This entry is aimed at a succinct review of practical impacts of grid integration of renewable energy systems on effectiveness of power networks. The renewable energy resources focused on include solar energy, wind energy, biomass energy and geothermal energy, as well as renewable hydrogen/fuel cells, which, although not classified purely as renewable resources, are a famous energy carrier vital for future energy sustainability. Although several world energy outlooks have suggested that the renewable resources available worldwide are sufficient to satisfy global energy needs in multiples of thousands, the different challenges often associated with practical exploitation have made this assertion an illusion to date. Thus, more research efforts are required to synthesize the nature of these challenges as well as viable solution strategies, hence, the need for this review study. Overviews and general state-of-the-art information are provided in this entry, for the aforementioned renewable energy resources.

- concentrated solar power (CSP)

- photovoltaic (PV)

- biomass and geothermal energy

- wind energy

- renewable hydrogen and fuel cells

- Introduction

1. Introduction

Global demand for energy is on the rise year by year, obviously in response to the increasing population of the world, and this trend is likely to subsist for quite a while [1]. The World Energy Outlook of the International Energy Agency (IEA) [1] reports also that about 80% of global energy generation is still based on fossil fuels, notwithstanding the huge efforts and resources being committed to renewable energy research. However, the unsustainability of fossil-based energy plants is acknowledged widely and cannot possibly be over-emphasized. For one, emissions from these systems pose serious threats to continued sustenance of man, due to rapid degradation of health and the environment, consequences of which we already live with today. Furthermore, fossil-based energy resources are expected to become depleted someday, no matter how long, inasmuch as they are continuously exploited without any possibility for replenishment. Thus, the search for alternative and clean sources of energy should remain a critical area of research, as conspicuously captured by number 7 of the United Nation’s sustainable development goals (SDGs) 2030.

As hinted above, a lot is currently being done to facilitate the development and practical deployment of renewable energy systems, albeit with limited growth in real applications due to myriads of on-field difficulties [2]. Most of the challenges hindering high penetration of renewable energy resources into modern energy systems often have their roots in the transient nature of the majority of these resources. Based on this, it is common for renewable energy systems to be characterized by low dispatchability/reliability, low conversion efficiency and high costs of operation at generation level [3]. Similarly, the transient nature of most renewable resources often leads to low power quality during integration into the electrical grid, in addition to instability of voltage and frequency, and high power losses, amongst several others [3,4][3][4]. In essence, efforts should be more intensified toward seeking and mitigating all the attendant issues that affect high penetration of renewable energy resources if the growing demand for energy can continually be satisfied in a sustainable manner.

This paper is aimed at a succinct review of the common challenges that limit the effectiveness of renewable energy systems integrated with electrical grids, as well as often employed viable state-of-the-art solution strategies . The renewable resources in focus in this paper are solar energy, wind energy, biomass energy, geothermal energy, as well as renewable hydrogen/fuel cells, which, despite not existing purely in nature as distinct renewable resources, possess strong features as energy carrier and are thus vital to future energy sustainability. Suffice it to mention also that, although hydropower, ocean currents, tidal power and wave power (marine energy) are suitable renewable energy resources [5], they are excluded from the discussions in this paper for the sake of brevity and to avoid rowdy clustering of useful scientific information. After giving brief overviews of the different renewable energy resources in focus, the grid integration challenges and potential solution strategies are discussed in turn for each of the resources, first at the power generation stage and then during power grid integration. Following that, an expert opinion is provided, which captures some aphorisms deducible from the review study on where current research activities should be focused in order to facilitate practical and stable integration of the studied renewable energy resources with electricity networks. As a contribution to the body of knowledge, this paper provides lucid information for renewable energy researchers and practitioners on steps being taken to mitigate the different challenges often encountered in practice towards integration of renewable energy sources. Additionally, it provides a roadmap and guide on specific research topics requiring attention in this research field, all of which would ultimately contribute to increased penetration of the renewables into the modern energy systems towards the achievement of the relevant SDGs.

- General Overview of Renewable Energy Resources of Main Interest

2. General Overview of Renewable Energy Resources of Main Interest

Renewable energy sources encompass all self-existing natural resources with one form or the other of infinitely exploitable energy contents. Generally, solar energy, wind energy, biomass energy, geothermal energy, hydropower and marine (wave and tidal) energy fall within this category. It is opined that renewable energy resources, if properly exploited, are capable of satisfying all of the global energy needs, even surpassing them in a multiple of about 3000 [6]. Although applications are growing for use of renewable resources in global energy infrastructure, a lot is left to be done to attain a world powered exclusively by renewable energy systems.

While some of the resources, such as wind and solar, rely strongly on climatic and weather conditions, others correlate strongly with geological formations of the earth’s crust and aridity of lands. Solar, wind and other weather-dependent energy resources are highly intermittent in availability, although they could be exploited almost everywhere globally at varying intensity. Conversely, although biomass, geothermal and most other renewable resources that depend on nature of the earth’s surface could be stable for better exploitation, they are often not universally accessible. These characteristics often pose different natures of challenges on optimal exploitation of renewable energy resources, and each resource type should be examined based on its peculiarities. This review study focuses on solar, wind, biomass and geothermal resources, as well as renewable hydrogen, which is a secondary energy carrier vital for future energy sustainability. Prior to the intended discussions on the impacts of these renewable resources on power generation and integration into distribution and transmission power grids, a brief overview is given on each of them, as highlighted hereunder.

2.1. Solar Energy

Solar energy is one renewable resource that attracts keen attention around the world today, perhaps due to its free and universal accessibility [7]. Solar irradiation could currently be exploited for power generation using either photovoltaic (PV) or concentrated solar power (CSP) technologies [8–10][8][9][10]. While CSP converts energy of the sun first to thermal energy by collectors and then to electrical energy by turbo-generator, PV systems are capable of converting solar light directly to electricity [11]. With regard to generation for power grid integration, CSP is an indirect technology that produces alternating current (AC) which could be applied directly [12], while PV is a simpler technology which produces direct current (DC) that must be transformed into AC by interfacial devices such as inverters [11,13][13]. This makes PV systems quite scalable and affordable, making them a more embraced and popular solar technology for real life applications [14]. PV plants can range from micro scale in few kilowatts [15] to mega scale in several megawatts [16], with an average thermal conversion efficiency typically of around 18% [17]. However, CSP technology is considered equally important for the generation of thermal power for use in different applications, which includes conversion to electrical power using different power cycles [18]. CSP systems are also small-to-large scale in size, ranging from hundreds of kilowatts to several megawatts, although few micro-scale plants in tens of kilowatts also exist [12]. The average solar conversion efficiency of most CSP plants is usually around 20% [8]. Thus, both PV and CSP plants are astounding solar technologies. They should play substantial roles in increasing renewable energy penetration into the future energy mix, and they are both succinctly captured in this review study.

2.1.1. Solar Photovoltaic

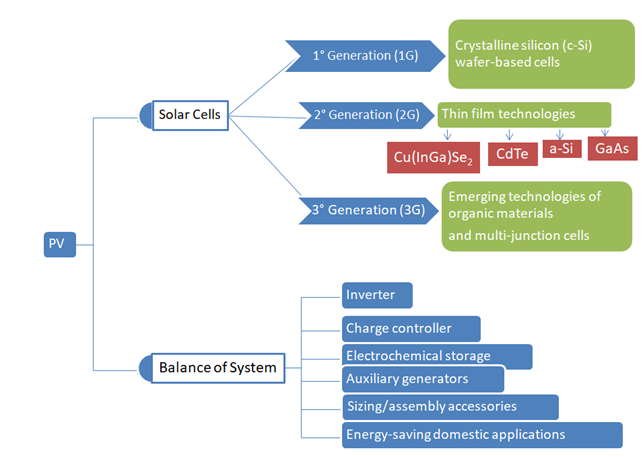

Solar photovoltaic systems make use of arrays of semiconductors, technically known as solar cells, to convert to electrical power the photonic effects of solar radiation. In addition to solar cells, which are assembled in small modules up to the desired size, PV systems also consist of other ancillary devices, often called balance of systems (BoS) components, which perform a range of complementary functions essential to the value chain of continuous power production and usage. Some of the auxiliary functions of PV BoS devices include mechanical assemblage and connections of solar cells into panels, chemical protection of the cells, auxiliary power generation, power inversion, electrochemical storage of electrical power as well as charge monitoring and control, etc. [13].

