Industrial symbiosis (IS) can contribute to achieving a win-win situation between industry and environment for local and regional circular economies. Many authors have recognized that a variety of barriers can hinder the implementation of industrial symbiosis (IS) and eco-industrial development. It is imperative to understand and prioritize the barriers which will provide guidance for the realization of IS projects and assist practitioners and stakeholders with more effective implementation. This, in turn, will contribute to development of circular economies. Through an extensive literature review, this paper proposes a model which combines the Analytic Hierarchy Process (AHP) and the Technique for Order Preference by Similarity to Ideal Solution (TOPSIS) to evaluate thewe summarized the research on IS barriers from two aspects: (1) identification of IS barriers and (2) classification of IS barriers. It shows that the current research related to IS barriers semi-quantis mainly qualitatively. This model assists in identifying and prioritizi. There is very little research of a quantitative nature assessing the fundamental barriers for implementation of IS in a comprehensive manner. An operating IS, the Hai Hua Group (HHG), in Shandong Province, China is used as a operating industrial symbioses. Thus, it is imperative to prioritize the barriers in a comprehensive manner with more case study to test the proposed model. The results show that the top four genericies. It provides empirical evidence for the study of IS barriers are technological, economic, safetynd should be helpful for managers, decision-makers, and informationalpolicy planners to understand the IS barriers. More specifically, the , focus on several critical barriers are information platforms, human safety and health, technology involved with extending industrial chains, product added value, and costs. The paper concludes by discussing managerial implications for promoting the establishment and operation of IS, and set comprehensive efforts for improving the operation of an IS, which could facilitate the transition to a circular economy.

- industrial symbiosis

- industrial ecology

- barriers

- circular economy

1. Introduction

Industrial symbiosis (IS) has been well-recognized as a key subfield of industrial ecology (IE) [1,2]. IS research is flourishing and has covered a broad range of topics and cases [3]. IS helps to increase the industrial system’s circularity [4] and is considered to be a circular economic business model [5]. It can often create economic, environmental, and social benefits [4,6,7], which assists in promoting local and regional sustainable development [8]. In recent years, IS has been considered to be a core strategy [6,9,10] and a key practical approach to promote the circular economy (CE) [4,11]. Fraccascia and Yazan [11] have argued that the catalytic role of IS in achieving a circular economy should be encouraged. In China, IS has been incorporated into national policies that were specifically formulated for CE, and has been identified as a key element for promoting national CE development [12], especially at the mesolevel [13].

A variety of barriers have been identified [3,4,6,9,14–17], which will influence the viability of IS and eco-industrial development [1]. Barriers for IS have been identified as one of the key topics which current IS research addresses [18] and are in urgent need of being examined [4,6].

The operation of IS remains a complex and dynamic process [2,19], which requires continuous improvement [2,20]. Cervo et al. [4] stressed that the “creation of a symbiosis is a multi-step process that goes from the identification of an opportunity to its implementation and operation” (p. 6). When organizations implement IS, it is important to start from understanding the barriers that they could face [21]. For operating industrial symbioses, there are still barriers hindering their full potential development [15,17,22]. Barriers can arise at different phases of the symbiotic development and the importance of a barrier will vary at different stages of the process [2,15]. Thus, it is crimperative to prioritizetical to understand the barriers which hinder the implementation and development of IS [2,15,20,23].

2. Identification of IS Barriers

In Tgeneral, the current researchis will provide guidance for the realiz on identifying barriers related to IS can be mainly divided into three groups, i.e., specific barriers, generic barriers, and evaluation of IS projects [18] and abarriers using mathematical methods, which is summarized in Table 1.

2.1 Identification of Specific Barriers

Some researchersist stakeholders and IS practitioners to create policies aiming at the fundamental identified some specific barriers related to IS from different perspectives, such as institutional barriers [24–26], organizational perspective [3], environmental regulation barriers [27], and sectoral boundary barrier [28]. They are summarized in Table 1.

2.2 Identification of Generic Barriers

The generic barriers relato improve the development of IS [14], which could also facilitate the transition to CE. However, from an extensive literature review, ied to IS were also put forward by some researchers. Some of these studies chose some IS or EIP cases to identify barriers, such as the Kwinana and Gladstone of Australia [15,17], the industrial estates of Canada [29], the Ulsan EIP project of Korea [30], and the EIPs of China [31]. These generic barriers are listed in Table 1.

Table 1. Identification shows that theof barriers related to IS.

|

Categorization of IS Barriers |

Descriptions |

References |

|

Identification of specific barriers |

· Institutional barriers for development of IS |

[24–26] |

|

· Barriers of IS focusing on an organizational perspective |

[3] |

|

|

· Barriers for impeding the development of industrial ecosystem focusing on human dimensions |

[32] |

|

|

· Social barriers for waste exchange |

[33] |

|

|

· Barriers to intercompany cooperation |

[34] |

|

|

· Barriers for EIP focusing on the topic of management |

[35] |

|

|

· Environmental regulatory barriers that hinder the IS |

[27] |

|

|

· Barriers for development of interorganizational environmental management |

[36] |

|

|

· Sectoral boundary barrier for IS, which is caused by the traditional planning system of China |

[28] |

|

|

· Societal and environmental problems related to EIPs |

[37] |

|

|

· Barriers to reuse and recycle in IS |

[38] |

|

|

· Barriers of information and knowledge for IS |

[39] |

|

|

Identification of generic barriers |

· The critical limiting factors for EIPs from the worldwide EIP experiences are categorized as symbiotic business relationships, economic value added, awareness and information sharing, policy and regulatory frameworks, organizational and institutional setups, and technical factors. |

[40] |

|

· Barriers for the development of IS include categories of economics, information availability, corporate citizenship and business strategy, region-specific issues, regulation and technical issues. |

[17] |

|

|

· Factors influencing the development and sustained operation of regional IS networks include technical, political, economic and financial, informational, organizational, and motivational. |

[41] |

|

|

· Barriers associated with eco-industrial activities in CIE and PEBZ include costs, roles and responsibilities, knowledge, and regulations. |

[29] |

|

|

· Potential barriers for developing EIPs include technical barriers, informational barriers, economic barriers, regulatory barriers, and motivational barriers. |

[42] |

|

|

· Challenges in the Ulsan EIP project include the reluctance of companies and industrial representatives to take an active role in the initiative, environment regulations and standards, and no integrated management of the two industrial complexes. |

[30] |

|

|

· Barriers for establishing IS relationships include technical, economic, informational, organizational, and regulatory (legal). |

[43] |

|

|

· From industrial park senior manager perspectives, barriers for EIP development in 51 Chinese industrial parks include capital, policy, informational, tangible resources, and intangible resources. |

[31] |

|

|

· Barriers to IS based on a case study of Gladstone include commitment to sustainable development, information, cooperation, technical, regulatory, community, and economic. |

[15] |

|

|

· Barriers which can hinder the implementation of IE at the industrial estate level include technical barriers, information barriers, economic barriers, regulatory barriers, and motivational barriers. |

[44] |

|

|

· Challenges that organizations may face when developing byproduct synergy include regulatory, economic, technical, and organizational barriers. |

