You're using an outdated browser. Please upgrade to a modern browser for the best experience.

Please note this is a comparison between Version 2 by Camila Xu and Version 1 by Ariel Pulmon Conversion.

Computational fluid dynamics (CFD) is a powerful numerical analysis approach in solving various engineering and environment problems. It is a simulation technique that uses numerical equations and digital computers for iterative methods to model and to predict various heat, mass, and momentum transfer and fluid flow problems for the optimization of designs. Concentrated solar power (CSP) is a promising technology for harnessing and utilizing a clean and sustainable source of energy. CSP consists of a solar concentrator that collects and intensifies the heat energy from the Sun and a solar receiver that converts the heat generated to produce electrical energy.

- computational fluid dynamics

- concentrated solar power

- solar dish

1. Introduction

Concentrated solar power (CSP) is a promising technology for harnessing and utilizing a clean and sustainable source of energy. CSP consists of a solar concentrator that collects and intensifies the heat energy from the Sun and a solar receiver that converts the heat generated to produce electrical energy. Despite its recent adoption and acceptance from both the scientific communities and energy investors, solar power still accounts for a very small percentage of total energy use [1]. The challenge in the optimal design of CSP is to make the technology more cost-efficient and environmentally friendly. With the advancement of numerical modeling software and computational hardware, most of the design problems in CSP technology have recently been solved using computational fluid dynamics (CFD).

Previous reviews have reported the application of CFD in the field of solar energy. Al-Abidi et al. [2] reviewed the various phase-changing materials (PCMs) in solar photovoltaic (PV) ventilation and the application of CFD in the evaluation of its heat transfer behavior. Liu et al. [3] recently reviewed the different models and equations used to describe the PCM composites. Yadav and Bhagoria [4] conducted a review on the assessment of the heat transfer and the fluid flow of numerous solar air heaters using CFD. A solar air heater is a technology that converts solar energy into thermal energy and is usually integrated into solar PV panels. Kasaeian et al. [5] provided a comprehensive review of previous experimental, analytical, and simulation studies (which include the CFD approach) related to solar chimney applications. Moreover, Nadda et al. [6] presented a review of studies that investigate the application of jet impingement in increasing solar PV efficiency. The investigation approaches include experimental, CFD, and mathematical modeling. Chen et al. [7] published a bibliometric review on the development of concentrated solar power technologies but did not mention any use of CFD modeling. Only a few reviews were found which discussed the application of CFD modeling in concentrated solar power technologies and focused on a parabolic trough. As an example, Yılmaz and Mwesigye [8] performed a comprehensive review on several computational approaches that include CFD in the design of parabolic trough solar collectors. Olia et al. [9] and Bellos et al. [10] also presented a review on the application of nanofluids with CFD modeling in the enhancement of the thermal performance of parabolic trough technology. However, for solar dish technology with CFD modeling, no prior bibliometric review has yet been presented.