The science of solar cells is multidisciplinary, and there are currently extensive, diverse and progressive research activities aimed at the development of modular solar cells and PV systems in general. The different forms of solar cells include crystalline silicon (c-Si) cells; thin-film silicon cells, such as amorphous silicon (a-Si) cells, copper indium gallium di-selenide Cu(InGa)Se2 cells, cadmium telluride (CdTe) cells as well as single-junction gallium arsenide (GaAs) cells; and high-efficiency III-V multi-junction cells and dye-sensitized or organic-based cells [11]. Shubbak [13] reported attempts by researchers to categorize these solar cells into groups based on time of development and degree of market penetration. The c-Si are the earliest and by far the most established ones with market penetration of over 90%, generally referred to as first generation (1G) solar cells. The more recent thin-film silicon cells constitute the second generation (2G) solar cells, sharing most of the remaining market in PV systems, while the most recent and emerging multi-junction solar cells and organic-based ones constitute the third generation (3G). A lucid representation of PV system overview is shown in Figure 1.

Figure 1. Photovoltaic (PV) system overview.

In order to improve economic performance of traditional PV systems where solar cells are mounted on stationary panels with large cross sectional areas of multiple cells, solar concentration and tracking mechanisms have been proposed for integration into modern PV set up. This entails the use of trackers to always position optical devices (mirrors and lenses) in the trajectory of solar radiation so as to focus sunlight on cells with smaller cross sectional area, known as concentrated photovoltaic (CPV) systems [19]. CPV systems are classified on the basis of types of optics and the adopted tracking mechanism, similar to what is obtained in the CSP systems, as elucidated in the following section. Furthermore, CPV systems are nowadays being modified to also exploit solar thermal energy in the form of hybrid CPV-thermal systems [20[20][21],21], which could be enhanced further by waste heat recovery processes [22].

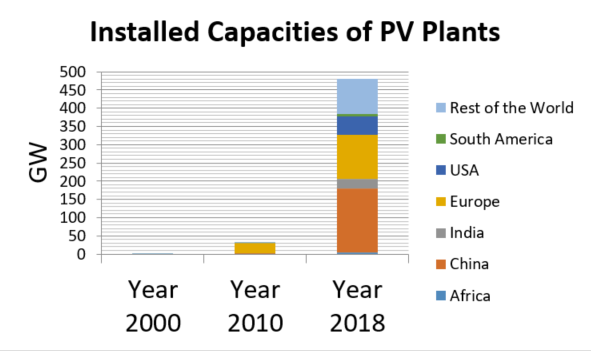

Suffice it to mention here that solar PV technology is about the biggest driver of renewable energy exploitation for practical applications, with about 100 GW capacity installed globally in 2018, amounting to about 55% of new renewable energy capacity [23]. This could be attributed to advancement in technologies of PV cells and BoS, which consequently reduces costs of investment. The installed capacities of PV plants are illustrated in Figure 2 for selected countries and regions. Furthermore, large-scale PV projects now compete favorably with conventional technologies for cost-effective electricity production, especially in Chile, Mexico, Peru and UAE where new records were set in 2016 and 2017 for low-cost solar power purchase agreements [24]. Specifically, 2019 PV economic data provided by IRENA [25] revealed that production costs are falling significantly in many countries, with the lowest levelized cost of electricity (LCOE) of about 0.04 USD/kWh obtained in India and the highest of about 0.14 USD/kWh reported in Japan. Additionally, LCOE values below 0.07 USD/kWh were reported in China, Spain and Italy.

Figure 2. Installed PV capacities for selected countries and regions [26].

2.1.2. Concentrated Solar Power

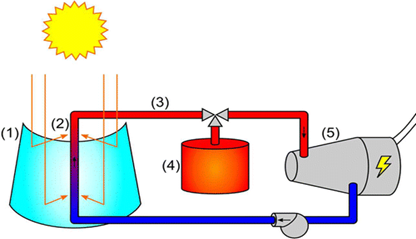

Concentrated solar power systems produce thermal power primarily by focusing energy contents of the sun to collecting devices [27]. Specifically, collectors are positioned using some forms of tracking mechanisms, for direct impingement of solar rays on their external surfaces. Then, the solar rays are directed onto a receiver, which encompasses the absorber where solar energy is converted to useful thermal energy, as well as the pipe network, which transports the produced thermal energy through a heat transfer fluid (HTF) [28]. Next, the HTF flows either through a heat engine for production of electrical power from the exploited solar heat, or through a thermal energy storage (TES) system where the thermal energy is accumulated for deferred usage [29]. The different components of a typical CSP system are illustrated in Figure 3.

Figure 3. Basic components of a conventional concentrated solar power (CSP) system: (1) concentrator, (2) receiver, (3) heat transfer fluid (HTF), (4) thermal energy storage (TES), and (5) heat engine. Reproduced with permission from [29]. Copyright 2015 American Chemical Society.

In some instances, TES and perhaps HTF are excluded, for instance, in CSP systems where the absorber is integrated with the application device for immediate use of the exploited thermal energy. In essence, actual composition of the CSP system is case specific, depending on the intended application.

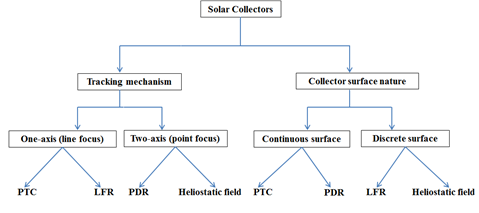

Concentrated solar technologies are often classified on the bases of the type of tracking mechanism adopted and the nature of collecting surface. Regarding the classification based on tracking mechanisms, some collectors are positioned to follow the sun’s movement only on its main axis as it rotates from east to west, usually called one-axis tracking [30]. On the other hand, some other solar collectors are positioned to follow the solar movement both from east–west and north–south axes, usually referred to as two-axis tracking. The collectors adopting one-axis tracking impinge solar rays on a line, and are therefore also known as line-focus collectors. Linear Fresnel reflectors (LFR) and parabolic trough collectors (PTC) are the main solar collector technologies in this category [31]. Conversely, collectors adopting two-axis tracking mechanism impinge solar irradiation on a point, and are therefore also referred to as point-focus solar collectors. The main solar technologies in this category are the heliostatic field (often interchanged with the central solar receiver as well as the solar tower) and parabolic dish reflectors (PDR). The point-focus collectors are advantageous in that they are able to achieve higher concentration ratios relative to the line-focus collectors. However, they are equally characterized by certain disadvantages, particularly regarding the complicated technical specifications required to achieve two-axis solar tracking, which also often result in much higher costs when compared with line-focus collectors [32].

Regarding the nature of collecting surface which is the second basis of classifying CSP systems, systems exist with continuous collector surfaces, in which case the collectors are fixed to form a single unit with receiver, and they therefore move together to track solar irradiation [33]. This arrangement obliges the system the merit of very high concentration ratios, as well as a relatively simple solar tracking mechanism. The main CSP technologies in this category are PTC and PDR. On the other hand, in this respect, other systems have discrete facets collector surfaces—in which case, the receiver is stationary and is markedly dissociated from the mirrors. The advantage of this arrangement is that the collectors are less affected by wind thrust since they can be installed closer to the ground, and they can be easily accessible for maintenance. However, solar collectors based on discreet facets surfaces are often associated with low concentration ratios [34]. Main CSP technologies in this category are the heliostatic field and LFR. Based on the foregoing, it is clear that the main types of solar collectors in use are PTC, LFR, PDR and the heliostatic field. Figure 4 summarizes the aforementioned classifications of CSP technologies.

Figure 4. Classification of CSP technologies.

