You're using an outdated browser. Please upgrade to a modern browser for the best experience.

Please note this is a comparison between Version 2 by Rita Xu and Version 1 by Parthana Parthanadee.

Cassava harvest practices and choose a pricing scheme between farmers and factories, cassava yards, and collectors in Thailand. Harvest practices represent all activities from land preparation to harvest.

- cassava

- harvesting age

- pricing scheme

1. Introduction

Cassava is an important economic crop of Thailand. In 2020, Thailand’s cassava production amount (29 million tons) was at the third rank in the world [1]. Thailand cassava export, in the forms of cassava dried (chips and pellets) and cassava starches, was ranked first with approximately 57% of global market share due to relatively much lower domestic consumption [2]. The total export volumes had ever been around 11 million tons from 2014 to 2017 but have been decreasing since 2018 and were at 7.14 million tons in 2020 [3]. However, unlike most developed countries, where agricultural products are produced in large farms under contract farming with the buyers, there are a large number of small-sized cassava farms in Thailand, mostly without contract farming. In 2020, there were 587,754 cassava farming households with an average farm size of 2.57 hectares [4].

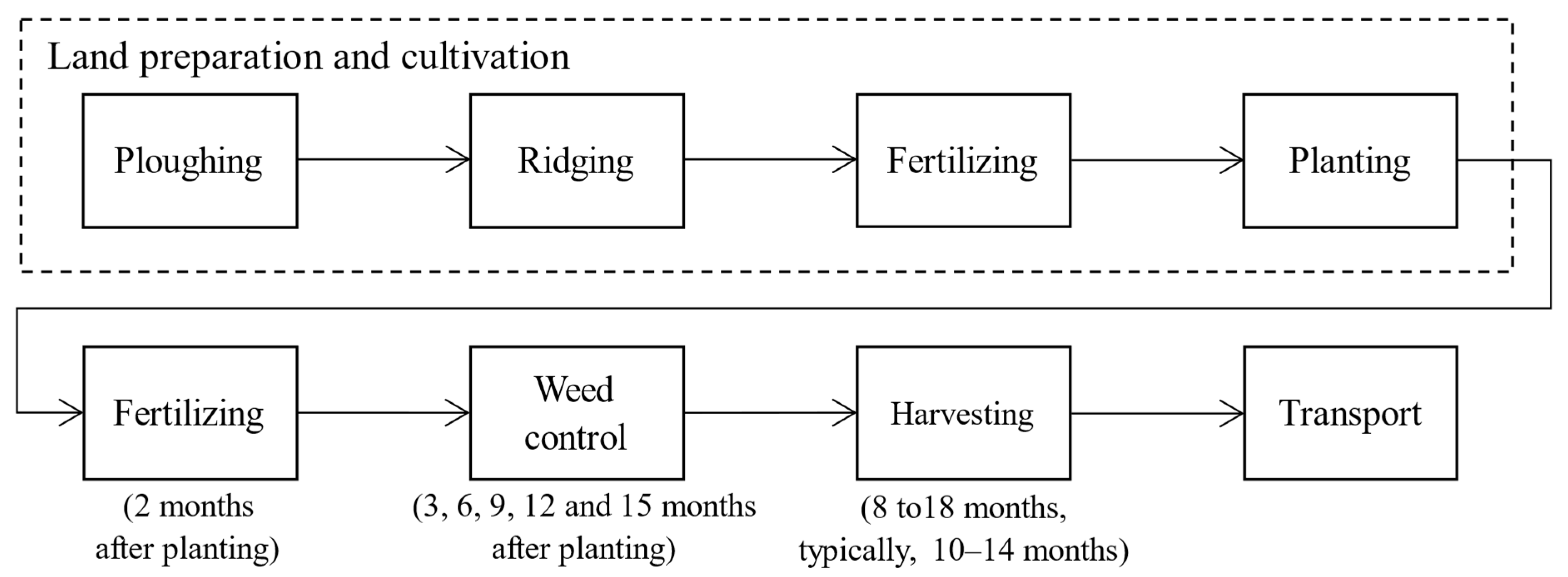

In general, fresh cassava root production (Figure 1) consists of the following activities: land preparation and cultivation, fertilizing, weed control, harvesting, and transportation. First, the land is ploughed at least once prior to ridging. Then, organic fertilizers, e.g., compost and chicken manure, are added, and stems are planted. After two months, fertilizer, usually a chemical type, is applied to enhance nutrients in the soil. Then, weed control is performed every three months, either by using herbicide or manual removal by human workers in order to protect the cassava stems from weeds. Finally, the cassava is harvested and transported to a cassava yard or starch factory.

Figure 1. Typical cassava production process in Thailand.

Factors that directly affect farmers’ profit from selling their harvests include the cost of cultivation activities that is directly driven by the harvesting age, yield (amount and starch content, expressed as a percentage), market price, and the pricing basis in which to sell the products to local buyers, defined as “pricing scheme” in this paper. Among these factors, market price and yield, to a lesser degree, are not under the farmers’ control. Although cultivation activities can affect yield, there are other uncontrollable external factors related to climate change, such as amounts of rainfall, drought, flood, pest and disease