1. Introduction

Continuous casting practices for steelmaking have been constantly evolving ever since the early 1930s, when Junghans was first researching ways to pour liquid steel into an open-bottomed, water-cooled mold, to withdraw the partially solidified steel out of it, continuously, in the form of a round or square billet or slab

[1,2]. He envisioned that once these continuously cast shapes had become fully frozen, their solidified ends could be cut off for further processing. In this way, they could be transformed into “rebar” to reinforce concrete, or into bars from which nails, bolts, tire cord wire, etc., could be fashioned,

or into slabs, from which sheet

steel products could be fashioned by rolling mills, etcc. Reference

[1] 1, edited by Dr. Manfred Rasch, contains detailed articles from many of the key companies, personnel, and timelines of events in his review of the development of continuous casting practices for steel, beginning with Sir Henry Bessemer (1813–1898), and followed by Siegfried Junghans (1887–1954).

Historical developments in North America are covered in [2]Thus, the underlying goal of Junghans’ early research was to try to replace the static mold ingot casting systems used in virtually all steel plants up until the 1960s with a continuous process. This would effectively eliminate the ~10–20% losses associated with the “top and tailing” of the thick ingots (up to ~30, or 760 mm) typically being produced. Thus, after the cast ingots had cooled sufficiently (~5 h), to allow them to be safely withdrawn from their ingot molds, they were sent, still partially molten inside, to the soaking pits for temperature homogenization. This could last from approximately 10 h for a hot ingot, or up to 18 h for a cold, ingot. During this treatment time, the micro-segregation of solute elements (C, S, P, Mn, etc.) could be mitigated within the inter-dendritic solidification structure. In the meantime, temperature profiles within the ingot had become uniform, to ~±2 °C, ready for rolling down to semi-finished products. Thus, after proper soaking, the eight or more ingots within the soaking pit would be ready for transfer to the adjacent hot mill for rolling into “flat” or “long” products at temperatures of around 1100 °C.

First, the ingots were sent to the “roughing mill” for ingot “break down”. This was accomplished by passing them back and forth under the roughing mill, thereby transforming the original 25–30 inch thick ingot (635–760 mm) into a long, 1–2” (25–50 mm) thick “transfer bar”. This bar then had to be “topped” and “tailed”’ to eliminate the rolled-in surfaces at the transfer bar’s extremities, where surface overlap had occurred during compression and thickness reduction to 30 mm or ~2–3 inches. Similarly, any macroscopic shrinkage holes formed during solidification also needed topping before sending the transfer bar to the stands of the rolling mill. All of this automatically led to a mandatory 10–15% loss in steel yield.

Therefore, for sheet steel products, following a further removal of iron oxide skin from the transfer bars using high velocity, high- pressure water jets just ahead of a six- or seven-stand hot rolling mill, the transfer bars were reduced to much thinner hot rolled steel sheet products, ~1–3 mm thick, using appropriate cooling schedules to create the specific hot grades being targeted (e.g., HSLA, etc.).

Clearly, Junghans’ research, which lead to the Conventional Continuous Casting (CCC) method, promised to eliminate much of the material losses associated with the ingot casting approach, and thereby produce a step-up increase in steel productivity.

However, approximately seventy-odd years before Junghans’ early research work, Henry Bessemer, inventor of the first tonnage steel process, had proposed a far more elegant process to cast liquid steel into near-net shape products, namely the Twin Roll Casting (TRC) process. He envisioned pouring liquid steel into the cavity produced by a twin set of contra-rotating rolls to freeze the exiting steel directly into ~1–2 mm thick sheet steel products. Following minimal rolling and heat treatment, this would be ready for sale. While many researchers had since tried to fulfill Bessemer’s twin-roll casting “dream” and produce a commercial system for thin steel sheet production over the ensuing century before Junghans’ research work, none had succeeded in producing high-quality sheets of steel.

His TBC system was approximately ten times more productive and proved to be a commercial success for copper, lead and zinc alloys, and certain grades of aluminum and magnesium alloys. TBC casters are now in worldwide use within the non-ferrous industry, but not for casting liquid steel. Previous attempts by Hazelett Strip Casting Corp., in collaboration with Sumitomo Metals Corporation, and earlier with U.S Steel/Bethlehem Steel in the 1980s, had failed to develop a satisfactory commercial system for the steel industry.

