The fast expansion of digital culture has fostered the creation of makerspaces such as fabrication laboratories (FabLabs) that, thanks to their flexibility and their use of open source tools, strengthen the sense of community and produce true transformations within those communities.

Fabrication laboratories (FabLabs) are an integral part of “communities and spaces with more or less open to the public levels, with objectives and targets agreed by its members in which, through learning processes, production, prototyping, design, and manufacturing, both tangible and intangible assets, complex two-way exchanges of information are produced, knowledge, technology, skills and resources among users, users and society and between users and industry” that constitute the new wave of collaborative ecologies into which elements such as makerspaces, hackerspaces, living-labs or co-workings also fall, highlighted by its origin and its capacity as an international organization. A FabLab is a strong social space offering affordable and accessible manufactured tools and is sometimes conceived as an appropriate platform to begin the prototyping and development processes of any object. They emerged in the 2000s at the Massachusetts Institute of Technology (MIT) from Professor Neil Gershenfeld’s subject, called “How to Make (Almost) Anything”. Thanks to the creation of this first FabLab, Professor Gershenfeld’s students could realize their designs, popularizing digital manufacturing and making the subject successful.

- fablabs

- digital manufacturing

- sustainability

- FabLab

- MakerSpace

1. Introduction

2. Distinctive Features

Once the physical, social and economic conditions laboratories are identified, wthe researchers focus on their distinguishing characteristics, among which are the ability to promote entrepreneurship (through fast prototyping, level of innovation, collaboration with other entities, or due to independence in project development), the training offered and the public documentation of projects undertaken to conclude with their contribution to the community.2.1. Entrepreneurship and Fast Prototyping