breakouts. Cassava yield also changes with harvesting age. Naturally, cassava root’s weight increases, while starch content tends to decrease, as cassava grows older. In addition, there is a relationship between the decrease in starch content and high rainfall during the harvesting period, as the cassava plant reinitiates its growth and creates new sprouts, and translocate the nutrients from the root to the top of the plant [5,6,7][5][6][7].

Since most Thai farmers perform common cultivation activities, the two important factors under farmers’ control that affect cost, revenue, and thus, profitability are the length of harvesting practices and pricing scheme. The amount of resources required for cassava’s harvesting practices is driven primarily by its harvesting age. The harvesting age can range from eight months (the earliest age that cassava is harvested) to 18 months (the oldest age of cassava sold in the market). Moreover, there is some variation in the length of harvesting practices that farmers prefer. Harvesting practices length may be fixed or varying within an interval. The most common practice among Thai farmers is to harvest once a year, i.e., a fixed harvest cycle of 12 months. However, some farmers consider market price when making their harvest timing decision. In other words, the market price trend directly affects the likelihood of harvesting, as farmers prefer to harvest when the market price is high, or they may postpone harvesting when the market price is low. This leads to harvesting practices with some variations in its length. For example, a 10-month to 14-month varying length implies that most farmers may harvest their cassavas as early as 10 months, or as late as 14 months after planting.

After harvesting, farmers have to choose where to sell their produce, based on factory-gate buying prices and pricing schemes. In Thailand, there are two pricing schemes: weight-based and starch-content-based. Weight-based pricing is widely used by collectors, cassava chip manufacturers, and some starch manufacturers, while the starch-content-based pricing is mainly used at starch manufacturers. With weight-based pricing, the harvest is sold according to the weight (in tons) only; whereas with starch-content-based pricing, the quality of the harvest is evaluated at the factory gate to determine the percentage of starch content and the per-kilogram buying price. The market price is quoted at a level of starch content, either at 30%, or 25%. When the cassava has lower starch content, the buyer decreases the buying price, depending on the measured starch content of the harvest. Usually, in a particular area, the quoted market price at 30% starch content is higher than the market price of the weight-based pricing.

