Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 3 by Dean Liu and Version 2 by Dean Liu.

The simple and highly sensitive measurement of the refractive index (RI) of liquids is critical for designing the optical instruments and important in biochemical sensing applications. Intensity modulation-based polymer optical fiber (POF) RI sensors have a lot of advantages including low cost, easy fabrication and operation, good flexibility, and working in the visible wavelength.

- polymer optical fiber

- refractive index sensing

- intensity modulation

1. Introduction

The refractive index (RI) is an important optical parameter of material. Some physical quantities such as concentration, temperature, and pressure, etc., can be reflected by the change of RI [1]. Therefore, RI measurement has great value of applications and is widely used in disease diagnosis [2], environmental monitoring [3], food safety [4], and biochemical sensing fields [5]. Optical fiber sensing technology employs the optical fiber to detect the optical information changes caused by the interaction between the transmitted light and the analytes. This technique first appeared in the 1960s, and with the development of optical fiber technology and optical fiber communication technology, the optical fiber sensing technology has gradually developed in recent decades. Compared with the electrical sensors, optical fiber sensors have the advantages of electromagnetic immunity, chemical corrosion resistance, electrical isolation, and are capable of distributed sensing and remote sensing, which makes them suitable for employing in the occasions when electrical sensors cannot be used [6].