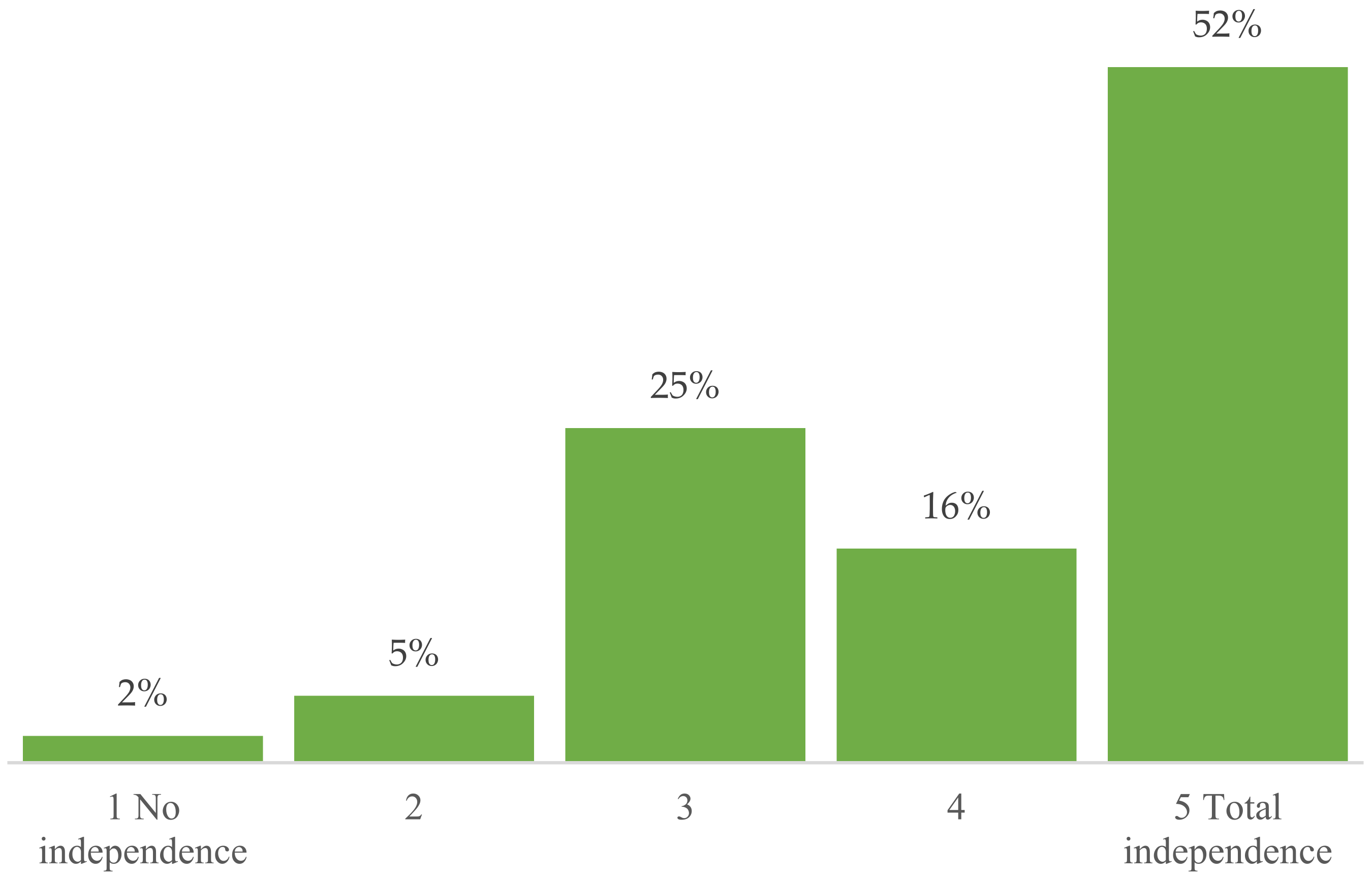

The FabLab can serve as a vivarium for business development, improving products and processes or generating prototypes that constitute the minimum viable product of a commercial initiative. Among the FabLab Global Survey participants, 22.9% had witnessed the creation of a new commercial initiative, stressing the importance of these processes. The economic sustainability of these laboratories is, however, even today, an added difficulty for their own characteristics, causing many of them to depend in one way or another on the entity that hosts them. This kind of dependence could well place a limitation on the development of projects by establishing clear preferences in their choice, skewing the typology of their development or limiting the involvement of the laboratory in certain types of activities. Answers provided by the participants show a high perception of the contribution of the FabLab as a factor in the development of entrepreneurial culture (73% of respondents rated their agreement with a 4 or 5 out of 5). A positive impact is noted on the contribution of the close ecologies to the FabLab, as positive factors in the development of entrepreneurial culture (73% of respondents rated their agreement with a 4 or 5 out of 5). The perception of fast prototyping as a contribution is also highly considered (90% of respondents rated it with 4 or above out of 5 as seen ), probably due to involvement in innovation processes. The FabLab Global Survey evaluated the perception of independence in carrying out different projects. The participants were asked to indicate the perceived independence of the realization of the FabLab projects on a 1 to 5 scale, with 1 meaning a null independence, and therefore a full dependence, and 5 meaning a complete independence. It is important to consider that while a large percentage of laboratories are dependent on institutions to ensure sustainability, 68% of laboratories indicated a high level of independence, and 52% of the participants indicated a level of absolute independence (Figure 15).