1.2. Concentrated Solar Power

1.1. Concentrated Solar Power

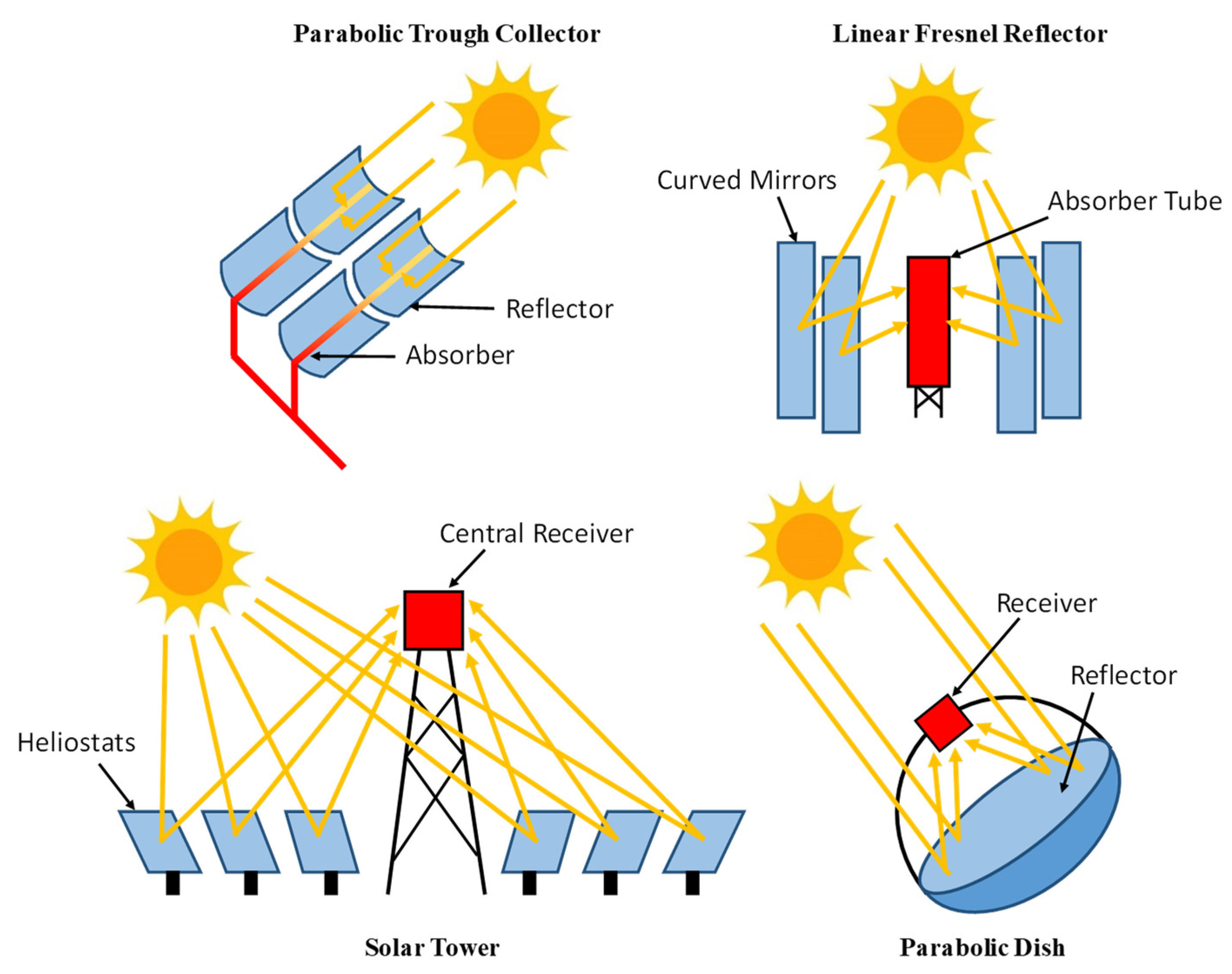

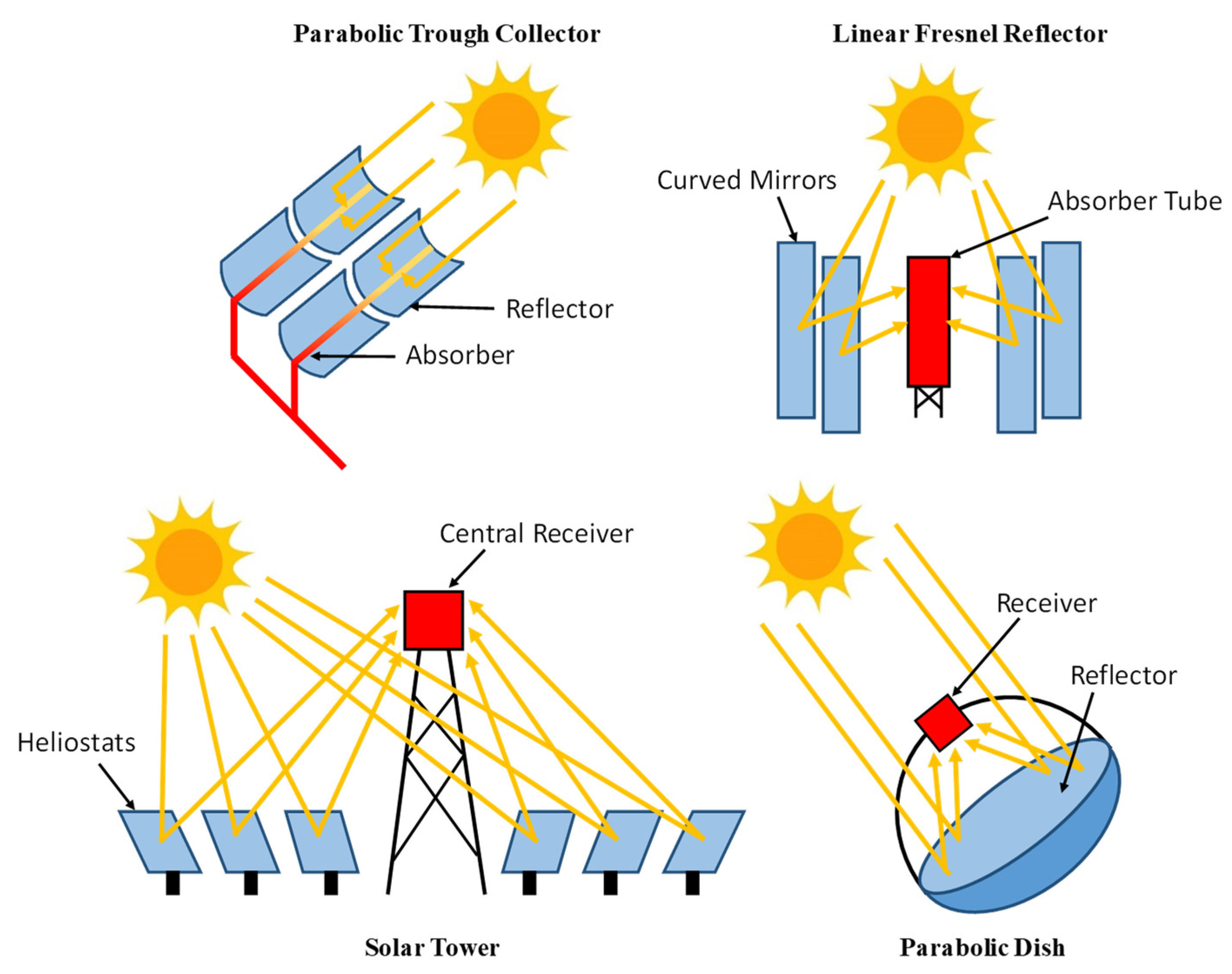

Concentrated solar power (CSP) is based on the principle of photons coming directly from the Sun being concentrated and collected instead of just being scattered by the Earth’s atmosphere. Direct normal irradiance is the technology’s major energy source [13][11]. Throughout the years, CSP technology has been proven to have a significant share in the production of renewable sources of sustainable electricity [14,15][12][13]. The heat energy from the Sun is collected through optical systems or solar concentrators such as highly reflective mirrors and then concentrated in a receiver that contains heat transfer fluid (HTF). The HTF in the receiver is heated, causing a rise in temperature, by absorbing the concentrated radiation. Then, the heated HTF is used for either electricity production through thermal cycles or as a heat source for industrial and commercial applications [15][13]. There are four main types of CSP technology, namely, parabolic trough collector (PTC), solar tower, parabolic dish (or solar dish), and linear Fresnel reflector (LFR). These four are classified into two groups based on the manner of focusing the solar energy: (1) the line focusing systems, as in the case of PTC and LFR, or (2) the point focusing systems, which are for solar tower and solar dish [16][14]. Figure 1 shows the illustration of these four types of CSP technologies.

Figure 1. Concentrated solar power technologies.

Concentrated solar power technologies.

