Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 2 by Camila Xu and Version 1 by M. Azizur Rahman.

Additive manufacturing (AM) is a digital technology of layered fabrication by adding material where no cutting tool is required as in the case of a subtractive manufacturing process. AM is bridging the digital and physical world as a 3D computer-aided manufacturing (CAM) method. The usage of AM has made the supply chain of the aviation spare parts industry simpler, more effective, and efficient.

- additive manufacturing

- spare parts

- aircraft industries

- supply chain

1. Introduction

Additive manufacturing (AM) is a digital technology of layered fabrication by adding material where no cutting tool is required as in the case of a subtractive manufacturing process. In the earlier time, the application of AM was confined to rapid prototyping for physical product validation in the product development process. However, AM has been turned into a form of direct manufacturing technology due to the emerging advancement of its technological capability. It is estimated that AM industry will reach 35.6 billion USD by 2024, which was 7.34 billion USD in 2017 [1]. One of the top prospects behind the scenario is the capability of AM for mass customization of the product [2], fabrication of complex parts, on-demand product fabrication, cost-minimization, and waste-reduction [3,4][3][4]. Such characteristics of AM not only permit complex shape or customization in products but also are capable of fabricating high-performance aerospace components [5] and low volume production in the aerospace industry [6,7][6][7]. Hence, AM has become a potential fabrication process for the aerospace industry [8]. However, strategic implications have been adopted to apply AM in various applications, such as automotive, aerospace, and engineering by exploiting the potential and advantages of AM [9].

In Aircraft industries, high quality, safety standards and preventive maintenance are the dominant factors. Moreover, these industries require highly valued spare parts in larger volumes due to uncertain and unpredictable demand [10]. The unprecedented demands for spare parts occur when preventive maintenance has taken place, or any components fail randomly during the part life cycle [11]. Therefore, spare parts management has become crucial; and it incurs a higher holding cost [12]. Nevertheless, high shortage costs and obsolesce risk are inevitable for the spare parts [13]. Therefore, suppliers face an unpredictable barrier in their business investments as they need to produce older spare parts for a short life cycle. High stock levels can be a solution for this issue but it can increase obsolescence cost risk, holding cost and barriers to cash flow. Furthermore, a shortage of spare parts may lead to a lack of reliability, slow responsiveness, and poor cycle service level (CSL), which finally results in poor supply chain performance [14].

The aircraft industry also consists of maintenance, repair, overhaul (MRO) and original equipment manufacturers (OEMs) with MROs and OEMs being the prime service providers. GE aviation, Airbus, Boeing, and Rolls-Royce are notable OEMs in the aircraft industry [15]. MRO organizations manage the facilities to run the aircraft company’s processes and facilities smoothly [16]. Aircraft companies require MROs to deliver much-needed spare parts with high responsiveness and a higher fulfillment rate at a low cost [17]. Therefore, MRO services face significant challenges in aircraft spare parts supply chains to minimize costs [18]. Moreover, both the MROs and OEMs struggle to optimize the design and production processes to minimize the production lead times and waste by implementing lean manufacturing approaches [8]. Very few OEMs like BAE System, Raytheon, and Lockheed Martin are associated with manufacturing and designing aircraft’s main component systems due to the high market entrance barriers [19]. With computer-aided designs, advanced automation in AM has improved the products and services that are currently taking center stage in this endeavor [20]. With the advancement of AM, OEMs expect the spare parts manufacturing facility to locate near service areas [13]. The benefits of AM can reduce inventory, transportation, safety stock, uncertainty, and the overall supply chain costs. Accordingly, the complex supply chain of the aerospace industry needs to be more agile and efficient through the integration of AM. Therefore, extensive analysis is required with respect to the existing work in this field. To understand the current state of the literature, contributions of related research are summarized in Table 1.

Table 1.

Summary contribution of related articles.

| Author name | Supply Chain | Additive Manufacturing | Industry 4.0 | Spare Parts | Material Selection | Aircraft Industry |

|---|---|---|---|---|---|---|

| (Khajavi et al., 2014) [17] |

. Moreover, companies need to avoid evaluating a large number of spare parts covering multiple criteria as it is a time-consuming process. However, understanding the suitability of spare parts with AM is also important. By analyzing additively manufactured part characteristics, Artificial Intelligence (AI) can be a suitable technique according to regulatory bodies’ standards [86,87,88][54][55][56]. AI can ensure feature recognition characteristics for spare parts selection with AM that will not be repeated even if a new spare part is developed. As less research has been conducted in this process, identifying missing classification approaches and promising opportunities can be future research.

Table 62.