2.2. Development of Joint Projects with Other Institutions and Groups

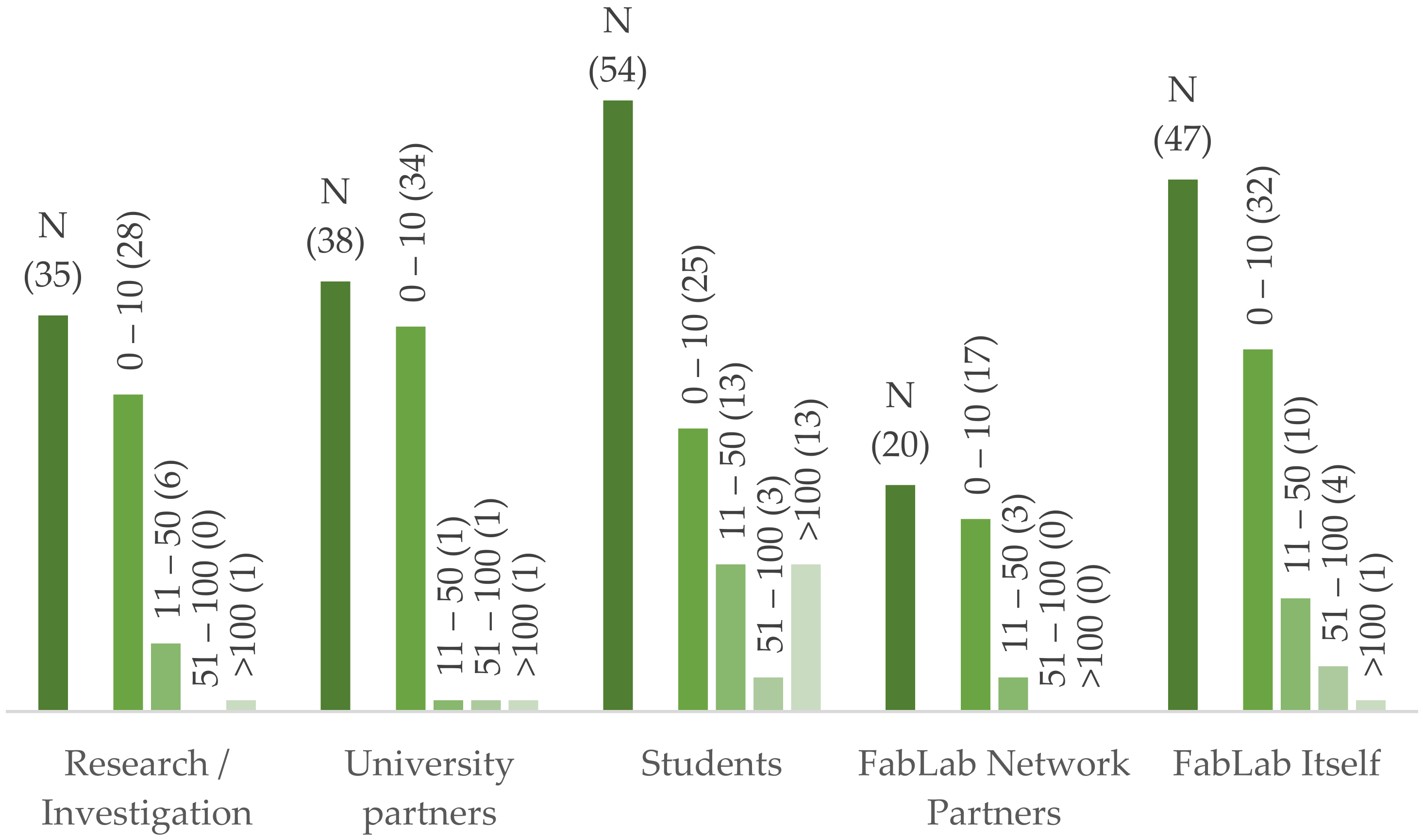

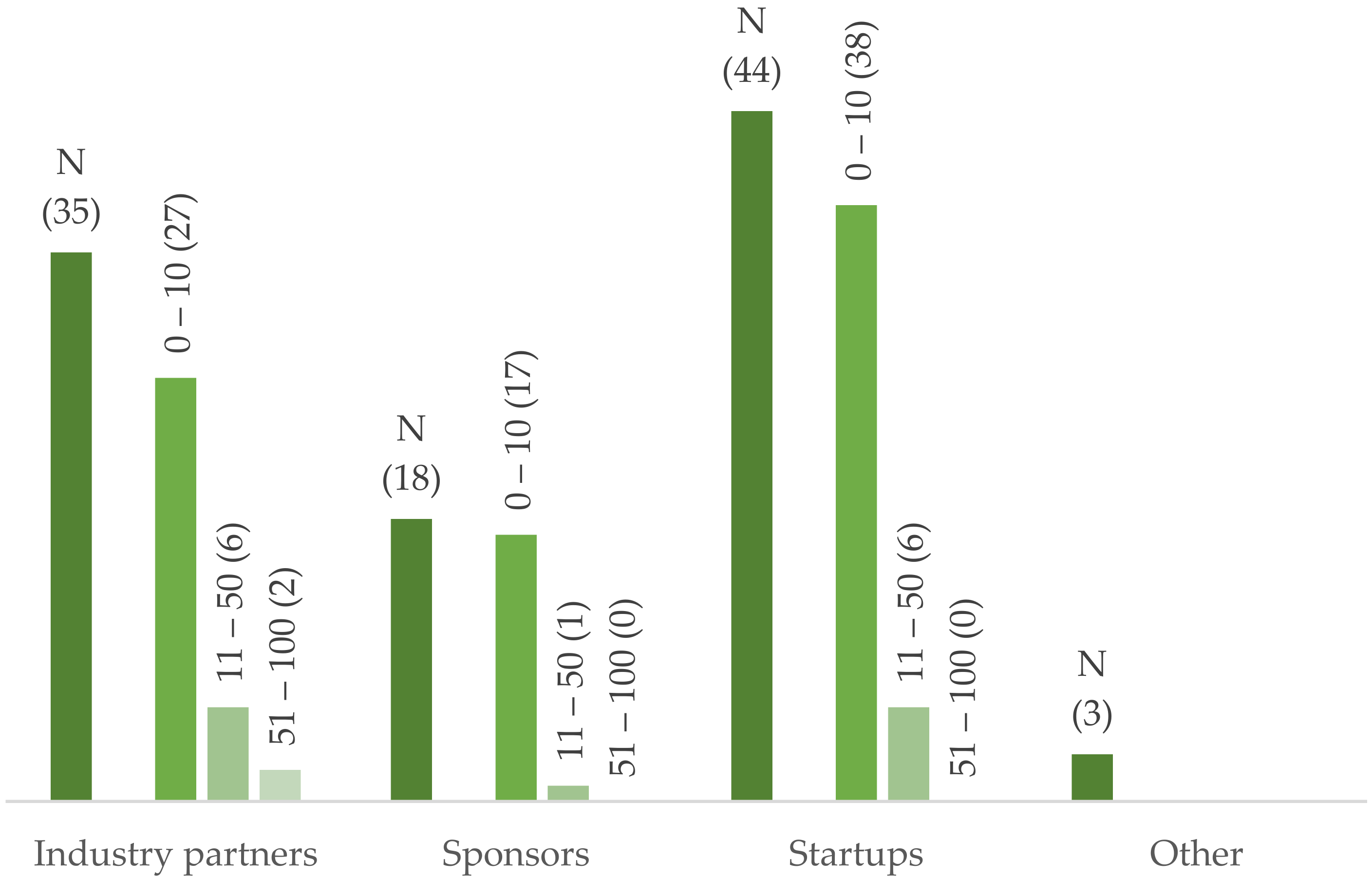

In the FabLab Global Survey, the participants were asked about the realization of joint projects with certain typical institutions in the FabLab environment. Among the participating laboratories, 43.5% had jointly carried out projects with external industries, although only 9.4% of the participants had carried out more than 10 projects. Twenty-four percent of participants reported having developed projects with sponsors, but only one participant carried out more than 10 projects. On the other hand, 45.9% of the participants indicated that they had carried out projects with research entities, although only 8.2% of the participants had completed more than 10 projects of this type. While 48.2% of the laboratories had carried out projects in collaboration with universities, only 1.18% of the laboratories developed more than 10 projects of this type. The projects carried out with students were the most common collaborative projects, present in 68.2% of the cases, where 34% of the participants exceeded 10 projects of this type and 15.3% had developed 100 projects. Only 24.7% of the laboratories had carried out joint projects with other laboratories in the FabLab Network, and only 3.5% had realized 10 projects (Figure 16 2 and Figure 173).