Therefore, today, the dominant casting process within the steel industry is the Conventional Continuous Caster (CCC), as developed by Rossi and partners with their CONCAST Corporations in Europe and the USA, following Junghans’ death and Rossi’s sole acquisition of patent rights from Junghans’ widow

[1,2].

2. The Past

Thus, thanks to the initial research efforts and work carried out by Siegfried Junghans (1887–1954) in Germany, aimed at eliminating the wastage caused by the ingot casting process, a disruptive paradigm was brought to the steel industry. Thus,

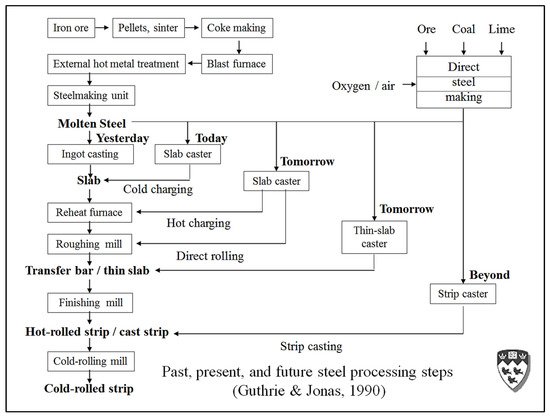

Figure 1 illustrates the evolutionary sweep in continuous casting developments ever since that seismic change from ingot casting technologies to CCC

[3] [3].

It began in the 1950s, following the first designs of continuous casting machines by CONCAST. These casters were developed in collaboration with some early companies and their dedicated researchers, who recognized the important economic implications deriving from this new type of casting machine

[1]. For the fixed CCC approach, the formulations for mold powders are important for protecting the surface of molten steel from significant heat losses and by remaining molten at ~900 °C to provide lubrication between the surface of the forming slab and the oscillating walls of the copper mold.

A key role in the development of the continuous casting method was played by Iain Halliday at Barrow Steel Works, in Scotland. He perfected the Junghans–Rossi oscillation mode (i.e., three-quarters of the cycle down and one quarter up), by imposing a relative velocity during the down-stroke, with the mold going down slightly faster than the strand, which he termed “negative strip”. This invention helped to resolve the sticking of the growing frozen steel shell onto the copper mold and allowed him to reach casting speeds of 14.5 m/min in 1958. This casting speed is still a world record for these “fixed or stationary” mold technologies. Conventional continuous casting machines, nearing process perfection in recent years, allow partially solidified slabs, blooms, or billets, to be continuously withdrawn through their open-bottomed molds, at productivity levels equivalent to ingot casting technology, but with a 10–15% yield advantage. Some 1.8 billion tons per year are now cast through them.

Thus, the growing steel industries in Japan and Korea in the 1960s, as well as the well-established companies in the Nordic countries, were the first to adopt this new way of casting. Asian countries went on to become dominant global players in CCC, exporting much of their steel abroad, including to North America. Meantime, many conventional integrated steel plants in North America gradually walked into bankruptcy, some even before being able to adopt this new technology. For example, Dofasco escaped by the skin of its teeth thanks to the warnings and the advice of Dr. Dante Cosma of their Research Department to the President of the Company, Mr. Frank Sherman. He heeded Dante’s advice over that of all the other “experts” within his company and canceled the new ingot casting aisle midway through construction. Nonetheless, approximately ten years later, Dofasco could not escape the clutches of ArcelorMittal (AM) in the “race to the bottom” at the start of the second millennium. This take-over seems to have been achieved by selling off Dofasco’s valuable iron ore mines in Ontario and Quebec after having first acquired the company, thereby allowing AM to cover its initial expense for Dofasco’s acquisition. Naturally, the Board of Directors of Dofasco had already been handsomely rewarded in the original sale of the company.

Nonetheless, and fortunately for North America, the mini-mill concept and its first implementation in the new steelmaking plant built in Oshawa, Ontario, had been confirmed by Dr. Gerald Heffernan and his co-workers in ~1985

[2] [2]. This had been followed a couple or so years later by a succession of NUCOR plants being built in the countryside of the USA; as a new revolution in North America (N.A.), steelmaking practices began to take shape

[2] [2]. As such, many newer plants in N.A. have shifted away from the conventional blast furnace-BOF steelmaking model towards a 100% scrap-melting/continuous casting technology. Many of the recent continuous casting technologies now presented, were researched by the conventional integrated steel companies, but were brought into the steel industry through efforts by Minimills to invade the more lucrative niches for steel production. Nevertheless, to the authors’ knowledge, a

ll

most all the steel sheet products used for “body in white” automobiles remain within the exclusive domain of advanced C

onventional Continuous Casting (CCC) machinesCC steel plants around the world.