A summary of factors for spare parts selection.

| Spare Parts Selection Parameters | Description | Author Reference | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| ✓ | ✓ | |||||||||

| Part size, Build volume | AM machines have limitations of build volume as well as part size which depends on the resolution of the machine. | [ | ✓ | |||||||

| 79 | , | 89,90] | [47][57][58] | (Frandsen et al., 2019) [21] | ✓ | ✓ | ✓ | |||

| (Ceruti et al., 2019) [ | ||||||||||

| Supplier availability, demand pattern, lead time, predictability of delivery time | Normally AM is a time-consuming process rather than the machining process depending on the process parameters and part quality. Therefore, high resolution products can take large fabrication time rather than machining process, which may result in large lead time and delivery time need to be predicted to supply the spare parts in time | [90] | [58] | 22] | ||||||

| Appropriate material | ✓ | ✓ | Different materials have different mechanical properties, and their application may vary depending on their characteristics. | ✓ | ||||||

| [ | 91 | ] | [ | (Kalender et al., 2019) [23] | ✓ | ✓ | ✓ | |||

| 59 | ] | (Li et al., 2017) [24] | ✓ | ✓ | ✓ | |||||

| (Caesarendra et al., 2018) [25] | ✓ | ✓ | ||||||||

| (Zijm et al., 2019) [26] | ✓ | ✓ | ✓ | |||||||

| Appropriate material, Dimensional accuracy | The formability of complex shapes can affect the product dimension. Hence, proper material needs to be employed depending on material properties. | [92] | [60] | |||||||

| Post-production shrinkage; Appropriate material, water, and temperature resistance |

The AM fabrication process is conducted in an ambient temperature depending on the material. After producing the parts, it tends to have shrinkage and resulting change in the product dimensions. As accuracy and tolerance is a big factor for aviation spare parts, so the shrinkage, dimensional accuracy and temperature resistance need to be considered for the fabrication process | [3] | (P. Liu et al., 2014) [ | |||||||

| Stiffness to weight ratio, Appropriate material, support material, strength to weight ratio | The part mechanical properties like stiffness to weight ratio, and strength to weight ratio need to be considered for better performance under a loading environment. The mechanical properties also depend on the product material and support material to sustain under loading. | [93] | [61] | 27] | ✓ | ✓ | ✓ | ✓ | ||

| Layer thickness, Build speed | Optimized layer thickness, and printing speed needed for better part quality and material consumption. | [94] | [62] | |||||||

| Supplier availability, demand pattern, lead time, responsiveness, downtime cost, maintenance type | The spare parts need to be easy to change or repair. Otherwise, it will increase downtime in the maintenance work. | [5,95] | [5][63] | (Chekurov et al., 2021) [19] | ✓ | ✓ | ✓ | |||

| Supplier availability, demand pattern, lead time, Annual consumption value | The annual consumption of materials and spare parts plays a vital role in the MRO’s yearly revenue. | ✓ | ||||||||

| [ | 21 | ,96 | (Mehrpouya et al., 2019) [28] | ✓ | ✓ | ✓ | ||||

| (Yusuf et al., 2019) [29] | ✓ | ✓ | ✓ | |||||||

| (H. Khajavi et al., 2018) [30] | ✓ | ✓ | ✓ | ✓ | ||||||

| (de Souza et al., 2011) [31] | ✓ | ✓ | ✓ | |||||||

| This Paper | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

Despite the increasing number of publications in this field, there are currently insufficient techniques and models that thoroughly address and organize this topic. There exists a gap in the proper extensive literature review in this field. To the best of our knowledge, there seems to be a lack of review papers in additive manufacturing of spare parts concentrating on the aviation industry, compared to many other topics in AM. Through a survey of relevant literature, the reseauthorchers hope to make tangible fundamental and technical contributions. The goal is to use the findings of this research to develop new scientific methodologies and models for assessing and enhancing the supply chain of the spare parts (SP) industry through AM.