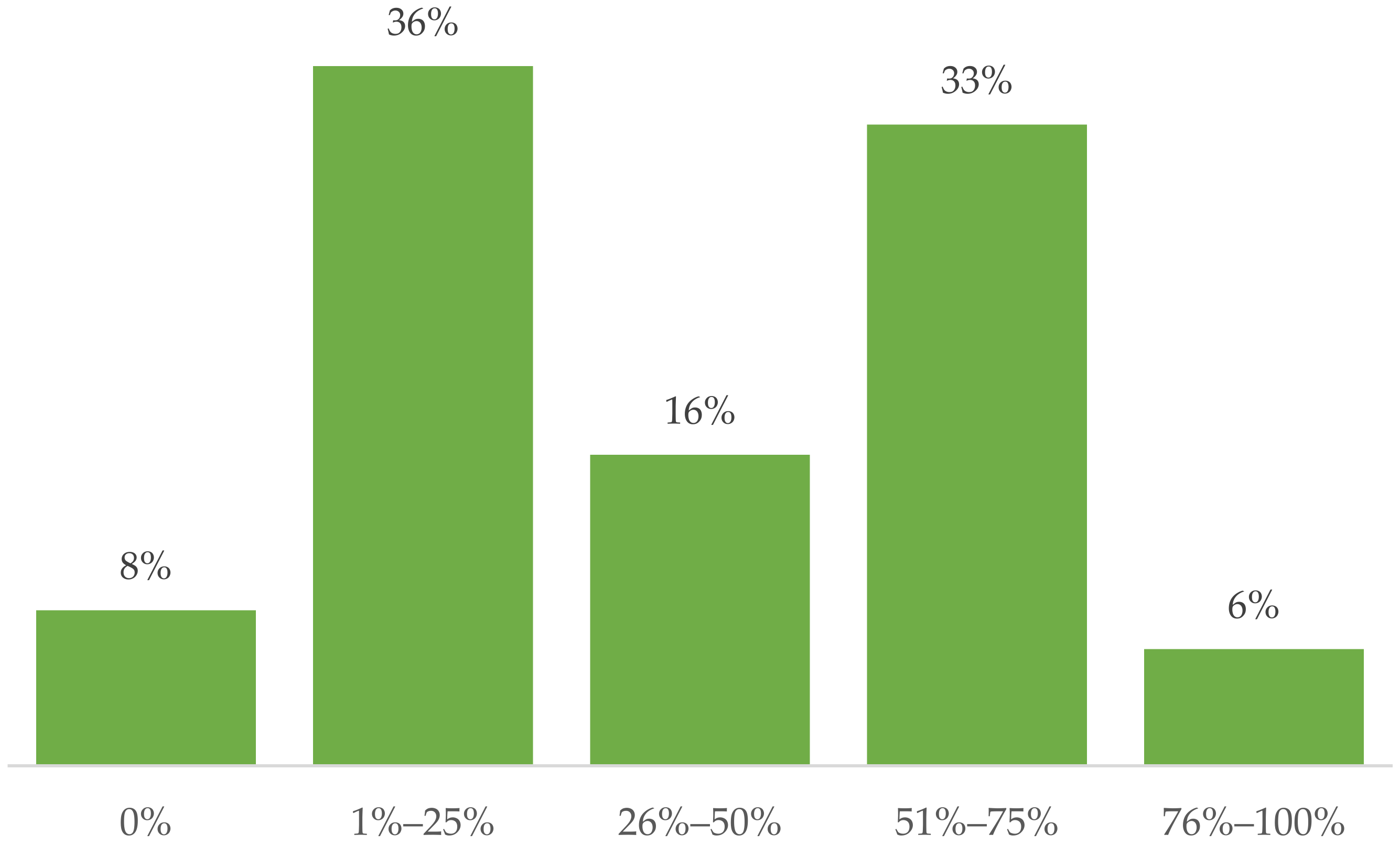

2.3. Level of Innovation, the Percentage of Innovation Projects Developed Jointly

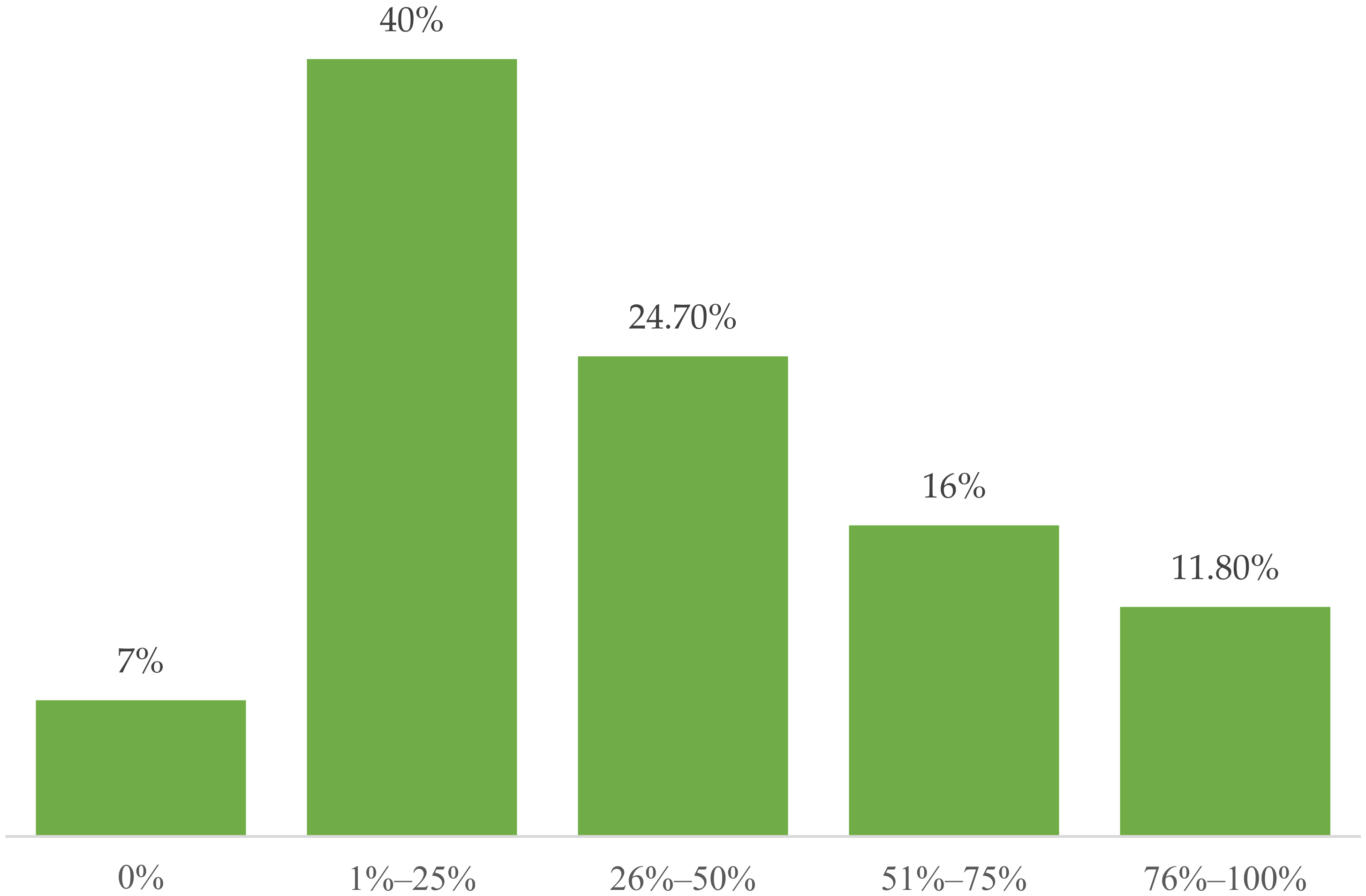

The projects developed in the environment of FabLabs are adjusted to multiple and different interests and objectives and, therefore, tend to be varied despite their common ground in digital manufacturing. One of the interests of this research was identifying the contribution of the projects carried out in the laboratories to innovation, for which an item was included in the FabLab Global Survey where participants were asked about the approximate percentage of projects carried out dedicated to innovation for research and development for industrial companies or small businesses. The results reveal that 27.8% of the laboratories had a high percentage of projects linked with innovation—more than 50% of the projects—with 11.8% of the cases considered as a very high level—more than 75% of the projects. By contrast, 40% of the laboratories reported a very low level of projects linked to innovation—less than 25% of projects dedicated to innovation. A meager 7% of the laboratories reported no projects linked to innovation (Figure 184).

