Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 1 by Jianqing Wu and Version 2 by Conner Chen.

Road defects are important factors affecting traffic safety. In order to improve the identification efficiency of road diseases and the pertinence of maintenance and management, intelligent detection technologies of road diseases have been developed. The problems of high cost and low efficiency of artificial inspection of road diseases are solved efficiently, and the quality of road construction is improved availably. This is not only the guarantee of highway quality but also the guarantee of people’s lives and safety.

- intelligent transportation

- defects detection

1. Introduction

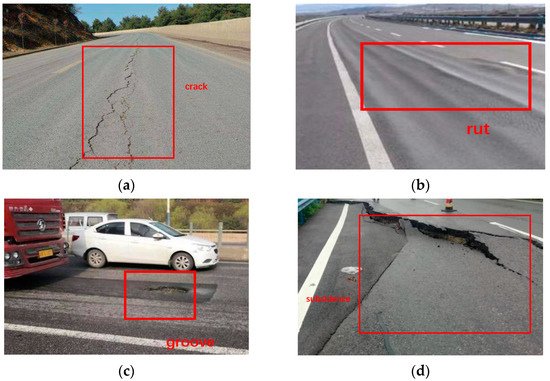

The quality of roads can directly affect the development of the city. With the erosion of roads caused by rain and vehicles, various defects may appear on the road surface, such as cracks, ruts, grooves, and subsidence [1]. The common types of pavement defects are shown in Figure 1.

Figure 1.

(

a

) The diagram of crack; (

b

) The diagram of rut; (

c

) The diagram of groove; (

d

) The diagram of subsidence.

Cracks are one of the most common diseases on the pavement. It mainly has transverse cracks, longitudinal cracks, and reticular cracks. It is extremely harmful to the road surface. Especially in winter and spring, due to the infiltration of rain and snow water, the road disease that is already in a crack state is more serious under the action of driving load [2]. Ruts are the permanent grooves in the road surface under the repeated action of vehicle loads [3]. This is mainly due to the unreasonable design of the asphalt mixture gradation or insufficient compaction during construction. This can make the road surface drainage poorly on rainy days, and the driving vehicle is prone to drifting and affecting the safety of high-speed driving. The grooves [4] are mainly formed due to the lack of timely maintenance after the surface layer is cracked, which has the potential to cause a flat tire in a moving vehicle and cause a traffic accident. These defects can bring damage to the vehicles on the road. Uneven or irregular roads can lead to tire wear. What is more, it can lead to a flat tire and cause a traffic accident. To ensure driving safety, the funding for road maintenance is increasing every year [5]. Identifying road defects timely is important for pavement maintenance. Manual inspection is intuitive with the high cost and low efficiency. In order to solve this problem, various intelligent detection methods for road surface defects detection have been developed [6]. However, there is a lack of studies summarizing the advantage and disadvantages of those intelligent detection methods.