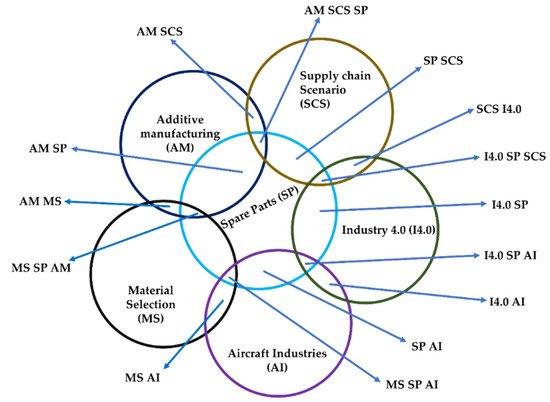

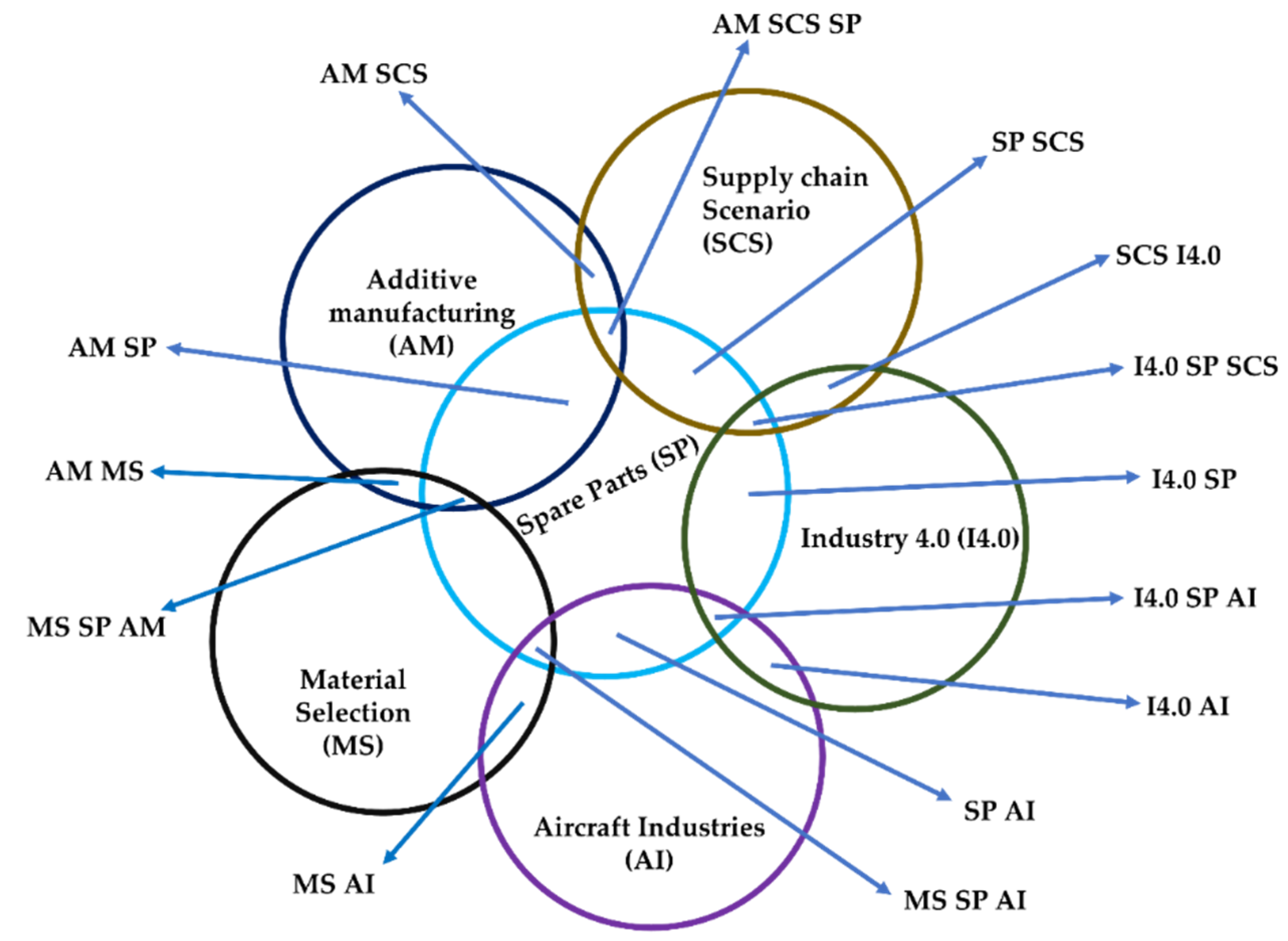

The framework of core subject areas, explained in this preseaperrch, is illustrated in Figure 1. The shared portions of the frameworks are described in this preseaperrch through a systematic literature search and literature review. Consolidation of information from various literature was induced towards bringing proper value to the research.

Figure 1. Framework of Core Subject Areas Mapping.

Figure 1. Framework of Core Subject Areas Mapping.2. Spare Parts with Additive Manufacturing for Aviation Industry

Additive manufacturing (AM) is established as the manufacturing process that increases the revenue of the aerospace industry with the repairing operation and supply chain [27]. AM provides new opportunities to make sustainable, topologically optimized, lightweight spare parts for aircraft. Various sophisticated components and subcomponents assemble them, and a multi-tiered manufacturing structure is required. Therefore, intensive work is needed in the inventory and supply chain to continue smooth operation in the aircraft assembly. However, continuous improvements in process are still required to ensure safety and quality in the aeronautical industry considering the below attributes.

2.1. Quality Assurance and Standardization

Some structural parts and critical components of engines are made of metals using AM, which may bring catastrophic and consequent events if they fail. These components require rigorous assessments to get certified. ISO/TC261 and ASTM F42 have been formed to establish standards on terminology, materials, processes, and test procedures for AM [65][32]. While SAE International primarily works on aerospace-related AM standards, both ISO and ASTM are responsible for AM standard publications [66][33]. Therefore, FAA and EASA have established certification and testing protocols to clear any components for service on the required application [67][34]. Major leading regulatory bodies like ASTM, ANSI, and SAE international have collaborated frequently with aviation regulatory bodies, such as NASA, FAA, and EASA [68,69][35][36]. This effort has accelerated the certification process and ensured continued operational safety for adopting AM in the aerospace industry [70][37]. However, a well-established standardization has not been conducted yet, and the process is quite costly and lengthy.