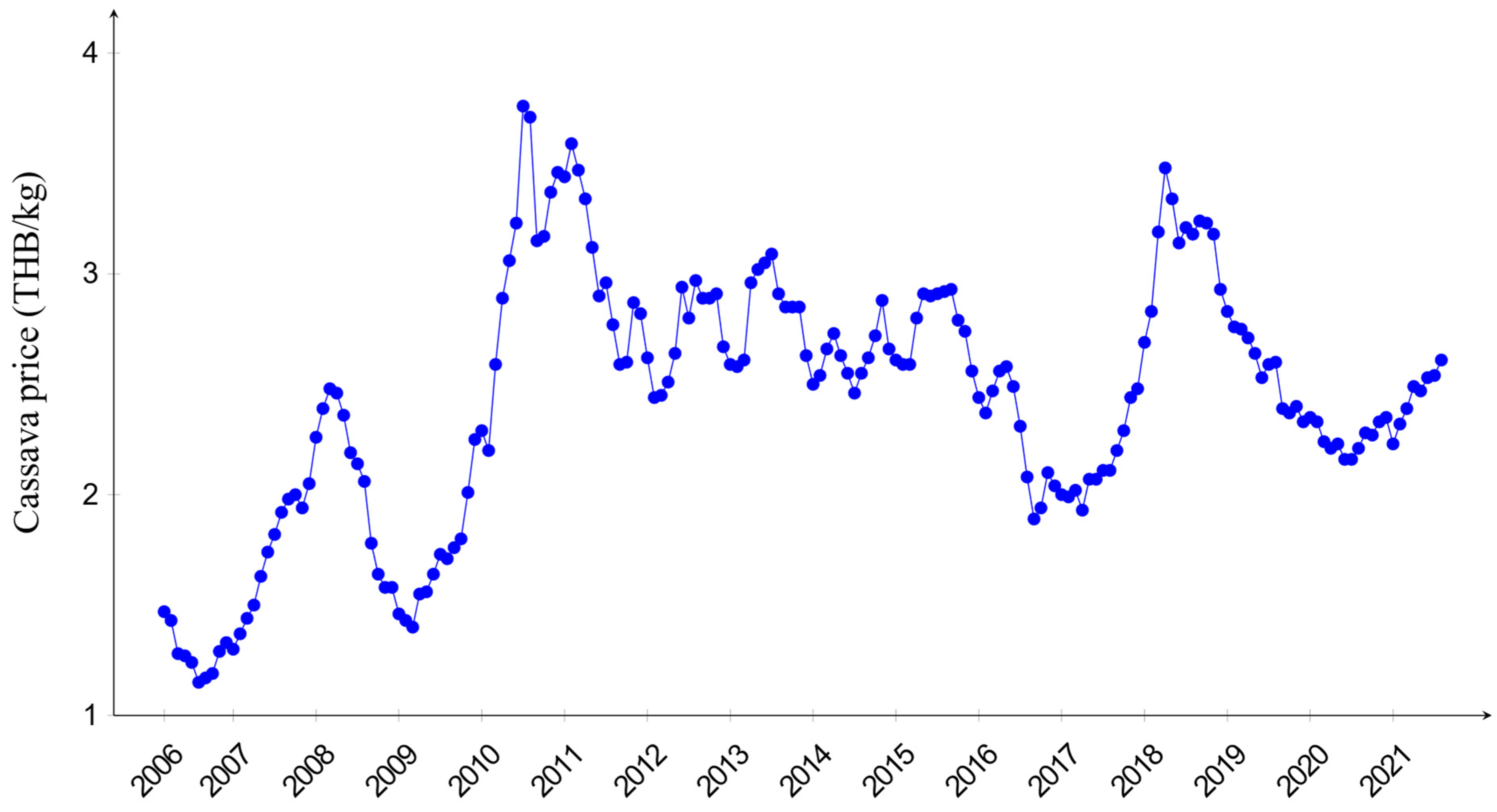

As a commodity product, changes in cassava supply and market demand lead to price fluctuation. In the past decade, the market trend is somewhat positive due to increasing demand from emerging market (China) that uses cassava as raw material for producing alternative energy, i.e., biodiesel. In recent years, some influential events and factors, e.g., an outbreak of diseases, climate change, world economy, technological change, government policies, contribute to higher uncertainty in the demand and supply of cassava, which highly affects cassava market prices. Figure 2 illustrates the market price of cassava over the past decade. It can be seen that the price fluctuates in an unpredictable manner, i.e., the price pattern does not necessarily repeat itself from season to season. Making decisions under such volatile market situations to achieve economic sustainability is clearly a challenge for farmers.