3. The Present (the 2020s)

3. The Present (2020s)

Referring to Figure 1, the left-hand side of the diagram shows the situation before the advent of continuous casting in the mid-1950s. North America’s first commercially successful vertical mold continuous casting machine was commissioned in 1954 to produce slabs of stainless steel at the Welland Plant of Atlas Steels in Ontario, Canada, using a “stick caster”. Today, all ingot casting has been eliminated worldwide, apart from some specialty steel applications.

For this new paradigm in casting technology, yield increases of approximately 10–15% have been achieved thanks to the successful development of slag-lubricated, oscillating, open-ended mold machines. These molds, and the behavior of their mold fluxes, are at the very heart of the various continuous casting machines dominating steel casting processes.

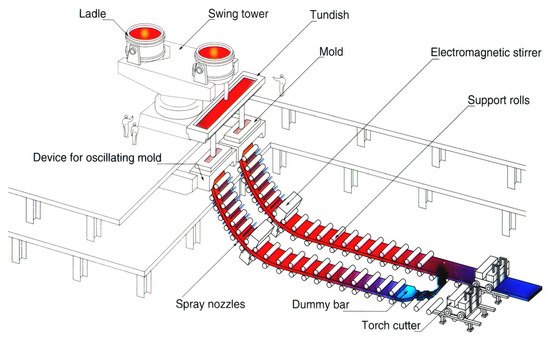

Figure 2 shows a conventional continuous casting

(CCC) operation comprising a tundish, a water-cooled, chromium-plated, copper alloy mold, a mold oscillator, a group of cast strand supporting rolls, rolls for bending and straightening the strand, rolls to pinch and withdraw the cast strands, groups of water spray nozzles to extract heat from the strand, a torch cutter for cutting the cast strand, and a dummy bar

[4]. This dummy bar fits in the bottom of the open mold at start-up, providing a starting base on which the strand can freeze. The dummy bar then extracts the cast strand, and finally moves away to “storage” once the forming strand has approached the torch cutter.

The overall set-up is generic, in that a “ladle” sits on a rotating “turret” or “swing tower” and empties liquid steel into a “tundish” set below via a protective ladle shroud (or tube). This tundish is used to distribute metal to one, two, four, six, or even eight oscillating molds/strands, set below. In the case of slab casting operations, it is common to have twin slab production. In the diagram, an SEN(Submerged Entry Nozzle) is used to protect the streams entering the mold from re-oxidation. Once the ladle has been emptied of steel, the tundish is allowed to drain while the turret rotates a newly filled ladle into position. In this way, “sequence”, or “continuous, continuous” casting can be achieved, with uninterrupted runs in the order of up to 1000 ladle changes being possible, using the flying tundish technique for the rapid replacement of a spent tundish.

Another popular type of fixed-mold conventional continuous caster is the “vertical, curved mold”-type caster, in which, the mold and support rolls are arranged vertically to maximize the chances for inclusions to float out of the deep sump of molten steel before being trapped in the solidifying shell. The strand is then bent and straightened to deliver the strand horizontally, and continuously. In comparison, the first “stick”, or vertical mold casters, froze single vertical strands in the same way as today’s DC (Direct Chill) casters for the aluminum industry. The fact that curved mold and low-head curved mold machines tend to capture a band of inclusions approximately mid-distance from the top surface of the strand, and its central axial plane, led to the popularity of the vertical-curved bending machine. In technically advanced steel mills, where surface quality is good (freedom from scabs, slivers, and deep oscillation marks), these slabs, blooms, and billets can be hot charged directly to a reheat furnace without surface inspection before further size reduction.

