens of thousands of products in the event of a problem. Those directly affected can be identified immediately by locating a consignment of corroded components during transport from abroad [19][59].

In the sales field, the digital twin of a vehicle with 3D vehicle reconstruction and visual representation can make a possible buyer alter its color when visiting an automotive manufacturer’s site. The same applies to different vehicle aesthetic elements such as the interior, allowing for a customized product tailormade for the customer. In the case of used cars, buyers often have no other option but to speculate about the condition of a vehicle. A used vehicle with digital identity assists with the tracking about its maintenance record with the digital twin containing all relevant data [20][21][60,61].

Digital Twin technology also has great potential in electric vehicles. The modus operandi in this case suggests that an electric vehicle should be linked with its customized digital twin. Via installed IoT sensors on the vehicle, the sensors can exchange data with the vehicle’s digital twin. This information gathered as feedback enables the manufacturer to maintain a digital record of the working condition of the car and also detects potential problems at an early stage before they evolve in order to avoid potential repairs. For example, the American automotive manufacturer Tesla utilizes Digital Twin technology in every vehicle they produce. The partner company that developed Tesla’s Digital Twin application (called “Thinkwik”) states that real-time mechanical issues in Tesla Motors, regardless of their magnitude, are being fixed by simply downloading over-the-air (OTA) software updates. The uninterrupted continuous transmission of the relevant data between the vehicles and the manufacturer aids toward improving the quality of its products. The use of Digital Twins along with pioneering technologies such as the Internet of Things (IoT) and artificial intelligence (AI) has made feasible such processes that were thought to be unachievable [22][23][24][25][26][27][28][29][30,62,63,64,65,66,67,68].

A Vehicle’s Meta-Life

There is a variety of elements that form a customer’s view of an automotive product, such as fuel savings, comfort while driving, and performance, but safety is always a factor of paramount importance. Advanced Driver Assistance Systems (ADASs) is the terminology used regarding the safety supplements designed to increase the driver’s, passengers’, and pedestrians’ safety by minimizing the number and seriousness of automotive accidents. The purpose of an ADAS is to notify users when potential impending hazards are identified, to intervene when necessary in order for the user to achieve proper control of the automobile, and to prevent accidents or to reduce the severity of an accident when it might happen [30][69]. ADASs rely heavily on Digital Twin technology because they use sensors to detect future threats. The system works in conjunction with the cloud in which all data are stored and recalled if needed. The knowledge obtained from these data may increase the ability to respond to or detect threats from existing ADAS architectures [31][70].