1.3. Computational Fluid Dynamics

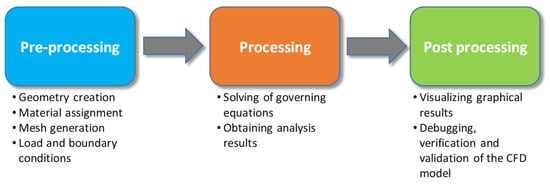

1.2. Computational Fluid Dynamics

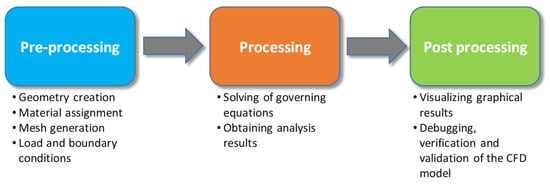

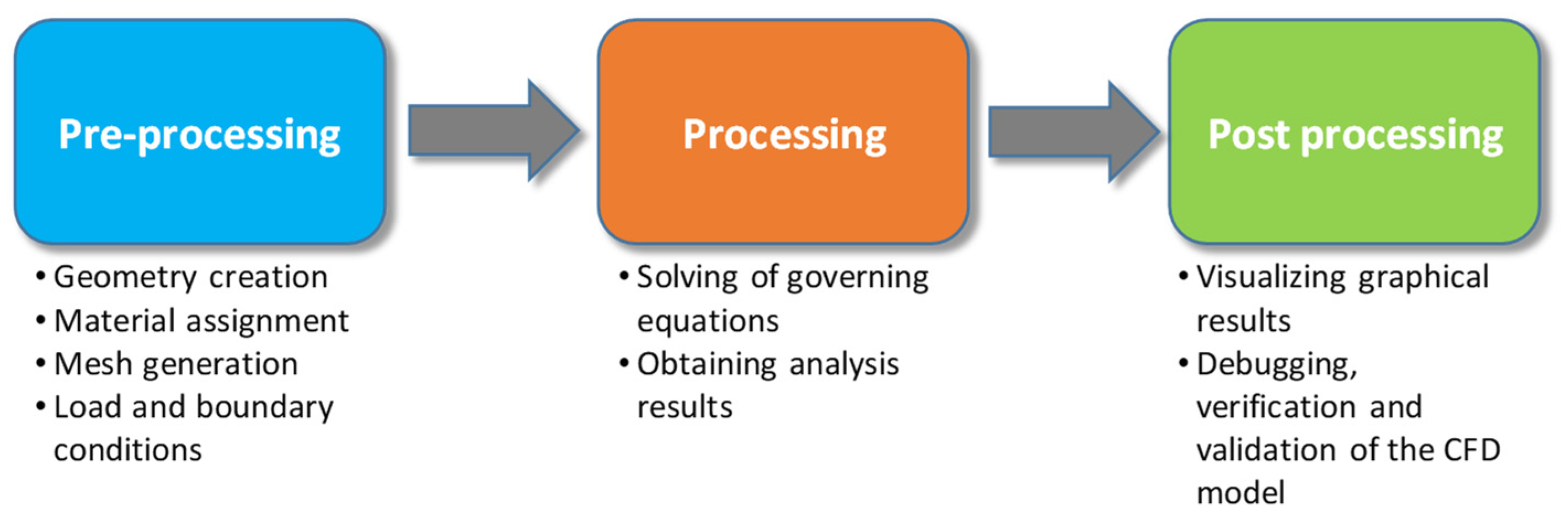

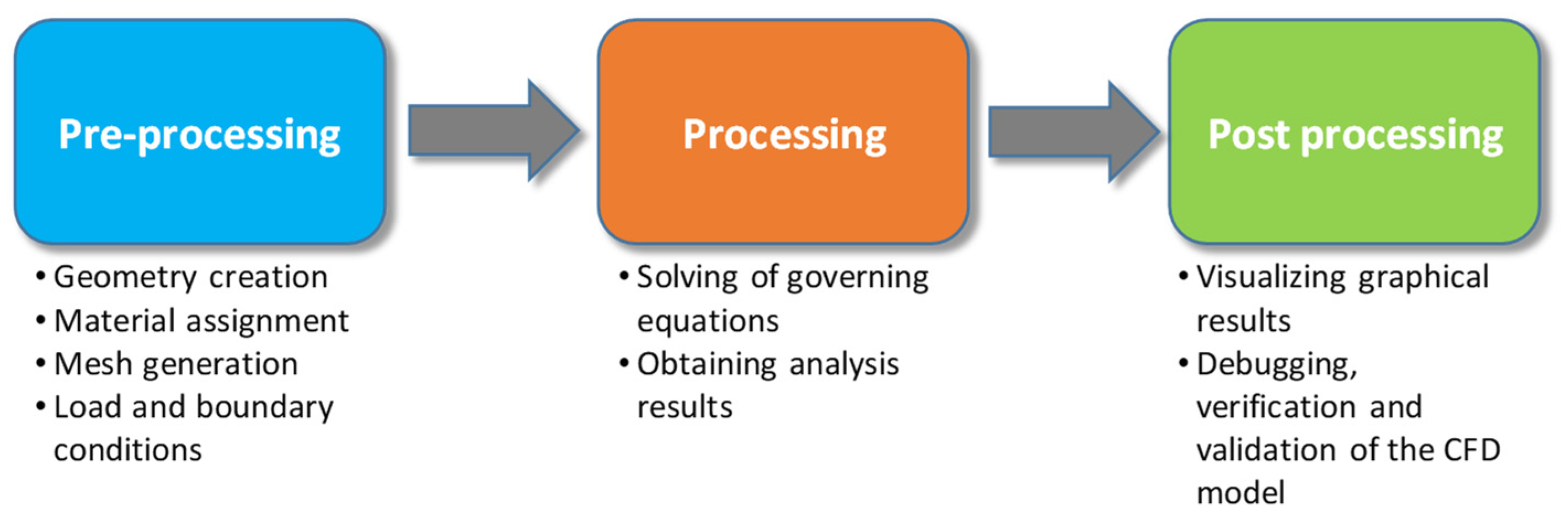

Computational fluid dynamics (CFD) is a powerful numerical analysis approach in solving various engineering and environmental problems. It is a simulation technique that uses numerical equations and digital computers for iterative methods to model and predict various heat, mass, and momentum transfer and fluid flow problems for the optimization of designs [4]. CFD is an accepted methodology by the scientific and engineering communities to design various types of renewable energy technologies [17][15]. There are three main stages of the CFD study, as shown in Figure 2: pre-processing, processing, and post-processing. The pre-processing stage includes geometry creation, material assignment, mesh generation, and assignment of load and boundary conditions. After that, the governing equations such as the Navier–Stokes equation and the set of algorithms are computed and automatically processed by computers. Finally, the obtained results are visualized and interpreted during the post-processing stage.

Figure 2. Computational fluid dynamics stages.

Computational fluid dynamics stages.