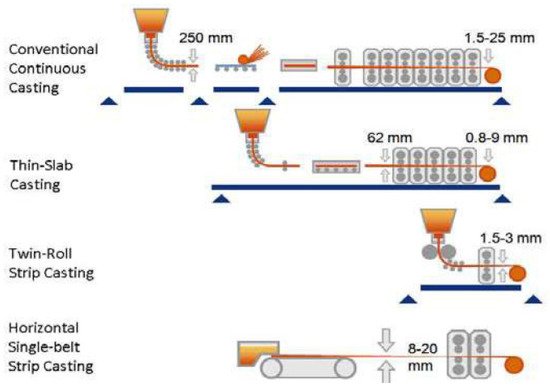

However, a certain amount of scale (iron oxides) will usually form on the slab’s surfaces during their time in the reheating furnace. This can be useful in moderation since surface blemishes can then be removed during passage through the high-powered water jets of the de-scaler. In the case of slabs for sheet products, a roughing mill then rolls the slab down to a “transfer bar” some 25–50 mm (1–2 ins) thick. In most current commercial operations for sheet production in integrated steel plants, the transfer bar is then fed into a six- or seven-stand hot strip mill, where a steel sheet, 1–4 mm thick, is produced at speeds approaching 15 m/s (3000 ft/min). Strip temperatures, alloy compositions, and rates of compression are all carefully controlled to manipulate the solid-state phase transformations and thereby optimize steel microstructures and attendant mechanical properties. Since the early adoption of CCC machines by the large integrated steel mills, there has been considerable pressure on reducing the capital and running costs of these mammoth steel plants. The first development in the commercial continuous casting of steel was the Thin Slab Caster (TSC) in 1985 [

1]. These casting machines, illustrated in

Figure 3, are aimed at servicing the rapidly growing EAF-based mini-mills in North America, thereby allowing them to enter the lucrative sheet metal market.

4. Thin Slab Casting, TSC

Thus, in the last thirty-odd years, progress towards the goal of process rationalization has been aided through the development of thin slab casting, which is also based on the fixed, oscillating mold. This development has allowed scrap-base-EAF mini-mills such as NUCOR to enter the flat products business

[2] [2].

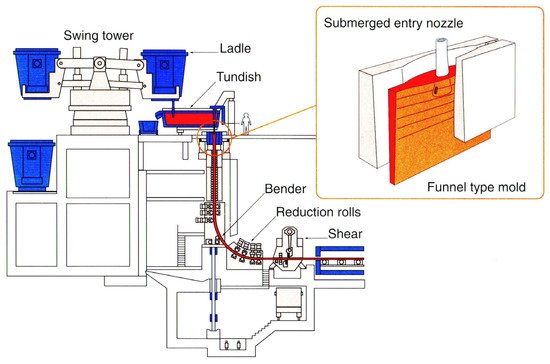

Thin slab casting technology eliminates the need for a conventional rougher/breakdown mill, followed by a seven-stand hot rolling mill, with a muffle furnace for temperature stabilization, followed by more modest in-line rolling requirements. As a result, an integrated line, comprising an advanced EAF-thin slab caster, can produce up to approximately 800,000 tons/year in facilities with lower investment costs, less manpower, and much-reduced energy consumption, compared to an integrated mill. Figure 4 illustrates the layout of such a machine and the funnel-shaped, tapered type of mold that allows for the placement of an SEN (Submerged Entry Nozzle) between its narrow faces. In all TSC cases, casting velocities ~5 m/min are needed to compete with the highly productive conventional casters typically running at 1.2–1.6 m/min.

A more recent approach by Arvedi

[5][6] is a bow-type, low head, endless strip production TSC, developed in 2009. It uses a straight tapered, 80 mm wide, oscillating, fixed mold. This new caster started operations in 2015 in Italy. Its key advantage is that it is an “endless caster”, or “Endless Strip Production” (ESP), capable of producing steel strip products endlessly. This means that there is no interruption between pouring liquid steel and producing the final hot strip in one continuous line. This leads to further increases in productivity and environmental benefits.

For instance, the ESP has demonstrated that mill threading can be suppressed, allowing the production of hot-rolled coils in thinner gauges, down to 0.8 mm hot-rolled (HR) strip products. These, in turn, can be used to form cold-rolled (CR) strips down to 200 microns, or 0.2 mm, suitable for electrical grades of steel, for instance. Other advantages claimed vs. standard TSC operations include a halving of operating costs and energy consumption.