[45] |

|

|

· Barriers in forming an IS network in an industrial park in the Philippines include lack of trust among locators, lack of information sharing among locators, lack of top management support, lack of training for implementing IS, lack of policy to incentivize initiative of IS, lack of funding to promote IS, lack of technology and infrastructure readiness, lack of institutional support for integration, coordination, and communication, lack of willingness to collaborate, and lack of awareness of IS concepts. |

[14] |

|

|

Evaluation of barriers using mathematical methods |

· The IS maturity grid includes seven IS barriers that are tested against five stages of IS maturity and was applied to a real IS example of Gladstone industrial region of Queensland, Australia. |

[15] |

|

· Adopt a factor analysis to identify and group a number of barriers for EIP development, and adopt cluster analysis to categorize and evaluate the levels of barriers perceived by senior officials who manage the EIPs. |

[31] |

|

|

· Adopt the Decision Making Trial and Evaluation Laboratory (DEMATEL) method to identify barriers for implementing IS in an industrial park. |

[14] |

|

|

· Propose a methodological framework which combines DEMATEL, Interpretive Structural Modeling (ISM), and Fuzzy Analytic Network Process (ANP) to analyze the barriers of designing and implementing an EIP. |

[23] |

2.3 Evaluation of Barriers Using Mathematical Methods

A currfentw research related to ISers have introduced mathematical methods to evaluate the barriers is mainlyof IS. Golev et al. [15] proposed a qualitative. Evaluation of the method, the IS maturity grid, to analyze IS barriers is still very limited. Only one paper was found examining the . It was concluded that the method is helpful for determining the most critical nontechnical barriers which influence the development of a regional IS and identifying mitigation measures to remove the most critical identified barriers using an operating IS as a case study [15]. Furthermore, the. Zhu et al. [31] introduced a factor analysis and cluster analysis to evaluate a number of barriers for EIP development of China. Bacudio et al. [14] adopted the Decision Making Trial and Evaluation Laboratory (DEMATEL) method to identify barriers evaluated are still focused on genericand concluded that it assists in detecting which barriers. No literature has been found that utilizes a model designed as a can be categorized as cause or effect factors. Based on the work of Bacudio et al. [14], Promentilla et al. [23] proposed a methodological framework to analyze the barriers for an EIP in the Philippines. The related contents are also listed in Table 1.

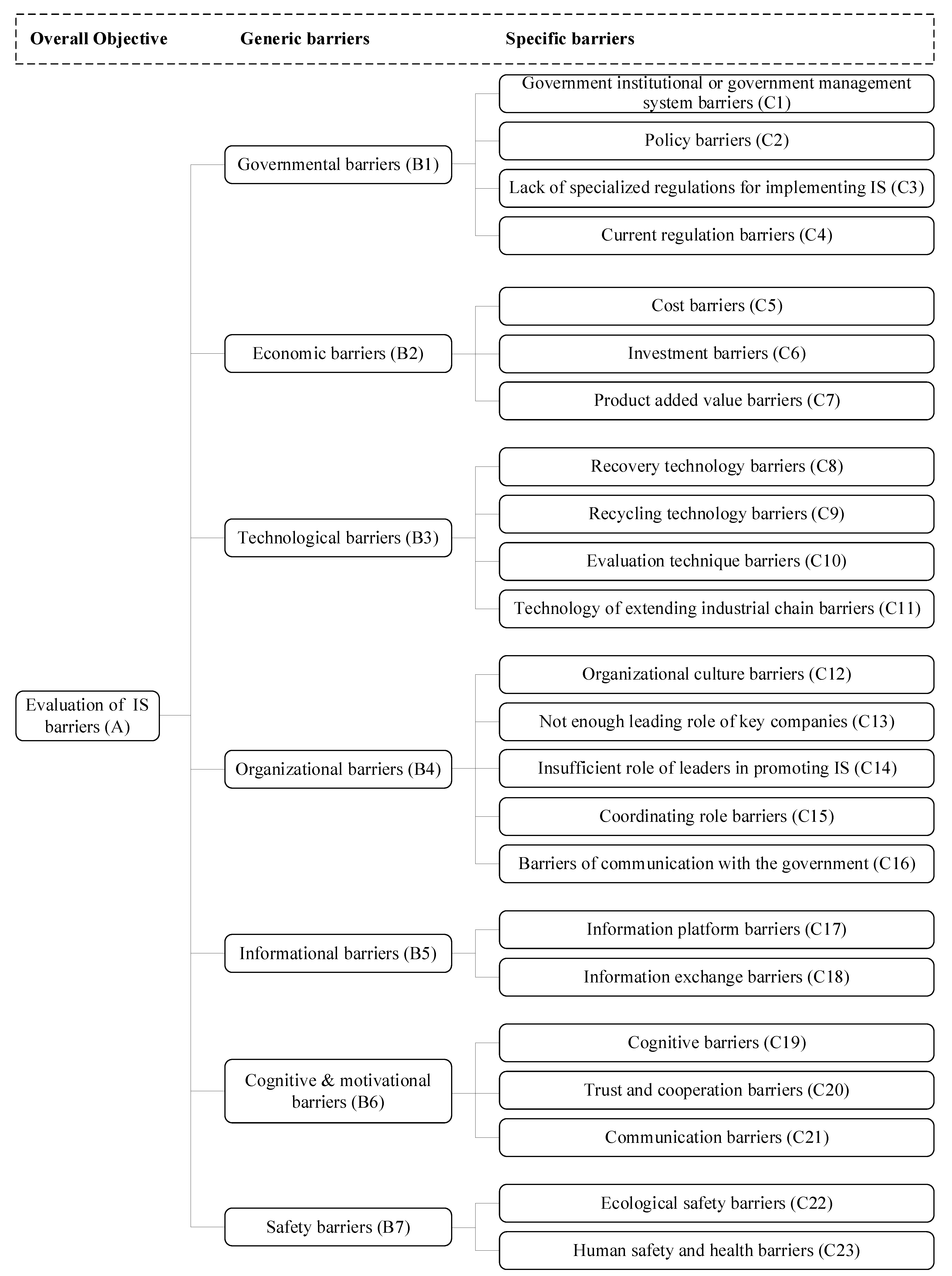

3. Classification of IS Barriers

In the current IE fierarchical structure embracing both theld, the literature on barriers related to IS, which is briefly described in Section 2, can be arranged into seven generic and the specific IScategories. This is summarized in Table 2. Many barriers.

To have been identifill the research gap,ed in the literature. These are referred to as specific barriers in this paper aims to uncover the natu. We have attempted to combine these into generic categories.

3.1 Governmental Barriers

Many governme of the various barriers and identify their significance in a semi-quantitative manner. A hierarchical evaluntal actions maybe hinder the development of EIP [16,46]. Policies, regulations, and the institutional system of a government can influence IS [3,28]. Chiu and Geng [47] demonstrated that some policies restrict the development of IS because they do not coordinate with industrial innovation. Van Eijk [48] reported that circularity is not effectively incorporated into innovation policies. Lehtoranta et al. [49] put forward that policy documents rarely consider structural change within industries, cooperation model which combines the Anamong companies, and the colocation of plants, which, in turn, restricts the development of IS.