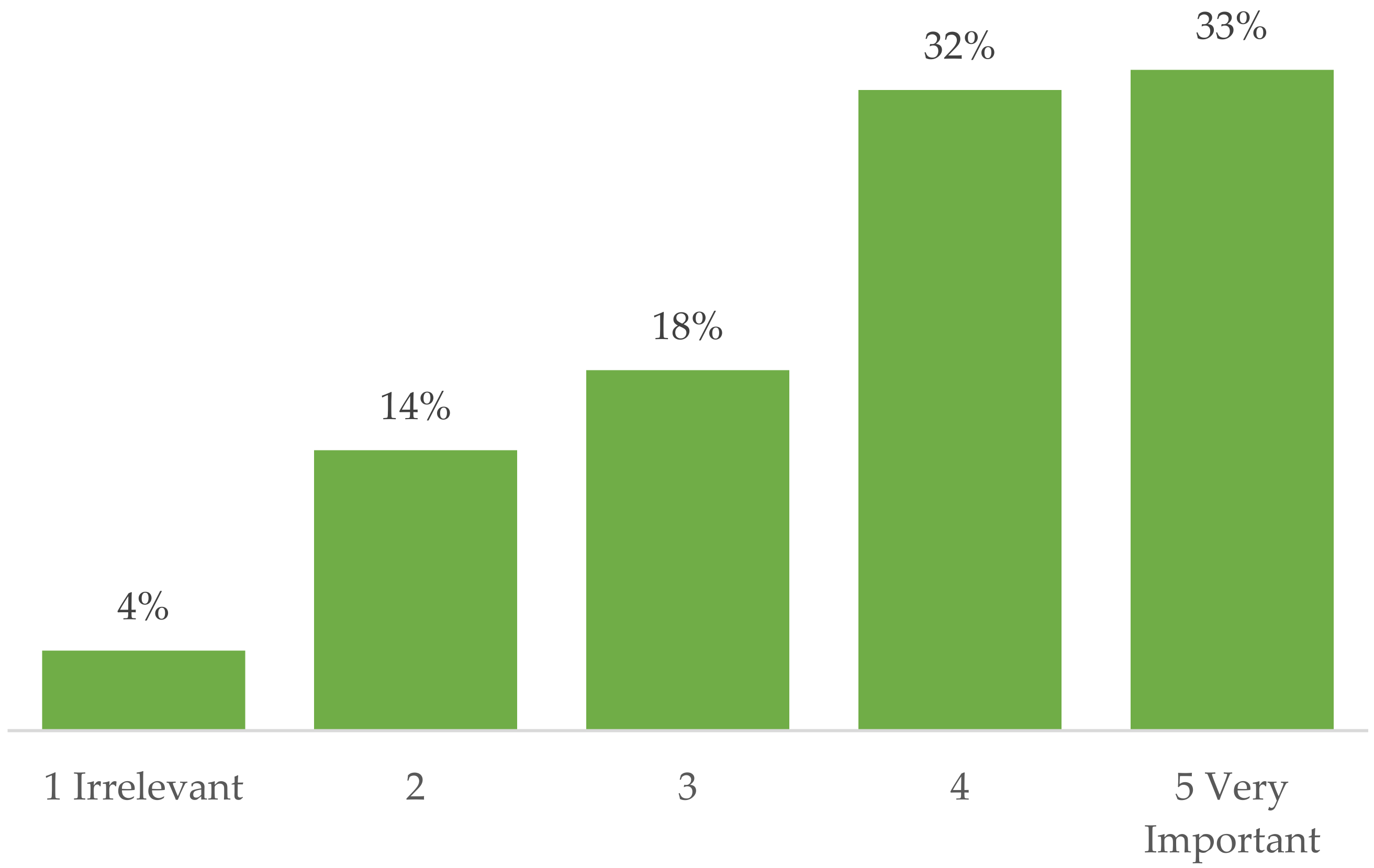

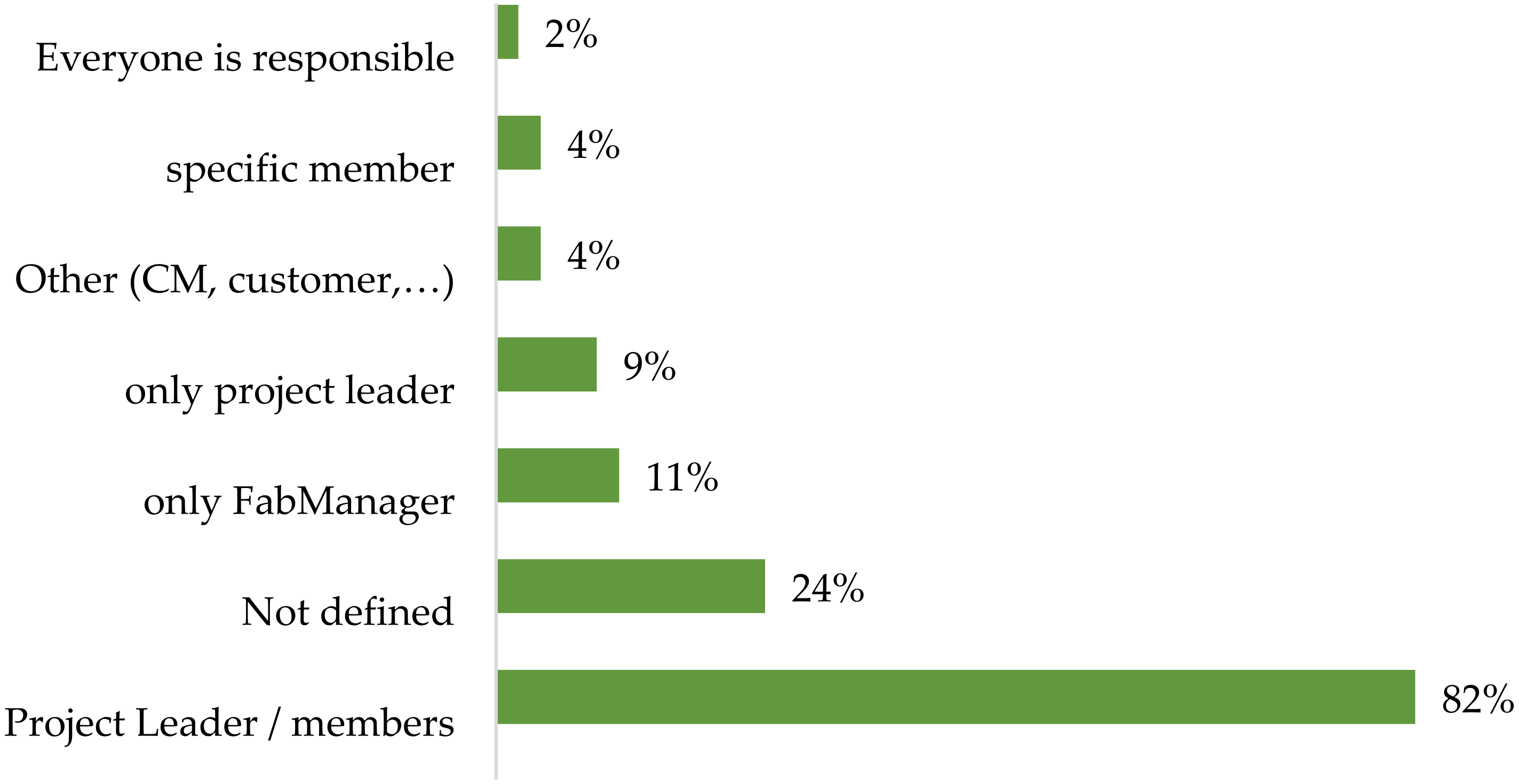

2.4. Documentation

Another important aspect to consider in this section involves the internal processes associated with public FabLab project documentation. As suggested by the FabLab Charter [2,8[3][12][13],40], a FabLab has a responsibility to disseminate the knowledge generated in the projects through its public documentation. Project documentation is an added difficulty in development since it involves time and resources, rarely available in digital manufacturing laboratories. This feature is not exclusive to FabLabs, as it is shared with the culture of the maker movement. Documentation seems to be perceived as an obstacle and represents a serious difficulty in the development of projects; however, a common platform for the documentation process has not been established (although some joint initiatives from within the network of FabLabs have been developed and there are some attempts to standardize the documentation process), and relatively few laboratories make the public documentation process a priority using an online platform. Several items were included in FabLab Global Survey concerning the documentation process, from the items designed to assess the perception of documentation to items that were intended to determine who is ultimately responsible for the documentation process and items that evaluate the actual percentage of documented projects. Most of the participants expressed the great importance of project documentation as one of the main benefits of FabLab (68% of participants) and also the difficulty that it represents (53% participants). When asked about the importance of documentation in their own FabLab in particular, 65% of participants reported a high or very high importance and 18% admitted a relatively low importance. Although 68% of respondents considered the public documentation of projects as one of the great strengths of the FabLab, 51% recognized it as one of its great difficulties (Figure 195).

2.5. Education

Knowledge sharing is one of the main advantages of FabLabs. In the FabLab Global Survey, items were included to evaluate perceptions about FabLab contributions to training in new digital fabrication technologies, including the 3D design and open hardware platforms. The results revealed certain differences in processes associated with training each of the above aspects. For open hardware development platforms, the majority opinion was that the FabLab provides adequate training (74%) in these technologies and, although values are subtly lower, the perception of training in additive manufacturing and 3D technology training (69% and 61%, respectively) was similar. WeIt must not shouldn't be forget that, although the open hardware platforms and the communities associated with their use have democratized and simplified previously unthinkable processes for the ordinary user, they require high knowledge of aspects as diverse as electronics or programming projects.2.6. FabLab Contribution to Users and the Community