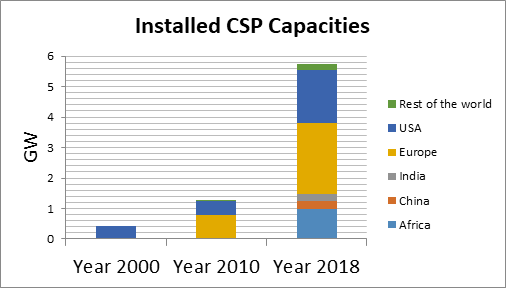

The most matured CSP technology is by far the PTC [35]. This can be demonstrated by the very high number of CSP projects around the world that adopt PTC today when compared to other collector types. As of August 2019, around 100 of global CSP projects make use of PTC technology; around 37 make use of heliostatic field (Solar Tower); about 15 make use of LFR; and only about 2 adopt PDR [36]. Although CSP production costs are generally high at the moment, standing between 0.15 and 0.3 USD/kWh, it is opined that the costs will continue to fall in response to ongoing developmental efforts, and the solar tower can attain LCOE of 0.09 USD/kWh by 2025 [24]. The installed capacities of CSP plants are illustrated in Figure 5 for selected countries and regions.

Currently, researchers work assiduously to investigate new collector configurations that could improve solar collection/absorption capabilities [37]. Furthermore, a significant amount of effort is being directed at investigating viable ways of cleaning/removing dirt and film formations often deposited on collector surfaces in order to minimize efficiency losses [38], amongst others. It is a general opinion in the literature that research efforts need be intensified towards cost reduction of small-scale CSP systems [8,39][39]. In this case, researchers have hinted that use of water as HTF in solar collectors could be particularly viable, known technically as direct steam generation (DSG) [8]. In addition, integrated solar combined cycle systems are being investigated, where it is possible to use carbon dioxide as a heat transfer fluid in place of expensive thermal oils [40].

Figure 5. Installed CSP capacities for selected countries and regions [26].

2.2. Wind Energy

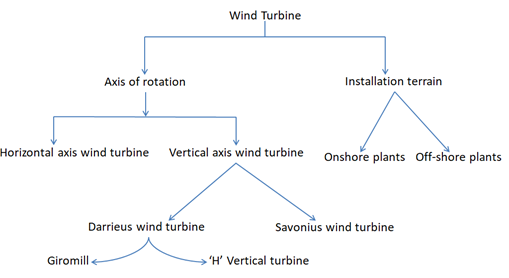

Wind energy entails conversion of the kinetic energy of air motion into a useful form of energy, such as electricity, through a mechanical device known as wind turbine [41]. In a wind turbine, the force of wind impinges on suitably shaped blades radiating from a shaft, which encompasses an electricity generating device known as a wind turbine generator. Wind turbines can be classified according to the axis of rotation, or according to location of installation [42].

Turbines can rotate around a horizontal axis (horizontal axis wind turbines, HAWT), or on a vertical axis (vertical axis wind turbines, VAWT) [43]. HAWTs have their main rotor shaft and electric generator at the top of a tower, and must be pointed into the wind. Small turbines are pointed to the wind by using a simple wind vane, while large ones generally use a wind sensor coupled with a servo motor. Most HAWTs have a gearbox, which turns the slow rotation of the blades into a quicker rotation that is more suitable to drive an electric generator [44]. The first generations of HAWT types were windmills introduced in the 12th century, but they have been displaced by modern multi-bladed wind turbines. Conversely, VAWT types can more effectively exploit wind energy from any direction, and do not necessarily have to be pointed in the direction of the wind. The generator and gearbox can be placed near the ground, so the turbine tower does not need to support it, and a VAWT is thus more accessible for maintenance. Drawbacks are that some designs produce pulsating torque. Drag may also be created when the blade rotates into the wind [45]. The main types of VAWT include the Darrieus wind turbine (including the Giromill and ‘H’ vertical wind turbine) and the Savonius wind turbine. The most practical wind turbine installations are those of HAWT types when compared to VAWT types [44,45][44][45]. They range in sizes from small scale of about 1 kW in distributed systems to large scale of about 3.5 MW in offshore power generation. Typically, about 50% of the wind energy transited by the turbine rotor is successfully exploited [46].

Furthermore, on the basis of installation location, wind turbines are classified into onshore and offshore types. Onshore wind turbines are those situated on firm ground or on some city shores, while those located in open seas are called offshore wind turbines. Regardless of type, single or very few wind turbines can be installed to meet certain specific energy needs, or in clusters of multiple turbines often referred to as wind farms. The different classifications of wind turbines are illustrated in Figure 6.

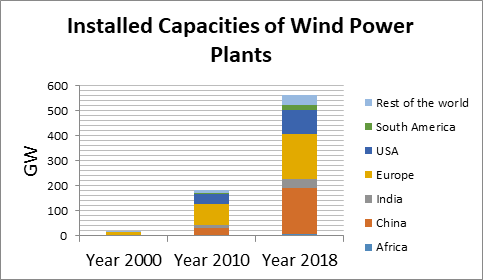

Here too, suffice it to mention that wind power plants contribute substantially to the growth of energy generation from renewable sources, representing about 28% of new renewable energy capacity installed globally in the year 2018 [23]. Although wind energy plants are availably rated in a few kilowatts [47], most practical systems usually range from hundreds of kilowatts to several megawatts [48]. The installed capacities of wind power plants are represented in Figure 7 for a selected parts of the world, showing a drastic increase in wind energy penetration into the global energy mix. Economically, wind power plants are improving steadily in competitive electricity generation even in the absence of financial incentives. In 2016, new onshore wind power plants recorded average LCOE in the range of 0.05–0.12 USD/kWh, while for offshore projects, slightly higher values were obtained between 0.10 and 0.21 USD/kWh [49].

Figure 6. Wind turbine classifications.

Figure 7. Installed capacities of wind power plants for selected world regions [26].

2.3. Biomass Energy

Biomass generally connote organic resources produced from metabolic processes of animate and inanimate organisms [50]. Depending on origin, it is possible to classify them as forest biomass, agricultural biomass, and renewable wastes, which include municipal and industrial wastes [51]. Raw forest woods and residues are often classified under forest biomass, while agricultural biomass usually encompass energy and rotation crops and their residues [52]. Depending on the source of generation, biomass resources can exist physically in solid, liquid or gaseous states. However, a widely acknowledged opinion holds that biomass resources exist most abundantly in solid state, and solid biomass are therefore the most commonly used ones [53].

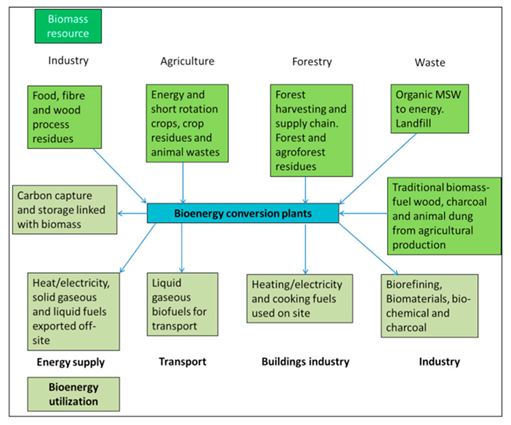

Depending on targeted sector of application, industrial biomass products, energy biomass products and transportation biomass products are the major classes of products obtainable from different biomass processes. In the energy sector, heat is produced from processed biomass resources, which can be applied directly or further used in heat engine for production of electricity, either as a sole product or in form of combined heat and power (CHP). Vast numbers of small-scale biomass plants exist rated below 200 kW [54], while several others are much larger in tens of megawatts power ratings [55,56][55][56]. In addition, it is common to process biomass resources into fuels laden with chemical energy, including hydrogen, which could in turn be employed in myriads of applications in the energy sector. In the transportation sector, biomass resources are commonly processed into fuels in liquid and gaseous forms, which could be applied directly or indirectly to propel vehicular engines. The fuels produced from biomass resources are often referred to as biofuels [57]. Moreover, it is on record that state-of-the-art biomass resources are applicable in the production of fuels and raw materials required in certain industrial processes, among which are biochemical, bio-refining, charcoal and biomaterials [58,59][58][59]. Figure 8 represents the various sources and products obtainable from biomass.

