Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 1 by Zichong Lyu and Version 2 by Amina Yu.

Logistics problems involve a large number of complexities, which makes the development of models challenging. While computer simulation models are developed for addressing complexities, it is essential to ensure that the necessary operational behaviours are captured, and that the architecture of the model is suitable to represent them. The early stage of simulation modelling, known as conceptual modelling (CM), is thus dependent on successfully extracting tacit operational knowledge and avoiding misunderstanding between the client (customer of the model) and simulation analyst.

- simulation conceptual modelling

- discrete-event simulation

- agile method

- freight logistics

1. Introduction

Logistics problems involve a large number of complexities. These are introduced by the variety in vehicle fleet composition [1], vehicle allocation and routing [2], shipment consolidation and dispatching [3], diverse types of infrastructure, network design [4], day-to-day variability of customer consignments, difficulty of obtaining accurate parameter data [5], and complex operational systems [6]. Computer simulation methods including agent-based simulation (ABS), system dynamics (SD) and discrete-event simulation (DES) have been used to deal with randomness. They can represent the behaviour of logistics transportation systems with randomness: the process workflow; logical structure and decision modules; parameters of different types; stochastic uncertainty; interactions between agents; availability of resources; long-haul and short-haul, and so onetc. Long-haul refers to intercity transport between depots/warehouses, and short-haul is pickup and delivery between customer locations and the depot/warehouse. However, a model must be created before it can be interrogated for results, and the complexity of logistics problems makes this a difficult undertaking.

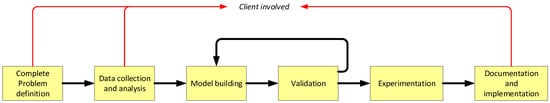

Conceptual modelling (CM) is the most crucial and challenging part of simulation modelling because it determines the structure and accuracy of the future model [7][8][7,8]. It provides the initial layout of the model, and increases the validity of the final model [9][10][9,10]. There are three main issues in the early modelling stage or the conceptual modelling stage. The first is to design the architecture of the model [11], include the necessary factors, solicit the tacit knowledge, and ensure the model is extendable and refinable. The second is to obtain data on the various parameters and apply them to the simulation. The last is to validate the model, especially from the operational perspective [12]. Inadequacies in any of these stages may lead to technical debt in the future phases.

The data approach involves the industry client providing the simulation analyst with the data. Disadvantages of the conventional approach are the sometimes-unreasonable information burden placed on the client and the introduction of errors into the model due to undetected deficiencies in problem definition and data. Consequently, there is a risk of technical debt occurring, whereby the deficiencies are structurally incorporated into the architecture of the model, which then may have to be substantially reworked at a future time. Structural changes to models are effortful to change later because the validation partly depends on the structure of the model. This is because any validation process involves an element of tuning of parameters, and those parameters are determined by the structure of the model. Hence, reformulating the model at a future date involves changes to the tuneable parameters, and therefore a need for revalidation. Communication and collaboration with the client are necessary for model definition and validation. Client participation and facilitation improve the quality of the model, but can lead to other issues such as problems in gathering sufficient data [13], paradigm incommensurability, and cognitive difficulty [14].

Current methods for conceptual modelling have several weaknesses. First, there is a scarcity of simulation models with a systematic and explicit method for involving communication and collaboration with the client. Previous models including participative modelling and facilitated modelling have been proposed to alleviate these issues [13][15][13,15]. These methods mainly focus on client involvement rather than the model itself. Second, issues such as knowledge boundaries and tacit knowledge elicitation are seldom explicitly included, at least not in the simulation onliterature. Third, client engagement is complex in terms of model definition, data acquisition, and data validation. There is a need for better methods to solve multiple information issues. Fourth, the process for transforming the conceptual model into a detailed model is not always clear.

2. Methods for Solving Logistics Problems

Logistics transportation problems can be categorised into long-haul (intercity transport between depots/warehouses) and short-haul (pickup and delivery between client location and depot/warehouse). Typical problems, which apply to both long- and short-haul differently, include vehicle allocation problems, vehicle routing problems, shipment consolidation and dispatching problems, and network design problems [3].2.1. Analytical Methods

Operations problems of simple to medium complexity may be solved by analytical methods such as linear programming and regression analysis. Mixed-integer linear programming is a prevalent mathematical optimisation method that includes objective functions and constraints. This method is frequently applied to transportation problems; e.g., in multimodal transport [16][17][16,17], scheduling [18][19][18,19], rail transport systems [20], and transport energy analysis [21]. Although analytical models can be quickly developed, there are several limitations of these models. One limitation is the difficulty in describing dynamic and transient effects. Additionally, analytical models are limited to simulating randomness of the system due to the complexity of the calculations [6], so these models normally simplify real problems. For example, for routing models, analytical techniques lack considerations of path constraints and practical scheduling of vehicles [22]. Moreover, clients may struggle to interact with these models due to the mathematical formulations.2.2. Computer Simulation Methods

Typical simulation approaches here include ABS, SD, and DES. ABS focuses on individual entities who make their own decisions; whereas DES concentrates on system analysis, and the process relies on model architecture. Therefore, from the perspective of consultation and collaboration between simulation analysts and industrial clients, DES is more straightforward, and has been widely implemented [23]. Table 1 summarises recent applications of simulations in logistics. Typical DES software includes Arena, SIEMENS Plant Simulation, and SIMUL8. These use program diagrams with logic to mimic real operational procedures [24]. Compared with traditional mathematical models, simulation models are able to analyse stochastic events by including logic functions (decision modules) and probability distributions (using Monte Carlo methods), so uncertainties such as delay time, arrival time, and arrival rate can be reflected in the system. Once the model is validated, simulations can quickly analyse different scenarios.Table 1.

Applications of ABS and DES on logistics.

| Logistics Areas | Problems | Methods |

|---|---|---|

| Truck platoon planning | Investigate truck platoon possibilities and evaluate waiting times [1] | ABS |

| Freight operations | Evaluate freight-unloading operations [25] Freight pickup and delivery [26] |

DES DES |

| Multimodal and intermodal transport | Analyse multimodal freight-routing system [27] | DES |

| Railway network design | Avoid collisions [28] | ABS |

| Analyse queuing systems of rail network [4] | DES | |

| Rail yard design | Design rail transhipment yard [29] | ABS |

| Evaluate processing capabilities of rail yard [30] | DES | |

| Integrate high-speed rail lines with conventional railways [31] | DES | |

| Port operations | Simulate container logistics [32] | DES |

| Supply chain management | Estimate last-mile distance [33] | DES |

| Conduct inventory analysis [34] | DES |