You're using an outdated browser. Please upgrade to a modern browser for the best experience.

Please note this is a comparison between Version 1 by Michael Buttery and Version 2 by Catherine Yang.

Spacecraft mechanisms commonly undergo extended periods of storage, either on-ground, or in-flight and there are an increasing number of missions for which some element of long-term storage may be required.

- lubrication

- spacecraft

- vacuum

- tribology

- long-term storage

1. Introduction

Spacecraft mechanism components are commonly stored before or after spacecraft integration for a considerable time. Such storage can occur prior to launch (on-ground storage), or in-flight where a mechanism remains dormant but exposed to the flight environment potentially for some years prior to operation. Whilst the “ideally benign” on-ground storage conditions for the most sensitive lubricants (e.g., sputtered MoS2) are typically considered as dry nitrogen (DN2) of 1–3% ppm moisture, for practical reasons some relaxation of this criteria is commonly followed. Extended on-ground storage at spacecraft level is often under a continuous long-term purge of semi-dry nitrogen (~10–20% relative humidity (RH)), with periodic “exercising” of the components under DN2. For in-flight storage, mechanisms are exposed to the thermal vacuum conditions of space, but usually without any possibility for “exercise”. Storage periods can continue for months and occasionally for many years both before and after launch.

The general consideration is that this storage period under “benign” conditions will have a negligible impact on the tribological behaviour of the employed lubricants (assuming they are correctly applied). However recent activities (at ESTL and elsewhere) have cast some doubt onto this understanding, for both storage and operational environment conditions. There are growing concerns over the impact of on-ground or in-flight storage on subsequent performance, especially where such storage is for longer than the originally specified design requirement for the mechanism and/or under sub-optimal conditions.

2. On-Ground Storage Behaviours

In addition to the operational environment, attention must be given to pre-operational storage conditions for lubricated components. Storage conditions are ideally selected on the assumption that the environment is benign, but often this has not been explicitly demonstrated.2.1. Maturation of Sputtered MoS2

Recent experimental investigations suggest that sputtered MoS2 may “mature” upon storage, such that the tribological properties of freshly deposited MoS2 differ following some period of storage. This has been investigated in detail by ESTL where a series of PoD tests were performed over a period of 60 days on a single batch of sputtered MoS2 lubricated 52100-steel discs. Test coupons were stored in DN2 prior to the assessment. Taken together these experimental investigations provide evidence of a “maturation” effect of MoS2. The initial phase of this maturation appears to occur over a few months following the deposition of the coating, before plateauing and maintaining consistent tribological behaviour beyond this point, implying some level of passivation-type behaviour. The exact details of how this maturation occurs are not known but may be related to the observation from [1][7] that the presence of contaminants (including H2O, CO2, O, N2 and H2) within an operational environment is favourable for the MoS2 lubrication.2.2. Long Term Storage of Fluids

Fluid lubricants are particularly susceptible to effects of on-ground storage which may influence their tribological properties. These include oxidation effects which have the potential to change the viscosity of lubricants over time (particularly MAC-based oils), absorption of moisture, loss of additives, and chemical degradation as well as physical effects such as base oil separation (for greases) and lubricant creep. As a result, fluid lubricant manufacturers often provide guidelines for lubricant storage (often at low temperatures) and shelf lives of typically ~5yrs. However recent SOT testing performed by ESTL on historical PFPE oils, some stored under uncontrolled conditions (i.e., room air) for 40-years, have shown similar tribological behaviour to new as-formulated PFPE oils, with no reduction in lubricating lifetime. This indicates that there may be no significant effect of uncontrolled air storage on the tribological performance of PFPE oils.2.3. Phenolic Cages