Thai cassava farmers usually choose the time to harvest and pricing scheme based on their experiences, financial needs, and market price, without proper guidelines on choosing the harvesting age and pricing scheme. This may not lead to optimal and/or robust decisions. Thus, the objective of this paper is to provide a guideline for choosing harvesting age and pricing scheme, while considering uncertainties regarding other factors including market price, amount of resources required, its cost, yield amount and percent starch that change with age, through the use of a computer simulation model.

Simulation modelling is a methodology that can be used to analyze such an agricultural system that contains various sources of uncertainty. A simulation model imitates the real system with a logical/mathematical, computerized model. The major benefit of using simulation is that the system behavior can be studied through computational experiment in advance without disrupting the real system. InA this paper, a ssimulation model is developed to imitate cassava production processes under uncertainties. Using the model, farmers’ decision makings regarding the harvesting age and pricing scheme are analyzed under volatile market scenarios so as to maximize the economic benefit, i.e., profit, for the farmers. It is important to emphasize that the harvesting age governs the farming activities and resources required until harvest. Therefore, from this perspective, the harvesting age essentially represents the harvesting practices. Input data of the model are from an extensive survey study using face-to-face interviews with the farmers. After constructing the model, model verification and validation are properly performed to ensure that the model is a good representative of the real system. In addition, clustering analysis on market price is performed to identify common price scenarios that farmers may face. Different harvesting age and pricing scheme decisions are then tested under these market price scenarios in order to determine not only the optimal decisions that maximize profit, but also to obtain robust decisions. Analysis of the computational experiment results lead to the guideline for farmers to choose a harvesting age and a pricing scheme that maximize their average monthly profit. The guideline is based on a comparison between the market price posted at factory gate and the actual purchase price the farmer will receive based on the estimated starch content of their cassava roots.