2.2. Part Consolidation

In conventional machining processes, complex shapes cannot be fabricated easily. Thereby, in CM processes, simple parts are joined together to construct or assemble complex aerospace parts which require different types of joins or fasteners like welds, braze, nut bolts, etc. However, these joining processes are less reliable and sustainable with respect to a single part [71][38]. Moreover, any error in tolerance, misalignment, or geometric error would complicate the assembly process [72][39]. Additive Manufacturing can solve this problem by fabricating a complex part combining components that enables feature integration and increases reliability, sustainability, and performance [73][40]. Moreover, it will reduce inventory, lead time, assembly-line footprint, and supply chain pressure by increasing components’ performance [5,74][5][41]. For example, a hydraulic housing tank containing 126 parts can be reduced into a single component using AM [64][42]. Similarly, GE aviation has consolidated conventionally manufactured 855 components into a dozen parts using AM, resulting in a 20% improvement in fuel burn and 10% more power [75][43].

2.3. Materials Selection for Spare Parts in Additive Manufacturing

Spare parts forecasting is challenging as the demand pattern is intermittent [76][44]. A higher service level is required to avoid downtime costs, making the spare parts planning more complicated [77][45]. Therefore, companies need to keep high inventories of spare parts to compete with service-level requirements. AM allows producing low-volume parts away from CM processes. By removing disrupted parts with part consolidation and low volume parts from traditional fabrication methods, AM can maximize the service level for spare parts by availing time [77,78][45][46]. AM can increase responsiveness by balancing inventory levels and minimizing carbon emissions and disruptions in the supply network of spare parts [77][45]. AM reduces the supply risk for spare parts for low-demand parts while conventionally manufactured part is unavailable in low quantity [79][47]. However, a limited volume of AM, inadequate quality and post-processing requirements are the challenges for this purpose [80][48]. Additively manufactured spare parts can be used to repair damaged parts without replacing the whole parts, such as repairing the burner tip of a gas turbine by Siemens [26]. Aircraft MROs require fabricating parts in minimal quantities; hence, they face a widely distributed supply chain and unpredictable demand [11]. The demand is often affected by disputable factors like failure rates, type of maintenance, and wear behaviors [81][49]. Many aircraft spare parts are highly valued, ordered infrequently, and require a long replenishment lead time [82][50]. Hence, a literature gap remains where the lead time can be simulated for varying AM spare parts percentages in the overall system and its effect on the replenishment lead time can be monitored. Sometimes, repairing tools become unavailable from OEMs [74][41]. AM may play a recovery role in this perspective. For example, by using AM instead of milling, the lead time and cost to repair a helicopter part have been reduced from 45 days and $2000 to 2 days and $412 respectively [83][51]. The U.S. air force has collaborated with ‘America Makes’ to supply on-demand production to reduce the lead time for maintenance and replacement components of aircraft [84][52]. A summary of factors to be considered for spare parts selection is given in Table 62. Appropriate supply chain and technical factors should be considered to classify spare parts with AM. Moreover, companies are not classifying spare parts with a systematic data-driven way to choose the suitable spare parts for AM, which tends to fail in searching for the potential aspects and is a time-consuming exercise. A data-driven approach and multi-criteria decision-making (MCDM) techniques may assist in prioritizing the factors [85][53]

2.4. Material Criteria

Titanium, Aluminum, Nickel, stainless steel, tool steel, etc., are commonly used in AM for the aerospace industry [98][66]. However, the most popular materials used are Nickel and Titanium base alloys due to their remarkable properties at elevated temperature which is well suited for aerospace application [99][67]. Moreover, silver, gold as well as platinum can be used for selective application in the aerospace industry [53][68]. Furthermore, Ti6Al4V alloy has been used extensively due to its high strength and fracture toughness, low density, low thermal coefficient, etc. [100][69]. In addition, the titanium alloy is used widely for mass manufacturing of turbine blades for use in commercial aircraft [101,102][70][71].