Regulalytic Hierarchy Process (AHP) and Technique for Order Preference by Similarity to Ideal Solution (TOPSIS) is utilizedons and laws can be a barrier for development of IS. They may prevent companies from being linked together [42], thus hindering regional IS development [17]. Regulatory barriers may result from “the jungle of environmental laws and regulations” [43] (p. 988) or “uncertainties in this study to systematically evaluate the barriers. An operating IS, the IS of Hai Hua Group (HHG) of China is taken as a case study to test the proposed model. The study results should provide managers with insightse legislative framework” [17] (p. 69). Gibbs and Deutz [50] found that “the regulation of wastes leaves little opportunity for product reuse as feedstocks” (p. 1693). LeBlanc et al. [29] found that “regulations tend not to support innovative business practices” (p. 13). Although redefining wastes as byproducts may be required for IS, it has proven to be complicated to transform wastes into by-products under current environmental regulations [27], which prevents the reuse of wastes [15]. Based on EU policy and legal framework, Watkins et al. [26] concluded that the current end-of-waste criteria of the Waste Framework Directive (WFD) do not support the development of IS. Singh et al. [51] reported that “there is a lack of clarity on various areas of European Union legislation such as re-use and recovery” (p. 101752). Regulations may also impede transportation and reuse of wastes [45,52]. Van Beers et al. [17] mentioned strict transportation procedures and requirements that need to be applied for addressing barriers to improve the operation of IS. In this paper, we have included eco- byproduct that is classified as a controlled waste. Desrochers [38] mentioned that it is prohibited to export wastes categorized as “hazardous waste” to the United States under the Resource Conservation and Recovery Act (RCRA). Papathanasoglou et al. [25] reported that industrial units belonging to certain categories are not permitted to be located in the same industrial parks (EIPs) in the discussionarea in terms of the existing institutional framework in Greece, which restricts the shift towards the establishment of IS because most EIP projects and studies have f. Furthermore, Papathanasoglou et al. [25] argued that besides barriers of IS resulting from implementation of the current regulations, lack of comprehensive and specialized legislation hinders the development of IS as well.

In addition, cused on symbiotic relationships among industrieslosely related to the context of China, the planned economic system that was previously chosen by the Chinese government resulted in sectoral boundary barriers, which impeded the development of IS [28].

2. The

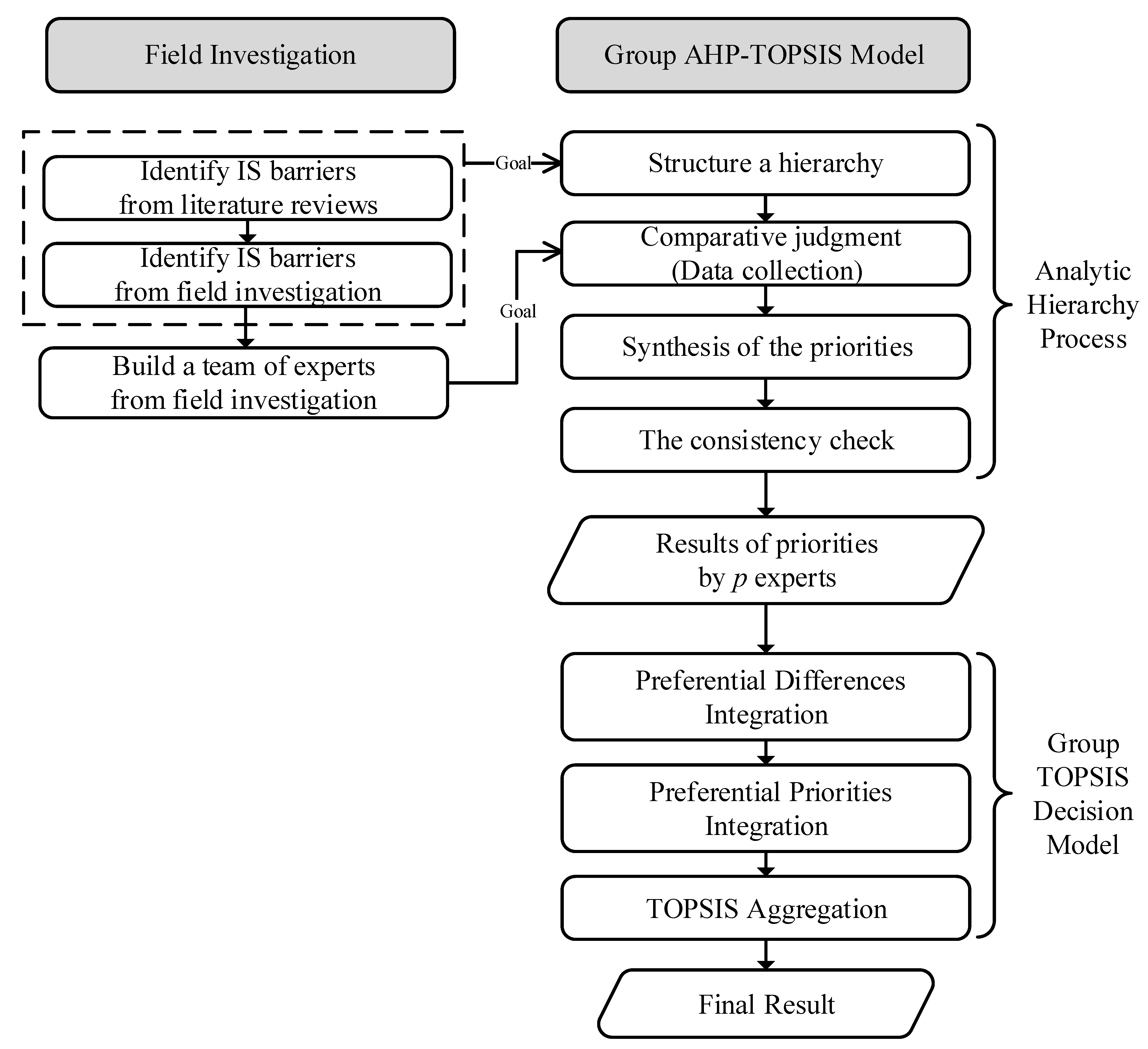

3.2 GrEcoup AHP-TOPSIS Model for Evaluating the nomic Barriers to Industrial Symbiosis

TheEconomic constructure of the Group AHP-TOPSIS Model proposed in this paper to systematiderations are a critical factor for the success of IS [2,41,53,54]. The existing pricing mechanism for waste products can be a barrier to IS [15]. Ayres [55] argued that “many industrial wastes cannot be economically recycled” (p. 428). Thus, from a company perspective, waste exchange relationships might be economically uncover the priority of various barriers for an operating IS is shown in Figure 1. And the hierarchical sound or risky, which restricts potential IS activities [43,50,56]. Salmi et al. [27] argued that transportation of waste, especially hazardous waste and potential impurities, would result in a high risk cost. This will cause companies to give up utilizing wastes as raw materials, which impedes the development of IS [3,27]. Some researchers considered that a large investment in new techniques and infrastructure for IS barriers of HHG, which is c related to IS would also prevent companies from implementing IS [3,49,57].