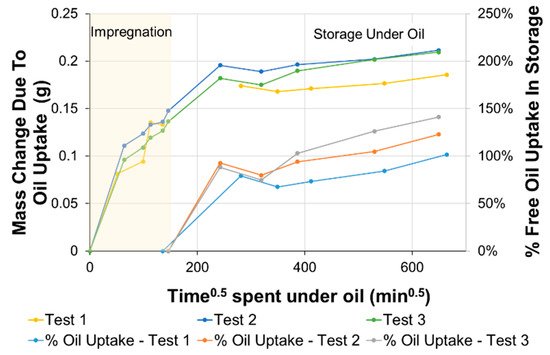

In many applications of fluid lubrication, bearings are fitted with cotton fabric reinforced phenolic cages (retainers). It is common practice to vacuum-impregnate such cages with the base-oil of the fluid lubricant used in the bearings to saturate the cotton fabric with the lubricant oil prior to use (and inhibit the uptake of the free oil within the bearing). There is however evidence [2][18] that even “fully impregnated” cages when continuously wetted by further exposure to oil may absorb a significant additional oil mass as the oil is gradually taken up by the phenolic matrix itself. It can be shown that the typical capacity of the cage for this additional oil uptake, represents a disturbingly high percentage of available free oil. For example, the infiltration of oil into the phenolic matrix is a slow process, taking months, but as shown in Figure 16 the total mass absorbed can be relatively high. Assuming this oil is absorbed entirely from the free oil quantity typically added to a bearing, the proportion of oil taken-up can quickly reach 100%. This phenomenon is potentially an overlooked lubricant loss route which may cause the onset of starvation/dry running within a bearing.

2.4. Creep Barriers

Creep barriers are commonly used to mitigate and control the unwanted creep of lubricant within a fluid lubricated application. Shelf lives for creep barriers are often quoted as 1 year, and Minimum Order Quantities (MOQ) can be, relative to the quantity needed, prohibitively large (e.g., MOQ ~5 kg). Product lead-times may also be long, and as a result, it is common that a creep barrier intended for an application may be formally borderline “life-expired” or even fully beyond its quoted shelf life when required for use. In order to verify whether the performance of such formally expired creep barriers remains acceptable for a flight application, a re-lifing process must be completed, with a series of tests performed and the results compared against the desired/known behaviour of the in-life product. These tests should include an optical inspection if the creep barrier fluid, a check of the UV marker (if the creep barrier contains one), surface energy assessment (i.e., via contact angle), crosshatch adhesion test, and FTIR analysis.2.5. Corrosion

Substrate corrosion can occur in the presence of a condensing environment. This may be caused by residual contamination (e.g., chlorides) or by the acidic by-product of the reaction between MoS2 and moisture in a condensing environment (Reaction (2) above). This can initiate corrosion of the substrate and is relevant to components lubricated with PVD MoS2 and self-lubricating polymers that contain MoS2 which may be exposed to a condensing environment. The speed of this reaction is a function of temperature. In a non-condensing environment, the oxidation of MoS2 (Reaction (1), above) is limited to a very thin outer surface layer (~100 Angstroms) and the reaction product is non-acidic, meaning that in the absence of other reacting species, corrosion is unlikely to be an issue. Substrate corrosion is typically identified by detailed visual inspection. In addition, there is the risk that, in the presence of a moist environment, corrosion is initiated between metals with highly different electrochemical potentials. For example, mechanisms having several different metallic interfaces (e.g., from industry a threshold of >0.25V electro-chemical potential difference is taken as a cause for concern) in local contact (bearings, housings, end-caps and clamp rings for example) could be at risk from galvanic corrosion. In this case, a representative “equivalent assembly” or witness sample subassembly may be more useful for assessing the impact of storage.2.6. Seals Under Loading

Creep under load of polymeric seals (O-rings) has been reported as a concern by the recent European spacecraft programmes. This may be quantified at the component level by a load vs. deflection measurement made as a sealed interface is offloaded.3. Dwell Effects and In-Flight Storage

In-flight operation and storage (i.e., prolonged in-vacuum stasis prior to operation—as for example in robotic devices for planetary missions or in devices required for de-orbiting spacecraft at end-of-mission) will bring its own considerations, challenges and mitigations. Where possible for fluid-lubricated mechanisms, the orientation of the spacecraft or mechanism should be selected to minimise its average temperature during the storage period. This is due to lubricant creep, degradation (including due to potential autocatalysis of PFPEs), and the evaporation rate of oils all displaying strong dependencies upon temperature. This measure will inhibit most degradation phenomena and maintain the fluid lubricant within the mechanism to the maximum extent – but may not always be feasible for spacecraft operational reasons. For in-flight storage, the environment can be highly variable dependent on the mission profile. Whilst typically high/ultra-high vacuum and ranging from, say −40 to +80 °C, the environment for in-flight storage can also encompass more extreme thermal excursions for exposed items. For mechanisms on different types of science missions a full range from ~20K to ~600K and environments including CO2, H2, traces of CH4 or, for LEO, atomic oxygen could be relevant depending on mechanism location and mission type. The vacuum level in GEO is typically of order 10−13 mbar, however, near a satellite, the pressure is higher, about 10−10 mbar, as a result of outgassing from the satellite body. Within the spacecraft itself the pressure is yet higher. Calculations have shown, for a Solar Array Drive Mechanism (SADM) for example, that the internal pressure reaches ~10−5 mbar soon after orbital height is attained and decreases during the first year of operation to about 10−7 mbar (comprising ~80% water vapour and ~20% carbon monoxide) depending on the balance between the pump-out speed of venting orifices and declining outgassing rates [3][19]. Furthermore, in the case of reaction wheels there is the possibility of in-flight storage as well as operation under a partial vacuum (believed to be typically around 10−3 mbar).3.1. Evaporation Effects