Various cabin accessories in aircraft like seatbacks, entry door parts, transparent headlights, full-size panels, and functional knobs have been manufactured in a highly detailed manner with SLA clear resins [103][72]. Moreover, Aurora Flight science and Stratasys have fabricated the largest Unmanned Aerial vehicle (UAV) with ULTEM 9085 material with the FDM process [61][73]. NASA’s Mars rover has used 70 Production grade thermoplastic parts in the FDM process. Mainly, plastic materials are used because they are lightweight yet durable and strong enough to withstand stringent conditions [104][74]. Noteworthy, in CM processes, the fabrication of a part starts with cutting down a large ingot to the desired shape. Therefore, multiple component fabrication requires more ingots and machining, resulting in high wastage of around 90%, and low material utilization, with a high ‘buy-to-fly ratio’ of nearly 10:1 [105][75]. The ‘buy-to-fly ratio’ is an established concept in AM for the aerospace sector that refers to the weight ratio of raw material and the component itself [106,107][76][77]. Approximately 70% weight reduction of the original weight is possible in AM process [89,108][57][78]. The main advantage of AM is to fabricate the product to near net shape with approximately 1:1 ‘buy-to-fly ratio’ and significantly minimize material waste by nearly 10–20% [109][79]. Even though the material cost is higher for AM than CM, a lower ‘buy-to-fly ratio’, minimum wastage, mass customization, and recyclable capabilities significantly reduce the overall manufacturing cost in AM [110][80]. AM can be considered an economical and better option than CM with added operational, inventory, and supply chain benefits.

Recently, AM has been applied to various complex-shaped spare parts fabrication by showing significant inroads in manufacturing novel components. However, AM’s drawbacks remain on maintenance requirements, standardization, part size, geometry accuracy, printing quality, limited materials, and costs for spare parts production in the Aerospace industry. Therefore, further research on design methods, consolidated part configuration, and novel materials are required to overcome the challenges and maximize the applications of AM in the aerospace spare parts industry.

References

- Wohlers, T.T. Wohlers, T.T. Wohlers Report 2019: 3D Printing and Additive Manufacturing State of the Industry. In Wohlers Associates; ASTM International: Washington, DC, USA; Fort Collins, CO, USA, 2019; p. 369.

- Reeves, P.; Tuck, C.; Hague, R. Additive Manufacturing for Mass Customization. In Mass Customization; Springer: Berlin/Heidelberg, Germany, 2011; pp. 275–289.

- Horn, T.J.; Harrysson, O.L.A. Overview of Current Additive Manufacturing Technologies and Selected Applications. Sci. Prog. 2012, 95, 255–282.

- Ford, S.; Despeisse, M. Additive Manufacturing and Sustainability: An Exploratory Study of the Advantages and Challenges. J. Clean. Prod. 2016, 137, 1573–1587.

- Liu, R.; Wang, Z.; Sparks, T.; Liou, F.; Newkirk, J. Aerospace Applications of Laser Additive Manufacturing. Laser Addit. Manuf. Mater. Des. Technol. Appl. 2017, 1, 351–371.

- Zhu, L.; Li, N.; Childs, P.R.N. Light-Weighting in Aerospace Component and System Design. Propuls. Power Res. 2018, 7, 103–119.

- Abdulhameed, O.; Al-Ahmari, A.; Ameen, W.; Mian, S.H. Additive Manufacturing: Challenges, Trends, and Applications. Adv. Mech. Eng. 2019, 11, 1–27.

- Altıparmak, S.C.; Xiao, B. A Market Assessment of Additive Manufacturing Potential for the Aerospace Industry. J. Manuf. Process 2021, 68, 728–738.

- Beyer, C. Strategic Implications of Current Trends in Additive Manufacturing. J. Manuf. Sci. Eng. Trans. ASME 2014, 136, 064701.

- Simao, H.; Powell, W. Approximate Dynamic Programming for Management of High/Value Spare Parts. J. Manuf. Technol. Manag. 2009, 20, 147–160.

- Regattieri, A.; Gamberi, M.; Gamberini, R.; Manzini, R. Managing Lumpy Demand for Aircraft Spare Parts. J. Air Transp. Manag. 2005, 11, 426–431.

- Syntetos, A.A.; Babai, M.Z.; Altay, N. On the Demand Distributions of Spare Parts. Int. J. Prod. Res. 2012, 50, 2101–2117.

- Holmström, J.; Partanen, J. Digital Manufacturing-Driven Transformations of Service Supply Chains for Complex Products. Supply Chain Manag. 2014, 19, 421–430.

- Gu, J.; Zhang, G.; Li, K.W. Efficient Aircraft Spare Parts Inventory Management under Demand Uncertainty. J. Air Transp. Manag. 2015, 42, 101–109.

- Gudmundsson, S.V. Thriving on Strategic Alliances: The Competitive Positioning of MTU in the Aircraft Engine Business. SSRN Electron. J. 2014, 7–10.

- Dinis, D.; Barbosa-Póvoa, A.; Teixeira, Â.P. A Supporting Framework for Maintenance Capacity Planning and Scheduling: Development and Application in the Aircraft MRO Industry. Int. J. Prod. Econ. 2019, 218, 1–15.

- Khajavi, S.H.; Partanen, J.; Holmström, J. Additive Manufacturing in the Spare Parts Supply Chain. Comput. Ind. 2014, 65, 50–63.

- Huang, S.H.; Liu, P.; Mokasdar, A.; Hou, L. Additive Manufacturing and Its Societal Impact: A Literature Review. Int. J. Adv. Manuf. Technol. 2013, 67, 1191–1203.