Compoaniesed of 7 gener need to be profitable. Some authors argued that economic barriers and 23 specific barriers is shown is Figure 2may inhibit the incentive to utilize waste without a reliable market for them, which would lead to unsatisfactory economic benefits [42,56]. Mangan and Olivetti [45] mentioned that companies are less likely to engage in IS without a clear demonstration of potential benefits.

Figure 13.3 The flow chart of the Group AHP-TOPSIS Model.

FigurTe 2. Hierarchical structure for IS bnological Barriers of HHG.

3. Conclusions

TConcerns about the technis paper proposed a Group AHP-TOPSIS Model to semi-quantitatively evaluate thecal feasibility of waste exchange can be a barrier for IS [43,45]. Van Beers et al. [17] noted that IS concerns the capture, recovery, and reuse of byproducts. They reported that many potential IS opportunities have been prevented from being realized because of technology challenges, such as availability of (reliable) recovery technologies [17]. Liu et al. [58] mentioned some technical barriers which impede the implementation of IS. The model is designed as a two-level hierarchical structure, which assists in identifying the degrees of importance of generic barriers and the specificassociated with waste water regeneration and solid waste reutilization. Gibbs [42] perceived the possibility that local companies have no potential to ‘fit together’ as an example of technical barriers. In addition, lack of evaluation technique related to IS has received attention by some researchers. Costa et al. [59] emphasized lack of evaluation of the potential recycling function of manufacturing technologies already in place as a challenging technological barriers corresponding to their generic barri. Sakr et al. [40] considered that “the lack of local technical know-how capable of identifying and evaluating IS opportunities” (p. 1166) is an important technical issue.

3.4 Organizational Barriers

Heeres. This helps to uncover the et al. [43] mentioned that the anticipated waste exchange might not conform to the current corporate organizational structure, which can be considered as an organizational barriers of IS in a more comprehensive manner.

T for IS. Walls and Paquin [3] argued that organizational structure can result in insufficient autonomy of subsidiaries for engakging HHG as a case study, it iin waste exchanges, thus limiting IS. For example, some researchers found that a variety of barriers exist for this operating IS, which hinders the establishment and operation of IS andcompanies which are subsidiaries of national or international corporations may be “unable to alter materials linkages” [50] (p. 1693), or may lack interest in IS exchange [3,40]. This is considered to be a result of having limited decision-making powers [29,40,50]. Furthermore, Heeres et al. [43] found that in the case of the Fairfield EIP project, “absence of an entrepreneurs association that represents all Fairfield industries/companies” (p. 993) is one of the factors causing problems for this project.

The cultransition to CE. Applying this model to HHG demonstrates that it assists in prioritizing the different barriersure of an organization plays an important role in implementing IS practices. A shared vision and beliefs can form a common culture among actors of an IS [3,60,61]. Some researchers argued that organizational cultures with low levels of interfirm cooperation could cause a certain reluctance against taking part in symbiotic relationships [41], or could prevent companies from working across organizational borders [50].

In Iaddition, Tudor et showsal. [54] postulated that at the generic barriers level, the top four degrees of importance of generic“one of the main enterprises leaving or looking elsewhere for its materials/products” (p. 204) will influence the functioning of the entire chain in a small industrial network. Heeres et al. [43] found that in the Rietvelden/Vutter (RiVu) EIP project, having “few large, financially strong companies” (p. 993) is one of the barriers are techfor this project.

3.5 Informational Barriers

Infological barriers, economic barriers, safety barriers, andrmational support assists in discovering IS opportunities through identification of possible compatible flows [2,20] and making decisions on the establishment of IS [62]. Heeres et al. [43] further suggested that informational barriers. Technological barriers are the most important generic can be perceived as “the right people do not have the needed information at the right time” (p. 987). Gibbs [42] argued that it may be difficult to find new uses for waste products due to barrier for the IS of HHG and should be given the most s such as poor information on the potential market and potential supply. Chertow [63] found that business managers “often lack access to information about their neighbors in different industries” (p. 24).

Heeres et al. [43] found ttention to be managed or eliminated. The top five specific bhat a communication platform is critical for EIP projects. Raabe et al. [39] considered that one major barrier faced by companies participating in IS is lack of information relating to possible and available byproducts. They suggested that a collaboration platform providing information could be helpful for companies engaging in a symbiosis [39].

In arrdditiers areon, there is difficulty in exchanging information platform barriers, human safety and health barriers, technology of extending between companies. LeBlanc et al. [29] found that some businesses, especially the large ones, “seemed hesitant to participate openly in eco-industrial chain barriers, product added value barriers, and cost barriers. Iactivities because of the risks associated with sharing information with potential competitors” (p. 12). Based on the context of Egyptian industry, Sakr et al. [40] found that companies resist exchanging information platform barriers are the m“for fear that it may be used against them by the regulatory authorities” (p. 1163).

3.6 Cognitive Barriers

Cosgnit important specificion or perception is identified as one of the barrier and should be emphasized. The work of this paper is one of the first to be undertaken to examine the barriers to an operating IS using mathematical methodss for the development of IS by some researchers [45,64]. Mangan and Olivetti [45] pointed out that waste is often perceived as something with negative connotations by companies. This makes companies unwilling to focus on waste and participate in IS relationships [45]. Ehrenfeld and Gertler [64] argued that it is difficult for companies to integrate wastes into their strategic processes because wastes have a long history of being ignored. Notarnicola et al. [22] found that a main constraint for IS implementation is that the strategic approach of companies is highly oriented to the primary product with a case study. It provides empirical evidence for the study of ISfocus on core business. In this circumstance, the waste is regarded as something to be disposed of quickly [22]. Some authors found that one of the barriers and should be helpful for managers, decision-makerin enabling IS is that companies lack understanding of concepts, principles, potential benefits, and policooperation related to IS activities [29,34,37,39,40].

3.7 Motivational Barriers

Some researchers argued that there may planners to understand the IS be motivational barriers wherein stakeholders must be willing to cooperate [34,42,44]. In this respect, the barriers, focus on several critical barriers, and set comprehensive efforts for improving the operation of an IS, may be a lack of trust [42–44]. Gibbs [42] also noted that a lack of trust would inhibit the establishment of a symbiotic relationship. Compared with Dutch industry, Heeres et al. [43] found that when participating in EIP projects, US companies have more distrust towards the local government that acts as the EIP project promoter. Lehtoranta et al. [49] suggested that creation of trust is more challenging for larger regions when attempting to implement IS.

3.8 Safety Barriers

Chertow [63] argued wthich could facilitate the transition to a CEat concern about the use of industrial byproducts, especially in symbioses involving agriculture, needs to be carefully examined because it is an important environmental and health issue.

This meanstudy still has limitations; future research can be that an IS relationship focusing on utilizing wastes may be hindered if it can cause safety problems for environment and human health. Chertow [63] further extended in the following aspects. First, thepointed out that there is still no widely reported evidence of environmental health problems results of the ing from byproduct exchanges that has been found. In a case study are from one single industrial symbiosis which is operating in China; more industrial symbioses from different countriesof IS around the Gulf of Bothnia, Salmi et al. [27] found that while there were no significant technological barriers on utilization of wastes around that region, from an ecological point of view, they argued that the marine transport of hazardous materials across the open sea during winter is certainly risky and recommended that a risk assessment on marine transport should be conducted [27].