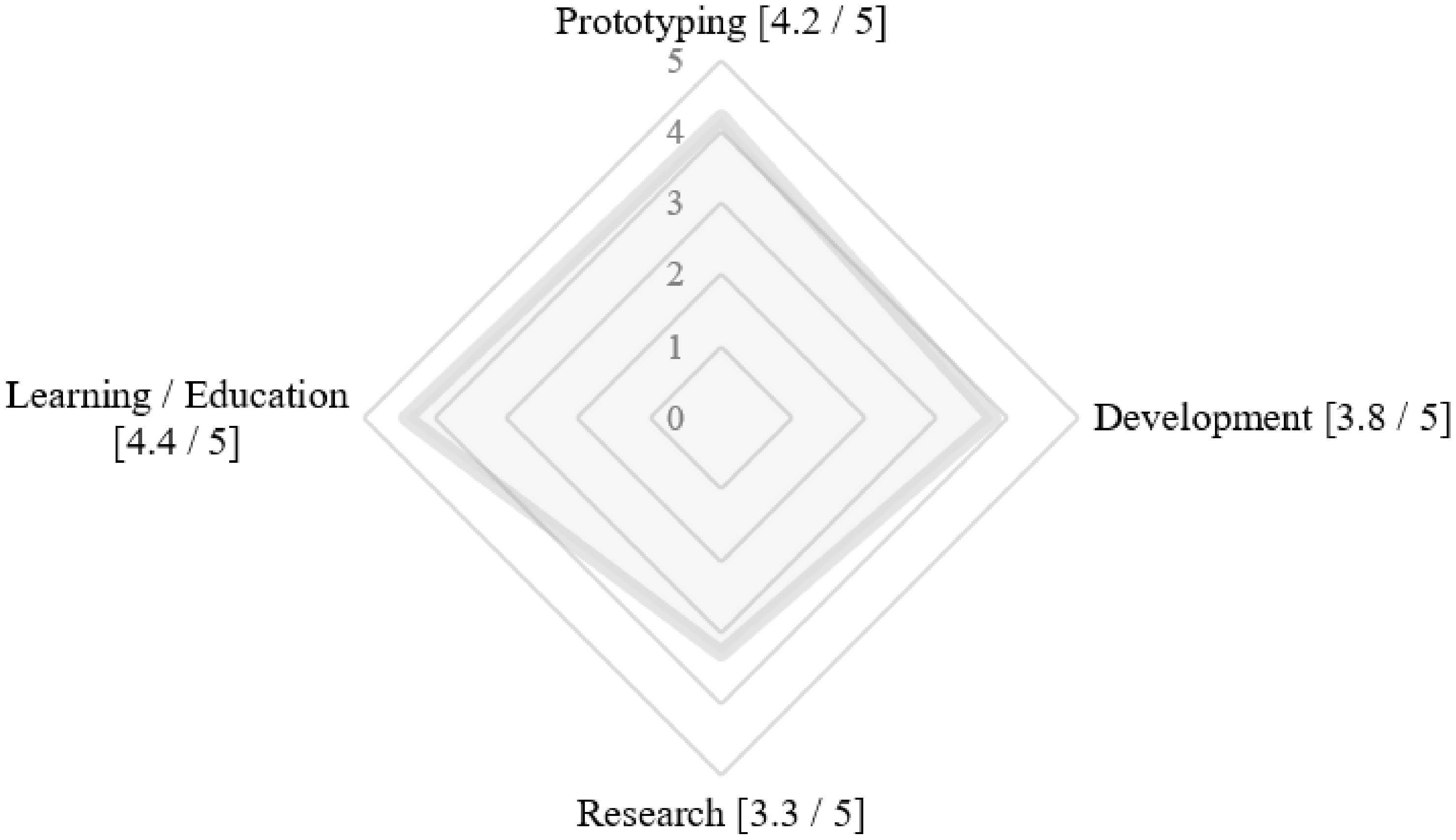

Digital fabrication laboratories provide a framework for social relationships where there is an exchange of knowledge about technological aspects. This exchange of knowledge takes shape through the FabLab activities. These activities were divided into four main processes that try to include, in a generic way, the most common aspects of the interaction and implementation of value proposals. A FabLab Global Survey item aimed to obtain information about the real contribution that FabLab makes to its users through a question in which the participants evaluated different proposals from 1 to 5 and in which it was possible to add new options in case those suggested do not apply. In ourthe survey, the possible contributions are as follows:-

Education and learning. FabLabs are a true learning community where their users, regardless of the existence of a guru or not, learn by doing and watching what others do. They learn to overcome their difficulties with the support of the community, interact in finding solutions and discover aspects that otherwise would have required a complex journey through regulated education. It is an informal, competitive and dynamic learning-centered interest and is based on project learning. FabLab’s contribution of education and learning to its users was valued very highly by the participants—a score of 4.4 out of 5 points—and was considered of very high relevance in 87% of the cases. Only 4% of cases considered this contribution as low in importance (Figure 228).

-

Research. Open innovation processes include research elements set out in FabLabs. In some cases, this research is conducted jointly with other entities to become a true development laboratory. This type of activity was evaluated as of intermediate importance by participants—obtaining a value of 3 out of 5 points—and considered relevant in the possible contributions of the laboratory in 44% of cases. Twenty-four percent of participants felt that FabLab did not contribute to these processes for its users.

-

Development. In tThis section, wee researchers distinguish the application of processes to product development as part of the non-specific standard innovation process and included in the dynamics of the existing systems in FabLab. In this respect, 65% of FabManagers considered the contribution FabLab makes to their development processes (3.8 points out of 5) as being of high importance.

-