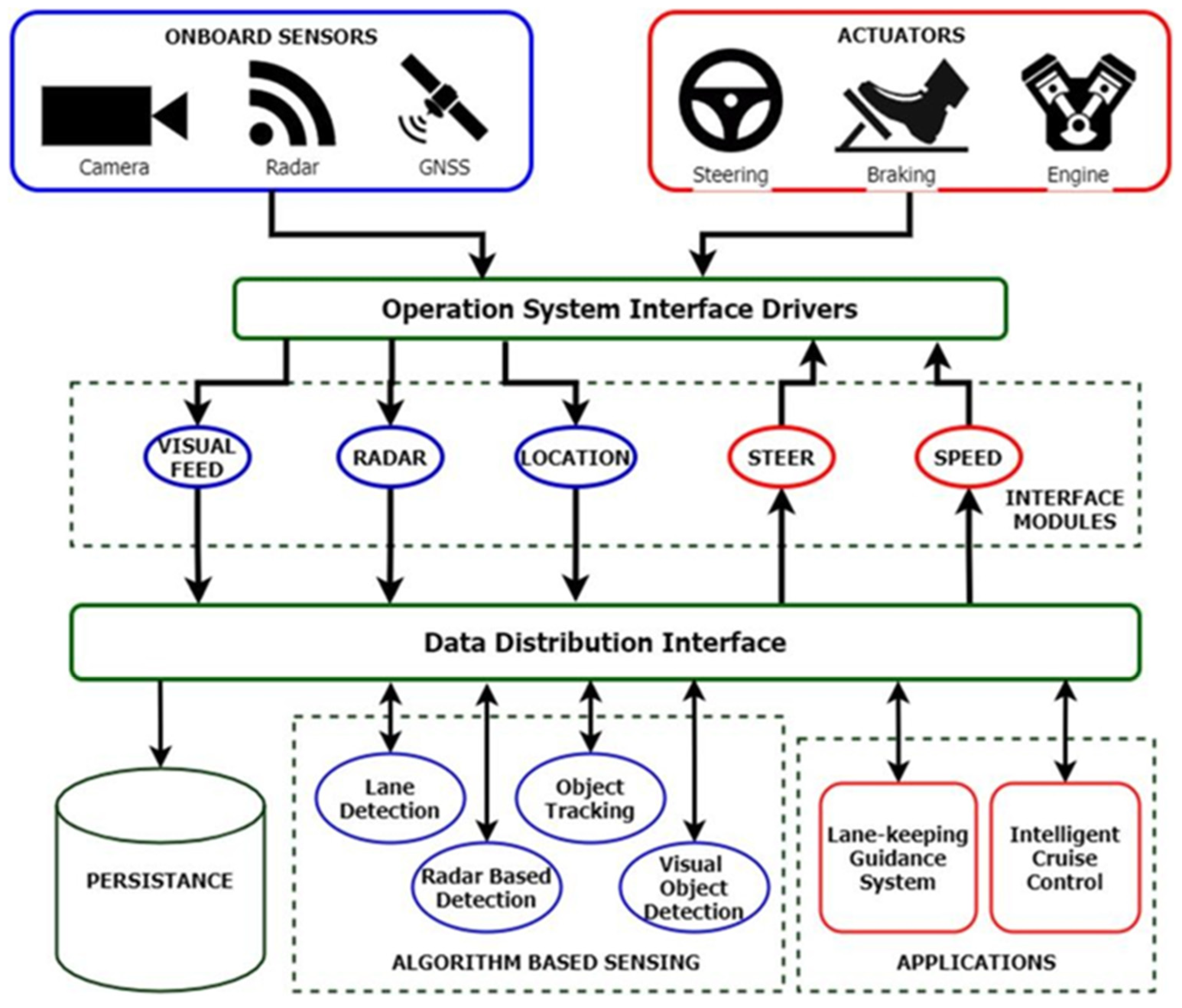

An attempt is made to use Digital Twin technology by incorporating fuzzy cloud-based logic to draw conclusions to elevate the efficiency of telematics-based user aid. Employing fuzzy logic in ADAS Digital Twin systems is considered crucial for facilitating the transition from manned to autonomous vehicles. To achieve the goal of flawless human–computer interaction while taking into account greater standards and regulations [32][71], a complex architecture is created where the Digital Twin can aid toward achieving user safety by analyzing real-time sensor data from the real-world car along with the knowledge base of the relevant protection regulation context. This leads to a smart ADAS that respects personal data within the laws’ limits, enhancing public perception and market shares [33][72]. Figure 4 depicts a driver’s assistance system architecture.

Figure 4. Driver’s assistance system architecture.