3. Economic Sustainability of Cassava Farmers

A number of research studies have been conducted in applying simulation modelling to various industries such as manufacturing, logistics, and agriculture. In the manufacturing industry, simulation is widely used as a decision support tool for productivity improvements such as reducing production lead-time and work-in-process inventory [9,10,11,12,13][9][10][11][12][13]. In the logistics industry, simulation played a role in transportation analysis for both domestic and export systems. For example, Mobini et al. [14] used simulation to investigate the logistics of supplying forest biomass to a potential power plant. Turner et al. [15] applied the simulation to assess the performance of a domestic grain transportation system in various scenarios while varying resources, which are truck and driver capacity, and considering uncertain parameters related to the transportation process. Simulation was implemented to achieve productivity improvement and assist decision-making in agricultural production systems in the following studies. Stehfest et al. [16] adapted the agro-ecosystem model for the simulation of major crops at a global scale. The objective is to address the issue of the earth system as it changes global biogeochemical and water cycles, while global environmental change affects land productivity and future land-use decisions. Martin-Clouaire and Rellier [17] studied a computer simulation framework for production activities, flexible plans, and material resources in agricultural production systems. Van der Vorst et al. [18] proposed a new integrated approach towards logistics, sustainability, and food quality analysis, and implement the approach by introducing a new simulation environment. Martin et al. [19] presented a simulation framework to construct simulation models of grassland-based beef-cattle farms for evaluation and empirical design purposes. Furthermore, in the past decade, Hameed et al. [20] developed and applied an object-oriented simulation model which simulates in detail in-field machine activities during the execution phase in order to deal with complex operations involving capacity constraints and cooperating units. Ooster et al. [21] presented a simulation of labor processes in a greenhouse with a rose cultivation system. The objective is to quantify the effects of production system changes by means of a flexible and generic model approach. Bergez et al. [22] built a specific modelling platform to help model, simulate and evaluate cropping systems to find new solutions to produce goods due to significant changes in agro-ecological contexts. Linker et al. [23] improved efficiency of water consumption in cultivating cotton, potato, and tomato by using simulation analysis results to perform irrigation scheduling. She et al. [24] presented an application of simulation in modelling a ground-based timber harvesting system to estimate machine performances including cycle times, productivities, and utilization. Gittins et al. [25] developed an approach that combines simulation result and interviews with farmers. The objective is to evaluate the impact of changing in socio-political circumstances and to find strategies for livestock management. The simulation was also applied to support seeding and harvesting decisions in two recent studies. Kadigi et al. [26] performed simulation experiments to evaluate alternative rice farming systems, specifically, traditional rice farming practices and the proposed rice intensification (SRI) practices, to improve farmers’ income. Deepradit et al. [27] presented a simulation model for aromatic coconut manufacturing to determine an appropriate harvest amount and harvesting age that maximize annual profit under uncertainty. For cassava-based products, simulation-related studies and the study objective are as follows. Amamullah et al. [28] developed a simulation model to estimate cassava growth in order to identify the treatment combinations (forage intercropping and organic manures) that maximize cassava growth rate. Yu and Tao [29] implemented a Monte Carlo simulation to assess the energy efficiency of cassava-based ethanol fuel on the vehicle energy consumption. In another study by the same authors, Yu and Tao [30] constructed a Monte Carlo simulation of the life cycle emission models to assess and compare environmental emissions of three biomass-based fuel ethanol (BFE), including wheat-based, corn-based, and cassava-based, from different feedstock planting areas in China. Da et al. [31] studied recycling process in cassava starch production process using continuous simulation model. Specifically, the reduction of effluents volume, measured in terms of water consumption, through a recycling process in the cassava extraction operation is modelled using MATLAB Simulink. Different strategies of recycling are tested and the most water-volume saving strategy is identified. Mithra et al. [32] proposed a process model for simulating the growth of cassavas. The objective is to predict the final yield under different field conditions, crop phenology, solar radiation and photosynthesis, levels of stress due to shortage of water, nitrogen and potassium. Zhang et al. [33] analyzed the cost of using cellulase enzyme and stream energy in cassava-based ethanol product. A flowsheet simulation model of the system is constructed using Aspen Plus. Recently, Le et al. [34] proposed an environmental policy integrated climate (EPIC) model to assess the impact of conservation agriculture (CA) and conservation tillage (CT) on the yields of important crops, which also included cassava, in Cambodia. The model inputs include crop parameters, management practices, soil properties, plot topographic conditions, and daily weather. In particular, the simulations of cassava yield and cassava biomass show satisfactory results that the model can capture the behavior of the actual crop system. Jiao et al. [35] implemented a Monte Carlo simulation to analyze uncertainty in the development of cassava-based fuel ethanol in China. The objective is to identify the stages and factors that mostly affect the life cycle performance of cassava ethanol.References

- Office of Agricultural Economics (OAE). Agricultural Statistics of Thailand 2020; Ministry of Agriculture and Cooperatives: Bangkok, Thailand, 2012.

- Office of Agricultural Economics (OAE). Situation of Important Agricultural Products and Trends in 2021; Ministry of Agriculture and Cooperatives: Bangkok, Thailand, 2012. (In Thai)

- Information Technology and Communication Center, Ministry of Commerce of Thailand. Exports Structure. 2021. Available online: https://tradereport.moc.go.th/Report/ReportEng.aspx?Report=MenucomRecode&Option=5&Lang=Eng (accessed on 13 September 2021).

