Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 1 by Ruddy Guerrero Alvarez and Version 2 by Jessie Wu.

The automotive industry is one of the most important economic sectors in the world. At the beginning, vehicles only had mechanical components, so the use of an automotive wire harness was not indispensable. Cars today are equipped with electronic components that, in addition to the basic operations of moving, turning, and stopping, perform more and more functions every day. Wiring harnesses are indispensable for controlling these electronic components.

- wiring harnesses

- cars

- machines

1. Introduction

For confidentiality reasons, the company that provided the data needed to develop this researchticle will be referred as Cables SA.

The automotive industry started at the beginning of the twentieth century. The first cars were treated as objects of luxury and were exclusively accessible to wealthy people. At the beginning, vehicles only had mechanical components, based on the steam motor, so the use of automotive cable was not indispensable. The history of the automotive industry has evolved with the times and adapted to the circumstances and needs of society. The steam engine was replaced by the internal combustion engine, which is currently hampered by restrictions on emissions legislation, as well as by the limited availability of petroleum-derived fuels and, consequently, by the cost of the fuel.

Historically speaking, the assembly line, introduced by Henry Ford in 1913, made it possible to speed up the production and reduced the unit costs of manufacturing. Production and demand for automobiles began to grow rapidly and the automobile was no longer just a luxury within the reach of the very few, becoming a commodity for the middle class. Mass production is a common method used by most automotive companies in producing cars and mobile devices, opening new opportunities for industry and consumers. Mass production adjusted its costs and manufacturing times, allowing consumers access to products and services previously reserved for the richest. The fact that everyone bought the same thing did not matter, the interesting fact was that the products were available to them. In the industry today, priorities have changed, and now, consumers are looking to differentiate themselves. Demand for customized products has increased and, associated with it, a change in manufacturing processes; although, with the same strategy as always: to execute it in short cycles and with low costs. Thanks to Industry 4.0, this is possible. Not only because of the possibilities offered by the new technological tools, but also because it is available to the customer to participate directly in the customization of the products to be purchased. This new production scope makes the automotive supply chain more dynamic and complex.

Furthermore, wiring harnesses are controlling electronic components, transmitting power and signals to every part of the vehicle. Consisting of connectors, terminals, clamps, sheaths, and other elements surrounding a core of electrical wires, they are crucial components similar to blood vessels and nerves in the human body. Figure 1 illustrates how a wiring harness is distributed inside an automobile. It shows the complexity of the wiring harness, which is distributed throughout the automobile. Moreover, it facilitates a better understanding of the product on which the present study is focused.

Figure 1.

Wiring harness inside an automobile.

2. Wire Harness

The principal electrical component of the automobile is the wiring harness. It consists of a set of cables that transmit electrical power and information from the various components of the automobile. The number of wiring harnesses in a car depends mainly on the design of the car model, and it is divided at the request of the company that manufactures it. For this reason, it is not possible to say the exact number of wire harnesses that a car has. On the other hand, two types are well differentiated by their complexity and the way that they are logistically handled. These two types of wiring harnesses are presented below:

-

Autarkes: These are the smallest wiring harnesses with low variability. These are produced in batches (in large quantities) because they have few variations. Among these types of wiring harnesses reswearchers can find the following:

- –

-

Front and back doors: these are the most variable types of Autarkes, mainly the front doors, and especially the driver door;

- –

-

Front and back bumpers: these contain different sensors, such as shock sensors, for example;

- –

-

Seats: these are mainly used to control heated seats, weight detection alarms, and seat belts.

-

Customer-Specific Wiring Harness (KSK, which stands for Kundenspezifischer Kabelstrang in German): These wiring harnesses are very complex to manufacture because they contain many more elements and they have hundreds of variants. The orders of these wiring harnesses are customized, which means that in addition to the functionalities that are necessary for the correct performance of the car, the final user chooses some additional functionalities. These harnesses are usually divided into two types:

- –

-

Motor wiring: these wiring harnesses are critical, as they are the most exposed to the weather, so they are provided with a special isolation to resist water penetration and the high temperatures of the motor;

- –

-

Car’s inner structure: these sections show great importance since they control the operation of the car control systems being protected by the car body.