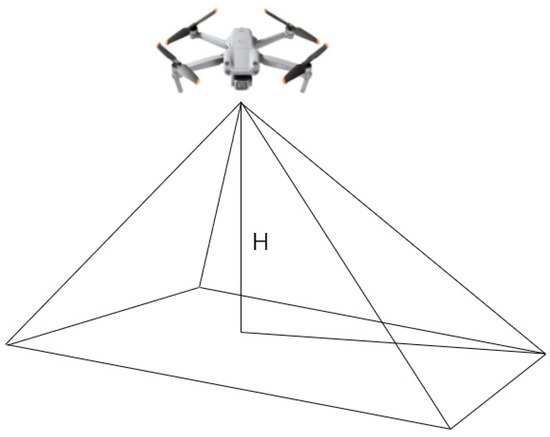

2. Camera

Many researchers used cameras for pavement image collection [7][8][9][10][11][11,12,13,14,15]. The image can then be used for pavement texture analysis [12][16], pavement crack detection [13][17], and asphalt mixture crack detection [14][18]. Y. Du et al. [15][19] collected a large number of pavement defect images, including timestamp and location information, using car-mounted cameras. Repeated collection and overlapping of pavement defects images were found during the collection process. Therefore, a feature matching and image mosaic method for pavement disease detection based on multi-vehicle images was proposed. Tang [16][20] developed intelligent road inspection equipment with existing road inspection vehicles installed with cameras. The qualitative and quantitative assessment of road surface quality can be then achieved. Du et al. [17][21] used the high-resolution industrial cameras installed on vehicles to collect pavement images. The detection and classification method of pavement diseases based on the You Only Look Once (YOLO) network was combined. Grabowski, D. et al. [18][22] proposed a method for estimating pavement conditions based on images obtained from onboard cameras. A set of algorithms was created to process images from depth cameras and RGB (red, green, blue) cameras. The neural network model was trained by video samples from the camera for road defects classification. Studies showed that the processing accuracy of the application of digital image processing technology reached more than 80%. Jahanshahi, M. R. et al. [19][23] used RGB-D sensors to detect and quantify pavement defects. The sensor system consisted of an RGB color image, an infrared projector, and a camera as a depth sensor. Combined with the corresponding algorithm, the automatic detection of road diseases such as cracks and potholes can be completed. In addition, the global positioning system was combined with the proposed system to locate the detected defects. It can be used as an auxiliary sensor system for road surface assessment vehicles. Cui, X et al. [20][24] used profiling and digital image technology to achieve a three-dimensional reconstruction of asphalt pavement contours. Image processing technology helped to locate the precise coordinates of each point on the model. According to the contour method, a comprehensive calculation program for texture depth was established. With the development of unmanned aerial vehicles (UAVs), more and more pavement engineers or researchers are starting to install cameras on UAVs for the detection of various road diseases [21][22][23][25,26,27], as shown in Figure 23. Junqing, Z. et al. [24][28] proposed that the road detects information were collected by drones using high-resolution cameras. A drone platform for road surface image acquisition was assembled, and the flight settings were studied to obtain optimal image quality. The acquired images were processed and annotated for model training. Combined with the YOLOv3 algorithm, the average accuracy (MAP) of data processing was 56.6%. Zhijian, M. et al. [25][29] analyzed the development technology of unmanned aerial vehicles in the field of intelligent transportation to improve the accuracy of road surface disease detection. A framework for road disease recognition and perception based on drones was constructed. The Yuneec H520 UAV was used to collect road surface image data, and the road surface disease image preprocessing technology based on wavelet threshold transformation was analyzed. Inzerillo, L. et al. [26][30] used data collected by drones to analyze structural self-motion (SfM) techniques at different heights. This technology was applied to old pavements on the campus of the University of Palermo. The technology accurately identified pavement diseases and developed an integrated approach to optimizing pavement management strategies.

Figure 23.

Aerial model of a drone.