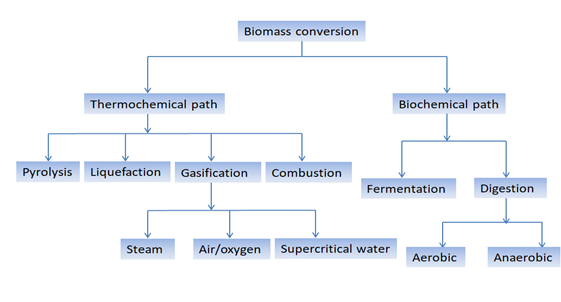

Furthermore, based on the products intended from biomass conversion, the conversion processes are often classified into biochemical and thermochemical processes. In biochemical conversion, biomass resources undergo fermentation or digestion process to give the desired products [60]. Digestion could be aerobic if it takes place in the presence of oxygen, or anaerobic if it excludes oxygen [61]. Conversely, heat is produced directly from thermochemical biomass conversion technologies, just as the name suggests. The technologies could employ pyrolysis (encompassing liquefaction), combustion or gasification processes for biomass conversion [62]. Hydrothermal and hydrolysis processes have equally been highlighted in the literature [63[63][64],64], but these are downplayed here.

Figure 8. Overview of biomass resources and common products. Reprinted with permission from [65].

Hot combustion flue gases from the combustion process could be used directly for a desired purpose, known generally as direct combustion, or could be recovered and used in secondary heat exchange processes, for example, in steam production and generation of power, amongst others. Devices such as boilers, driers, kilns and ovens are generally applicable for biomass combustion process [66].

In the case of biomass gasification, a mixture of gases (known technically as syngas) is produced from solid biomass, which is made to change phase by the thermally driven conversion process [67]. The syngas is generally readily combustible, and it is typical to thus ignite it for production of useful heat, electricity or CHP [68]. In addition, it is possible to process the syngas obtained from biomass gasification process into fuels and chemicals, as it is obtained in bio-refineries [69]. Partial oxidation reaction or the external heat exchange process could be employed to supply heat required for the biomass gasification process [70][70]. Fixed and fluidized bed reactors are among the most popular technologies of biomass gasifiers, exemplified respectively by updraft/downdraft gasifiers and circulating/bubbling fluidized bed reactors [71]. Some other technologies are entrained and plasma gasifiers [71].

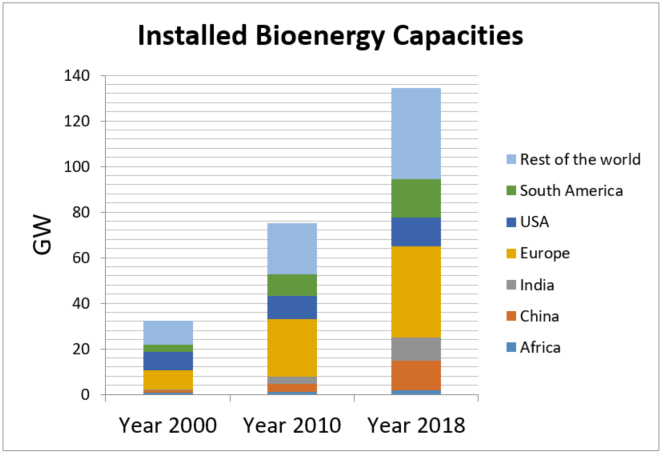

Next, it is possible to convert biomass simultaneously into liquid, gas and charcoal by decomposing it in the absence of oxygen. This conversion process is often referred to as pyrolysis [72]. The pyrolysis process could be influenced to favor one product over others. For instance, substantial liquid biofuels are produced, known as liquefaction process, when the fast heating rate process is employed during biomass pyrolysis, while substantial charcoal yields from the same process by employing an extremely slow heating rate process [73]. Figure 9 also captures common conversion technologies of solid biomass. Efficiencies of biomass power generation devices vary significantly by size, and for small-scale biomass power plants in the range of 1–3 kW, an average thermal efficiency of 10-12% is typical [74]. The installed capacities of bioenergy power plants are represented in Figure 10 for selected countries and regions. Depending on type of biomass fuel and location, the levelized cost of electricity (LCOE) can range typically from 0.03 to 0.14 USD/kWh, and can sometimes reach as high as 0.25 USD/kWh [75]. The weighted average stands at about 0.03 USD/kWh in India, 0.05 USD/kWh in China and about 0.085 USD/kWh in Europe and North America over the last decade [75].

Figure 9. Overview of common biomass conversion processes. Adapted with permission from [65].

Overall, current research efforts focus on improvement of techno-environmental as well as social performance indices of biomass plants, seeking specifically to enhance available conversion technologies [62]. Additionally, several studies are targeted at investigating the sustainability and suitability of different biomass resources for dedicated industrial applications. This is especially true in industries requiring high-temperature processes, for instance in steel and cement industries, etc. [63]. These efforts, if intensified, could promote areas of applications of biomass resources, with attendant reduction in use of fossil fuels, if not complete elimination.

Figure 10. Installed capacities of bioenergy power plants for selected world regions [26].

2.4. Geothermal Energy

The term “geothermal energy” is rooted in two Greek words: geo translating to earth, and “thermal” meaning heat; thus, geothermal energy can be defined as heat form of energy produced from the earth [76]. In more detail, the geothermal reservoir, an aquifer of water with high thermal energy content, is formed from water flowing into the crust through deep faults, and is based primarily on the heat generated and stored in the mantle and core of the earth [77]. Given that the flow of heat from the depth is a natural and continuous process, geothermal resources are hardly depleted, and they are thus considered as renewable energy sources.

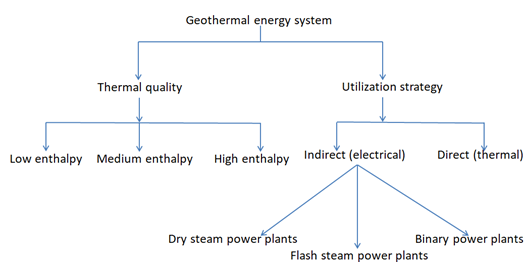

Geothermal energy is usually classified based on temperature range of the reservoir fluid, as well as utilization strategy. On temperature range classification basis, there are high-enthalpy geothermal energy resources (1500–2800 kJ/kg), medium-enthalpy resources (1100–1500 kJ/kg) and low-enthalpy resources (950–1100 kJ/kg) [78,79][78][79]. Regarding utilization strategies, geothermal energy is often classified into direct and indirect systems, respectively for heat and electricity generation applications [80]. Direct use of geothermal energy entails exploitation of the thermal contents of reservoir hot water in various household and industrial applications, such as agriculture crop drying, aquaculture pond and raceway heating, bathing and swimming, snow melting, as well as space heating and cooling, including district heating, with or without integration of heat pumps, amongst others [81]. In indirect applications, which is of main interest in this paper, geothermal energy is employed in a secondary thermodynamic process for electricity generation. Typically, geothermal resources with temperature higher than 150 °C are considered suitable for power generation applications. However, it is opined that the use of organic Rankine cycles in geothermal systems can allow for exploitation at lower temperature values [82].

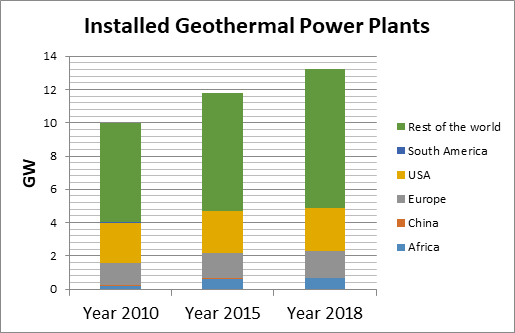

The grid-connected geothermal power system was first built in 1914 at Larderello, Italy, about a decade after Prince P.G. Conti set up at the same location a device able to generate electricity from geothermal heat. The power system made use of a turbo alternator to generate about 250 kW of power [76,83][83]. In modern day, power generation from geothermal resources are based on three technologies: dry steam power plants, where high-temperature vapor from geothermal reservoir drives a turbo-generator for power production; flash steam power plants, where liquid-dominant geothermal fluid is first separated in flash vessels before vapor is channeled to drive the turbo-generator; and binary power plants, where low-temperature geothermal water is used to evaporate a different working fluid in a closed thermodynamic cycle, prior to expansion of the working fluid in turbo-generator [83]. Data from a worldwide review of global geothermal plants reported average efficiency of about 12%, with size ranging generally from hundreds of kilowatts to several megawatts [84]. Figure 11 illustrates the basic classifications of geothermal energy systems.

Furthermore, geothermal energy is being considered in hybridization with other intermittent renewable resources, such as solar energy, and this has been purported to be a viable way of improving performance [85]. The installed capacities of geothermal power plants are represented in Figure 12 for selected countries and regions. Depending on whether the geothermal project is from a virgin field or based on secondary field development, LCOE can range from 0.04 to 0.14 USD/kWh [86].