Over a long duration storage period, the loss of fluid lubricant through evaporation must be considered. This is particularly true in instances where storage temperature is elevated for some or all of the storage period (of greater concern during in-flight storage than on-ground). Such evaporation is generally controlled through labyrinth sealing. Losses due to evaporation can be estimated using the Langmuir equation approach. However, in general, a lubricant may have components of different molecular weights and a range of volatilities. This can render analysis using the Langmuir equation and published vapour pressure data too simplistic, the true situation is that the rate of mass loss, even for nominally single component fluids without additives is dependent on the thermal history of the lubricant. Indeed, there is evidence [2][18] that the Langmuir equation may predict higher loss rates than found in practice by approximately an order of magnitude at typical operating temperatures.3.2. Fluid Separation and Creep

Concern exists regarding the separation of the oils (also known as “oil bleed”) from the grease, allowing migration to other surfaces. This can cause changes in the consistency of the grease and in so doing may alter its tribological properties. In the extreme, it may create lubrication-starved conditions during initial operations. Oil separation usually occurs on static components and is thus likely to occur during prolonged storage. It is considered that when using oils and greases in long-term applications or when mechanisms are subjected to long periods of storage, it is advisable to run the unit in question periodically to redistribute the lubricant if there has been pooling of oil due to oil separation or slumping due to storage conditions and orientation – implicitly this suggests such periodic “exercising” can locally re-mix oil back into the grease. In this respect, the use of creep barriers is also important as it restricts the surface migration of oil from the lubricated area. Without such barriers, oil could be lost irretrievably during prolonged storage from lubricated areas. Where a small quantity of oil is used, 1-g migration is minimised as the lubricant tends to remain within the contact and on the surfaces of the component, due to surface energy effects. This is true for relatively small quantities of oil, of order ~1% to <~5% free-volume fill (i.e., this amounts typically to ~1 µL/mm bearing PCD). However, for larger volume fills, as might be used if viscous losses are less a concern or total evaporative losses over the mission duration expected to be high (due to, for example, high-temperature operation and/or long lifetime), migration in 1-g is a much more likely phenomenon as the mass of the fluid body is high compared to the retaining viscous forces and substrate oil-film surface energetics. Such 1-g migration may impact the subsequent flight lifetime of the mechanism if the oil is able to exit the bearing envelope. During on-ground storage creep is driven by surface energy differentials and also by gravity, and can be minimised partly by control of surface features (less likely on smooth surfaces, or to migrate around sharp edges) and (primarily) by the appropriate application of anti-creep coatings which have a lower surface energy than the lubricating fluid.3.3. Dwell Behaviours of Solid Lubricants

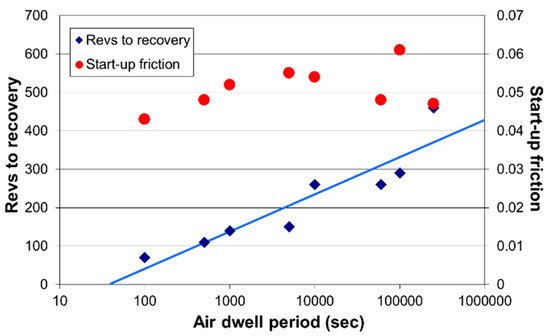

The influence of in-situ (vacuum and air) dwell periods on the subsequent in-vacuum tribological properties of PVD MoS2 and lead has been investigated at PoD and angular contact bearing level [4][20]. When assessed in pure sliding, exposure to an in-air dwell period acted to increase the start-up friction coefficient of sputtered MoS2. The rate of increase in friction with exposure time appears to level off at exposure periods of 105 s, demonstrating a saturation effect. Steady-state friction values are unaffected by in-air dwell periods, but the recovery period (i.e., the number of disc revolutions required to re-establish low friction in vacuum) increases logarithmically (Figure 27).

