Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 2 by Amina Yu and Version 1 by Ashoka Sriyani Gamage.

Starch is one of the most abundant biodegradable biopolymers from renewable sources; it also contains tunable thermoplastic properties suitable for diverse applications in agriculture. Functional performances of starch such as physicomechanical, barrier, and surface chemistry may be altered for extended agricultural applications. Furthermore, starch can be a multidimensional additive for plasticulture that can function as a filler, a metaphase component in blends/composites, a plasticizer, an efficient carrier for active delivery of biocides and so on.

- biodegradable polymers

- starch

1. Introduction

Fossil-derived plastics take more than 100 years to break down in the environment [232][1]. Even though various plastic waste-management systems have been proposed for mitigation, execution is somewhat challenging in plastic recycling, incineration, and disposal into landfills at the end of their service life. Mismanaged plastics create adverse impacts on the environment due to the generation of pollutant gases and toxic substances such as dioxins, furans [233][2], and endocrine disruptors [234][3], along with the production of leachate consisting of heavy metals that pollute water and soil. As a result, there is an alarming necessity for biodegradable plastics and expanding investigations on understanding the biodegradation pathways of biopolymers [235,236][4][5]. Petrochemical plastic production is over 400 million tons as of 2020 [237][6], and global bioplastic production is expected to exceed 7.5 tons in 2026 [238][7].

It is crucial to evaluate the biodegradability of agricultural polymers before using them in various processes and industrial applications. The American Society for Testing and Materials (ASTM), the European Committee for Standardization (EN), and the International Standards Organization (ISO) have established standardized tests to assess biodegradability and the degree of biodegradability of polymers [239,240][8][9]. Aerobic and anaerobic digestions are the main methods to define biodegradation assays and microbial activity that impact the decomposition rates into environmentally friendly components such as carbon dioxide, methane, water, biomass, and inorganic elements (sodium, potassium, phosphorous, and calcium) [241][10]. Another biodegradation assay evaluates ecotoxicity in various plants and animal species such as cress and earthworms [240][9]. Moreover, other standard methods evaluate biodegradability by using material exposure to specific microorganisms [242][11]. Such methods may be subjected to at least one or a few of the following evaluation methods of samples after the assay [240][9]: (a) molecular weight, (b) molecular weight distribution, (c) carbon dioxide and/or methane, (d) weight loss of the material, and (e) the visual observations of changes. In addition to the aforementioned items, different analytical techniques can be used to assess biodegradability, such as Fourier transform infrared spectroscopy, differential scanning calorimetry (DSC), nuclear magnetic resonance spectroscopy (NMR), X-ray photoelectron spectroscopy, scanning electron microscopy (SEM), atomic force microscopy (AFM), and X-ray diffraction. After the biodegradation, the tensile properties of polymers (tensile strain, tensile strength, elongation, and tensile modulus) are evaluated before and after comparison [242][11].