Figure 11. classification of geothermal energy systems.

Figure 12. Installed capacities of geothermal power plants for selected world regions [26].

In sum, Table 1 highlights the global electricity generation from different renewable energy resources, including projections up to the year 2040 based on stated policies committed to be put in place by different stakeholders.

Table 1. Global renewable energy consumption for electricity generation [1].

|

Generation by resource type |

2000 |

2018 |

2030 |

2040 |

|

Hydro |

2613 |

4203 |

5255 |

6098 |

|

Bioenergy |

164 |

636 |

1085 |

1459 |

|

Wind |

31 |

1265 |

3317 |

5226 |

|

Solar PV |

1 |

592 |

2562 |

4705 |

|

Geothermal |

52 |

90 |

182 |

316 |

|

CSP |

1 |

12 |

67 |

196 |

|

Marine |

1 |

1 |

10 |

49 |

|

Renewable electricity generation (TWh) |

2863 |

6799 |

12,479 |

18,049 |

|

Share of total electricity generation |

19% |

26% |

37% |

44% |

2.5. Renewable Hydrogen and Fuel Cell

Hydrogen is the most frequently occurring element in the universe, appearing on earth bounded to other elements, as it appears in water, hydrocarbons, etc. Although it has found applications for decades in chemical and petrochemical industries, its exploitation as a viable energy carrier is more recent, and extensive research as well as practical demonstrations are ongoing globally [87]. Applications of hydrogen in the energy industry are diverse and varied, but they can be classified into three main categories. First, hydrogen could be employed as sustainable electricity storage medium in systems based on other transient renewable resources, based on its amenability to power-to-X-to-power conversion processes, X being gas, liquid or solid [88,89][88][89]. Second, hydrogen could undergo clean and direct conversion processes to produce power, heat or electricity [87,90,91][90][91]. Third, hydrogen could be employed alongside fuel cells in power units to complement storage and direct power production applications [92–94][92][93][94]. These are the main motivations for including hydrogen in this study, coupled with its future potentials to compete favorably well with natural gas as a final source of energy for different applications. In fact, the supposed world’s first industrial-scale integrated power-to-X-to-power hydrogen gas turbine demonstrator is currently being developed under the HyflexPower project, a consortium made up of Engie Solutions (Paris, France), Siemens Gas and Power GmbH & Co. KG (Munich, Germany), Centrax Ltd. (Abbot, England), Arttic, German Aerospace Center (DLR; Cologne, Germany) and four European universities [95].

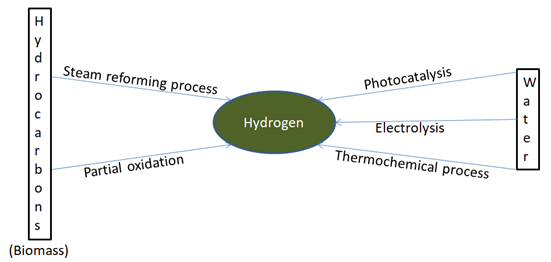

As aforementioned, water and hydrocarbons, such as fossil fuels and biomass, are the main sources of hydrogen. It is reported that hydrogen production from hydrocarbon by steam reforming process is by far the most matured process at the moment, with fossil fuels being the most exploited sources with market share of about 96–98% of total production as at 2017 [87,96,97][96][97]. However, enormous research efforts are underway aimed at promoting the use of biomass and other renewable sources in place of fossil fuels, which is the focus here [98,99][98][99]. Similarly, partial oxidation is being researched and promoted as a viable process of producing hydrogen from hydrocarbons, as well as production from electrolysis, thermochemical and photo-catalytic processes [100,101][100][101]. These renewable hydrogen production sources and processes are summarized in Figure 13.

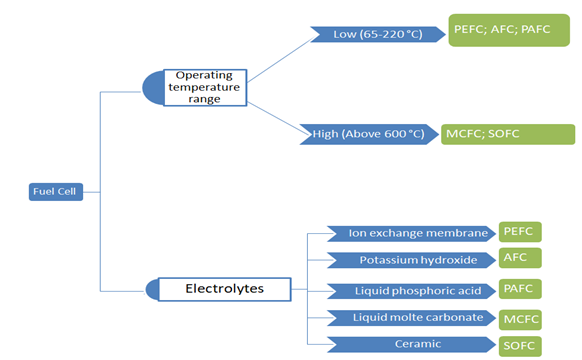

Fuel cells are generally regarded as compact energy conversion systems used for production of electricity and heat from chemical energy. A cell consists of an anode and a cathode on either side, separated by an ion-conducting and electron-blocking device known as an electrolyte. Although a good number of fuels would suffice for use in fuel cells, those allowing for application of hydrogen are highly desirable, owing to the high efficiency that they provide the system with [87]. Fuel cells are often classified based on the electrolytes adopted and range of temperature required. The most prominent types include the proton exchange membrane fuel cell (PEMFC), solid oxide fuel cell (SOFC), alkaline fuel cell (AFC), phosphoric acid fuel cell (PAFC) and molten carbonate fuel cell (MCFC), all using different kinds of electrolytes. Amongst these fuel cell types, PEMFC and AFC require relatively low temperatures (typically below 100 °C) for their electrolytes to conduct ions, while PAFC, MCFC and SOFC operate with 205 °C, 650 °C and in the range 600–1000 °C, respectively [87,102,103][102][103]. The classification basis and types of fuel cells are succinctly illustrated in Figure 14. A similar classification suffices even for electrolyzers.

Regarding the economics of hydrogen-based power generation systems, a recent study by Hydrogen Council [104] suggests that hydrogen-based heavy duty turbines for grid-integrated power generation can assume LCOE value of about 0.14 USD/kWh, with an assumed hydrogen import cost of 3 USD/kg. For electricity generation using the hydrogen-based fuel cell, LCOE value of 0.433 EUR/kWh was reported for a 10 MW PEM electrolyzer type in 2013, with projection of dramatic reduction to about 0.056 EUR/kWh by the year 2030 [105].

Figure 13. Sources of renewable hydrogen and production processes.

Figure 14. Classifications of fuel cells

[1][2][3][4][5][6][7][8][9][10][11][12][13][14][15][16][17][18][19][20][21][22][23][24][25][26][27][28][29][30][31][32][33][34][35][36][37][38][39][40][41][42][43][44][45][46][47][48][49][50][51][52][53][54][55][56][57][58][59][60][61][62][63][64][65][66][67][68][69][70][71][72][73][74][75][76][77][78][79][80][81][82][83][84][85][86][87][88][89][90][91][92][93][94][95][96][97][98][99][100][101][102][103][104][105]

References

- World Energy Outlook 2019; IEA: Paris, France, 2019; ISBN 2025869592.

- Sim, J. The economic and environmental values of the R&D investment in a renewable energy sector in South Korea. Clean. Prod. 2018, 189, 297–306, doi:10.1016/j.jclepro.2018.04.074.

- Sinsel, S.; Riemke, R.L.; Hoffmann, V.H. Challenges and solution technologies for the integration of variable renewable energy sources—A review. Energy 2020, 145, 2271–2285, doi:10.1016/j.renene.2019.06.147.

- Worighi, I.; Maach, A.; Hafid, A.; Hegazy, O.; Van Mierlo, J. Integrating renewable energy in smart grid system: Architecture, virtualization and analysis. Energy Grids Netw. 2019, 18, 100226, doi:10.1016/j.segan.2019.100226.

- Machrafi, H. Green Energy and Technology; Springer: Berlin/Heidelberg, Germany, 2012; ISBN 9781608054220.

- Ellabban, O.; Abu-Rub, H.; Blaabjerg, F. Renewable energy resources: Current status, future prospects and their enabling technology. Sustain. Energy Rev. 2014, 39, 748–764, doi:10.1016/j.rser.2014.07.113.

- Sansaniwal, S.K.; Sharma, V.; Mathur, J. Energy and exergy analyses of various typical solar energy applications: A comprehensive review. Sustain. Energy Rev. 2018, 82, 1576–1601, doi:10.1016/j.rser.2017.07.003.