2. The CFD Modeling of Solar Dish System

2.1. The Semantic Network of Keywords and Authors

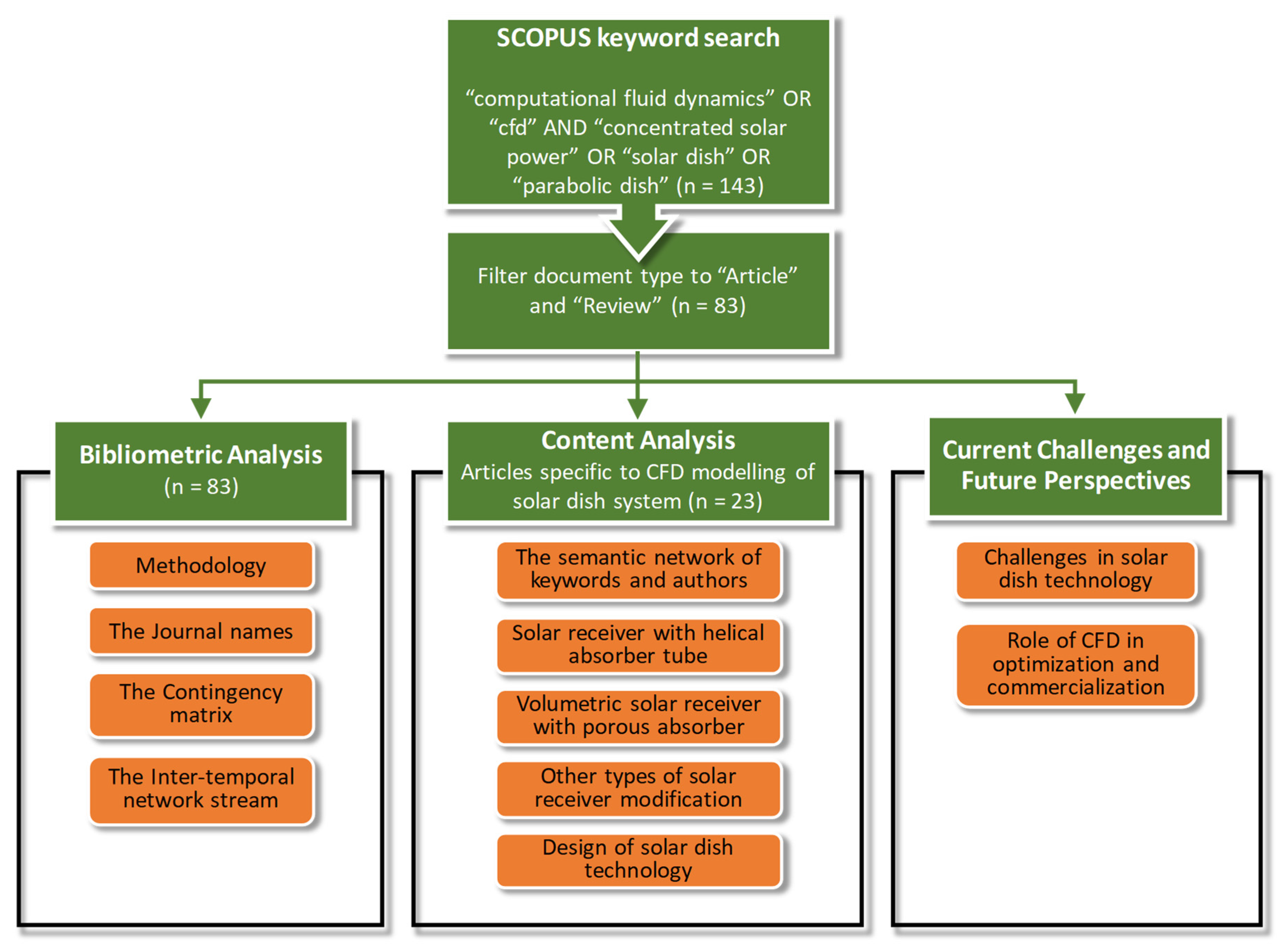

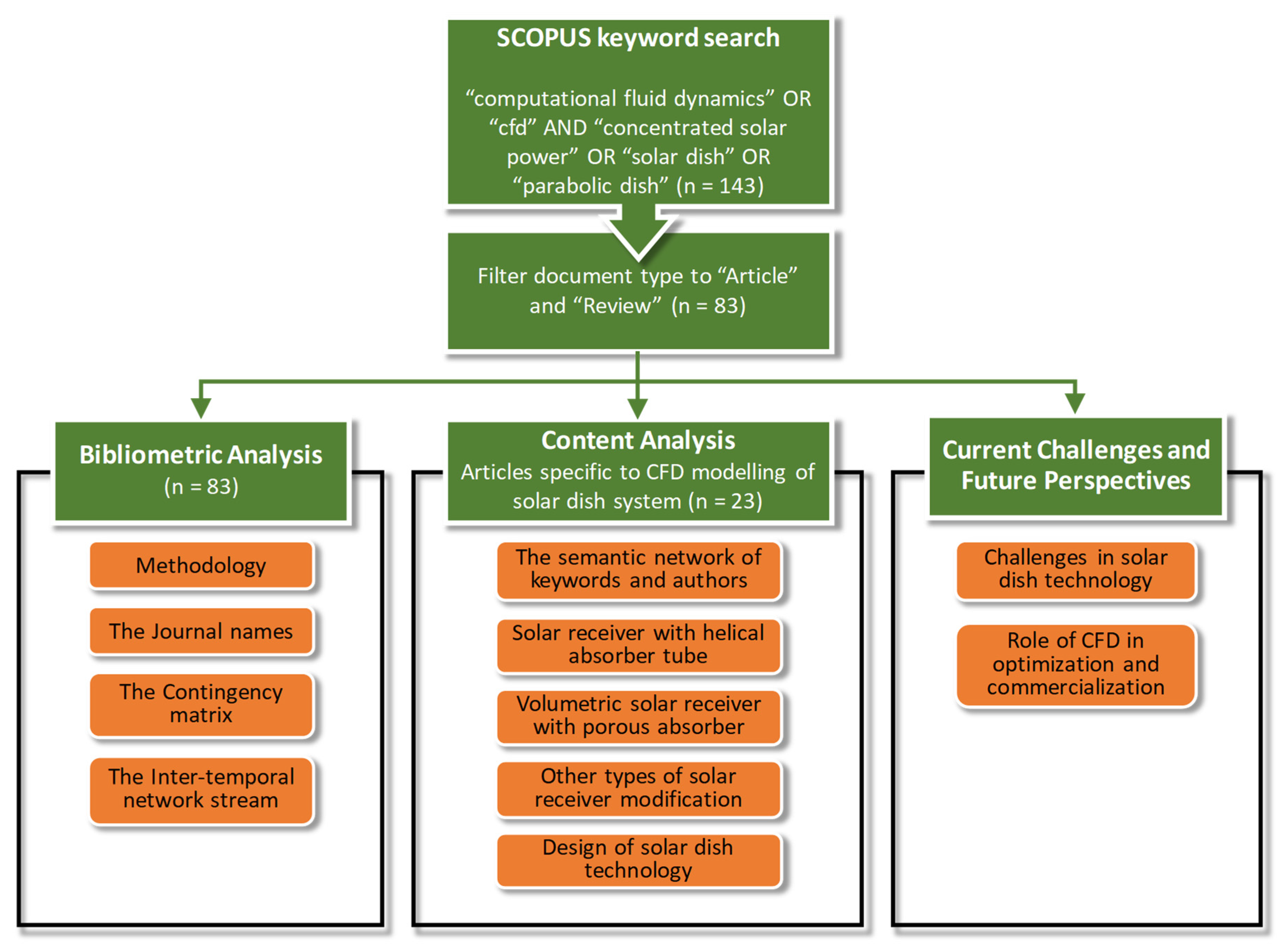

In this section, the contents of published journal articles relevant to the topic of computational fluid dynamics modeling of solar dish are analyzed. A review paper by Hachicha et al. [16][14] presented content analyses on the numerical models of the other types of CSP, which are central receiver or solar tower and parabolic through concentrator (PTC), but not on the solar dish type of CSP. This restudyearch concentrates on the CFD modeling of the solar dish. Out of 80 published articles yielded from the Scopus database related to CFD modeling of CSP as of 1 December 2020, only 23 of these are specific to the solar dish system.