2.1. Wiring Harness Evolution

In recent years, the automotive industry has shown a constant evolution, and consequently, an important progress in wiring harnesses. Automobile variety has been steadily increasing for most of this century [1]. The growing number of electrical components has been accompanied by an increase in the total weight and length of the wiring harnesses [2]. In 2008, if res wearchers considered the total number of innovations in the automotive sector, 80% are related to software and 90% are associated with electronic components [3]. Modern automobiles are becoming more and more similar to computers [4]. In the 1960s, a vehicle had mainly mechanical components. The total cumulative length of electrical wiring harnesses is approximately 8000 m of cable, containing 40 electronic control units and 10 million lines of code [4][5][4,5]. Similarly, hybrid vehicles have even more wires and require the incorporation of safety mechanisms to eliminate possible damage from a short circuit [6]. These safety mechanisms increase the number of cables by duplicating electrical networks and electronic control units. The connectors and wiring harness components of an electric or hybrid car have to be able to perform at their optimum without any risk of failure or malfunction. This is the reason why it is necessary to install a series of fail-safe mechanisms in each wiring harness.

Likewise, transport is responsible for about 30% of total CO2 emissions in the European Union (https://www.europarl.europa.eu/news/en/headlines/society/20190313STO31218/co2-emissions-from-cars-facts-and-figures-infographics (accessed on 20 April 2022)). Electric and hybrid cars are a potentially environmentally friendly product [7][8][7,8]. Reducing the weight of wiring harnesses is a challenging task, since electrical components in automobiles have gradually gained importance over the decades [9][10][9,10]. The medium-sized vehicle contains cables weighing more than 20 kg, and reducing the mass of the wiring harness minimizes fuel consumption [11]. Thus, in a more complex wiring harness scenario, manufacturers have to adjust and find a way to make the unit as light as possible. Consequently, the introduction of methods that contribute to reducing the impact of additional technology on weight, cost, complexity, and packaging space is essential for wiring harnesses. High-voltage cables, which previously were made of copper, are now replaced by aluminum. The aluminum wiring harness reduces the weight of the automobiles [12]. Another technology used to increase wiring harness density is component miniaturization, which reduces mass, decreases costs, and improves efficiency [13].

2.2. Product Description

RIn the presearchersnt work, we have chosen the development of a simulation model for the production of door wiring harnesses. Researchers'Our choice is based on the fact that it is the most variable of the Autarkes, without being as complex as the wiring harnesses (KSK) for the car’s inner engine. These wiring harnesses have eight different variants that consist of different combinations of wires, soldering, splices, connectors, and clips. Hence, the production of the wiring harnesses is performed in batches of size n and in a number of m iterations. This means that a quantity equal to the set batch size of variants of the same type is produced before moving on to the production of the next variant. This process is repeated as many times as the number of defined iterations.

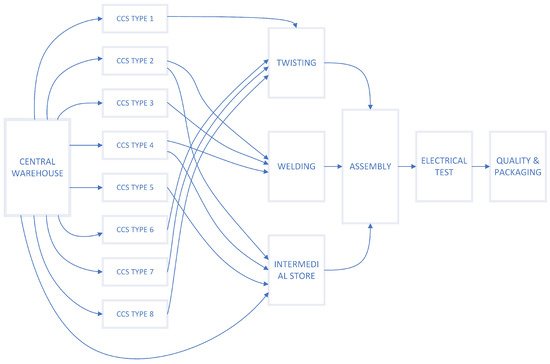

Thus, the processes involved in the wiring harness components manufacturing are listed below, considering the devices where they are developed:

-

Cutting, crimping, and seals (CCS) machines: There are eight machines that carry out these processes and they have different numbers of tools. In this manner, 46 types of wires are created that are used in the construction of the wire harness;

-

Twisting machines: these devices twist wires to avoid magnetic fields, considering five types of twisting;

-

Welding machines: This process on the assembly line is quality-critical, more time consuming, and more costly than others, because it requires special bulky equipment. For that reason, most of the welding process is performed outside of the assembly line, and three types of welds are used to construct this wiring harness;

-

Assembly line: There are eight different variants of this wiring harness, and all the parts are assembled together to form the wiring harness. Moreover, the assembly process has four sub-processes that are performed sequentially on four work stations;

-

Electrical test stations: in this process, the wiring harness is checked for continuity and insulation before being sent to the customer;

-

Quality and packaging: This is the last process that rwesearchers take into account in the simulation. In this process, the quality tests and the packaging of the wiring harnesses are performed.

The flow diagram of the different processes and the relationships between them can be seen in Figure 2. The diagram represents the warehouses and processes involved in the manufacture of the wiring harnesses treated in this project. The flow of materials are described between the processes connected by arrows. The As we can see, the first transformations of the cables are performed in the CCS machines. Then, some of the wires go through the twisting machine, while others are processed by the welding machine. Wires that are not used in the previous processes go to an intermediate storage. Next, the assembly process takes place, where all the parts are joined together. Later, the correct functioning of the finished product is checked using an electrical test. Finally, a quality control and packaging of the wire harnesses is made.

Figure 2.

Flow diagram of the production process