5 NNSC Moving Mold Technologies for the Future

Meanwhile, as noted previously, ever since the 1860’s, there have been many efforts to fulfill the dream of Sir Henry Bessemer to cast steel strips directly from a pool of liquid steel using a twin-roll casting approach. Many consortia and companies had been doggedly researching the potential and characteristics of these Near Net Shape Casting (NNSC) machines for casting liquid steel. Finally, commercial success was achieved in ~ 2015, more than 150 years later, by CASTRIP (NUCOR/BHP/IHI). They reported success with a twin set of ~0.4m diam. rolls, contra-rotating at peripheral speeds of 1-2m/s, producing cast steel sheet of 2-0.7mm thickness, at ~300,000tonnes/year.[6]

However, since 1997, there has been an alternate process that was being researched by Prof. Klaus Schwerdtfeger and Aassociates in Clausthal, Germany[7], and by Promyself. Rod Guthrie and MMPC members, in Canada[8]. This is the Horizontal Single Belt Caster (HSBC) concept, which can be designed and matched to any required steel throughputs, using a horizontal, water-cooled belt, of appropriate length. This makes it ideal for integrated steel plants producing 2-6Mt/year. That is roughly 4 to 12 timesdouble or triple that achievable by the CASTRIP/ Bessemer Casting machines, which are suitable for 0.5Mt/year. Commercial success with this alternate NNSC process was achieved by Salzgitter Steel working with Mannesmann Demag, as machine builders, for casting steel sheet, 10-15mm thick, in ~2015, using a water-cooled belt, 10m long, and ~1.4m wide, running at ~12m/min. for a steel production of ~1Mt/yr.[9]

Similar results, at the pilot-scale, were achieved with the pilot-scale caster at MMPC/MetSim, in Montreal, researching the production of many alloys of aluminum (AA6111, AA2024, AA5182, etc.), copper alloys (Cu-Ni-Sn), and steels (TWIP, HSLA, TWIN, Fe-Si). By mid-2020, our experimental research activities were terminated, and the caster was acquired by Materion, in Elmore, USA, for commercial activities for copper alloy systems.

So, returning to Figures 1 and 3, one sees that the way forward for casting metals in the future is for significantly lower cost, more eco-friendly alternatives versus the conventional CCC and TSC casters of today. The clear difference between CCC and TSC machines vs NNSC machines is the thickness of the slab being cast. As NNSC casting aims to produce ~1-15mm thick cast sheet, this eliminates most casting defects arising from too- slow a solidification process. As such, macro-segregation and large grain sizes associated with the casting of 300 mm thick steel slabs, areis avoided. Similarly, NNSC even eliminates the inverse macro-segregation encountered in Direct Chill (DC) cast aluminum. However, this requires that the top and bottom surfaces remain completely flat during solidification. Salzgitter has proved that this is possible for 15mm cast sheet production. Finally, in producing the conventional ranges of microstructures presently in use, HSBC involves cooling rates of ~100oC/s, versus cooling rates ~1000oC/s cooling rates for liquid metal sheets produced by Twin Roll Casting (TRC). This has enormous implications for the range of microstructures, and properties of steels cast by the two processes. Further, HSBC involves no center-line porosity, etc., vs TRC, in that it represents unconstrained solidification. In this respect, it is superior to all the other casting processes, i.e. the CCC, the TSC, the TBC, and the versus the TBC, TRC, or Bessemer, Casting PTBC processes.

- Conclusions

One It can be considered fundamentally superior to the TSC ESP process, of Dr Giovanni Arvedi, which represents the apex of TSC advances, leading to many commercial advantages, as well as high-quality strip products suitable for the automobile industry.

6. Conclusions

One can conclude from this articonclude from above contente, that there is an inevitable convergence in the designs of fixed and moving mold casting machines towards the manufacture of steel sheets into one continuous process. The result will be shorter plants, less equipment, fewer personnel, and greater efficiencies. The Arvedi caster for steel [7], the ALCOA micro mill for aluminum alloys[10] [16], and the BCT-Belt Casting Technology (or HSBC)[7][8][11] [15] shprowve that these NNSC processes are technically possible and that they can drastically reduce manufacturing costs while significantly helping to address environmental concerns. As such, they could be poised to revolutionize the tonnage casting of steel and aluminum alloy sheet materials as a in disruptive technology, by removing all current bottlenecks to present-day systems and processes, at a fraction of current capital and operating cos. By the same token, we believe that it will be possible to make equivalent advances in the production of long products. It is only a matter of time, given the practicality and superiority of this Near Net Shape Casting ( NNSC) HSBC Process, for steelmakers to make the move away from CCC, to HSBC to accomplish the final logical steps toward the ideal NNSC approaches. Time will tell, but timing is everything!