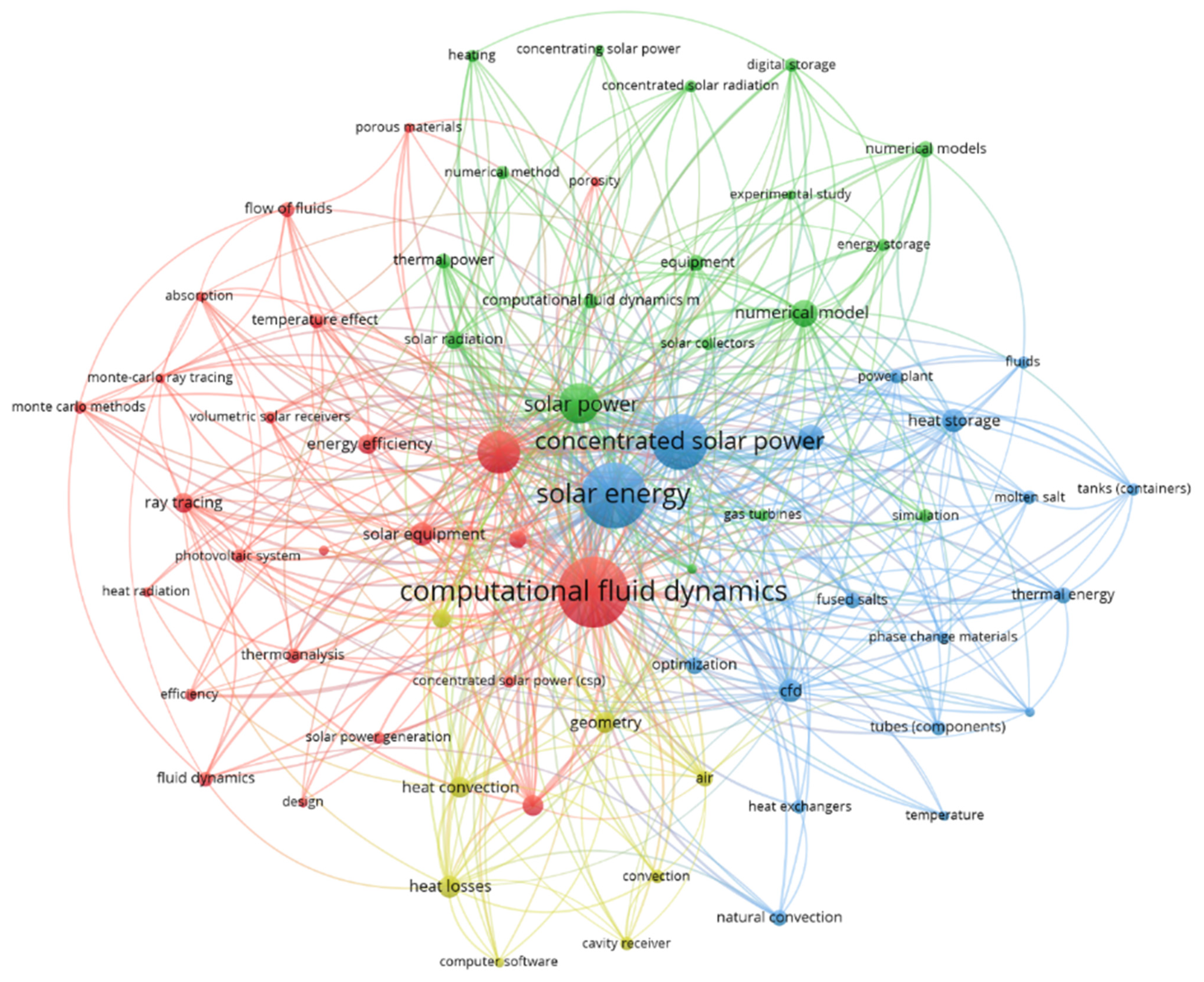

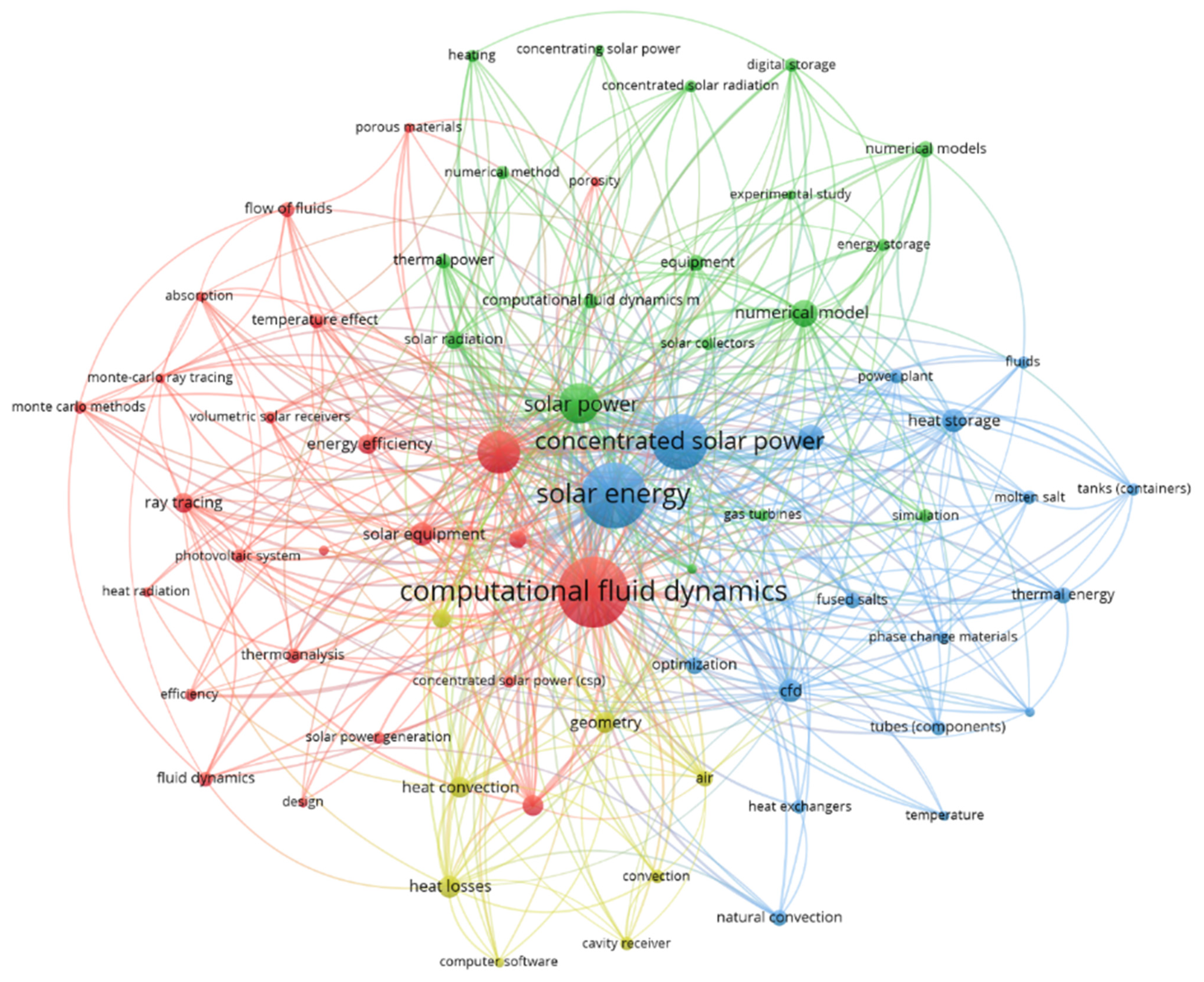

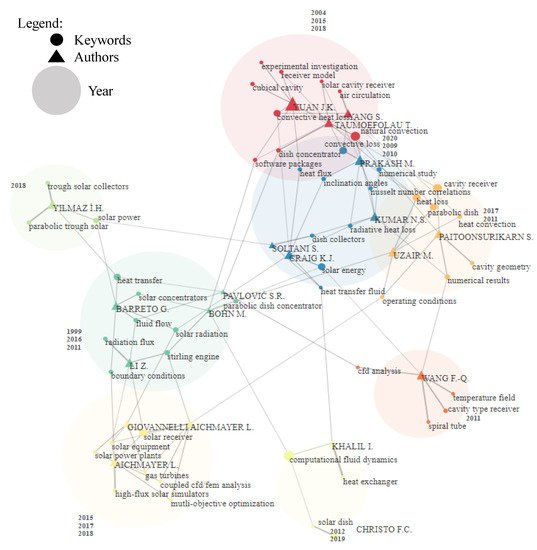

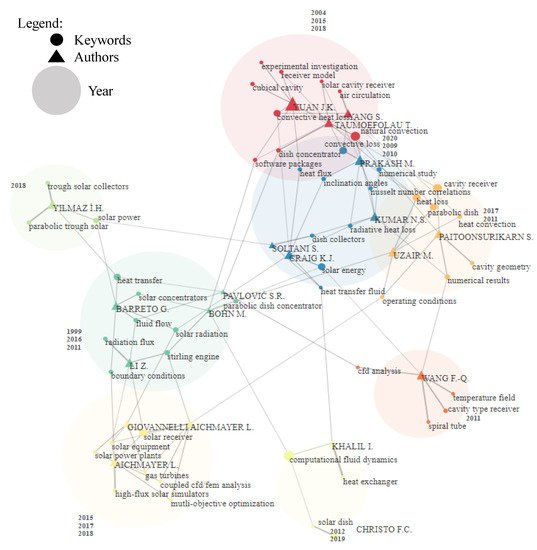

Figure 3 shows the semantic network of keywords and authoresearchers of articles specific to the solar dish system with CFD modeling with their corresponding published year. There are three categories identified and subject to content analysis, namely, solar receiver with helical absorber tube, volumetric solar receiver (VSR) with porous absorber, and the rest which did not belong to either of the two were categorized as others. They were classified based on the type of solar receiver used in the solar dish system. Table 1 shows the extracted data of the solar collector and receiver, which include the collector size and reflectivity, the solar irradiance used, the type of receiver configuration, the size of the receiver cavity (including porosity for volumetric solar receiver), the tube size for tubular absorber, and the receiver material.

Figure 3. The semantic network of the keywords and authors based on the Scopus search keywords “computational fluid dynamics” and “solar dish” or “parabolic dish” (1 December 2020).

Figure 3. The semantic network of the keywords and authors based on the Scopus search keywords “computational fluid dynamics” and “solar dish” or “parabolic dish” (1 December 2020).

Figure 3. The semantic network of the keywords and authors based on the Scopus search keywords “computational fluid dynamics” and “solar dish” or “parabolic dish” (1 December 2020).

Figure 3. The semantic network of the keywords and authors based on the Scopus search keywords “computational fluid dynamics” and “solar dish” or “parabolic dish” (1 December 2020).Table 1. Solar dish and receiver data.

| References | Collector Size (mm) | Collector Reflectivity | Solar Irradiance (W/m | 2 | ) | Receiver Type | Receiver Size (mm) | Tube Size (mm) | Receiver Material |

|---|---|---|---|---|---|---|---|---|---|

| [24] | [16] | - | 0.8 | 1000 | rectangular with helical pipe | - | - | highly oxidized stainless steel at 1000 K | |

| [25] | [17] | - | 0.95 | 500–1000 | cylindrical with helical tube | dr = 200, L = 300 | dt = 8 | steel with copper tube | |

| [26] | [18] | - | 0.95 | 800 | cylindrical porous volumetric receiver | dr = 50, L = 50 | 3 (pore size) | open-cell SiC ceramic foam absorber | |

| [27] | [19] | - | - | - | square porous absorber module | s = 10 × 10, L = 40 | - | ||

| [28] | [20] | D = 5060 * f = 3200 |

0.9 | 1000 | conical with built-in helical pipe | dmax = 460 L = 170–630 Loop no. = 4–15 |

dt = 42 | 304 stainless steel (pipe and outer cover) | |

| [29] | [21] | D = 1120 f = 700 |

0.95 | 800 | cylindrical porous volumetric receiver | dr = 50, L = 50 | 3 (pore size) | open-cell SiC ceramic foam absorber | |

| [30] | [22] | S = 1600 (square) | 0.92 | 826 | conical with helical tube | dmax = 38, L = 50 | - | Inconel sheets coated with Pyromark 2500 paint | |

| [31] | [23] | D = 2880 f = 1500 |

0.75 | 787 | cylindrical with helically baffled cavity | dr = 200, L = 400 | - | carbon steel | |

| [32] | [24] | - | - | - | porous volumetric solar receiver | - | - | SiC ceramic foam absorber | |

| [33] | [25] | - | - | - | cylinder with hollowed cylindrical cavity zoom with U-shaped air channel | dr = 290, L = 320 | w × t = 68 × 4 | ||

| [34] | [26] | D = 200 | 0.737 | 800 | porous volumetric solar receiver | - | 4 (pore size) porosity = 85% | SiSiC open cell foam absorber | |

| [35] | [27] | - | - | 500 | cylindrical container with 12 U-tubes | dr = 380, L = 440 | dt = 15 | Silicon Carbide (SiC) | |

| [36] | [28] | D = 5000 f = 1840 |

- | - | conical | dr = 300, L = 710 | - | ||

| [37] | [29] | D = 1000 | - | - | cylindrical, conical, and spherical with helical tube | dr = 200, L = 250 dr = 200, L = 354.3 dr = 200, L = 218 |

dt = 10 | copper tube | |

| [38] | [30] | D = 1000 to 5000 | - | 500–1000 | cylindrical, conical, and spherical with helical tube | dr = 225, L = 235 dr = 225, L = 240 d r= 225, L = 257 |

dt = 19 | copper tube | |

| [39] | [31] | D = 1000 f = 455–555 |

0.95 | 525 | cylindrical, conical, and spherical with helical tube | dr = 200, L = 250 dr = 200, L = 354.3 dr = 200, L = 218 |

dt = 20 | copper tube | |

| [40] | [32] | D = 3800 f = 2260 |

0.98 | 800 | flat circular disk with spiral coil receiver | dmax = 404 | dt = 9.3 | ||

| [41] | [33] | - | - | 906 | porous volumetric solar receiver | dr = 145.3 | 4 (cell diameter) 81.1% (porosity) |

open-cell SiC ceramic foam absorber | |

| [42] | [34] | - | - | - | cylindrical dish receiver | - | - | ||

| [43] | [35] | f = 13,100 A = 425 m | 2 | - | - | - | - | ||

| [20] | [36] | - | 0.95 | 1000 | shallow semi-ellipsoidal receiver, hemispherical, deep semi-ellipsoidal receiver | - | - | ||

| [44] | [37] | - | - | - | hemispherical with spiral tubes | copper tube | |||

| [18] | [38] | - | - | - | cylindrical with helical tube | dr = 330, L = 500 | dt = 9 | copper tube coated with polyurethane |

* D = aperture diameter; f = focus length; S = square aperture side; A = aperture area; dr = receiver diameter; dmax = maximum receiver diameter; dt = tube diameter; w × t = width and thickness; L = receiver height; s = side dimension.