- Office of Agricultural Economics (OAE). Cassava: Planted Area, Number of Households, and Average Planted Area per Planted Area by Province in 2020; Ministry of Agriculture and Cooperatives: Bangkok, Thailand, 2012. Available online: https://www.oae.go.th/assets/portals/1/fileups/prcaidata/files/Casava Holdland 63.pdf (accessed on 13 September 2021). (In Thai)

- Rojanaridpiched, C.; Pulsanguan, P.; Phuddachareon, S.; Jeamjamnanja, J.; Saengkaewsook, W. Study on planting season of cassava. Agric. Nat. Resour. 1987, 21, 119–125. (In Thai)

- Ceballos, H.; Perez, J.C.; Calle, F.; Jaramillo, G.; Lenis, J.I.; Morante, N.; López, J. A new evaluation scheme for cassava breeding at CIAT. In Cassava Research and Development in Asia: Exploring New Opportunities for an Ancient Crop. Proceedings of the Seventh Regional Workshop, Bangkok, Thailand, 28 October—1 November 2002; Howeler, R.H., Ed.; The Centro Internacional de Agricultura Tropical (CIAT) and the Department of Agriculture (DOA): Bangkok, Thailand, 2007; pp. 125–135.

- Moreno, L.P.; Gourdji, S.M. Cassava Starch Content and Its Relationship with Rainfall; CCAFS Info Brief; CGIAR Research Program on Climate Change, Agriculture and Food Security (CCAFS): Copenhagen, Denmark, 2015.

- Thai Tapioca Starch Association. Weekly Tapioca Starch Price. 2019. Available online: http://www.thaitapiocastarch.org/en/information/statistics/weekly_tapioca_starch_market (accessed on 3 October 2019).

- Abdulmalek, F.A.; Rajgopal, J. Analyzing the benefits of lean manufacturing and value stream mapping via simulation: A process sector case study. Int. J. Prod. Econ. 2007, 107, 223–236.

- Parthanadee, P.; Buddhakulsomsiri, J. Simulation modeling and analysis for production scheduling using real-time dispatching rules: A case study in canned fruit industry. Comput. Electron. Agric. 2010, 70, 245–255.

- Kampa, A.; Gołda, G.; Paprocka, I. Discrete event simulation method as a tool for improvement of manufacturing systems. Computers 2017, 6, 10.

- Lidberg, S.; Aslam, T.; Pehrsson, L.; Ng, A.H. Optimizing real-world factory flows using aggregated discrete event simulation modelling. Flex. Serv. Manuf. J. 2020, 32, 888–912.

- Yang, S.L.; Xu, Z.G.; Li, G.Z.; Wang, J.Y. Assembly transport optimization for a reconfigurable flow shop based on a discrete event simulation. Adv. Prod. Eng. Manag. 2020, 15, 69–80.

- Mobini, M.; Sowlati, T.; Sokhansanj, S. Forest biomass supply logistics for a power plant using the discrete-event simulation approach. Appl. Energ. 2011, 88, 1241–1250.

- Turner, A.P.; Sama, M.P.; McNeill, L.S.G.; Dvorak, J.S.; Mark, T.; Montross, M.D. A discrete event simulation model for analysis of farm scale grain transportation systems. Comput. Electron. Agric. 2019, 167, 105040.

- Stehfest, E.; Heistermann, M.; Priess, J.A.; Ojima, D.S.; Alcamo, J. Simulation of global crop production with the ecosystem model DayCent. Ecol. Modell. 2007, 209, 203–219.

- Martin-Clouaire, R.; Rellier, J.P. Modelling and simulating work practices in agriculture. Int. J. Metadata Semant. Ontol. 2009, 4, 42–53.

- van der Vorst, J.G.; Tromp, S.O.; Zee, D.J.V.D. Simulation modelling for food supply chain redesign; integrated decision making on product quality, sustainability and logistics. Int. J. Prod. Res. 2009, 47, 6611–6631.

- Martin, G.; Martin-Clouaire, R.; Rellier, J.P.; Duru, M. A simulation framework for the design of grassland-based beef-cattle farms. Environ. Model. Softw. 2011, 26, 371–385.