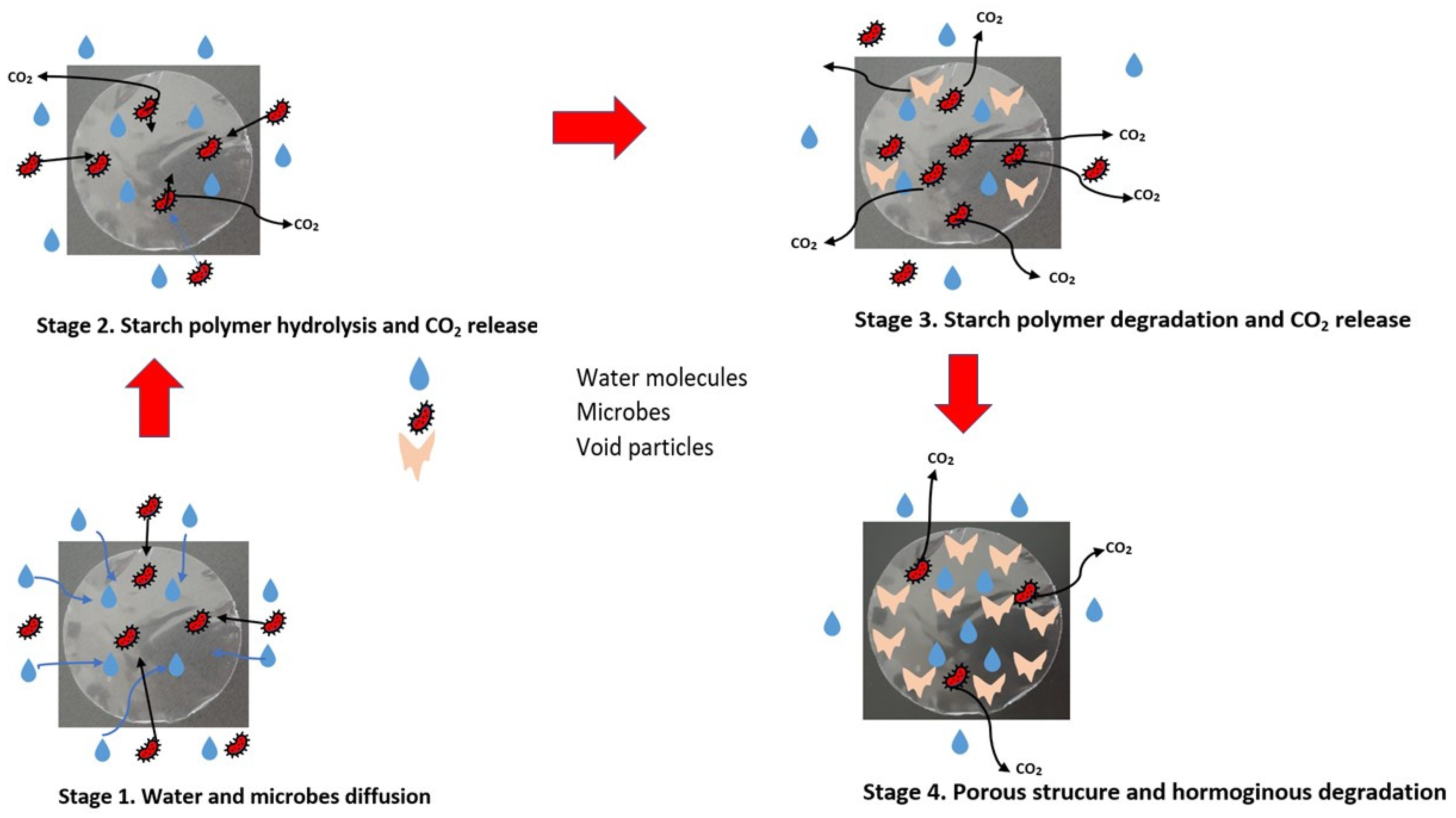

The degradation of starch and starch blends under natural conditions is a complex process that may be facilitated by water adsorption, hydrolysis, and polymer biodegradation [243,244][12][13]. There are three stages involved in biodegradation: biodeterioration, biofragmentation, and assimilation [245][14]. In soil and natural conditions, biodegradation is promoted by microorganisms and enzymes. Complete justification must be given to blends, composites, and surface-modified biodegradable materials due to the tendency to behave differently in biodegradation (Figure 91).

Figure 91.

Degradation of biodegradable cassava starch film in soil.

2. Biodegradation of Starch/PVA

Starch/PVA blends are of great importance in packaging and agricultural applications due to their high compatibility and excellent film properties [241][10]. Several studies have been conducted to investigate the biodegradability of starch/PVA blends while preparing various wheat starch/PVA/glycerol blends following the solution cast technique in complying with ISO 14855; they studilearned composting under degradation for 45 days. After allowing the blends to compost for 45 days, it was observed that starch and glycerol were degraded, leaving the PVA fraction intact. Moreover, the blend characteristics were enhanced without interfering with the biodegradation of starch from surface modification with chitosan [242][11]. Another studyone evaluated the biodegradation of PVA/starch blends using a 180-day assay and explained the biodegradation in terms of the changes in molecular weights. These blends had various amounts of cross-linked starch (CLS) compared to PVA blends with acid-modified starches (AMSs).

In similar research, the biodegradation of PVA/AMS blends improved with the increase in AMS percentage. PVA/AMS samples demonstrated a higher degree of biodegradation than PVA/CLS blends [243][12]. Degradation properties of blow molded PVA/starch films in aqueous anaerobic digestion were studilearned using sludge from municipal wastewater treatment. This studywas highlighted that the degradation of PVA blended with native or plasticized starch was significantly increased in terms of degradation rate and elevation, even at a low starch level of 5 wt% [244][13]. Furthermore, ithe study was reported a higher degree of biodegradation, up to 60%, with loading starch from 21% to 42%, and mechanical properties of starch-modified PVA were declined. Other studiess further assessed the anaerobic degradation of glycerol-plasticized and biopolymer such as starch, gellan gum, and xanthan [245][14].