Prototyping. The innovation processes carried out in FabLabs emphasize the application of technology, and they own digital manufacturing processes to develop new projects or products that meet diverse needs. This development takes place through prototyping and knowledge sharing. Eighty-one percent of laboratories assigned high scores (4.2 out of 5 points on average) for the FabLab contribution to their users in prototyping, describing its importance as very high.

References

- Toffler, A. The Third Wave; Pan Books: London, UK, 1981.

- De Boer, J. The business case of FryskLab, Europe’s first mobile library FabLab. Libr. Hi Tech 2015, 33, 505–518.

- Hielscher, S.; Smith, A.; Fressoli, M. WP4 Case Study Report: FabLabs, Report for the TRANSIT FP7 Project, Brighton. 2015. Available online: https://grassrootsinnovations.files.wordpress.com/2015/04/fab-labs-final.pdf (accessed on 20 July 2018).

- Dreessen, K.; Schepers, S.; Leen, D. From hacking things to making things. Rethinking making by supporting non-expert users in FabLab. Interact. Des. Archit. 2016, 30, 47–64.

- Sotjmenova-Duh, E.; Kos, A. FabLabs as drivers for open innovation and co-creation to foster rural development. In Proceedings of the 2016 International Conference on Identification, Information and Knowledge in the Internet of Things (IIKI), Beijing, China, 20–21 October 2016; pp. 214–216.

- Diez, T. Personal fabrication: FabLabs as platforms for citizen-based innovation, from microcontrollers to cities. Nexus Netw J. 2012, 14, 457–468.

- Figols, P. Las Pelusas de tu Casa Sirven para un Experimento Científico. Heraldo, 22 de junio de 2017. Available online: https://www.heraldo.es/noticias/aragon/zaragoza-provincia/zaragoza/2017/06/22/las-pelusas-casa-sirven-para-experimento-cientifico-1182883–301.html (accessed on 20 July 2018).

- Sanz, F. Servet, Experimentos en la Estratosfera, 9 de Agosto de 2017. Available online: http://cesaretopia.com/servet/ (accessed on 20 July 2018).

- Voigt, C.; Unterfrauner, E.; Stelzer, R. Diversity in FabLabs: Culture, Role, Models and the Gendering of Making. Internet Science; Springer: Cham, Switzerland, 2017; pp. 52–68.

- Eychenne, F. Where Are the Women? In Brazilian FabLabs. Makery Media for Labs. 2014. Available online: http://www.makery.info/en/2014/11/03/ou-sont-les-femmes-dans-les-fablabs-bresiliens/ (accessed on 20 July 2018).

- Poderosas: FabLab Leon. Available online: https://poderosasleon.wordpress.com/ (accessed on 15 July 2018).

- Lena-Acebo, F.J.; García-Ruiz, M.E. Caracterización de los Fablabs como agentes de innovación. In Gobernanza Empresarial de las Tecnologías de la Información; Cobo, A., Vanti, A., Eds.; Universidad de Cantabria: Santander, Spain, 2015; pp. 443–456.

- Schmitz, C. Limesurvey: An Open Source Survey Tool. Limesurvey Project, Hamburg, Germany. 2012. Available online: http://www.limesurvey.org (accessed on 23 December 2016).