- Hameed, I.A.; Bochtis, D.D.; Sørensen, C.G.; Vougioukas, S. An object-oriented model for simulating agricultural in-field machinery activities. Comput. Electron. Agric. 2012, 81, 24–32.

- Ooster, A.; van’t Bontsema, J.; van Henten, E.J.; Hemming, S. GWorkS–A discrete event simulation model on crop handling processes in a mobile rose cultivation system. Biosyst. Eng. 2012, 112, 108–120.

- Bergez, J.E.; Chabrier, P.; Gary, C.; Jeuffroy, M.H.; Makowski, D.; Quesnel, G.; Ramat, E.; Raynal, H.; Rousse, N.; Wallach, D.; et al. An open platform to build, evaluate and simulate integrated models of farming and agro-ecosystems. Environ. Modell. Softw. 2013, 39, 39–49.

- Linker, R.; Ioslovich, I.; Sylaios, G.; Plauborg, F.; Battilani, A. Optimal model-based deficit irrigation scheduling using AquaCrop: A simulation study with cotton, potato and tomato. Agric. Water Manag. 2016, 163, 236–243.

- She, J.; Chung, W.; Kim, D. Discrete-event simulation of ground-based timber harvesting operations. Forests 2018, 9, 683.

- Gittins, P.; McElwee, G.; Tipi, N. Discrete event simulation in livestock management. J. Rural Stud. 2020, 78, 387–398.

- Kadigi, I.L.; Mutabazi, K.D.; Philip, D.; Richardson, J.W.; Bizimana, J.-C.; Mbungu, W.; Mahoo, H.F.; Sieber, S. An Economic Comparison between Alternative Rice Farming Systems in Tanzania Using a Monte Carlo Simulation Approach. Sustainability 2020, 12, 6528.

- Deepradit, S.; Ongkunaruk, P.; Pisuchpen, R. Tactical Procurement Planning under Uncertainty in Aromatic Coconut Manufacturing. Int. J. Technol. 2020, 11, 698–709.

- Amanullah, M.; Kailasam, C.; Safiullah, A.M.; Selvam, S.; Sivakumar, K. Crop simulation growth model in cassava. Res. J. Agric. Biol. Sci. 2007, 3, 255–259.

- Yu, S.; Tao, J. Energy efficiency assessment by life cycle simulation of cassava-based fuel ethanol for automotive use in Chinese Guangxi context. Energy 2009, 34, 22–31.

- Yu, S.; Tao, J. Simulation based life cycle assessment of airborne emissions of biomass-based ethanol products from different feedstock planting areas in China. J. Clean. Prod. 2009, 17, 501–506.

- Da, G.; Ferret, E.; Marechal, P.A.; Le Thanh, M.; Marouze, C.; Dufour, D. Modeling small-scale cassava starch extraction. Simulation of the reduction of water consumption through a recycling process. Process Biochem. 2010, 45, 1837–1842.

- Mithra, V.S.; Sreekumar, J.; Ravindran, C.S. Computer simulation of cassava growth: A tool for realizing the potential yield. Arch. Agron. Soil Sci. 2013, 59, 603–623.

- Zhang, J.; Fang, Z.; Deng, H.; Zhang, X.; Bao, J. Cost analysis of cassava cellulose utilization scenarios for ethanol production on flowsheet simulation platform. Bioresource Technol. 2013, 134, 298–306.

- Le, K.N.; Jeong, J.; Reyes, M.R.; Jha, M.K.; Gassman, P.W.; Doro, L.; Hok, L.; Boulakia, S. Evaluation of the performance of the EPIC model for yield and biomass simulation under conservation systems in Cambodia. Agric. Syst. 2018, 166, 90–100.

- Jiao, J.; Li, J.; Bai, Y. Uncertainty analysis in the life cycle assessment of cassava ethanol in China. J. Clean. Prod. 2019, 206, 438–451.

More