- Chekurov, S.; Salmi, M.; Verboeket, V.; Puttonen, T.; Riipinen, T.; Vaajoki, A. Assessing Industrial Barriers of Additively Manufactured Digital Spare Part Implementation in the Machine-Building Industry: A Cross-Organizational Focus Group Interview Study. J. Manuf. Technol. Manag. 2021, 32, 909–931.

- Khorasani, M.; Ghasemi, A.H.; Rolfe, B.; Gibson, I. Additive Manufacturing a Powerful Tool for the Aerospace Industry. Rapid Prototyp. J. 2022, 28, 87–100.

- Yusuf, S.M.; Cutler, S.; Gao, N. Review: The Impact of Metal Additive Manufacturing on the Aerospace Industry. Metals 2019, 9, 1286.

- Khajavi, S.M.; Holmström, J.; Partanen, J. Additive Manufacturing in the Spare Parts Supply Chain: Hub Configuration and Technology Maturity. Rapid Prototyp. J. 2018, 24, 1178–1192.

- de Souza, R.; Tan, A.W.K.; Othman, H.; Garg, M. A Proposed Framework for Managing Service Parts in Automotive and Aerospace Industries. Benchmarking 2011, 18, 769–782.

- Frandsen, C.S.; Nielsen, M.M.; Chaudhuri, A.; Jayaram, J.; Govindan, K. In Search for Classification and Selection of Spare Parts Suitable for Additive Manufacturing: A Literature Review. Int. J. Prod. Res. 2019, 58, 970–996.

- Ceruti, A.; Marzocca, P.; Liverani, A.; Bil, C. Maintenance in Aeronautics in an Industry 4.0 Context: The Role of Augmented Reality and Additive Manufacturing. J. Comput. Des. Eng. 2019, 6, 516–526.

- Kalender, M.; Kilic, S.E.; Ersoy, S.; Bozkurt, Y.; Salman, S. Additive Manufacturing and 3D Printer Technology in Aerospace Industry. In Proceedings of the 2019 9th International Conference on Recent Advances in Space Technologies (RAST), Istanbul, Turkey, 11–14 June 2019; pp. 689–695.

- Li, Y.; Jia, G.; Cheng, Y.; Hu, Y. Additive Manufacturing Technology in Spare Parts Supply Chain: A Comparative Study. Int. J. Prod. Res. 2017, 55, 1498–1515.

- Caesarendra, W.; Pappachan, B.K.; Wijaya, T.; Lee, D.; Tjahjowidodo, T.; Then, D.; Manyar, O.M. An AWS Machine Learning-Based Indirect Monitoring Method for Deburring in Aerospace Industries Towards Industry 4.0. Appl. Sci. 2018, 8, 2165.

- Zijm, H.; Knofius, N.; van der Heijden, M. Additive Manufacturing and Its Impact on the Supply Chain; Springer International Publishing: Cham, Switzerland, 2019.

- Liu, P.; Huang, S.H.; Mokasdar, A.; Zhou, H.; Hou, L. The Impact of Additive Manufacturing in the Aircraft Spare Parts Supply Chain: Supply Chain Operation Reference (Scor) Model Based Analysis. Prod. Plan. Control 2014, 25, 1169–1181.

- Mehrpouya, M.; Dehghanghadikolaei, A.; Fotovvati, B.; Vosooghnia, A.; Emamian, S.S.; Gisario, A. The Potential of Additive Manufacturing in the Smart Factory Industrial 4.0: A Review. Appl. Sci. 2019, 9, 3865.

- Committee F42 on Additive Manufacturing Technologies. Available online: https://www.astm.org/get-involved/technical-committees/committee-f42 (accessed on 16 January 2022).

- The I/O Buffer Information Specification (IBIS) Open Forum Releases the IBIS Version 7.1 Specification. Available online: https://www.sae.org/news/2018/06/sae-international-issues-first-aerospace-additive-manufacturing-technical-standards (accessed on 16 January 2022).

- Singamneni, S.; LV, Y.; Hewitt, A.; Chalk, R.; Thomas, W.; Jordison, D. Additive Manufacturing for the Aircraft Industry: A Review. J. Aeronaut. Aerosp. Eng. 2019, 8, 1–13.

- Hrabe, N.W.; Barbosa, N.; Daniewicz, S.; Shamsaei, N. Findings from the NIST/ASTM Workshop on Mechanical Behavior of Additive Manufacturing Components; National Institute of Standards and Technology: Boulder, CO, USA, 2016.

- SAE Standards Works. Available online: https://www.sae.org/works/committeeHome.do?comtID=TEAAMSAM (accessed on 16 January 2022).

- FAA. In Joint Federal Aviation Administration–Air Force Workshop on Qualification/Certification of Additively Manufactured Parts; Tech Report, United States, (DOT/FAA/TC-16/15); Department of Transportation. Federal Aviation Administration. William J. Hughes Technical Center: Atlantic City, NJ, USA, 2016; p. 227.