Parallel research has further evaluated the biodegradability of some starch/PVA-blended films in soil environments using a 6-month soil burial test in which the weight loss over time was measured [246][15]. The results showed a better degradation of the citric acid-added films than those with glycerol added, and 80% of the total film degradation occurred with an increasing degradation rate while the rate of degradation was slow [246][15]. This rewasearch revealed that the biodegradability of starch/PVA-blended films that incorporated glacial acetic acid (crosslinking agent) in moist soils might take up to 30 days. ResearchIt was explainsed that the biodegradation rates of PVA-blended films were governed by moist vs. dry soil and the molecular weight (31 × 103 to 205 × 103 g/mole). It has been reported that degradation was initiated within 3 days in the moist soil, while in dry soils the initiation time of biodegradation increased from 10 to 14 days [247][16]. The effect of starch content on biodegradability starch/PVA films prepared using melt processing was further discussed in recent research [248][17]. In tThis study, the evaluation was carried out by determining the weight loss of specimens buried in soil for 30 days. With increasing starch fraction, the weight loss increased under the same burial test conditions as the highest value of weight loss of the films was obtained at the highest loading of starch in blends. Other researchers affirm the same trend that loading starch in PVA-blended films favors the biodegradation rate; up to 28% to 38% increase in biodegradation rate was achieved at 0–30 wt% loading of starch in PVA blends tested from soil burial method for 45 days [249][18].

Blends of starch/PVA films from solvent casting resulted in higher susceptibility towards enzymatic degradation in both soil and compost with increasing corn starch loading, which led to achieving up to 85% increase in biodegradation when the burial time is extended in both soil and compost for 8 weeks [123][19]. The same research further justified that the strength of the blends decreased as the percentage of corn starch was increased. It has been reported that microorganisms from different sources can degrade starch/PVA blends at various degradation rates. Bacteria and fungi species isolated from municipal sewage sludge successfully digested starch components, the amorphous regions of PVA, plasticizer in starch/PVA blends, and glycerol [242][11]. In similar contexts, two fungi species Penicillium and Apergillus flavus, isolated from aerobic compost, were able to digest PVA/starch films, resulting in nearly 71% weight loss after 300 days [250][20]. The same one wastudy describesd that when two of these fungi activated separately, a higher degradation rate was observed, up to 60% in the actual compost over the same period. Parallel investigations have been executed to assess the biodegradability of PVA/starch blends that have undergone modifications. Fibrous composites of PVA and natural lignocellulosic fibers from orange wastes incorporated with and without cornstarch biodegraded within 30 days in the soil in 80% mineralization [251][21]. It has been reported that PVA degradation was enhanced with the addition of fibers while both starch and lignocellulosic fiber degraded faster than PVA.

In contrast, nanoparticles may have a lower impact on the biodegradation of composites. AIt studywas concludesd that in nano-SiO2-reinforced starch/PVA nanocomposite films, the nanoparticles have no significant effect on the biodegradability of the films as the reference films prepared (without nanoparticles) resulted in a total weight loss of up to 60%. Biodegradation of metaphase films prepared from clay/starch/PVA has been reported to depend on the characteristics of nanoparticles in a composite, such as the type, content, and composition [113][22]. Some studiweres represented that the starch/PVA blends are not readily biodegradable and subjected to exposed environmental conditions. This fact can be supported by the following comparative research, which indicated the achievement of a certain degree of biodegradation in solvent-casted starch/PVA films exposed to manure soil. This studyIt was further confirmed the similar trend observed in other studies, obtaining a significant increment in biodegradation rate with the increase of the starch content. Moreover, the ultimate weight loss obtained from starch/PVA films did not exceed 40% over three months, confirming that starch/PVA blend films are not easily biodegradable in natural conditions [252][23]. In contrast, it was also reported that the rate of degradation increased with the addition of starch in a study that followed China National Standards (CN:14432). This studyIt was analyzed the biodegradability of starch/PVA blends using bio-reactivity kinetic models. According to first-order kinetics, the microorganism’s growth rate increased with the loading of more quantity of starch in blended film preparation. Thereby, the decomposition rate of the the starch/PVA blend reached only around 36.66% after 180 days. It is conclusive that starch/PVA blends may not undergo complete biodegradation within a short period under natural environments [243][12].

3. Biodegradation of Starch/PLA

Following ISO methods, the biodegradability of co-extruded starch/PLA blends in different environments such as liquid, inert solid, and composting media were studilearned. In the given ISO method, the minimum required mineralization percentage for a compound to be classified as a biodegradable compound is 60%. Concerning starch/PLA blends, it was reported that the percentage of mineralization was higher than 60% and found that starch/PLA blends can be considered biodegradable. Furthermore, this research highlighted that the rate of biodegradation is enhanced with the addition of starch in the liquid medium [253][24]. In contrast, another study used the standard procedures described under ASTM D 5209–92, 5338–92, ISO/CEN 14852, and 14855 to measure the biodegradability of the starch/PLA films which were exposed to ultraviolet light at 315 nm prior [190]. Thine was study reported that the numerical values of the results are independent of the procedures applied in stage two as the results showed the biodegradation rate was higher when in the liquid medium, 92.4–93.4%, compared to the inert medium, 80–83%. These results make strong inferences with the two-step biodegradation study of agricultural co-extruded starch/PLA mulch films [254]. used the standard procedures described under ASTM D 5209–92, 5338–92, ISO/CEN 14852, and 14855 to measure the biodegradability of the starch/PLA films which were exposed to ultraviolet light at 315 nm prior