Table 2. Classificationves of IS barriers.

|

Categories of Barriers |

Type of Barrier |

References |

|

Governmental barriers |

· Policy barriers |

[3,47,49,64,65] |

|

· Regulatory barriers |

- |

|

|

· Barriers resulting from implementation of current regulations |

[15,17,26,27,29,38,41,43,45,50–52,65,66] |

|

|

· Barriers resulting from lack of specialized regulations |

[25] |

|

|

· Government institutional or government management system barriers |

[25,28,41] |

|

|

Economic barriers |

· Cost barrier |

[3,17,27,41,65] |

|

· Investment barrier |

[3,49,57] |

|

|

· Benefit barriers |

[42,45,56] |

|

|

Technological barriers |

· Lack of recovery and recycling technology |

[17,58] |

|

· Lack of evaluation technique |

[40,42,59] |

|

|

Organizational barriers |

· Organizational structure |

[3,29,40,41,43,50] |

|

· Organizational cultures |

[41,50] |

|

|

· Main companies |

[43,54] |

|

|

Informational barriers |

· Lack of access to information |

[39,41–43,56,63] |

|

· Difficulty in exchanging information |

[29,40] |

|

|

Cognitive barriers |

· Lack of understanding related to IS activities |

[22,29,34,37,39,40,45,64] |

|

Motivational barriers |

· Lack of trust and cooperation |

[42–44,49] |

|

Safety barriers |

· Potential risks for human health |

[63] |

|

· Potential risks for environment or ecology |

[27,63] |

4. Prioritizing the IS barriers in a comprehensive manner with more case studies

From an extensigated with this model in futureve literature review, it can be seen that the current research. Secondly, while this model focused on an operating symbiosis, it could be combined related to IS barriers is mainly qualitative. Evaluation of the IS barriers is still very limited. It is imperative to prioritize the barriers in a comprehensive manner with the maturity gridmore case studies. There has one study which proposed by Golev et al. [15], allowing researchers to delve into yet more detail. Thirdly, this paper focused on evaluating thea Group AHP-TOPSIS Model to semi-quantitatively evaluate the barriers which impede the implementation of IS [67]. The model is designed as a two-level hierarchical structure, which assists in identifying the degrees of importance of generic barriers and the specific barriers corresponding to their generic barriers. An operating IS of China is taken as a case study to test the proposed model. It shows that at the generic barriers level, the top four degrees of importance of generic barriers are technological barriers, economic barriers, safety barriers and did not put forward measures to, and informational barriers. Technological barriers are the most important generic barrier for the IS and should be given the most attention to be manage or remove thed or eliminated. The top five specific barriers. The two-level hierarchy structure included in the model are information platform barriers, human safety and health barriers, technology of extending industrial chain barriers, product added value barriers, and cost barriers. Information platform barriers are the most important specific barrier and should be helpful to managers for identifying more targeted measures for managing or removing theseemphasized. This demonstrates that the model assists in prioritizing the different barriers in a comprehensive manner. In the future, more research on prioritizing the IS barriers with case studies from different countries needs to be developed. This will help to provide empirical evidence for the study of IS barriers. In the future, the model can be further applied and tested on other cases and should be helpful for managers, decision-makers, and policy planners to understand the IS barriers, focus on several critical barriers, and set comprehensive efforts for improving the operation of an IS, which could facilitate the transition to a circular economy.

References

- Chertow, M.R. INDUSTRIAL SYMBIOSIS: Literature and Taxonomy. Annu. Rev. Energy Environ. 2000, 25, 313–337. https://doi.org/10.1146/annurev.energy.25.1.313.Yang, T.; Liu, C.; Côté, R.P; Ye, J.; Liu, W. Evaluating the Barriers to Industrial Symbiosis Using a Group AHP-TOPSIS Model. Sustainability 2022, 14, 6815. https://doi.org/10.3390/su14116815.

- Yeo, Z.; Masi, D.; Low, J.S.C.; Ng, Y.T.; Tan, P.S.; Barnes, S. Tools for Promoting Industrial Symbiosis: A Systematic Review. J. Ind. Ecol. 2019, 23, 1087–1108. https://doi.org/10.1111/jiec.12846.Papathanasoglou, A.; Panagiotidou, M.; Valta, K.; Loizidou, M. Institutional Barriers and Opportunities for the Implementation of Industrial Symbiosis in Greece. Environ. Pract. 2016, 18, 253–259. https://doi.org/10.1017/S1466046616000454.

- Walls, J.L.; Paquin, R.L. Organizational Perspectives of Industrial Symbiosis: A Review and Synthesis. Organ. Environ. 2015, 28, 32–53. https://doi.org/10.1177/1086026615575333.Watkins, G.; Husgafvel, R.; Pajunen, N.; Dahl, O.; Heiskanen, K. Overcoming Institutional Barriers in the Development of Novel Process Industry Residue Based Symbiosis Products—Case Study at the EU Level. Miner. Eng. 2013, 41, 31–40. https://doi.org/10.1016/j.mineng.2012.10.003.

- Cervo, H.; Ogé, S.; Maqbool, A.S.; Mendez Alva, F.; Lessard, L.; Bredimas, A.; Ferrasse, J.-H.; Van Eetvelde, G. A Case Study of Industrial Symbiosis in the Humber Region Using the EPOS Methodology. Sustainability 2019, 11, 6940. https://doi.org/10.3390/su11246940.Salmi, O.; Hukkinen, J.; Heino, J.; Pajunen, N.; Wierink, M. Governing the Interplay between Industrial Ecosystems and Environmental Regulation. J. Ind. Ecol. 2012, 16, 119–128. https://doi.org/10.1111/j.1530-9290.2011.00403.x.

- Lüdeke‐Freund, F.; Gold, S.; Bocken, N.M.P. A Review and Typology of Circular Economy Business Model Patterns. J. Ind. Ecol. 2019, 23, 36–61. https://doi.org/10.1111/jiec.12763.Liu, C.; Ma, C.; Zhang, K. Going beyond the Sectoral Boundary: A Key Stage in the Development of a Regional Industrial Ecosystem. J. Clean. Prod. 2012, 22, 42–49. https://doi.org/10.1016/j.jclepro.2011.09.022.

- Boom-Cárcamo, E.; Peñabaena-Niebles, R. Analysis of the Development of Industrial Symbiosis in Emerging and Frontier Market Countries: Barriers and Drivers. Sustainability 2022, 14, 4223. https://doi.org/10.3390/su14074223.LeBlanc, R.; Tranchant, C.; Gagnon, Y.; Côté, R. Potential for Eco-Industrial Park Development in Moncton, New Brunswick (Canada): A Comparative Analysis. Sustainability 2016, 8, 472. https://doi.org/10.3390/su8050472.

- Côté, R.P. Exploring the Analogy Further. J. Ind. Ecol. 2000, 3, 11–12. https://doi.org/10.1162/108819899569502.Park, H.-S.; Won, J.-Y. Ulsan Eco-Industrial Park: Challenges and Opportunities. J. Ind. Ecol. 2008, 11, 11–13. https://doi.org/10.1162/jiec.2007.1346.