- Islam, T.; Huda, N.; Abdullah, A.; Saidur, R. A comprehensive review of state-of-the-art concentrating solar power (CSP) technologies: Current status and research trends. Sustain. Energy Rev. 2018, 91, 987–1018, doi:10.1016/j.rser.2018.04.097.

- Sultan, S.M.; Efzan, M.E. Review on recent Photovoltaic/Thermal (PV/T) technology advances and applications. Energy 2018, 173, 939–954, doi:10.1016/j.solener.2018.08.032.

- Sumathi, S.; Ashok Kumar, L.; Surekha, Solar PV and Wind Energy Conversion Systems; Springer: Berlin/Heidelberg, Germany, 2015; ISBN 978-3-319-14940-0.

- Handbook of Photovoltaic Science and Engineering; Luque, A., Hegedus, S., Eds.; John Wiley & Sons Ltd: Sussex, UK, 2003; Volume 1; ISBN 0471491969.

- Gauché, P.; Rudman, J.; Mabaso, M.; Landman, W.A.; Von BackströmT.W.; Brent, A.C. System value and progress of CSP. Energy 2017, 152, 106–139, doi:10.1016/j.solener.2017.03.072.

- Shubbak, M.H. Advances in solar photovoltaics: Technology review and patent trends. Sustain. Energy Rev. 2019, 115, 109383, doi:10.1016/j.rser.2019.109383.

- Hernández-Callejo, L.; Gallardo-Saavedra, S.; Alonso-Gómez, V. A review of photovoltaic systems: Design, operation and maintenance. Energy 2019, 188, 426–440, doi:10.1016/j.solener.2019.06.017.

- Albadi, M.H. Measured performance evaluation of a 1.4 kW grid connected desert type PV in Oman. Energy Sustain. Dev. 2018, 47, 107–113, doi:10.1016/j.esd.2018.09.007.

- Obeng, M.; Gyamfi, S.; Derkyi, N.S.; Kabo-Bah, A.T.; Peprah, F. Technical and economic feasibility of a 50 MW grid-connected solar PV at UENR Nsoatre Campus. Clean. Prod. 2020, 247, 119159, doi:10.1016/j.jclepro.2019.119159.

- Ali, H.M. Recent advancements in PV cooling and efficiency enhancement integrating phase change materials based systems—A comprehensive review. Energy 2020, 197, 163–198.

- Storm, K. Solar thermal power plant. Process Plant Constr. Estim. Man-Hour Anal. 2019, 187–215, doi:10.1016/b978-0-12-818648-0.00009-0.

- Hasan, A.; Sarwar, J.; Shah, A.H. Concentrated photovoltaic: A review of thermal aspects, challenges and opportunities. Sustain. Energy Rev. 2018, 94, 835–852, doi:10.1016/j.rser.2018.06.014.

- Vivar, M.; Clarke, M.; Pye, J.; Everett, V. A review of standards for hybrid CPV-thermal systems. Sustain. Energy Rev. 2012, 16, 443–448, doi:10.1016/j.rser.2011.08.008.

- Ben Youssef, W.; Maatallah, T.; Menezo, C.; Ben Nasrallah, S. Modeling and optimization of a solar system based on concentrating photovoltaic/thermal collector. Energy 2018, 170, 301–313, doi:10.1016/j.solener.2018.05.057.

- Ju, X.; Xu, C.; Liao, Z.; Du, X.; Wei, G.; Wang, Z.; Yang, Y. A review of concentrated photovoltaic-thermal (CPVT) hybrid solar systems with waste heat recovery (WHR). Bull. 2017, 62, 1388–1426, doi:10.1016/j.scib.2017.10.002.

- Dunnett, S.; Sorichetta, A.; Taylor, G.; Eigenbrod, F. Harmonised global datasets of wind and solar farm locations and power. Data 2020, 7, 1–12, doi:10.1038/s41597-020-0469-8.

- Solar Available online: https://www.irena.org/costs/Power-Generation-Costs/Solar-Power (accessed on 7 August 2020).

- Solar Available online: https://www.irena.org/Statistics/View-Data-by-Topic/Costs/Solar-Costs (accessed on 31 August 2020).

- IRENA— International Renewable Energy Agency. Available online: https://www.irena.org/ (accessed on 7 August 2020).

- Lovegrove, K.; Csiro, W.S. Introduction to concentrating solar power (CSP) technology. Sol. Power Technol. 2012, 3–15, doi:10.1533/9780857096173.1.3.

- Lovegrove, K.; Pye, J. Fundamental principles of concentrating solar power (CSP) systems. Sol. Power Technol. 2012, 16–67, doi:10.1533/9780857096173.1.16.

- Weinstein, L.A.; Loomis, J.; Bhatia, B.; Bierman, D.M.; Wang, E.N.; Chen, G. Concentrating solar power. Rev. 2015, 115, 12797–12838, doi:10.1021/acs.chemrev.5b00397.

- Chang, C. Tracking solar collection technologies for solar heating and cooling systems. Sol. Heat. Cool. 2016, 81–93, doi:10.1016/b978-0-08-100301-5.00005-9.

- Barlev, D.; Vidu, R.; Stroeve, P. Innovation in concentrated solar power. Energy Mater. Sol. Cells 2011, 95, 2703–2725, doi:10.1016/j.solmat.2011.05.020.

- Hafez, A.Z.; Yousef, A.; Harag, N. Solar tracking systems: Technologies and trackers drive types—A review. Sustain. Energy Rev. 2018, 91, 754–782, doi:10.1016/j.rser.2018.03.094.

- Hussain, M.I.; Ménézo, C.; Kim, J.T. Advances in solar thermal harvesting technology based on surface solar absorption collectors: A review. Energy Mater. Sol. Cells 2018, 187, 123–139, doi:10.1016/j.solmat.2018.07.027.

- Arancibia-Bulnes, C.; Peña-Cruz, M.I.; Mutuberría, A.; Díaz-Uribe, R.; Sánchez-González, M. A survey of methods for the evaluation of reflective solar concentrator optics. Sustain. Energy Rev. 2017, 69, 673–684, doi:10.1016/j.rser.2016.11.048.

- Cavallaro, F.; Zavadskas, E.; Streimikiene, D.; Mardani, A. Assessment of concentrated solar power (CSP) technologies based on a modified intuitionistic fuzzy topsis and trigonometric entropy weights. Forecast. Soc. Chang. 2019, 140, 258–270, doi:10.1016/j.techfore.2018.12.009.

- CSP Projects Around the World—SolarPACES.Available online: https://www.solarpaces.org/csp-technologies/csp-projects-around-the-world/ (accessed on 6 August 2019).

- Desai, NB; Pranov, H; Haglind, F. Techno-economic analysis of a power generation system consisting of a foil-based concentrating solar collector and an organic Rankine cycle unit. In Proceedings of ECOS 2019: 32nd International Conference on Efficiency, Cost, Optimization, Simulation and Environmental Impact of Energy Systems., Wroclaw, Poland, 23-28 June 2019; Institute of Thermal Technology, Silesian University of Technology, Poland, 2019.

- Noč, L.; Ruiz-Zepeda, F.; Merzel, F.; Jerman, I. High-temperature “ion baseball” for enhancing concentrated solar power efficiency. Energy Mater. Sol. Cells 2019, 200, 109974, doi:10.1016/j.solmat.2019.109974.

- Seshie, Y.M.; N’Tsoukpoe, K.E.; Neveu, P.; Coulibaly, Y.; Azoumah, Y.K. Small scale concentrating solar plants for rural electrification. Sustain. Energy Rev. 2018, 90, 195–209, doi:10.1016/j.rser.2018.03.036.

- Cau, G.; Cocco, D.; Tola, V. Performance and cost assessment of Integrated Solar Combined Cycle Systems (ISCCSs) using CO2 as heat transfer fluid. Energy 2012, 86, 2975–2985, doi:10.1016/j.solener.2012.07.004.

- Letcher, T.M. Why wind energy? In Wind Energy Engineering: A Handbook for Onshore and Offshore Wind Turbines; Elsevier Inc.: Amsterdam, The Netherlands, 2017; pp. 3–14; ISBN 9780128094297.

- Kalmikov, A. Wind power fundamentals. In Wind Energy Engineering: A Handbook for Onshore and Offshore Wind Turbines; Elsevier Inc.: Amsterdam, The Netherlands, 2017; pp. 17–24; ISBN 9780128094297.