Biodegradation of PLA blends with starch and wood floor was studilearned following the ISO 14855 standard for compost. Biodegradation rates of this study were increased by about 80% by increasing the starch loading up to 40% and were discovered to be relatively lower than those of pure PLA compared to starch/PLA and PLA/wood flour blends [255][27]. The compostability of pure PLA was further researched using starch/PLA blends at different loadings of starch. Based on the visual inspections, it was observed that all the test samples were completely biodegraded without leaving any residue after 30 days [256][28]. The same studyone justified the environmental impact and safe use in the ecosystem by ecotoxicity test of pure PLA and starch/PLA blends. Another group of researchers studilearned the biodegradation and degradation rates of the PLA–starch blends using cellulose as the control material in a controlled environment. PLA blends that incorporated chemically modified TPS (CMPS) were extruded, and within 42 days the biodegradability of the blends increased with increasing CMPS content in the blends, and neat CMPS was fully degraded [257][29]. The degradation of PLA and TPS blends in simulated soils was further investigated using stimulants such as tert-butyl hydroperoxide, myoglobin, and peroxide-activated myoglobin, in which TPS enhanced the degradation of degradation blends in all systems [258][30]. Several studies have been conducted using PLA together with starch and different compatibilizers or other substances to evaluate soil biodegradation kinetics and rate. Injection-molded tensile specimens prepared using various combinations of native cornstarch, PLA, and polyhydroxyester-ether (PHEE) were buried in soil for one year to assess the effects of starch and PHEE loading on biodegradation rate [205][31]. It was reported that the weight loss elevated with increasing starch and poly (hydroxyester-ether) (PHEE) loading in blends [205][31]. In a comparison studyone of PLA/starch blends vs. PLA/acrylic acid (AA) grafted starch composite (PLA-g-AA/starch), within 3 months, the starch in the composite was able to entirely degrade in the soil environment [259][32]. Loading more starch onto composites, the tensile strength at the breakpoint decreased and PLA-g-AA was not degradable as there was not a significant weight observed within 7–12 weeks [259][32]. Maleic anhydride (MA) has been used as an efficient compatibilizer for PLA/starch blends. The results demonstrated that MA compatibilized blends show better biodegradability than the reference starch/PLA blends in which biodegradability was indicated to be increased with the loading of more starch [260][33]. A similar studyone justifies the biodegradability of neat PLA and corn starch/PLA composites with/without lysine di-isocyanate that was examined following enzymatic degradation using Proteinase K and burial tests. According to the results, the degradation rate increased by incorporating more corn starch, and all the corn starch/PLA composites were gradually degraded over the given time period, except pure PLA [261][34]. In contrast, based on a five-month soil burial experiment designed to interpret the effects of adding PEG to PLA/TPS blends on biodegradation, the mixing of PEG gave an elevated degradation rate, a considerable change in weight loss, and improvement in mechanical properties. It is worth noting, further, that the degradation of blends was increased by incorporating more TPS. It was observed that blends with PEG showed more significant weight loss and enhanced biodegradation of TPS/PLA blends [136][35].

4. Biodegradation of Starch/PCL Blends

Modern research has conducted numerous experiments to evaluate and examine biodegradation and properties of starch/PCL blends. Biodegradation of starch/PCL blends was evaluated from weight loss and the amount of adipic acid immersed from PCL in two types of starch/PCL blends which are distinguished from the starch sources dried granulated sago starch and undried thermoplastic sago starch (TPSS). The biodegradation rate was enhanced by loading more sago starch, indicating a positive trend in mechanical and biodegradation properties in dried granulated sago starch added to PCL blends. Adipic acid liberation is a direct indication of PCL degradation. Granulated sago starch blends liberated more adipic acid as PCL and TPSS decreased biodegradability [262][36]. Different aerobic environments such as activated sludge and compost, in the presence of Pseudomonas putida, the biodegradation of three different types of films formulated from 100% PCL, a blend of 50% modified starch with 50% PCL, and a blend of 50% unmodified starch with 50% PCL blends were studilearned. Based on the results, there is no significant impact on degradation by P. putida. At the same time, considerable deformation in every film was observed within the first 7 days—in both activated sludge and compost the environment may accelerate biodegradation—and after 15 days, all the films had completely degraded [263][37].

Another one wastudy investigated the biodegradability of PCL blends with various starches in anaerobic aqueous environments specific to mesophilic sludge from municipal wastewater treatment [264][38]. In this studyone, native corn starch, genetically modified corn starch, gelatinized corn starch, and amaranth starch were used to prepare PCL blends. Then properties of these films were compared with a series of starch/PCL blends that incorporated glycerol. The results demonstrated that the blends that contained glycerol showed better mechanical properties and a higher degree of biodegradation. The biodegradability of the starches may range between 70% (maize starch) and 81% (amaranth starch), while the biodegradation of PCL was reported to be very low, only up to 2% [264][38]. Other studiweres assessed the biodegradation of metaphase PCL/starch blends included in various components under compost and soil burial tests.