2.2. Solar Receiver with Helical Absorber Tube

A solar receiver with a helical tube as an absorber is the most common type of receiver configuration used in the studies, accounting for 9 out of 23 published articles relevant to CFD modeling of solar dish systems as of 1 December 2022. Prakash et al. [18][38] performed a CFD simulation using Fluent to estimate the convective heat losses in a cylindrical receiver with a skirt. The inlet temperature (from 50 °C to 300 °C) was varied as well as the receiver inclination angle (0°, 30°, 45°, 60°, and 90°). The results of the numerical study were compared to the experimental data and yielded a maximum deviation of about 14%. Also using Fluent and SolidWorks Flow simulation software, Yuan et al. [42][34] were able to predict the convective heat losses for two different solar receiver models, which were cubical cavity and cylindrical cavity receivers. The simulation results were compared against the experimental data and showed that the simulation result for the cylindrical receiver model was in good agreement with the experimental result. The effect of different turbulence and air property model options in Fluent were also analyzed and compared. Daabo et al. [39][31] focused on evaluating the optical efficiency and heat flux distribution of cylindrical-, conical-, and spherical-shaped solar receivers. The absorption ratio of each geometric configuration was measured and showed that conical-shaped geometry has the highest value. The optimal distance of the focal location of the cavity receiver was also determined using OptisWorks software and the CFD simulation was carried out by Fluent and then validated by experimental results of published works. Daabo et al. [38][30] adapted the OptisWorks software based on the Monte Carlo Ray Tracing (MCRT) method and CFD software ANSYS Fluent to examine the optical and thermal performance of the same type of receiver used previously. The optical simulation result of irradiance absorbed by the receiver was used as an input parameter to the CFD analysis using User Define Function (UDF) to simulate the flow and heat transfer performance of the working fluid while varying some parameters such as reflector diameter and coil pitch of the helical tube. It was observed from the results that a zero-coil pitch has better performance than a 0.5 D pitch. It was added that the overall system performance can be enhanced when the receiver is covered by glass.

Then, Daabo et al. [37][29] studied the effect of coil pitch and tube diameter on the working fluid’s exit temperature and found that the conical-shaped receiver was more efficient than the other two geometries tested. Meanwhile, Uzair et al. [36][28] studied the influence of wind flow on the heat loss from the receiver while varying the orientation of the solar dish concentrator by employing computational fluid dynamics in ANSYS CFX. The heat loss analysis was different from most studies which focused on the heat loss due to natural convection. The results showed that the dish orientation indeed significantly affects the flow structure near the receiver, which consequently contributes to heat loss.

Zhang et al. [28][20] performed combined optical and thermal numerical modeling to optimize the performance of a solar conical receiver with a built-in helical pipe. The simulation was able to obtain the optimal values of conical angle, loop number, and insulation thickness to maximize the optical and thermal efficiency of the cavity receiver using TracePro optics software and ANSYS CFD software, which were also compared to published experimental data. Then, Daabo et al. [90][39] presented an optical and thermal simulation of a micro-scale cylindrical cavity receiver for the Brayton gas power cycle while varying the solar radiation. The flux distribution in the receiver cavity was predicted using OptisWorks software, and the obtained data became the basis for determining the energy absorbed by the compressed air as HTF through CFD simulation in ANSYS. The results, which were validated through experiments, showed the best configurations of the cavity receiver which can be used for domestic applications of concentrated solar power. Moreover, Craig et al. [24][16] employed the combined CFD and ray-tracing software in estimating the heat losses of a tubular cavity dish receiver at various inclination angles. The heat source profile was obtained using the Monte Carlo ray-tracing method in SolTrace software and was used as input in ANSYS Fluent through user-defined functions. It was concluded and validated through previous literature that the thermal efficiency was mainly affected by the convective heat losses.

2.3. Volumetric Solar Receiver with Porous Absorber

Another type of solar receiver configuration is the volumetric solar receiver with a porous media as the absorber. Based on the extracted data from Scopus, the first published article regarding CFD modeling of a volumetric solar receiver in a solar dish system was in 2015. Aichmayer et al. [41][33] designed a small-scale solar concentrator using a porous volumetric absorber in the solar receiver integrated with a hybrid micro-gas turbine system with considerations of system efficiency, pressure drop, and material utilization, and economic cost. The initial detailed analysis of the results was performed using a coupled CFD/FEM tool in COMSOL Multiphysics. It was found that the use of a volumetric receiver in a solar dish system is a promising technology for harnessing solar energy. Aichmayer et al. [34][26] utilized CFD/FEM in COMSOL software routines for the thermo-mechanical analysis of the OMSoP solar dish system using a porous receiver and coupled to a MATLAB-based ray-tracing routine for a heat source calculation. The numerical simulations were performed to verify the results of the presented systematic scaling methodology for the solar dish system using a KTH high-flux solar simulator before selecting a suitable receiver configuration for full-scale application. Then, Zhao et al. [32][24] employed CFD simulation to investigate and verify the results of coupled a multiple-relaxation-time lattice Boltzmann model (MRT-LBM) of flow and heat transfer performance of a porous volumetric receiver. Three types of porous structures have been developed and studied, and the influence of some parameters such as pore structure, Reynolds number, and thermal diffusivity of the solid matrix was presented. In addition, Barreto et al. [29][21] used three-dimensional modeling based on the finite volume method (FVM) in OpenFOAM (an open-source software) to analyze the thermal performance of cylindrical porous volumetric receivers made of open-cell SiC ceramic foam absorber. The propagation and absorption of solar radiation were developed in Octave software using the Monte Carlo ray tracing (MCRT) method which was then coupled to CFD. Different assumptions were applied such as the adiabatic boundary to obtain a detailed analysis of the temperature profiles near the wall. With this assumption in place, it was found that the most accurate results were obtained when the heat flux separation was applied between the solid and fluid located at the sidewall. Moreover, Barreto et al. [26][18] conducted a detailed CFD simulation using OpenFOAM for a cylindrical porous volumetric receiver with open-cell silicon carbide (SiC) ceramic foam as the absorber. Tonatiuh software was utilized for ray tracing from the parabolic dish to the receiver. A parametric analysis was performed to determine the optimal values of porosity, pore size, and inlet velocity. Meanwhile, Herrmann et al. [27][19] formulated a CFD model in ANSYS CFX to verify the proposed assimilation framework using blower actuation in addressing the current challenges in open volumetric solar receivers. The challenges presented included the fluctuation in the intensity of radiation flux which may sometimes produce thermal shocks and unexpected thermal loads on the porous ceramic absorber. The proposed solution was able to resolve the problems in the volumetric solar receiver by stabilizing the flow temperature gradients.

2.4. Other Types of Solar Receiver Modification

There are other types of solar receiver modifications that do not belong to either of the two categories. Kumar and Reddy [44][37] performed a numerical study based on asymptotic computational fluid dynamics (ACFD) in estimating the convective and radiation heat loss from a hemispherical receiver with spiral tubes while varying the inclination angles from 0° to 90° inclination. The influences of emissivity, temperature ratio, and diameter ratio on heat loss were also investigated. Li et al. [20][36] used TracePro ray-tracing software based on the Monte Carlo ray-tracing method to numerically simulate the radiation flux profiles in a solar receiver tested in three different types of configurations: shallow semi-ellipsoidal, hemispherical, and deep semi-ellipsoidal receiver. The obtained flux profile was then used as a boundary condition for CFD simulation to analyze the heat transfer fluid’s behavior in the cavity receiver of the Stirling power system. The numerical modeling results were validated through an experiment using Xe-arc lamps as a heat source. Christo [43][35] presented numerical calculations of velocity and pressure fields, and dust particle trajectories of a hexagonal parabolic dish using ANSYS Fluent. The wind speeds were varied and the flow field structure, as well as the lift and drag coefficients, were obtained while varying the dish orientations. The restudyearch provided a good assessment of how to effectively reduce the aerodynamics drag of the solar dish structure. Pavlović et al. [40][32] performed a numerical simulation using TracePro software from Lambda Research, USA, to compare the optical performance of a flat circular disk and corrugated coil receiver, both having a spiral absorber. The optimal position and diameter of the receiver were also investigated and it was presented in the results that the optimal position was 2.075 m from the reflector surface, which is lower than the focal point of the reflector, and the optimal diameter of the receiver was found to be 400 mm. Another receiver modification was developed by Giovannelli and Bashir [35][27], which was a solar receiver made of a cylindrical container with 12 U-tubes and submerged in a Phase Change Material (PCM) which acts as a short-term storage system. The charge and discharge behavior of the PCM were analyzed using ANSYS Fluent CFD and the results showed that the proposed concept of a short-term storage system has a potential application in solar dish micro gas turbine (MGT) systems since it was able to maintain the temperature in the working fluid for 20–30 min.