- Zhu, Q.; Côté, R.P. Integrating Green Supply Chain Management into an Embryonic Eco-Industrial Development: A Case Study of the Guitang Group. J. Clean. Prod. 2004, 12, 1025–1035. https://doi.org/10.1016/j.jclepro.2004.02.030.Zhu, Q.; Geng, Y.; Sarkis, J.; Lai, K.-H. Barriers to Promoting Eco-Industrial Parks Development in China: Perspectives from Senior Officials at National Industrial Parks. J. Ind. Ecol. 2015, 19, 457–467. https://doi.org/10.1111/jiec.12176.

- Henriques, J.; Ferrão, P.; Castro, R.; Azevedo, J. Industrial Symbiosis: A Sectoral Analysis on Enablers and Barriers. Sustainability 2021, 13, 1723. https://doi.org/10.3390/su13041723.Wolf, A.; Eklund, M.; Soderstrom, M. Towards Cooperation in Industrial Symbiosis: Considering the Importance of the Human Dimension. Prog. Ind. Ecol. Int. J. 2005, 2, 185–199. https://doi.org/10.1504/PIE.2005.007187.

- Mortensen, L.; Kørnøv, L. Critical Factors for Industrial Symbiosis Emergence Process. J. Clean. Prod. 2019, 212, 56–69. https://doi.org/10.1016/j.jclepro.2018.11.222.Ceglia, D.; de Abreu, M.C.S.; Da Silva Filho, J.C.L. Critical Elements for Eco-Retrofitting a Conventional Industrial Park: Social Barriers to Be Overcome. J. Environ. Manag. 2017, 187, 375–383. https://doi.org/10.1016/j.jenvman.2016.10.064.

- Yazan, D.M.; Fraccascia, L. Sustainable Operations of Industrial Symbiosis: An Enterprise Input-Output Model Integrated by Agent-Based Simulation. Int. J. Prod. Res. 2018, 58, 392–414. https://doi.org/10.1080/00207543.2019.1590660.Fichtner, W.; Tietze-Stöckinger, I.; Frank, M.; Rentz, O. Barriers of Interorganisational Environmental Management: Two Case Studies on Industrial Symbiosis. Prog. Ind. Ecol. 2005, 2, 73–88. https://doi.org/10.1504/PIE.2005.006778.

- National Development and Reform Commission The Leading Action of Circular Development. Available online: http://www.gov.cn/xinwen/2017-05/04/content_5190902.htm (accessed on 23 April 2022).Tessitore, S.; Daddi, T.; Iraldo, F. Eco-Industrial Parks Development and Integrated Management Challenges: Findings from Italy. Sustainability 2015, 7, 10036–10051. https://doi.org/10.3390/su70810036.

- Geng, Y.; Sarkis, J.; Ulgiati, S. Sustainability, Well-Being, and the Circular Economy in China and Worldwide. Science 2016, 6278, 73–76.Sinding, K. Environmental Management beyond the Boundaries of the Firm: Definitions and Constraints. Bus. Strategy Environ. 2000, 9, 79–91. https://doi.org/10.1002/(SICI)1099-0836(200003/04)9:2<79::AID-BSE235>3.0.CO;2-#.

- Bacudio, L.R.; Benjamin, M.F.D.; Eusebio, R.C.P.; Holaysan, S.A.K.; Promentilla, M.A.B.; Yu, K.D.S.; Aviso, K.B. Analyzing Barriers to Implementing Industrial Symbiosis Networks Using DEMATEL. Sustain. Prod. Consum. 2016, 7, 57–65. https://doi.org/10.1016/j.spc.2016.03.001.Lambert, A.J.D.; Boons, F.A. Eco-Industrial Parks: Stimulating Sustainable Development in Mixed Industrial Parks. Technovation 2002, 22, 471–484. https://doi.org/10.1016/S0166-4972(01)00040-2.

- Golev, A.; Corder, G.D.; Giurco, D.P. Barriers to Industrial Symbiosis: Insights from the Use of a Maturity Grid: Barriers to Industrial Symbiosis. J. Ind. Ecol. 2015, 19, 141–153. https://doi.org/10.1111/jiec.12159.Desrochers, P. Cities and Industrial Symbiosis: Some Historical Perspectives and Policy Implications. J. Ind. Ecol. 2001, 5, 29–44. https://doi.org/10.1162/10881980160084024.

- Neves, A.; Godina, R.; Azevedo, S.G.; Pimentel, C.; Matias, J.C.O. The Potential of Industrial Symbiosis: Case Analysis and Main Drivers and Barriers to Its Implementation. Sustainability 2019, 11, 7095. https://doi.org/10.3390/su11247095.Raabe, B.; Low, J.S.C.; Juraschek, M.; Herrmann, C.; Tjandra, T.B.; Ng, Y.T.; Kurle, D.; Cerdas, F.; Lueckenga, J.; Yeo, Z.; et al. Collaboration Platform for Enabling Industrial Symbiosis: Application of the By-Product Exchange Network Model. Procedia CIRP 2017, 61, 263–268. https://doi.org/10.1016/j.procir.2016.11.225.

- Van Beers, D.; Bossilkov, A.; Corder, G.; Berkel, R. Industrial Symbiosis in the Australian Minerals Industry: The Cases of Kwinana and Gladstone. J. Ind. Ecol. 2007, 11, 55–72. https://doi.org/10.1162/jiec.2007.1161.Sakr, D.; Baas, L.; El-Haggar, S.; Huisingh, D. Critical Success and Limiting Factors for Eco-Industrial Parks: Global Trends and Egyptian Context. J. Clean. Prod. 2011, 19, 1158–1169.

- Madsen, J.K.; Boisen, N.; Nielsen, L.U.; Tackmann, L.H. Industrial Symbiosis Exchanges: Developing a Guideline to Companies. Waste Biomass Valorization 2015, 6, 855–864. https://doi.org/10.1007/s12649-015-9417-9.Mirata, M. Experiences from Early Stages of a National Industrial Symbiosis Programme in the UK: Determinants and Coordination Challenges. J. Clean. Prod. 2004, 12, 967–983. https://doi.org/10.1016/j.jclepro.2004.02.031.

- Boons, F.; Chertow, M.; Park, J.; Spekkink, W.; Shi, H. Industrial Symbiosis Dynamics and the Problem of Equivalence: Proposal for a Comparative Framework. J. Ind. Ecol. 2016, 21, 938–952. https://doi.org/10.1111/jiec.12468.Gibbs, D. Trust and Networking in Inter-Firm Relations: The Case of Eco-Industrial Development. Local Econ. J. Local Econ. Policy Unit 2003, 18, 222–236. https://doi.org/10.1080/0269094032000114595.

- Grant, G.B.; Seager, T.P.; Massard, G.; Nies, L. Information and Communication Technology for Industrial Symbiosis. J. Ind. Ecol. 2010, 14, 740–753. https://doi.org/10.1111/j.1530-9290.2010.00273.x.Heeres, R.R.; Vermeulen, W.J.V.; de Walle, F.B. Eco-Industrial Park Initiatives in the USA and the Netherlands: First Lessons. J. Clean. Prod. 2004, 12, 985–995. https://doi.org/10.1016/j.jclepro.2004.02.014.