Another wastudy investigated the biodegradability of PCL blends with various starches in anaerobic aqueous environments specific to mesophilic sludge from municipal wastewater treatment [264][38]. In this studyone, native corn starch, genetically modified corn starch, gelatinized corn starch, and amaranth starch were used in the preparation of PCL blends. Then, properties of these films were compared with a series of starch/PCL blends that incorporated glycerol. The results demonstrated that the blends containing glycerol showed better mechanical properties and a higher degree of biodegradation. The biodegradability of the starches may range from 70% (maize starch) to 81% (amaranth starch), while the biodegradation of PCL was reported to be very low, only up to 2% [264][38]. Other studies assessed the biodegradation of metaphase PCL/starch blends, including various components under compost and soil burial tests.

Biodegradability-modified PCL following the reaction melt processing using glycidyl methacrylate (GMA) and benzoyl peroxide were studilearned using the compost method [265][39]. Two types of blends were not significantly degraded after 8 weeks, while higher degradation was achieved in the blends with lower GMA content. The application of azodicarbonomide (ADC) has been studilearned in simulated soil to accelerate the biodegradability of PCL/corn starch blends. Various proportions of ADC were incorporated into pure PCL and PCL/cornstarch (50/50) blends [204][40]. TheIt studywas reported minimal or no significant weight loss and measurable degradation reported only after 100 days [266][41]. Compared to pure PCL, the highest biodegradation was recorded in the 50:50 PCL/cornstarch blend. ADC showed no impact on the biodegradation of the blends, which might have inhibited the biodegradation of pure PCL [267][42]. Another one wastudy [268][43] used three types of PCL blends, high amylose starch [269][44], and CAB, to evaluate the biodegradation rates. Inside a mature compost made from autoclaved municipal solid wastes, these three blends were buried in a compost seed mixture of compost made from garden waste, which showed the degradation decreased with the decreasing of starch content [268][43]. The biodegradability of melt-blended PCL/corn starch nanocomposites that had introduced fatty hydroxamic acid to modify sodium montmorillonite (Na-MMT) was studilearned under the ASTM D5338-92 standard, which reported a higher degree of weight loss after 60 days in PCL nanocomposites than PCL/CS blends [269][44].

Another tewam studied s focused on various blends of TPS/PCL and PCL modified with an added MA compatibilizer in a soil environment after 21 days and reported that pure TPS was fully degradable. The rate of degradation was elevated with increasing TPS loading in the blend. The lowest biodegradation rate was demonstrated in the blend, which contained 5 wt.% of PCL-MA, and it was further concluded that the rate of biodegradation is independent of the TPS quantity [270][45]. Sisal fiber-reinforced PCL/starch blends were evaluated over 9 months using the soil burial test to evaluate biodegradation. Results indicate that the biodegradation was increased by adding fibers into starch/PCL blends [271][46]. Moreover, the researchers also investigated the biodegradation of twin-screw extruded TPS/PCL blends with 5% and 10% of sisal fiber loading and reported that the degradation declined with the incorporation of fibers in blends. At the same time, higher proportions of TPS could enhance the biodegradation of PCL. Furthermore, degradation kinetics of co-extruded TPS and TPS/PCL blends with introduced sisal whisker loadings of 5 and 10 wt.% has been studilearned. As per the findings, the addition of the whiskers improved the biodegradation of the TPS and the TPS/PCL matrices; also, PCL in TPS/PCL blends accelerates the biodegradation of TPS [272][47]. Sisal fibers may retard the biodegradation, and the fibers slowed down the biodegradation. Hence, incorporating fibers should be done under many considerations such as application, matrix, and loading level.

5. Biodegradation of Starch/PHB-V

Limited studiones have investigated degradation kinetics and biodegradation of starch/PHB-V blends using a soil compost test that varied the temperature between 100 °C and 140 °C. These blends were tested for 192, 425, and 600 h to induce thermal aging of extrusion-blended corn starch with poly(3-hydroxybutyrate)-co-poly(3-hydroxyvalerate) (PHB-V) or PCL. Biodegradation of starch/PHB-V at 25% starch loading of the starch impacted thermal aging while demonstrating a higher biodegradation rate within ten months compared to PCL blends. Moreover, the biodegradability of the starch PHB-V blends was increased by loading 50% of the starch into PHB-V, making its degradation time half of that of the PHB-V blend without starch [133][48]. Three types of TPS blends with potato starch, corn starch, and water-soluble potato starch were used in a similar studyone with two degrees of gelatinization of PHB under the soil burial test. The results indicate that weight loss decreased as PHB loading increased. In addition, weight loss increased as time and the glycerol content increased [273][49]. The biodegradability of melt-blended 1:1 PHB-V, and glycerol-TPS with m-MMT were investigated following the soil burial method [274][50]. The results justified an enhancement of mechanical properties in the blends in comparison to pure TPS and a faster degradation rate than pure PHB/V. Furthermore, biodegradation was accelerated up to 90% with increasing m-MMT loading in blends [274][50].