- Shapiro, A.A.; Borgonia, J.P.; Chen, Q.N.; Dillon, R.P.; McEnerney, B.; Polit-Casillas, R.; Soloway, L. Additive Manufacturing for Aerospace Flight Applications. J. Spacecr. Rocket. 2016, 53, 952–959.

- Saadat, M. Challenges in the Assembly of Large Aerospace Components. Integr. Syst. Des. Technol. 2011, 37–46.

- Duda, T.; Raghavan, L.V. 3D Metal Printing Technology. IFAC-PapersOnLine 2016, 49, 103–110.

- 3D Opportunity in Aerospace and Defense: Additive Manufacturing Takes Flight|Deloitte Insights. Available online: https://www2.deloitte.com/us/en/insights/focus/3d-opportunity/additive-manufacturing-3d-opportunity-in-aerospace.html (accessed on 9 January 2022).

- Najmon, J.C.; Raeisi, S.; Tovar, A. Review of Additive Manufacturing Technologies and Applications in the Aerospace Industry. Addit. Manuf. Aerosp. Ind. 2019, 7–31.

- An Epiphany of Disruption: GE Additive Chief Explains How 3D Printing Will Upend Manufacturing|GE News. Available online: https://www.ge.com/news/reports/epiphany-disruption-ge-additive-chief-explains-3d-printing-will-upend-manufacturing (accessed on 9 January 2022).

- Zhu, J.H.; Zhang, W.H.; Xia, L. Topology Optimization in Aircraft and Aerospace Structures Design. Arch. Comput. Methods Eng. 2015, 23, 595–622.

- Ghadge, A.; Karantoni, G.; Chaudhuri, A.; Srinivasan, A. Impact of Additive Manufacturing on Aircraft Supply Chain Performance: A System Dynamics Approach. J. Manuf. Technol. Manag. 2018, 29, 846–865.

- Sasson, A.; Johnson, J.C. The 3D Printing Order: Variability, Supercenters and Supply Chain Reconfigurations. Int. J. Phys. Distrib. Logist. Manag. 2016, 46, 82–94.

- Knofius, N.; Van Der Heijden, M.C.; Zijm, W.H.M. Selecting Parts for Additive Manufacturing in Service Logistics. J. Manuf. Technol. Manag. 2016, 27, 915–931.

- Kretzschmar, N.; Chekurov, S.; Salmi, M.; Tuomi, J. Evaluating the Readiness Level of Additively Manufactured Digital Spare Parts: An Industrial Perspective. Appl. Sci. 2018, 8, 1837.

- Lowas, A.F.; Ciarallo, F.W. Reliability and Operations: Keys to Lumpy Aircraft Spare Parts Demands. J. Air Transp. Manag. 2016, 50, 30–40.

- Basten, R.J.I.; van Houtum, G.J. System-Oriented Inventory Models for Spare Parts. Surv. Oper. Res. Manag. Sci. 2014, 19, 34–55.

- Additive Manufacturing Reduces Tooling Cost and Lead Time to Produce Composite Aerospace Parts-Global Print Monitor. Available online: http://globalprintmonitor.de/en/3d/3d-printing-news/aerospace/17617-additive-manufacturing-reduces-tooling-cost-and-lead-time-to-produce-composite-aerospace-parts (accessed on 19 January 2022).

- America Makes Announces Project Call Awardees-America Makes. Available online: https://www.americamakes.us/america-makes-announces-mamls-ph3-project-call-awardees/ (accessed on 18 January 2022).

- Bhattacharya, A.; Sarkar, B.; Mukherjee, S.K. Distance-Based Consensus Method for ABC Analysis. Int. J. Prod. Res. 2007, 45, 3405–3420.

- Shneiderman, B. Human-Centered Artificial Intelligence: Reliable, Safe & Trustworthy. Int. J. Hum.-Comput. Interact. 2020, 36, 495–504.

- Wischmeyer, T.; Rademacher, T. Regulating Artificial Intelligence; Springer: Cham, Switzerland, 2019; pp. 1–388.

- Dirican, C. The Impacts of Robotics, Artificial Intelligence on Business and Economics. Procedia-Soc. Behav. Sci. 2015, 195, 564–573.

- Lindermann, C.; Jahnke, U.; Moi, M.; Koch, R. Analyzing Product Lifecycle Costs for a Better Understanding of Cost Drivers in Additive Manufacturing. 2012. Available online: https://repositories.lib.utexas.edu/handle/2152/88402 (accessed on 10 January 2022).

- Chekurov, S.; Metsä-Kortelainen, S.; Salmi, M.; Roda, I.; Jussila, A. The Perceived Value of Additively Manufactured Digital Spare Parts in Industry: An Empirical Investigation. Int. J. Prod. Econ. 2018, 205, 87–97.