Yang et al. [33][25] proposed a forced airflow concept in reducing the convective heat loss in the solar dish receiver. The geometry considered was a hallowed cylindrical cavity zoom with a U-shaped air channel and modeled in Fluent and ICEM software for CFD calculation. There were also two types of air circulation modes compared, the clockwise and anticlockwise circulation, and the results showed that the system can be improved better using the anticlockwise mode. Soltani et al. [31][23] studied the optical and thermal performance of a helically baffled cylindrical cavity receiver both theoretically and experimentally. First, an optical simulation was conducted for solar flux distribution in the collector and receiver using SolTrace MCRT software to minimize the computational cost before proceeding to the thermal simulation of real flux distribution in ANSYS Fluent. The combined optical and thermal simulation increased the accuracy of the numerical simulation, and the results showed a good agreement with the experimental data with a maximum deviation of only about 2%. The results also concluded that the receiver aperture distance from the focal point of the concentrator has a significant effect on the thermal performance of the CSP system. Lastly, Khalil et al. [30][22] presented a three-dimensional CFD laminar model using ANSYS Fluent to predict the fluid flow and heat transfer behavior of a thermo-plate conical cavity receiver made of welded sheets of 0.5 mm Inconel-625 with pressurized water as the heat transfer fluid (HTF) and a serpentine fluid path. Since the Reynolds number exceeds the laminar flow domain, it was planned to test the flow field using a turbulent model.

2.5. Design of Solar Dish Technology

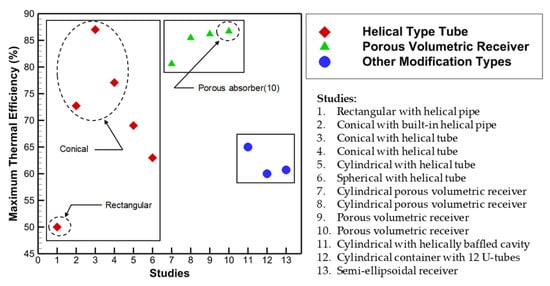

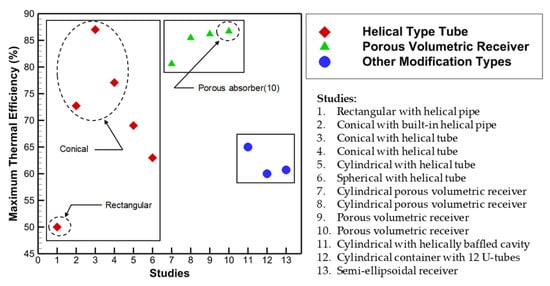

WResearchers observed in the published studies regarding computational fluid dynamics modeling of solar dish systems that there are two main types of solar receivers, the receiver with a helical tube absorber and the volumetric solar (VSR) receiver with a porous absorber. However, there are also other receiver modifications used for solar dish systems other than the two mentioned. For receivers with helical absorbers, the commonly used geometry configurations were cylindrical, conical, and spherical, but among these three, the conical shape was the most efficient type of receiver cavity, with an average thermal efficiency of 78.92%, and the rectangular cavity was the least efficient, with only 50% efficiency as provided in the literature. The data show that the thermal efficiency of receivers with helical tube absorbers varies largely depending on the shape of the receiver cavity. For the VSR, it was observed that the commonly used material for the absorber was made up of open-cell silicon carbide (SiC) ceramic foam. Between these two main types of solar receivers, the volumetric solar receiver with a porous absorber was more efficient compared to the tubular receiver, as presented in Figure 4. It is shown in the figure that the thermal efficiencies of VSR with a porous absorber from four different studies were observed to be consistently higher, with an average value of 84.74%, relative to the thermal efficiencies of the receiver with a helical absorber tube, with only 69.79% average thermal efficiency. This is due to the capability of the VSR to operate at relatively elevated temperatures [91,92][40][41]. In addition, the optimization of the geometry of the VSR by finding the optimal porosity and pore sizes of the absorber further enhances its thermal efficiency [26,41,44][18][33][37]. The other types of receivers with an average thermal efficiency of 61.9%, despite the modifications of the receiver design, were still less thermally efficient compared to the already established receiver designs such as the helical tube and the porous absorber.

Figure 4. The maximum thermal efficiency of different types of solar dish receiver: (1) Craig et al. [24][16], (2) Zhang et al. [28][20], (3) Daabo et al. [38][30], (4–6) Daabo et al. [39][31], (7) Barreto et al. [26][18], (8) Barreto et al. [29][21], (9) Aichmayer et al. [34][26], (10) Aichmayer et al. [41][33], (11) Soltani et al. [31][23], (12) Giovannelli & Bashir [35][27], (13) Li et al. [20][36].

Figure 4. The maximum thermal efficiency of different types of solar dish receiver: (1) Craig et al. [24][16], (2) Zhang et al. [28][20], (3) Daabo et al. [38][30], (4–6) Daabo et al. [39][31], (7) Barreto et al. [26][18], (8) Barreto et al. [29][21], (9) Aichmayer et al. [34][26], (10) Aichmayer et al. [41][33], (11) Soltani et al. [31][23], (12) Giovannelli & Bashir [35][27], (13) Li et al. [20][36].

Figure 4. The maximum thermal efficiency of different types of solar dish receiver: (1) Craig et al. [24][16], (2) Zhang et al. [28][20], (3) Daabo et al. [38][30], (4–6) Daabo et al. [39][31], (7) Barreto et al. [26][18], (8) Barreto et al. [29][21], (9) Aichmayer et al. [34][26], (10) Aichmayer et al. [41][33], (11) Soltani et al. [31][23], (12) Giovannelli & Bashir [35][27], (13) Li et al. [20][36].

Figure 4. The maximum thermal efficiency of different types of solar dish receiver: (1) Craig et al. [24][16], (2) Zhang et al. [28][20], (3) Daabo et al. [38][30], (4–6) Daabo et al. [39][31], (7) Barreto et al. [26][18], (8) Barreto et al. [29][21], (9) Aichmayer et al. [34][26], (10) Aichmayer et al. [41][33], (11) Soltani et al. [31][23], (12) Giovannelli & Bashir [35][27], (13) Li et al. [20][36].The largest solar dish collector ever modeled in CFD was by Zhang et al. [29][21], which has an aperture diameter of 5.06 m. It was also noted from the articles that the optimal distance of the receiver cavity from the collector aperture is not necessarily the focal distance of the parabolic collector. Moreover, optical modeling using the Monte Carlo ray-tracing method for the radiation flux distribution was usually performed first before proceeding to the actual radiation model using CFD. The most popular CFD software for this topic is ANSYS Fluent, while for the optics simulation, it is the OptisWorks software.

References

- Phillips, L. 9—Solar energy. In Managing Global Warming; Letcher, T.M., Ed.; Academic Press: Cambridge, MA, USA, 2019; pp. 317–332.

- Al-Abidi, A.A.; Bin Mat, S.; Sopian, K.; Sulaiman, M.Y.; Mohammed, A.T. CFD applications for latent heat thermal energy storage: A review. Renew. Sustain. Energy Rev. 2013, 20, 353–363.

- Liu, M.; Sun, Y.; Bruno, F. A review of numerical modelling of high-temperature phase change material composites for solar thermal energy storage. J. Energy Storage 2020, 29, 101378.

- Yadav, A.S.; Bhagoria, J.L. Heat transfer and fluid flow analysis of solar air heater: A review of CFD approach. Renew. Sustain. Energy Rev. 2013, 23, 60–79.

- Kasaeian, A.B.; Molana, S.; Rahmani, K.; Wen, D. A review on solar chimney systems. Renew. Sustain. Energy Rev. 2017, 67, 954–987.