6. Biodegradation of Starch/PBS and Starch/PBSA

Aerobic and anaerobic biodegradation of cornflour/PBSA and plasticized blends indicated that the biodegradability of blends decreases with incorporating PBSA [139][51]. In contrast, PBS/starch, PBS, and PLA biodegradation rates were further examined using powdered bioplastics from the soil burial method. According to the observations, the physicochemical structures of PBS and PBS/starch were comparatively more favorable for biodegradation than PLA under the same given test conditions. PBS/starch blends demonstrated the highest degradability and degradation rates, faster in PBS and PBS-starch than neat PLA [275][52].

7. Biodegradation of Ternary Blends

Limited research has been published on the biodegradation of ternary blends. The biodegradability and kinetics of TPS blends of PLA, PCL, and starch were explored. These blends were melt-blended and formulated by introducing acrylic acid grafted by melt blending. As per the results, these blends were rapidly degraded within the first 8 weeks under given soil burial test conditions [141][53]. Biodegradation of binary and ternary blends of PLA, TPS, and glycidyl methacrylate grafted poly (consider ethylene octane) was assessed following compost testing in complying with ISO 14855. The results indicate that the samples with 40% starch loading underwent more than 80% biodegradation within 10 weeks, compared to blends with 10–20% starch loading, which can only degrade up to 40% under given test conditions. Furthermore, higher biodegradation rates were observed in the blends with GPOE compared to those without GPOE [276][54].

References

- Villa, M.; Capill, V.; Gardé, J.; Rivera, J. Degradación biológica de polímeros mediante la selección y producción de potenciales cultivos iniciadores. Retema Rev. Técnica Medio Ambiente 2009, 136, 80–83.

- Wagner, M.; Oehlman, J. Endocrine disruptors in bottled mineral water: Total estrogenic burden and migration from plastic bottles. Environ. Sci. Pollut. Res. 2009, 16, 278–286.

- Katami, T.; Yasuhara, A.; Okuda, T.; Shibamoto, T. Formation of PCDDs, PCDFs, and coplanar PCBs from polyvinyl chloride during combustion in an incinerator. Environ. Sci. Technol. 2002, 36, 1320–1324.

- Gironès, J.; López, J.; Mutjé, P.; Carvalho, A.; Curvelo, A.; Vilaseca, F. Natural fiber-reinforced thermoplastic starch composites obtained by melt processing. Compos. Sci. Technol. 2012, 72, 858–863.

- Soroudi, A.; Jakubowicz, I. Recycling of bioplastics, their blends and biocomposites: A review. Eur. Polym. J. 2013, 49, 2839–2858.

- Chamas, A.; Moon, H.; Zheng, J.; Qiu, Y.; Tabassum, T.; Jang, J.H.; Abu-Omar, M.; Scott, S.L.; Suh, S. Degradation rates of plastics in the environment. ACS Sustain. Chem. Eng. 2020, 8, 3494–3511.

- European Bioplastics, European Bioplastics. December 2021. Available online: https://www.european-bioplastics.org/global-bioplastics-production-will-more-than-triple-within-the-next-five-years/ (accessed on 25 February 2022).

- Pagga, U. Compostable packaging materials–test methods and limit values for biodegradation. Appl. Microbiol. Biotechnol. 1999, 51, 125–133.

- Kyrikou, I.; Briassoulis, D. Biodegradation of agricultural plastic films: A critical review. J. Polym. Environ. 2007, 15, 125–150.

- Leja, K.; Lewandowicz, G. Polymer biodegradation and biodegradable polymers—A review. Pol. J. Environ. Stud. 2010, 19, 255–266.

- Jayasekara, R.; Harding, I.H.; Bowater, I.; Christie, G.B.Y. Biodegradation by Composting of Surface Modified Starch and PVA Blended Films. J. Polym. Environ. 2003, 11, 49–56.

- Chai, W.L.; Chow, J.D.; Chen, C.C. Effects of modified starch and different molecular weight polyvinyl alcohols on biodegradable characteristics of polyvinyl alcohol/starch blends. J. Polym. Environ. 2012, 20, 550–564.

- Pšeja, J.; Charvátová, H.; Hruzík, P.; Hrnčiřík, J.; Kupec, J. Anaerobic biodegradation of blends based on polyvinyl alcohol. J. Polym. Environ. 2006, 14, 185–190.