- Acarer, S. Peak lift-to-drag ratio enhancement of the DU12W262 airfoil by passive flow control and its impact on horizontal and vertical axis wind turbines. Energy 2020, 201, 117659, doi:10.1016/j.energy.2020.117659.

- James, P.A.B.; Bahaj, A.B.S. Small-scale wind turbines. In Wind Energy Engineering: A Handbook for Onshore and Offshore Wind Turbines; Elsevier Inc.: Amsterdam, The Netherlands, 2017; pp. 389–418; ISBN 9780128094297.

- Whittlesey, R. Vertical axis wind turbines: farm and turbine design. In Wind Energy Engineering: A Handbook for Onshore and Offshore Wind Turbines; Elsevier Inc.: Amsterdam, The Netherlands, 2017; pp. 185–202; ISBN 9780128094297.

- Wind Energy Factsheet. Center for Sustainable Systems. Available online: http://css.umich.edu/factsheets/wind-energy-factsheet (accessed on 4 August 2020).

- Sürgevil, T.; Akpınar, E. Modelling of a 5-kW wind energy conversion system with induction generator and comparison with experimental results. Energy 2005, 30, 913–929, doi:10.1016/j.renene.2004.09.002.

- Möllerström, E.; Gipe, P.; Beurskens, J.; Ottermo, F. A historical review of vertical axis wind turbines rated 100 kW and above. Sustain. Energy Rev. 2019, 105, 1–13, doi:10.1016/j.rser.2018.12.022.

- Wind Available online: https://www.irena.org/costs/Power-Generation-Costs/Wind-Power (accessed on 7 August 2020).

- Basu, P. Introduction. In Biomass Gasification, Pyrolysis and Torrefaction; Elsevier Inc.: Amsterdam, The Netherlands, 2013 pp. 1–27.

- Ashter, S.A. Biomass and its sources. In Technology and Applications of Polymers Derived from Biomass; Elsevier Inc.: Amsterdam, The Netherlands, 2018; pp. 11–36, doi:10.1016/b978-0-323-51115-5.00002-5.

- Garcia, R.; Pizarro, C.; Lavín, A.G.; Bueno, J.L. Biomass sources for thermal conversion. Techno-economical overview. Fuel 2017, 195, 182–189, doi:10.1016/j.fuel.2017.01.063.

- Bajwa, D.; Peterson, T.; Sharma, N.; Shojaeiarani, J.; Bajwa, S. A review of densified solid biomass for energy production. Sustain. Energy Rev. 2018, 96, 296–305, doi:10.1016/j.rser.2018.07.040.

- Situmorang, Y.A.; Zhao, Z.; Yoshida, A.; Abudula, A.; Guan, G. Small-scale biomass gasification systems for power generation (<200 kW class): A review. Sustain. Energy Rev. 2020, 117, 109486.

- Blondeau, J.; Museur, T.; Demaude, O.; Allard, P.; Turoni, F.; Mertens, J. Cost-effective flexibilisation of an 80 MW retrofitted biomass power plants: Improved combustion control dynamics using virtual air flow sensors. Case Stud. Therm. Eng. 2020, 21, 100680, doi:10.1016/j.csite.2020.100680.

- Hu, Z.; Wang, X.; Zhang, L.; Yang, S.; Ruan, R.; Bai, S.; Zhu, Y.; Wang, L.; Mikulčić, H.; Tan, H. Emission characteristics of particulate matters from a 30 MW biomass-fired power plant in China. Energy 2020, 155, 225–236, doi:10.1016/j.renene.2020.03.094.

- Li, P.; Sakuragi, K.; Makino, H. Extraction techniques in sustainable biofuel production: A concise review. Fuel Process. Technol. 2019, 193, 295–303, doi:10.1016/j.fuproc.2019.05.009.

- Hassan, S.; Williams, G.A.; Jaiswal, A. Moving towards the second generation of lignocellulosic biorefineries in the EU: Drivers, challenges, and opportunities. Sustain. Energy Rev. 2019, 101, 590–599, doi:10.1016/j.rser.2018.11.041.

- Cesário, M.T.; Da Fonseca, M.M.R.; Marques, M.M.; De Almeida, M.C.M.; Da Fonseca, M.; De Almeida, M. Marine algal carbohydrates as carbon sources for the production of biochemicals and biomaterials. Adv. 2018, 36, 798–817, doi:10.1016/j.biotechadv.2018.02.006.

- Chen, H.; Wang, L.; Chen, H.; Wang, L. Pandect of practice unit and process engineering of biomass biochemical conversion. Biochem. Convers. Biomass 2017, 11–19, doi:10.1016/B978-0-12-802417-1.00002-8.

- Xu, F.; Li, Y. Biomass digestion. Sustain. Technol. 2017, 197–204, doi:10.1016/b978-0-12-409548-9.10108-3.

- Pang, S. Advances in thermochemical conversion of woody biomass to energy, fuels and chemicals. Adv. 2019, 37, 589–597, doi:10.1016/j.biotechadv.2018.11.004.

- Malico, I.; Pereira, R.N.; Gonçalves, A.C.; Sousa, A.M.O. Current status and future perspectives for energy production from solid biomass in the European industry. Sustain. Energy Rev. 2019, 112, 960–977, doi:10.1016/j.rser.2019.06.022.

- Wikberg, H.; Grönqvist, S.; Niemi, P.; Mikkelson, A.; Siika-Aho, M.; Kanerva, H.; Käsper, A.; Tamminen, T. Hydrothermal treatment followed by enzymatic hydrolysis and hydrothermal carbonization as means to valorise agro- and forest-based biomass residues. Technol. 2017, 235, 70–78, doi:10.1016/j.biortech.2017.03.095.

- Mousa, E.A.; Wang, C.; Riesbeck, J.; Larsson, M. Biomass applications in iron and steel industry: An overview of challenges and opportunities. Sustain. Energy Rev. 2016, 65, 1247–1266, doi:10.1016/j.rser.2016.07.061.

- Mandø, M. Direct combustion of biomass. Biomass Combust. Sci. Technol. Eng. 2013, 61–83, doi:10.1533/9780857097439.2.61.

- Sansaniwal, S.K.; Pal, K.; Rosen, M.; Tyagi, S. Recent advances in the development of biomass gasification technology: A comprehensive review. Sustain. Energy Rev. 2017, 72, 363–384, doi:10.1016/j.rser.2017.01.038.

- Mansfield, A.B.; Wooldridge, M.S. The effect of impurities on syngas combustion. Flame 2015, 162, 2286–2295, doi:10.1016/j.combustflame.2015.01.026.

- Yasin, M.; Cha, M.; Chang, I.S.; Atiyeh, H.K.; Munasinghe, P.; Khanal, S.K. Syngas fermentation into biofuels and biochemicals. Biofuels Altern. Feed. Convers. Process. Prod. Liq. Gaseous Biofuels 2019, 301–327, doi:10.1016/b978-0-12-816856-1.00013-0.

- Samiran, N.A.; Jaafar, M.N.M.; Ng, J.H.; Lam, S.S.; Chong, C.T. Progress in biomass gasification technique – With focus on Malaysian palm biomass for syngas production. Sustain. Energy Rev. 2016, 62, 1047–1062, doi:10.1016/j.rser.2016.04.049.

- Watson, J.; Zhang, Y.; Si, B.; Chen, W.-T.; De Souza, R. Gasification of biowaste: A critical review and outlooks. Sustain. Energy Rev. 2018, 83, 1–17, doi:10.1016/j.rser.2017.10.003.

- Hu, X.; Gholizadeh, M. Biomass pyrolysis: A review of the process development and challenges from initial researches up to the commercialisation stage. Energy Chem. 2019, 39, 109–143, doi:10.1016/j.jechem.2019.01.024.

- Hawash, S.; Farah, J.Y.; El-Diwani, G. Pyrolysis of agriculture wastes for bio-oil and char production. Anal. Appl. Pyrolysis 2017, 124, 369–372, doi:10.1016/j.jaap.2016.12.021.

- Al Asfar, J.; AlShwawra, A.; Abu Shaban, N.; Alrbai, M.; Qawasmeh, B.R.; Sakhrieh, A.; Hamdan, M.A.; Odeh, O. Thermodynamic analysis of a biomass-fired lab-scale power plant. Energy 2020, 194, 116843, doi:10.1016/j.energy.2019.116843.