- Nadda, R.; Kumar, A.; Maithani, R. Efficiency improvement of solar photovoltaic/solar air collectors by using impingement jets: A review. Renew. Sustain. Energy Rev. 2018, 93, 331–353.

- Chen, Q.; Wang, Y.; Zhang, J.; Wang, Z. The knowledge mapping of concentrating solar power development based on literature analysis technology. Energies 2020, 13, 1988.

- Yılmaz, İ.H.; Mwesigye, A. Modeling, simulation and performance analysis of parabolic trough solar collectors: A comprehensive review. Appl. Energy 2018, 225, 135–174.

- Olia, H.; Torabi, M.; Bahiraei, M.; Ahmadi, M.H.; Goodarzi, M.; Safaei, M.R. Application of nanofluids in thermal performance enhancement of parabolic trough solar collector: State-of-the-art. Appl. Sci. 2019, 9, 463.

- Bellos, E.; Tzivanidis, C.; Tsimpoukis, D. Enhancing the performance of parabolic trough collectors using nanofluids and turbulators. Renew. Sustain. Energy Rev. 2018, 91, 358–375.

- Junginger, M.; Louwen, A. Chapter 1—Introduction. In Technological Learning in the Transition to a Low-Carbon Energy System; Junginger, M., Louwen, A., Eds.; Academic Press: Cambridge, MA, USA, 2020; pp. 3–7.

- Rodríguez, I.; Pérez-Segarra, C.D.; Lehmkuhl, O.; Oliva, A. Modular object-oriented methodology for the resolution of molten salt storage tanks for CSP plants. Appl. Energy 2013, 109, 402–414.

- Fornarelli, F.; Camporeale, S.M.; Fortunato, B.; Torresi, M.; Oresta, P.; Magliocchetti, L.; Miliozzi, A.; Santo, G. CFD analysis of melting process in a shell-and-tube latent heat storage for concentrated solar power plants. Appl. Energy 2016, 164, 711–722.

- Hachicha, A.A.; Yousef, B.A.A.; Said, Z.; Rodríguez, I. A review study on the modeling of high-temperature solar thermal collector systems. Renew. Sustain. Energy Rev. 2019, 112, 280–298.

- Ubando, A.T.; San, R.; Cruz, J.D.P. Savonius Wind Turbine Numerical Parametric Analysis Using Space-Filling Design and Gaussian Stochastic Process. Wind 2022, 2, 7.

- Craig, K.J.; Slootweg, M.; Le Roux, W.G.; Wolff, T.M.; Meyer, J.P. Using CFD and ray tracing to estimate the heat losses of a tubular cavity dish receiver for different inclination angles. Sol. Energy 2020, 211, 1137–1158.

- Daabo, A.M.; Bellos, E.; Pavlovic, S.; Bashir, M.A.; Mahmoud, S.; Al-Dadah, R.K. Characterization of a micro thermal cavity receiver—Experimental and analytical investigation. Therm. Sci. Eng. Prog. 2020, 18, 100554.

- Barreto, G.; Canhoto, P.; Collares-Pereira, M. Parametric analysis and optimisation of porous volumetric solar receivers made of open-cell SiC ceramic foam. Energy 2020, 200, 117476.

- Herrmann, B.; Behzad, M.; Cardemil, J.M.; Calderón-Muñoz, W.R.; Fernández, R.M. Conjugate heat transfer model for feedback control and state estimation in a volumetric solar receiver. Sol. Energy 2020, 198, 343–354.

- Zhang, Y.; Xiao, H.; Zou, C.; Falcoz, Q.; Neveu, P. Combined optics and heat transfer numerical model of a solar conical receiver with built-in helical pipe. Energy 2020, 193, 116775.

- Barreto, G.; Canhoto, P.; Collares-Pereira, M. Three-dimensional CFD modelling and thermal performance analysis of porous volumetric receivers coupled to solar concentration systems. Appl. Energy 2019, 252, 113433.

- Khalil, I.; Pratt, Q.; Spitler, C.; Codd, D. Modeling a thermoplate conical heat exchanger in a point focus solar thermal collector. Int. J. Heat Mass Transf. 2019, 130, 1–8.

- Soltani, S.; Bonyadi, M.; Madadi Avargani, V. A novel optical-thermal modeling of a parabolic dish collector with a helically baffled cylindrical cavity receiver. Energy 2019, 168, 88–98.

- Zhao, W.; Zhang, Y.; Xu, B.; Li, P.; Wang, Z.; Jiang, S. Multiple-relaxation-time lattice Boltzmann simulation of flow and heat transfer in porous volumetric solar receivers. J. Energy Resour. Technol. Trans. ASME 2018, 140, 082003.

- Yang, S.; Wang, J.; Lund, P.D.; Wang, S.; Jiang, C. Reducing convective heat losses in solar dish cavity receivers through a modified air-curtain system. Sol. Energy 2018, 166, 50–58.

- Aichmayer, L.; Garrido, J.; Laumert, B. Scaling effects of a novel solar receiver for a micro gas-turbine based solar dish system. Sol. Energy 2018, 162, 248–264.

- Giovannelli, A.; Bashir, M.A. Charge and discharge analyses of a PCM storage system integrated in a high-temperature solar receiver. Energies 2017, 10, 1943.

- Uzair, M.; Anderson, T.N.; Nates, R.J. The impact of the parabolic dish concentrator on the wind induced heat loss from its receiver. Sol. Energy 2017, 151, 95–101.

- Daabo, A.M.; Mahmoud, S.; Al-Dadah, R.K.; Ahmad, A. Numerical investigation of pitch value on thermal performance of solar receiver for solar powered Brayton cycle application. Energy 2017, 119, 523–539.

- Daabo, A.M.; Ahmad, A.; Mahmoud, S.; Al-Dadah, R.K. Parametric analysis of small scale cavity receiver with optimum shape for solar powered closed Brayton cycle applications. Appl. Therm. Eng. 2017, 122, 626–641.

- Daabo, A.M.; Mahmoud, S.; Al-Dadah, R.K. The optical efficiency of three different geometries of a small scale cavity receiver for concentrated solar applications. Appl. Energy 2016, 179, 1081–1096.

- Pavlović, S.R.; Vasiljević, D.M.; Stefanović, V.P.; Stamenković, Z.M.; Bellos, E.A. Optical analysis and performance evaluation of a solar parabolic dish concentrator. Therm. Sci. 2016, 20, S1237–S1249.

- Aichmayer, L.; Spelling, J.; Laumert, B. Preliminary design and analysis of a novel solar receiver for a micro gas-turbine based solar dish system. Sol. Energy 2015, 114, 378–396.

- Yuan, J.K.; Ho, C.K.; Christian, J.M. Numerical simulation of natural convection in solar cavity receivers. J. Sol. Energy Eng. Trans. ASME 2015, 137, 031004.

- Christo, F.C. Numerical modelling of wind and dust patterns around a full-scale paraboloidal solar dish. Renew. Energy 2012, 39, 356–366.

- Li, Z.; Tang, D.; Du, J.; Li, T. Study on the radiation flux and temperature distributions of the concentrator-receiver system in a solar dish/Stirling power facility. Appl. Therm. Eng. 2011, 31, 1780–1789.

- Christo, F.C. Numerical modelling of wind Kumar, N.S.; Reddy, K.S. Investigation of convection and radiation heat losses from modified cavity receiver of solar parabolic dish using asymptotic computational fluid dynamics. Heat Transf. Eng. 2010, 31, 597–607.

- Prakash, M.; Kedare, S.B.; Nayak, J.K. Investigations on heat losses from a solar cavity receiver. Sol. Energy 2009, 83, 157–170.

- Bashir, M.A.; Daabo, A.M.; Amber, K.P.; Khan, M.S.; Arshad, A.; Elahi, H. Effect of phase change materials on the short-term thermal storage in the solar receiver of dish-micro gas turbine systems: A numerical analysis. Appl. Therm. Eng. 2021, 195, 117179.

- Fend, T.; Hoffschmidt, B.; Pitz-Paal, R.; Reutter, O.; Rietbrock, P. Porous materials as open volumetric solar receivers: Experimental determination of thermophysical and heat transfer properties. Energy 2004, 29, 823–833.

- Ho, C.K.; Iverson, B.D. Review of high-temperature central receiver designs for concentrating solar power. Renew. Sustain. Energy Rev. 2014, 29, 835–846.

More