- Ritzén, S.; Sandström, G.Ö. Barriers to the Circular Economy—Integration of Perspectives and Domains. Procedia CIRP 2017, 64, 7–12. https://doi.org/10.1016/j.procir.2017.03.005.Brand, E.; Bruijn, T. de Shared Responsibility at the Regional Level: The Building of Sustainable Industrial Estates. Eur. Environ. 1999, 9, 221–231. https://doi.org/10.1002/(SICI)1099-0976(199911/12)9:6<221::AID-EET209>3.0.CO;2-Z.

- Notarnicola, B.; Tassielli, G.; Renzulli, P.A. Industrial Symbiosis in the Taranto Industrial District: Current Level, Constraints and Potential New Synergies. J. Clean. Prod. 2016, 122, 133–143. https://doi.org/10.1016/j.jclepro.2016.02.056.Mangan, A.; Olivetti, E. By-Product Synergy Networks: Driving Innovation through Waste Reduction and Carbon Mitigation. In Sustainable Development in the Process Industries; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2010; pp. 81–108; ISBN 978-0-470-58609-9.

- Promentilla, M.A.B.; Bacudio, L.R.; Benjamin, M.F.D.; Chiu, A.S.F.; Yu, K.D.S.; Tan, R.R.; Aviso, K.B. Problematique Approach to Analyse Barriers in Implementing Industrial Ecology in Philippine Industrial Parks. Chem. Eng. Trans. 2016, 52 , 811–816. https://doi.org/10.3303/CET1652136.Jiao, W.; Boons, F. Toward a Research Agenda for Policy Intervention and Facilitation to Enhance Industrial Symbiosis Based on a Comprehensive Literature Review. J. Clean. Prod. 2014, 67, 14–25. https://doi.org/10.1016/j.jclepro.2013.12.050.

- Chiu, A.S.F.; Geng, Y. On the Industrial Ecology Potential in Asian Developing Countries. J. Clean. Prod. 2004, 12, 1037–1045. https://doi.org/10.1016/j.jclepro.2004.02.013.

- Van Eijk, F. Barriers & Drivers towards a Circular Economy. Literature Review. Available online: www.circulairondernemen.nl/uploads/e00e8643951aef8adde612123e824493.pdf (accessed on 17 March 2022)

- Lehtoranta, S.; Nissinen, A.; Mattila, T.; Melanen, M. Industrial Symbiosis and the Policy Instruments of Sustainable Consumption and Production. J. Clean. Prod. 2011, 19, 1865–1875. https://doi.org/10.1016/j.jclepro.2011.04.002.

- Gibbs, D.; Deutz, P. Reflections on Implementing Industrial Ecology through Eco-Industrial Park Development. J. Clean. Prod. 2007, 15, 1683–1695. https://doi.org/10.1016/j.jclepro.2007.02.003.

- Singh, R.K.; Kumar, A.; Garza-Reyes, J.A.; de Sá, M.M. Managing Operations for Circular Economy in the Mining Sector: An Analysis of Barriers Intensity. Resour. Policy 2020, 69, 101752. https://doi.org/10.1016/j.resourpol.2020.101752.

- Chen, X.; Fujita, T.; Ohnishi, S.; Fujii, M.; Geng, Y. The Impact of Scale, Recycling Boundary, and Type of Waste on Symbiosis and Recycling. J. Ind. Ecol. 2012, 16, 129–141. https://doi.org/10.1111/j.1530-9290.2011.00422.x.

- Côté, R.P.; Cohen-Rosenthal, E. Designing Eco-Industrial Parks: A Synthesis of Some Experiences. J. Clean. Prod. 1998, 6, 181–188. https://doi.org/10.1016/S0959-6526(98)00029-8.

- Tudor, T.; Adam, E.; Bates, M. Drivers and Limitations for the Successful Development and Functioning of EIPs (Eco-Industrial Parks): A Literature Review. Ecol. Econ. 2007, 61, 199–207. https://doi.org/10.1016/j.ecolecon.2006.10.010.

- Ayres, R.U. On the Life Cycle Metaphor: Where Ecology and Economics Diverge. Ecol. Econ. 2004, 48, 425–438. https://doi.org/10.1016/j.ecolecon.2003.10.018.

- Guo, B.; Geng, Y.; Sterr, T.; Dong, L.; Liu, Y. Evaluation of Promoting Industrial Symbiosis in a Chemical Industrial Park: A Case of Midong. J. Clean. Prod. 2016, 135, 995–1008. https://doi.org/10.1016/j.jclepro.2016.07.006.

- Yu, F.; Han, F.; Cui, Z. Evolution of Industrial Symbiosis in an Eco-Industrial Park in China. J. Clean. Prod. 2015, 87, 339–347. https://doi.org/10.1016/j.jclepro.2014.10.058.

- Liu, Z.; Adams, M.; Côté, R.P.; Geng, Y.; Li, Y. Comparative Study on the Pathways of Industrial Parks towards Sustainable Development between China and Canada. Resour. Conserv. Recycl. 2018, 128, 417–425. https://doi.org/10.1016/j.resconrec.2016.06.012.

- Costa, I.; Massard, G.; Agarwal, A. Waste Management Policies for Industrial Symbiosis Development: Case Studies in European Countries. J. Clean. Prod. 2010, 18, 815–822. https://doi.org/10.1016/j.jclepro.2009.12.019.

- Panyathanakun, V.; Tantayanon, S.; Tingsabhat, C.; Charmondusit, K. Development of Eco-Industrial Estates in Thailand: Initiatives in the Northern Region Community-Based Eco-Industrial Estate. J. Clean. Prod. 2013, 51, 71–79. https://doi.org/10.1016/j.jclepro.2012.09.033.

- Park, H.-S.; Rene, E.R.; Choi, S.-M.; Chiu, A.S.F. Strategies for Sustainable Development of Industrial Park in Ulsan, South Korea—From Spontaneous Evolution to Systematic Expansion of Industrial Symbiosis. J. Environ. Manag. 2008, 87, 1–13. https://doi.org/10.1016/j.jenvman.2006.12.045.

- Geng, Y.; Doberstein, B. Developing the Circular Economy in China: Challenges and Opportunities for Achieving “Leapfrog Development.” Int. J. Sustain. Dev. World Ecol. 2008, 15, 231–239. https://doi.org/10.3843/SusDev.15.3:6.

- Chertow, M.R. “Uncovering” Industrial Symbiosis. J. Ind. Ecol. 2007, 11, 11–30. https://doi.org/10.1162/jiec.2007.1110.

- Ehrenfeld, J.; Gertler, N. Industrial Ecology in Practice: The Evolution of Interdependence at Kalundborg. J. Ind. Ecol. 1997, 1, 67–79. https://doi.org/10.1162/jiec.1997.1.1.67.