- Hrnčiřík, J.; Pšeja, J.; Kupec, J.; Bernkopfová, S. Anaerobic biodegradation of polyvinyl alcohol modified by extracellular polysaccharides. J. Polym. Environ. 2010, 18, 98–103.

- Yun, Y.; Yoon, S. Effect of amylose contents of starches on physical properties and biodegradability of starch/PVAblended films. Polym. Bull. 2010, 64, 553–568.

- Negim, E.; Rakhmetullayeva, R.; Yeligbayeva, G.; Urkimbaeva, P.; Primzharova, S.; Kaldybekov, D.; Craig, W. Improving biodegradability of polyvinyl alcohol/starch blend films for packaging applications. Int. J. Basic Appl. Sci. 2014, 3, 263–273.

- Râpă, M.; Grosu, E.; Stoica, P.; Andreica, M.; Hetvary, M. Polyvinyl alcohol and starch blends: Properties and biodegradation behavior. J. Environ. Res. Prot. 2014, 11, 34–42.

- Tanase, E.; Popa, E.; Rapa, M.; Popa, O.; Popa, I. Biodegradation study of some food packaging biopolymers based on PVA. Bull. UASVM Anim. Sci. Biotechnol. 2016, 73, 89–94.

- Azahari, N.; Othman, N.; Ismail, H. Biodegradation Studies of Polyvinyl Alcohol/Corn Starch Blend Films in Solid and Solution Media. J. Phys. Sci. 2011, 22, 15–31.

- Maiti, S.; Ray, D.; Mitra, D.; Mukhopadhyay, A. Isolation and characterisation of starch/polyvinyl alcohol degrading fungi from aerobic compost environment. Int. Biodeterior. Biodegrad. 2013, 82, 9–12.

- Imam, S.; Cinelli, P.; Gordon, S.; Chiellini, E. Characterization of biodegradable composite films prepared from blends of poly (vinyl alcohol), cornstarch, and lignocellulosic fiber. J. Polym. Environ. 2005, 13, 47–55.

- Tang, X.; Alavi, S. Recent advances in starch, polyvinyl alcohol based polymer blends, nanocomposites and their biodegradability. Carbohydr. Polym. 2011, 85, 7–16.

- Raj, B.; Somashekar, R. Structure–property relation in polyvinyl alcohol/starch composites. J. Appl. Polym. Sci. 2004, 91, 630–635.

- Gattin, R.; Copinet, A.; Bertrand, C.; Couturier, Y. Biodegradation study of a starch and poly (lactic acid) coextruded material in liquid, composting and inert mineral media. Int. Biodeterior. Biodegrad. 2002, 50, 25–31.

- Rhim, J.W. Physical and mechanical properties of water-resistant sodium alginate films. LWT Food Sci. Technol. 2004, 37, 323–330.

- Copinet, A.; Bertrand, C.; Longieras, A.; Coma, V.; Couturier, Y. Photodegradation and biodegradation study of a starch and poly (lactic acid) coextruded material. J. Polym. Environ. 2003, 11, 169–179.

- Petinakis, E.; Liu, X.; Yu, L.; Way, C.; Sangwan, P.; Dean, K.; Edward, G. Biodegradation and thermal decomposition of poly (lactic acid)-based materials reinforced by hydrophilic fillers. Polym. Degrad. Stab. 2010, 95, 1704–1707.

- Rudeekit, Y.; Siriyota, P.; Intaraksa, P.; Chaiwutthinan, P.; Tajan, M.; Leejarkpai, T. Compostability and Ecotoxicity of Poly (lactic acid) and Starch Blends. Adv. Mater. Res. 2012, 506, 323–326.

- Shin, B.; Jang, S.; Kim, B. Thermal, morphological, and mechanical properties of biobased and biodegradable blends of poly (lactic acid) and chemically modified thermoplastic starch. Polym. Eng. Sci. 2011, 51, 826–834.

- Rodrigues, C.; Tofanello, A.; Nantes, I.; Rosa, D. Biological Oxidative Mechanisms for Degradation of Poly (lactic acid) Blended with Thermoplastic Starch. ACS Sustain. Chem. Eng. 2015, 3, 2756–2766.

- Shogren, R.; Doane, W.; Garlotta, D.; Lawton, J.; Willett, J. Biodegradation of starch/polylactic acid/poly (hydroxyesterether) composite bars in soil. Polym. Degrad. Stab. 2003, 79, 405–411.

- Wu, C. Improving polylactide/starch biocomposites by grafting polylactide with acrylic acid–characterization and biodegradability assessment. Macromol. Biosci. 2005, 5, 352–361.

- Jang, W.; Shin, B.; Lee, T.; Narayan, R. Thermal properties, and morphology of biodegradable PLA/starch compatibilized blends. J. Ind. Eng. Chem. 2007, 13, 457–464.