- Bioenergy for Power. Available online: https://www.irena.org/costs/Power-Generation-Costs/Bioenergy- for-Power (accessed on 7 August 2020).

- Melikoglu, M. Geothermal energy in Turkey and around the World: A review of the literature and an analysis based on Turkey’s Vision 2023 energy targets. Sustain. Energy Rev. 2017, 76, 485–492, doi:10.1016/j.rser.2017.03.082.

- Malafeh, S.; Sharp, B. Role of royalties in sustainable geothermal energy development. Energy Policy 2015, 85, 235–242, doi:10.1016/j.enpol.2015.06.023.

- Lee, K.C. Classification of geothermal resources by exergy. Geothermics 2001, 30, 431–442, doi:10.1016/s0375-6505(00)00056-0.

- Nasruddin; Alhamid, M.I.; Daud, Y.; Surachman, A.; Sugiyono, A.; Aditya, H.; Mahlia, T. Potential of geothermal energy for electricity generation in Indonesia: A review. Sustain. Energy Rev. 2016, 53, 733–740, doi:10.1016/j.rser.2015.09.032.

- Zhu, J.; Hu, K.; Lu, X.; Huang, X.; Liu, K.; Wu, X. A review of geothermal energy resources, development, and applications in China: Current status and prospects. Energy 2015, 93, 466–483, doi:10.1016/j.energy.2015.08.098.

- Lund, J.W.; Freeston, D.H.; Boyd, T.L. Direct utilization of geothermal energy 2010 worldwide review. Geothermics 2011, 40, 159–180, doi:10.1016/j.geothermics.2011.07.004.

- Pantaleo, A.M.; Camporeale, S.M.; Miliozzi, A.; Russo, V.; Shah, N.; Markides, C.N. Novel hybrid CSP-biomass CHP for flexible generation: Thermo-economic analysis and profitability assessment. Energy 2017, 204, 994–1006, doi:10.1016/j.apenergy.2017.05.019.

- Chamorro, C.R.; Mondéjar, M.E.; Ramos, R.; Segovia, J.J.; Martín, M.C.; Villamañán, M.A. World geothermal power production status: Energy, environmental and economic study of high enthalpy technologies. Energy 2012, 42, 10–18, doi:10.1016/j.energy.2011.06.005.

- Zarrouk, S.J.; Moon, H. Efficiency of geothermal power plants: A worldwide review. Geothermics 2014, 51, 142–153, doi:10.1016/j.geothermics.2013.11.001.

- Li, K.; Liu, C.; Jiang, S.; Chen, Y. Review on hybrid geothermal and solar power systems. Clean. Prod. 2020, 250, 119481, doi:10.1016/j.jclepro.2019.119481.

- Geothermal Available online: https://www.irena.org/costs/Power-Generation-Costs/Geothermal- Power (accessed on 7 August 2020).

- Hamacher, T. Hydrogen and Fuel Cell: Technologies and Market Perspectives; Töpler, J., Lehmann, J., Eds.; Springer Verlag: Berlin/Heidelberg, Germany, 2014; ISBN 9783662449714.

- Colbertaldo, P.; Agustin, S.B.; Campanari, S.; Brouwer, J. Impact of hydrogen energy storage on California electric power system: Towards 100% renewable electricity. J. Hydrog. Energy 2019, 44, 9558–9576, doi:10.1016/j.ijhydene.2018.11.062.

- Mayyas, A.T.; Wei, M.; Levis, G. Hydrogen as a long-term, large-scale energy storage solution when coupled with renewable energy sources or grids with dynamic electricity pricing schemes. J. Hydrog. Energy 2020, 45, 16311–16325, doi:10.1016/j.ijhydene.2020.04.163.

- Juangsa, F.B.; Prananto, L.A.; Mufrodi, Z.; Budiman, A.; Oda, T.; Aziz, M. Highly energy-efficient combination of dehydrogenation of methylcyclohexane and hydrogen-based power generation. Energy 2018, 226, 31–38, doi:10.1016/j.apenergy.2018.05.110.

- Sanz, W.; Braun, M.; Jericha, H.; Platzer, M.F. Adapting the zero-emission Graz Cycle for hydrogen combustion and investigation of its part load behavior. J. Hydrog. Energy 2018, 43, 5737–5746, doi:10.1016/j.ijhydene.2018.01.162.

- Barakat, M.R.; Tala-Ighil, B.; Gualous, H.; Hissel, D. Modeling of a hybrid marine current-hydrogen active power generation system. J. Hydrog. Energy 2019, 44, 9621–9635, doi:10.1016/j.ijhydene.2018.10.020.

- Lin, C.; Wu, S.Y.; Lee, K.S.; Lin, P.J.; Chang, J.S. Integration of fermentative hydrogen process and fuel cell for on-line electricity generation. J. Hydrog. Energy 2007, 32, 802–808, doi:10.1016/j.ijhydene.2006.09.047.

- Ferreira-Aparicio, P.; Chaparro, A.M. Why Portable Electricity with Hydrogen Fuel Cells?; Elsevier Inc.: Amsterdam, The Netherlands, 2018; ISBN 9780128131282.

- HYFLEXPOWER: The World’s First Integrated Power-to-X-to-Power Hydrogen Gas Turbine Demonstrator. Press Company Siemens. Available online: https://press.siemens.com/global/en/ pressrelease/hyflexpower-worlds-first-integrated-power-x-power-hydrogen-gas-turbine-demonstrator (accessed on 9 June 2020).

- Muradov, N. Low to near-zero CO2 production of hydrogen from fossil fuels: Status and perspectives. J. Hydrog. Energy 2017, 42, 14058–14088, doi:10.1016/j.ijhydene.2017.04.101.

- Hori, M.; Matsui, K.; Tashimo, M.; Yasuda, I. Synergistic hydrogen production by nuclear-heated steam reforming of fossil fuels. Nucl. Energy 2005, 47, 519–526, doi:10.1016/j.pnucene.2005.05.053.

- Wang, M.; Wang, G.; Sun, Z.; Zhang, Y.; Xu, D. Review of renewable energy-based hydrogen production processes for sustainable energy innovation. Energy Interconnect. 2019, 2, 436–443, doi:10.1016/j.gloei.2019.11.019.

- Parthasarathy, P.; Narayanan, K.S. Hydrogen production from steam gasification of biomass: Influence of process parameters on hydrogen yield—A review. Energy 2014, 66, 570–579, doi:10.1016/j.renene.2013.12.025.

- Chaubey, R.; Sahu, S.; James, O.O.; Maity, S. A review on development of industrial processes and emerging techniques for production of hydrogen from renewable and sustainable sources. Sustain. Energy Rev. 2013, 23, 443–462, doi:10.1016/j.rser.2013.02.019.

- Liu, Y.; Lin, R.; Man, Y.; Ren, J. Recent developments of hydrogen production from sewage sludge by biological and thermochemical process. J. Hydrog. Energy 2019, 44, 19676–19697, doi:10.1016/j.ijhydene.2019.06.044.

- Van Biert, L.; Godjevac, M.; Visser, K.; Aravind, P. A review of fuel cell systems for maritime applications. Power Sources 2016, 327, 345–364, doi:10.1016/j.jpowsour.2016.07.007.

- Santoro, C.; Arbizzani, C.; Erable, B.; Ieropoulos, I. Microbial fuel cells: From fundamentals to applications. A review. Power Sources 2017, 356, 225–244, doi:10.1016/j.jpowsour.2017.03.109.

- Path to hydrogen competitiveness: a cost perspective. Available online: https://hydrogencouncil.com/wp-content/uploads/2020/01/Path-to-Hydrogen-Competitiveness_Full-Study-1.pdf (accessed on 31 August 2020).

- Ferrero, D.; Gamba, M.; Lanzini, A.; Santarelli, M. Power-to-gas hydrogen: Techno-economic assessment of processes towards a multi-purpose energy carrier. In Energy Procedia, Proceedings of the 71st Conference of the Italian Thermal Machines Engineering Association (ATI); Turin, Italy, 14 – 16 September 2016; Elsevier Ltd. : Amsterdam, The Netherlands, 2016; Volume 101, pp. 50–57.