- Stansbury, J.W.; Idacavage, M.J. 3D Printing with Polymers: Challenges among Expanding Options and Opportunities. Dent. Mater. 2016, 32, 54–64.

- Wang, X.; Jiang, M.; Zhou, Z.; Gou, J.; Hui, D. 3D Printing of Polymer Matrix Composites: A Review and Prospective. Compos. Part B Eng. 2017, 110, 442–458.

- Zaman, U.K.U.; Rivette, M.; Siadat, A.; Mousavi, S.M. Integrated Product-Process Design: Material and Manufacturing Process Selection for Additive Manufacturing Using Multi-Criteria Decision Making. Robot. Comput. Integr. Manuf. 2018, 51, 169–180.

- Molenaers, A.; Baets, H.; Pintelon, L.; Waeyenbergh, G. Criticality Classification of Spare Parts: A Case Study. Int. J. Prod. Econ. 2012, 140, 570–578.

- Huiskonen, J. Maintenance Spare Parts Logistics: Special Characteristics and Strategic Choices. Int. J. Prod. Econ. 2001, 71, 125–133.

- Lolli, F.; Ishizaka, A.; Gamberini, R. New AHP-Based Approaches for Multi-Criteria Inventory Classification. Int. J. Prod. Econ. 2014, 156, 62–74.

- Sarmah, S.P.; Moharana, U.C. Multi-Criteria Classification of Spare Parts Inventories-A Web Based Approach. J. Qual. Maint. Eng. 2015, 21, 456–477.

- Bourell, D.L.; Leu, M.C.; Rosen, D.W. Roadmap for Additive Manufacturing: Identifying the Future of Freeform Processing; The University of Texas at Austin: Austin, TX, USA, 2009.

- Bourell, D.; Kruth, J.P.; Leu, M.; Levy, G.; Rosen, D.; Beese, A.M.; Clare, A. Materials for Additive Manufacturing. CIRP Ann. 2017, 66, 659–681.

- Frazier, W.E. Metal Additive Manufacturing: A Review. J. Mater. Eng. Perform. 2014, 23, 1917–1928.

- Wu, X.; Liang, J.; Mei, J.; Mitchell, C.; Goodwin, P.S.; Voice, W. Microstructures of Laser-Deposited Ti–6Al–4V. Mater. Des. 2004, 25, 137–144.

- The Blade Runners: This Factory Is 3D Printing Turbine Parts for the World’s Largest Jet Engine|GE News. Available online: https://www.ge.com/news/reports/future-manufacturing-take-look-inside-factory-3d-printing-jet-engine-parts (accessed on 15 January 2022).

- Titanium Aluminide-MTU Aero Engines Develops New Turbine Blade Material-MTU Aero Engines. Available online: https://www.mtu.de/newsroom/press/press-archive/press-archive-detail/titanium-aluminide-mtu-aero-engines-develops-new-turbine-blade-material/ (accessed on 15 January 2022).

- Froes, R.B.F. Additive Manufacturing for the Aerospace Industry, 1st ed.; Froes, R.B.F., Ed.; Elsevier: Amsterdam, The Netherlands, 2019.

- World’s First Jet-Powered, 3D Printed UAV Tops 150 MPH|Stratasys. Available online: https://www.stratasys.com/explore/blog/2015/aurora-uav-3d-printing (accessed on 17 January 2022).

- NASA 3D Printing Case Study|Stratasys. Available online: https://www.stratasys.co.in/resources/search/case-studies/nasa (accessed on 17 January 2022).

- Watson, J.K.; Taminger, K.M.B. A Decision-Support Model for Selecting Additive Manufacturing versus Subtractive Manufacturing Based on Energy Consumption. J. Clean. Prod. 2018, 176, 1316–1322.

- Allen, J. An Investigation into the Comparative Costs of Additive Manufacture vs. Machine from Solid for Aero Engine Parts. 2006. Available online: https://www.sto.nato.int/publications/STO%20Meeting%20Proceedings/RTO-MP-AVT-139/MP-AVT-139-17.pdf (accessed on 10 January 2022).

- Weller, C.; Kleer, R.; Piller, F.T. Economic Implications of 3D Printing: Market Structure Models in Light of Additive Manufacturing Revisited. Int. J. Prod. Econ. 2015, 164, 43–56.

- Baumers, M.; Dickens, P.; Tuck, C.; Hague, R. The Cost of Additive Manufacturing: Machine Productivity, Economies of Scale and Technology-Push. Technol. Forecast. Soc. Change 2016, 102, 193–201.

- Rawal, S. Materials and Structures Technology Insertion into Spacecraft Systems: Successes and Challenges. Acta Astronaut. 2018, 146, 151–160.

- Wimpenny, D.I.; Pandey, P.M.; Kumar, L.J. Advances in 3D Printing & Additive Manufacturing Technologies; Springer: Cham, Switzerland, 2016; pp. 1–186.

More