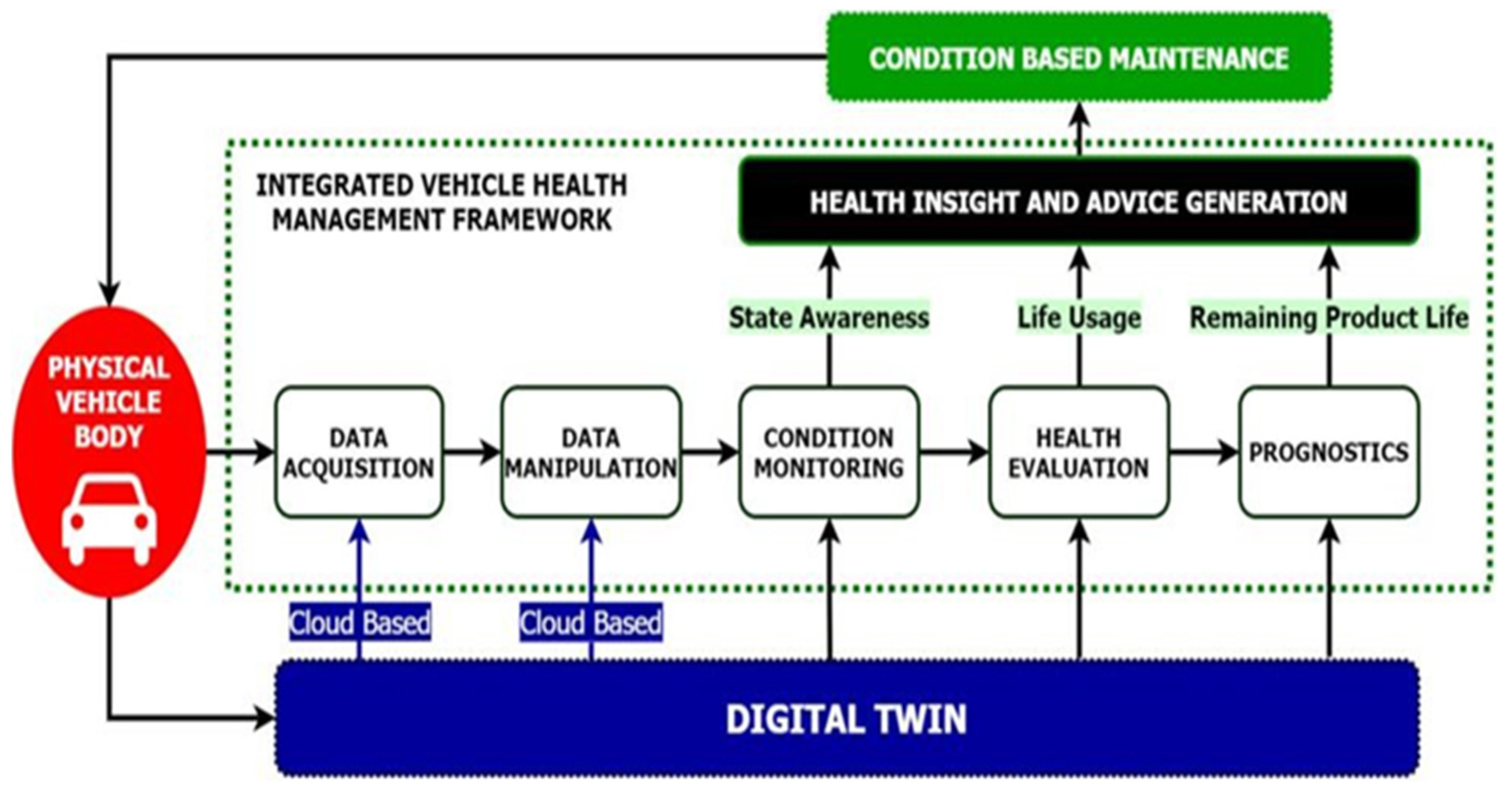

This technology can be used to facilitate Maintenance Repair Operations (MROs) by creating a smart interface between the car company and the driver. Using relevant data, the twin can perform an evaluation of the vehicle’s health state while predicting future maintenance requirements. The compiled twin simulates electronics, electromagnetic effects, brake pad wear levels, and vehicle dynamics data detection to provide meticulous information of the vehicle’s state [34][73]. A system that is subject to a gradual and inevitable degradation in electric vehicles is the electric motor, making health monitoring essential [35][74]. Figure 5 depicts a Digital Twin system diagram embedded within the Maintenance Repair Operations system.

Figure 5. Digital Twin technology embedded within the MRO.