References

- Rasch, M. Anmerkungen zur Fruhgeschichte des Stranggiebens. In Stranggieben—Continuous Casting; A Technical Revolution in the Steel Industry; Aschendorff Verlag: Münster, Germany, 2017; pp. 9–40.

- Guthrie, R.; Isac, M. The development of continuous casting machines for the production of steel in North America. In Continuous Casting; A Technical Revolution in the Steel Industry; Aschendorff, Verlag: Münster, Germany; 2017, pp. 283–288.

- Guthrie, R.I.L.; Jonas, J.J. Steel Processing Technology. In Metals Handbook, 10th ed.; Properties and Selection; ASM International: Materials Park, OH, USA, 1989; Volume 1, pp. 107–125.

- Monden, K. An Introduction to Iron and Steel Processing; Morita, Z., Emi, T., Enami, T., Hashimoto, O., Eds.; Kawasaki Steel 21st Century Foundation: Tokyo, Japan, 1997.

- (Sa GE, Mihaiela ISAC and Roderick Ian Lawrence GUTHRIE, Progress in Strip Casting Technologies for Steel; Technical Developments, ISIJ International, Vol. 53 (2013), No. 5, pp. 729–742).

- An Introduction to Iron and Steel Processing, 1997 Kawasaki Steel 21st Century Foundation, edited by Dr. Zen-ichiro Morita, and Dr. Toshihiko Emi, Chapter 6 Integrated of Advanced EAF, Thin Slab Caster and Strip Mill, page 6G, figure 6G

- Hohenbichler, G.; Mazzolari, F.; Linzer, B.; Jungbauer, A. Arvedi ESP Technology and Plant Design; Millenium Steel: Princeton, IN, USA, 2010; pp. 82–88.

- ForeCast; Volume II Issue 2; CASTRIP: Charlotte, NC, USA,

- New Technologies Could Slash the Cost of Steel Production. The Economist, 9 March 2017, Business Section—Recasting Steel.

- Isac, M.; Guthrie, R.I.L. Chapter 4.7: The design of a new casting process; from fundamentals to practice. In Treatise on Process Metallurgy; Elsevier Ltd.: Amsterdam, The Netherlands, 2014.; Volume 2, pp. 555–583.

- Spitzer, K-H.; Schwerdtfeger, K. Production of steel strip with a single-belt process. In Proceedings of the ISS 13th Process Technology Conference, Nashville, TN, USA, November 3-7, 1995; pp. 47–53.

- H. Spitzer, DSC Strip Casting: Process Development and Perspectives for New Materials, Proceedings of the Roderick Guthrie Honorary Symposium, on Process Metallurgy, published by McGill Metals Processing Centre, ISBN 978-0-986968-0-6, 2011, pp. 97–106.

- Ramirez-Lopez, P.E. Modelling Shell and Oscillation Mark Formation during Continuous Casting via Explicit Incorporation of Slag Infiltration. Ph.D. Thesis, Materials Department, Imperial College, London, UK, February 2010.

- Guthrie, R.I.L.; Isac, M.; Li, D. Ab Initio Predictions of Interfacial Heat Fluxes in Horizontal Single Belt Casting (HSBC), Incorporating Surface Texture and Air Gap Evolution. ISIJ Int. 2010, 50, 1805–1813.

- Spitzer, K.H. DSC Strip Casting: Process Development and Perspectives for New Materials. In Proceedings of the Roderick Guthrie Honorary Symposium on Process Metallurgy, Montreal, QC, Canada, 6–9 June 2011; McGill Metals Processing Centre: Montreal, QC, Canada, 2011, pp. 97–105, ISBN 978 0 986968 0 6.

- Faster, Stronger, Smarter. Introducing Arconic’s Micromill TM; YouTube 19 October 2016.

- Geerkins, C.; Fischer, L.; Wans, J.; Wilmes, R. High Productivity Plants and Innovative Technologies Meet Market Demands and Future Trends. In Proceedings of the Metec & 2nd ESTAD 2015, Dusseldorf, Germany, 15–19 June 2015.