- Branca, T.A.; Fornai, B.; Colla, V.; Pistelli, M.I.; Faraci, E.L.; Cirilli, F.; Schröder, A.J. Industrial Symbiosis and Energy Efficiency in European Process Industries: A Review. Sustainability 2021, 13, 9159. https://doi.org/10.3390/su13169159.

- Lombardi, R. Non-Technical Barriers to (and Drivers for) the Circular Economy through Industrial Symbiosis: A Practical Input. Econ. Policy Energy Environ. 2017, 1–2, 171–189. https://doi.org/10.3280/EFE2017-001009.

- Brand, E.; Bruijn, T. de Shared Responsibility at the Regional Level: The Building of Sustainable Industrial Estates. Eur. Environ. 1999, 9, 221–231. https://doi.org/10.1002/(SICI)1099-0976(199911/12)9:6<221::AID-EET209>3.0.CO;2-Z.

- Mangan, A.; Olivetti, E. By-Product Synergy Networks: Driving Innovation through Waste Reduction and Carbon Mitigation. In Sustainable Development in the Process Industries; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2010; pp. 81–108; ISBN 978-0-470-58609-9.

- Jiao, W.; Boons, F. Toward a Research Agenda for Policy Intervention and Facilitation to Enhance Industrial Symbiosis Based on a Comprehensive Literature Review. J. Clean. Prod. 2014, 67, 14–25. https://doi.org/10.1016/j.jclepro.2013.12.050.

- Chiu, A.S.F.; Geng, Y. On the Industrial Ecology Potential in Asian Developing Countries. J. Clean. Prod. 2004, 12, 1037–1045. https://doi.org/10.1016/j.jclepro.2004.02.013.

- Van Eijk, F. Barriers & Drivers towards a Circular Economy. Literature Review. Available online: www.circulairondernemen.nl/uploads/e00e8643951aef8adde612123e824493.pdf (accessed on 17 March 2022)

- Lehtoranta, S.; Nissinen, A.; Mattila, T.; Melanen, M. Industrial Symbiosis and the Policy Instruments of Sustainable Consumption and Production. J. Clean. Prod. 2011, 19, 1865–1875. https://doi.org/10.1016/j.jclepro.2011.04.002.

- Gibbs, D.; Deutz, P. Reflections on Implementing Industrial Ecology through Eco-Industrial Park Development. J. Clean. Prod. 2007, 15, 1683–1695. https://doi.org/10.1016/j.jclepro.2007.02.003.

- Singh, R.K.; Kumar, A.; Garza-Reyes, J.A.; de Sá, M.M. Managing Operations for Circular Economy in the Mining Sector: An Analysis of Barriers Intensity. Resour. Policy 2020, 69, 101752. https://doi.org/10.1016/j.resourpol.2020.101752.

- Chen, X.; Fujita, T.; Ohnishi, S.; Fujii, M.; Geng, Y. The Impact of Scale, Recycling Boundary, and Type of Waste on Symbiosis and Recycling. J. Ind. Ecol. 2012, 16, 129–141. https://doi.org/10.1111/j.1530-9290.2011.00422.x.

- Côté, R.P.; Cohen-Rosenthal, E. Designing Eco-Industrial Parks: A Synthesis of Some Experiences. J. Clean. Prod. 1998, 6, 181–188. https://doi.org/10.1016/S0959-6526(98)00029-8.

- Tudor, T.; Adam, E.; Bates, M. Drivers and Limitations for the Successful Development and Functioning of EIPs (Eco-Industrial Parks): A Literature Review. Ecol. Econ. 2007, 61, 199–207. https://doi.org/10.1016/j.ecolecon.2006.10.010.

- Ayres, R.U. On the Life Cycle Metaphor: Where Ecology and Economics Diverge. Ecol. Econ. 2004, 48, 425–438. https://doi.org/10.1016/j.ecolecon.2003.10.018.

- Guo, B.; Geng, Y.; Sterr, T.; Dong, L.; Liu, Y. Evaluation of Promoting Industrial Symbiosis in a Chemical Industrial Park: A Case of Midong. J. Clean. Prod. 2016, 135, 995–1008. https://doi.org/10.1016/j.jclepro.2016.07.006.

- Yu, F.; Han, F.; Cui, Z. Evolution of Industrial Symbiosis in an Eco-Industrial Park in China. J. Clean. Prod. 2015, 87, 339–347. https://doi.org/10.1016/j.jclepro.2014.10.058.

- Liu, Z.; Adams, M.; Côté, R.P.; Geng, Y.; Li, Y. Comparative Study on the Pathways of Industrial Parks towards Sustainable Development between China and Canada. Resour. Conserv. Recycl. 2018, 128, 417–425. https://doi.org/10.1016/j.resconrec.2016.06.012.

- Costa, I.; Massard, G.; Agarwal, A. Waste Management Policies for Industrial Symbiosis Development: Case Studies in European Countries. J. Clean. Prod. 2010, 18, 815–822. https://doi.org/10.1016/j.jclepro.2009.12.019.

- Panyathanakun, V.; Tantayanon, S.; Tingsabhat, C.; Charmondusit, K. Development of Eco-Industrial Estates in Thailand: Initiatives in the Northern Region Community-Based Eco-Industrial Estate. J. Clean. Prod. 2013, 51, 71–79. https://doi.org/10.1016/j.jclepro.2012.09.033.

- Park, H.-S.; Rene, E.R.; Choi, S.-M.; Chiu, A.S.F. Strategies for Sustainable Development of Industrial Park in Ulsan, South Korea—From Spontaneous Evolution to Systematic Expansion of Industrial Symbiosis. J. Environ. Manag. 2008, 87, 1–13. https://doi.org/10.1016/j.jenvman.2006.12.045.

- Geng, Y.; Doberstein, B. Developing the Circular Economy in China: Challenges and Opportunities for Achieving “Leapfrog Development.” Int. J. Sustain. Dev. World Ecol. 2008, 15, 231–239. https://doi.org/10.3843/SusDev.15.3:6.

- Chertow, M.R. “Uncovering” Industrial Symbiosis. J. Ind. Ecol. 2007, 11, 11–30. https://doi.org/10.1162/jiec.2007.1110.

- Ehrenfeld, J.; Gertler, N. Industrial Ecology in Practice: The Evolution of Interdependence at Kalundborg. J. Ind. Ecol. 1997, 1, 67–79. https://doi.org/10.1162/jiec.1997.1.1.67.

- Branca, T.A.; Fornai, B.; Colla, V.; Pistelli, M.I.; Faraci, E.L.; Cirilli, F.; Schröder, A.J. Industrial Symbiosis and Energy Efficiency in European Process Industries: A Review. Sustainability 2021, 13, 9159. https://doi.org/10.3390/su13169159.

- Lombardi, R. Non-Technical Barriers to (and Drivers for) the Circular Economy through Industrial Symbiosis: A Practical Input. Econ. Policy Energy Environ. 2017, 1–2, 171–189. https://doi.org/10.3280/EFE2017-001009.

- Yang, T.; Liu, C.; Côté, R.P; Ye, J.; Liu, W. Evaluating the Barriers to Industrial Symbiosis Using a Group AHP-TOPSIS Model. Sustainability 2022, 14, 6815. https://doi.org/10.3390/su14116815.