- Ohkita, T.; Lee, S. Thermal degradation and biodegradability of poly (lactic acid)/corn starch biocomposites. J. Appl. Polym. Sci. 2006, 100, 3009–3017.

- Wang, X.-L.; Yang, K.-K.; Wang, Y.-Z. Properties of Starch Blends with Biodegradable Polymers. J. Macromol. Sci. 2003, 43, 385–409.

- Ishiaku, U.; Pang, K.; Lee, W.; Ishak, Z. Mechanical properties and enzymic degradation of thermoplastic and granular sago starch filled poly (ε-caprolactone). Eur. Polym. J. 2002, 38, 393–401.

- Yavuz, H.; Babaç, C. Preparation and biodegradation of starch/polycaprolactone films. J. Polym. Environ. 2003, 11, 107–113.

- Hubackova, J.; Dvorackova, M.; Svoboda, P.; Mokrejs, P.; Kupec, J.; Pozarova, I.; Koutny, M. Influence of various starch types on PCL/starch blends anaerobic biodegradation. Polym. Test. 2013, 32, 1011–1019.

- Kim, C.; Jung, K.; Kim, J.; Park, J. Modification of aliphatic polyesters and their reactive blends with starch. J. Polym. Environ. 2004, 12, 179–187.

- Marsh, K.; Bugusu, B. Food Packaging—Roles, Materials, and Environmental Issues. J. Food Sci. 2007, 72, R39–R55.

- Rosa, D.; Rodrigues, T.; Graças, F.G.C.; Calil, M. Effect of thermal aging on the biodegradation of PCL, PHB-s with starch in soil compost, V, and their blend. J. Appl. Polym. Sci. 2003, 89, 3539–3546.

- Ali, S.F.A. Biodegradation properties of poly-εcaprolactone, starch and cellulose acetate butyrate composites. J. Polym. Environ. 2014, 22, 359–364.

- Praznik, W.; Huber, A.; Watzinger, S.; Beck, R. Molecular Characteristics of High Amylose Starches. Starch Starke 1994, 46, 88–94.

- Al-Mulla, E.A.J. A new biopolymer-based polycaprolactone/starch modified clay nanocomposite. Cellul. Chem. Technol. 2014, 48, 515–520.

- Guarás, M.; Alvarez, V.; Ludueña, L. Processing and characterization of thermoplastic starch/polycaprolactone/compatibilizer ternary blends for packaging applications. J. Polym. Res. 2015, 22, 1–12.

- Di Franco, C.; Cyras, V.P.; Busalmen, J.P.; Ruseckaite, R.A.; Vázquez, A. Degradation of polycaprolactone/starch blends and composites with sisal fibre. Polym. Degrad. Stab. 2004, 86, 95–103.

- Campos, A.; Teodoro, K.B.R.; Teixeira, E.M.; Corrêa, A.C.; Marconcini, J.M.; Wood, D.F.; Mattoso, L.H. Properties of thermoplastic starch and TPS/polycaprolactone blend reinforced with sisal whiskers using extrusion processing. Polym. Eng. Sci. 2013, 53, 800–808.

- Teixeira, S.; Eblagon, K.M.; Miranda, F.; Pereira, M.F.R.; Figueiredo, J.L. Towards Controlled Degradation of Poly(lactic) Acid in Technical Applications. J. Carbon Res. 2021, 7, 42.

- Lai, S.-M.; Don, R.-M.; Huang, Y.C. Preparation and properties of biodegradable thermoplastic starch/poly(hydroxy butyrate) blends. J. Appl. Polym. Sci. 2006, 100, 2371–2379.

- Magalhães, N.; Andrade, C. Properties of melt-processed poly (hydroxybutyrate-co-hydroxyvalerate)/starch 1:1 blend nanocomposites. Polímeros 2013, 23, 366–372.

- Jbilou, F.; Joly, C.; Galland, S.; Belard, L.; Desjardin, V.; Bayard, R.; Dole, P.; Degraeve, P. Biodegradation study of plasticised corn flour/poly(butylene succinate-co-butylene adipate) blends. Polym. Test. 2013, 32, 1565–1575.

- Adhikari, D.; Mukai, M.; Kubota, K.; Kai, T.; Kaneko, N.; Araki, K.; Kubo, M. Degradation of Bioplastics in Soil and Their Degradation Effects on Environmental Microorganisms. J. Agric. Chem. Environ. 2016, 5, 23–34.

- Liao, H.-T.; Wu, C.-S. Preparation and characterization of ternary blends composed of polylactide, poly(E-caprolactone) and starch. Mater. Sci. Eng. 2009, 515, 207–214.

- Shi, Q.; Chen, C.; Gao, L.; Jiao, L.; Xu, H.; Guo, W. Physical and degradation properties of binary or ternary blends composed of poly (lactic acid), thermoplastic starch and GMA grafted POE. Polym. Degrad. Stab. 2011, 96, 175–182.

More