3.4. Auto-Catalytic Degradation

Perfluorinated oil-based fluid lubricants such as the grease Braycote 601EF or Fomblin Z25 oil are highly susceptible to chemical degradation, whereby a reaction occurs between the fluorine released from the oil by the action of shearing and iron within the substrate steel [5][21]. This reaction produces the compound FeF3 which further increases the rate of fluid degradation. This reaction acts to destroy the long-chain polymers within the fluid, removing the attractive low shear properties of the fluid, causing a rapid increase in friction coefficient and ultimately restricting the lifetime of these lubricants. Although usually understood to occur during operation (i.e., shearing), it has been postulated that once this reaction has been initiated through the shearing of the fluid (for example during mechanism run-in, acceptance test or initial in-flight commissioning), degradation could potentially continue when the fluid is not being sheared due to the existing presence of FeF3 within the contacts [6][22]. Such behaviour is referred to as the Autocatalytic Effect (ACE) and could potentially cause continued degradation of PFPE lubricants, following initial shearing, when stationary (e.g., degradation potentially continuing during both ground storage and during periods of in-flight inactivity, such as for missions having a long cruise phase). The concern is that such behaviour could impact the overall lubricant lifetime or produce significantly higher torques upon restart of a mechanism following an extended dwell period either on the ground or in flight. Despite its theoretical feasibility, to date there is limited experimental evidence of auto-catalytic degradation of a PFPE lubricant from tribometer testing. Numerous experimental PoD and SOT campaigns performed by ESTL have been inconclusive in observing this effect in all instances beside those where test conditions were selected to be deliberately harsh and designed to induce autocatalytic degradation [6][22]. Nevertheless, ACE remains a concern, albeit theoretical, for fluid lubricated mechanisms.3.5. Periodic Actuation/Exercising

At the mechanism level, general practice is to always maintain mechanisms intended for on-ground storage in a dry nitrogen purge and to occasionally “exercise” the mechanism. The term exercise is used to describe the periodic operation on the ground for a low number of cycles in order to recover pre-storage levels of performance, or to detect incipient storage issues at a time when preventative action or rectification measures may be implemented. Whilst the requirement to exercise a mechanism during storage is usually taken as being most applicable to grease or oil lubricated devices for which the exercise operations may re-distribute or replenish the local supply of oil or grease within the tribo-contacts (discussed above), it should also be noted that limited exercising may also be appropriate for solid lubricated mechanisms in order to avoid or minimise the impact of localised lubricant film indentations occasionally reported due to lubricant creep within preloaded contacts. In addition to these effects local to preloaded, lubricated tribo-contacts, consideration must also be given to the avoidance or potential impact of preload spring (or diaphragm) stress-relaxation during storage (an early life effect which can be designed-out). Whilst it is conventional to calculate the required qualification lifetime test duration based upon foreseen on-ground and in-orbit operational cycles, it should be noted that any additional operational cycles required as a result of the need to carry out the periodic exercising of a device during long-term storage on-ground must preferably also be included (and appropriately factored) in the calculation of qualification lifetime. However, this may be practically difficult in some circumstances as the need for long-term storage cannot always be anticipated, it being potentially required due to prior launch failures or other unforeseen circumstances occurring after qualification and delivery of flight hardware. The frequency and duration of exercise operations during ground tests need to be considered carefully. The following considerations are applicable for different applications:-

For some applications, a few revolutions or cycles may represent a significant proportion of the in-flight lifetime. In these cases, the duration should be considerably reduced and may ultimately be replaced by small oscillations through an angle large enough to provide overlap of ball positions on bearing raceways (so preventing local lubricant build-up).

-

In other applications, operation in dry nitrogen or in air for a prolonged duration may generate excessive particulate debris or lubricant degradation which could compromise subsequent performance (e.g., for lead lubrication operated cumulatively beyond 105 cycles in air, or for MoS2 where even a few revs in the air can greatly impact subsequent in-vacuum lifetime [7][4]). Therefore, the exercise duration (and environment) should be carefully chosen to minimise such impacts.

-

In some applications, exercising the device will have some unique and potentially high risks (e.g., requiring de-integration from a spacecraft) which need to be weighed against the benefits obtained from the exercise regime.