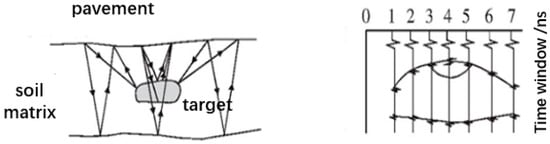

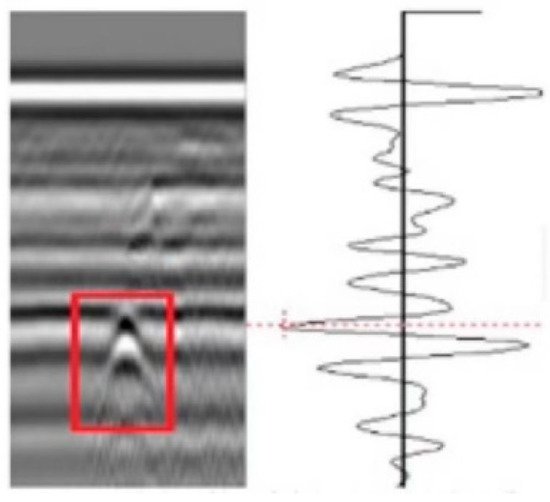

3. GPR

Compared to the camera, GPR detection technology [29][30][33,34] is more efficient for identifying roadbed diseases. This method does not need to destroy or excavate road surfaces and can effectively overcome the concealment of roadbed diseases. Road disease detection is an important basis for road maintenance and maintenance. Although the conventional drill core sampling method can achieve the purpose of pavement inspection, the detection results of this method are not comprehensive, and the damage to the pavement is large. As an efficient non-destructive testing technology, ground-penetrating radar offers the possibility of non-destructive testing of road diseases. Zhu et al. [31][35] discussed the effects of diseases such as road surface reflection cracks, subsidence, and uneven pavement on ground-penetrating radar image results, as shown in Figure 34 and Figure 45. Based on the influence of diseases on the image results of ground-penetrating radar and the detection results of ground-penetrating radar, the types and causes of road lesions in a certain section of the highway were successfully analyzed. Gao, J. et al. [32][36] used ground-penetrating radar (GPR) for road surface damage detection. Data processing in conjunction with the faster R-ConvNet algorithm to complete the task. The results showed that the accuracy was 89.13%. The stability of this model was better under different road structures. One of the problems encountered when conducting non-destructive testing of the road surface with ground-penetrating radar is the detection of multi-layered reflectors in the echoes of ground-penetrating radar. Lahouar, S. et al. [33][37] solved this problem by iteratively detecting strong reflections in GPR signals by using threshold or match filter detectors. The detected pulses were then used in the reflection model to synthesize a signal that is “similar” to the measured ground-penetrating radar signal in the least-squares sense. The synthesized signal was then subtracted from the measured signal to show the faint reflections that were masked. Then these reflections were detected iteratively using the same method. After testing, the study can be successful in disease detection. To test and evaluate the field application effect of asphalt pavement ground-penetrating radar rapid detection technology, Zhang et al. [34][38] conducted on-site test research based on the key points and implementation process of on-site detection technology. They relied on physical engineering and analyzed the accuracy of the detection results. The results showed that the compaction of the asphalt surface layer detected by ground-penetrating radar on-site was relatively accurate. The relative error can be controlled by 1%. The on-site detection results of the pavement disease ground penetrating radar were consistent with the scoring results, and the scanning image of the ground-penetrating radar can clearly reflect the structural condition of the asphalt pavement. To study the defect detection and identification of the road surface by ground-penetrating radar (GPR), Huang et al. [35][39] proposed a method with obvious effects on improving abnormal resolution and singular value decomposition by embedding metal plates at the interface of each layer in the surface of the road surface. It was applied to road field detection. The results showed that this can reduce the amount of work processing data and increase the accuracy of the detection.

Figure 34.

GPR detection process.

Figure 45.

Image of flaw reflection echo on GPR.

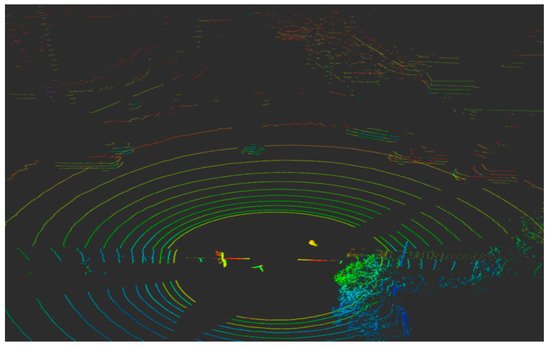

4. LiDAR

LiDAR is an emerging device for road surface defects detection with the unique advantages of high precision, high resolution, high automation, and high efficiency [41][42][45,46], as shown in Figure 56.

Figure 56.

Point cloud data collected by LiDAR.

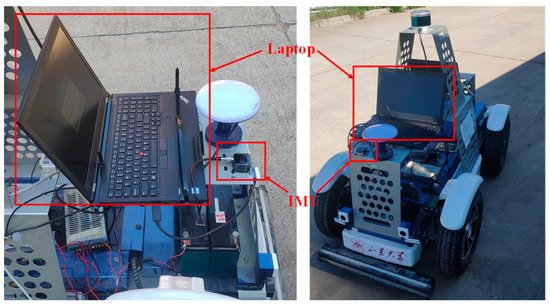

5. IMU

The IMU installed on the detection vehicle can detect whether the road surface is damaged by analyzing the data of the acceleration sensor, angular velocity sensor, and other components [56][57][58][60,61,62], as shown in Figure 67. Acceleration changes, angular velocity changes, and attitude changes in the process of vehicle movement can all be collected by IMU, which requires a small amount of calculation and can achieve high accuracy [59][60][61][63,64,65].

Figure 67.

IMU fixed to the inspection vehicle.