2. Different Types of Intensity Modulation POF-Based RI Sensors

2.1. Tapered POF-Based RI Sensors

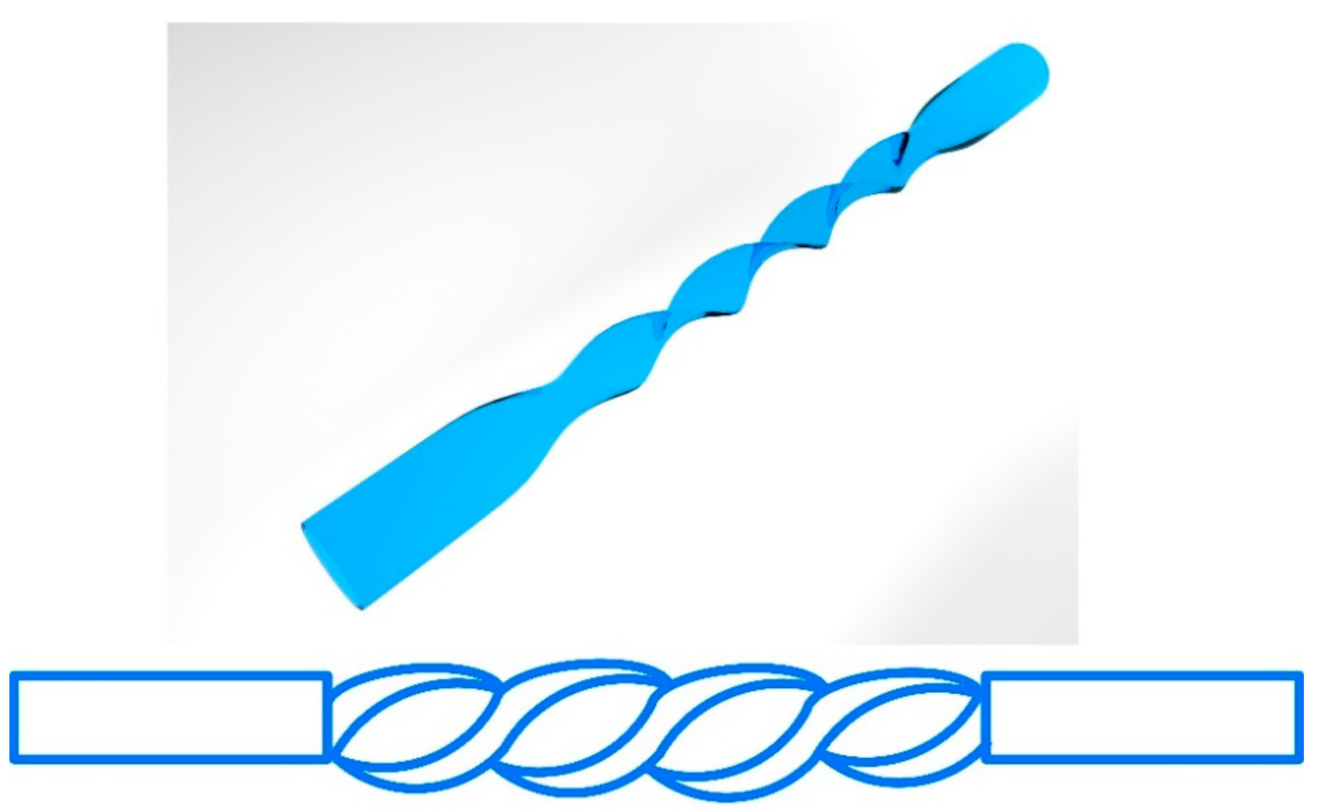

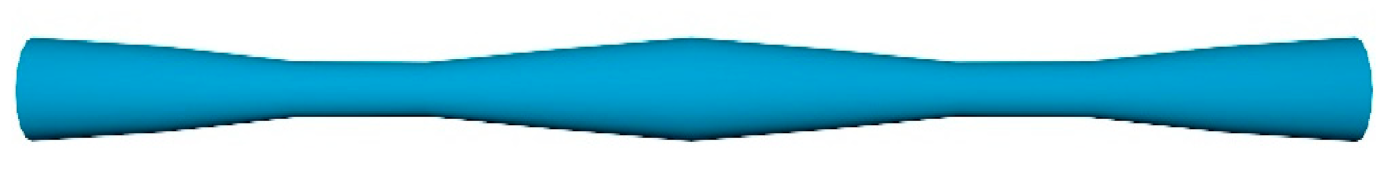

The tapered structure is shown in Figure 1. It consists of a taper-decreasing region and a taper-increasing region. The transmission characteristics of light can be changed by this structure of fiber. In the decreased tapered region, the coupling and conversion of propagation modes of light are generated, and the total reflection condition of transmitted light is easily destroyed when the RI of surrounding environment changes, which will introduce the propagation loss. In addition, the tapering fiber diameter will cause a continuous change in the propagation angle, which will not only increase the number of total reflections in the fiber, but also bring more evanescent field power [71][7].

Figure 1. The schematic diagram of tapered POF.

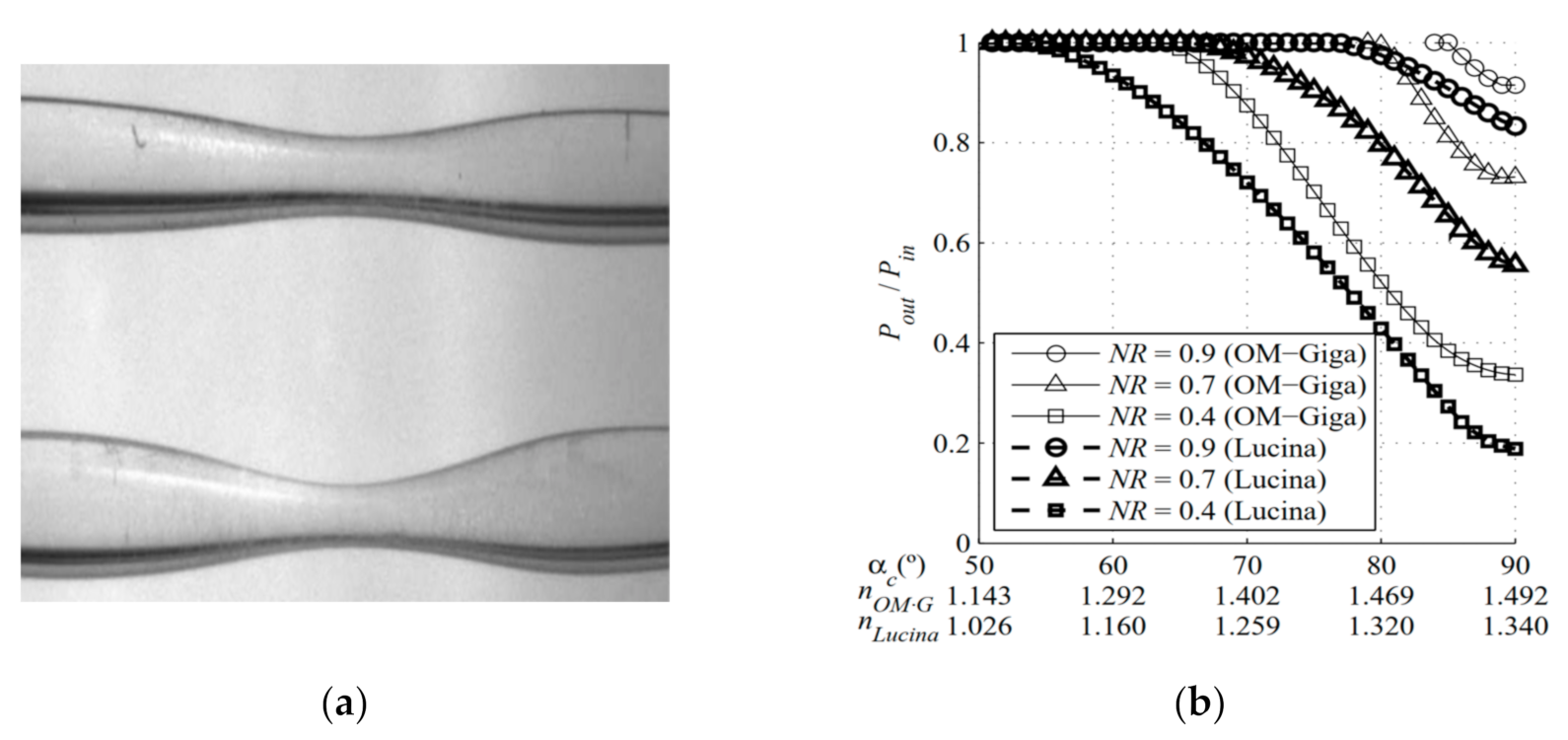

Figure 2. The photos of the tapered POFs (a), and the transmission behaviors of light for the OM-Giga/POF and the Lucina fibers with a different narrowing ratio in liquid with different RIs (b) [77][14].

Masayuki et al. [78][15] proposed a taper-type POF (with fiber core of PS material and cladding of PC material) sensor probe for ethanol solution measurement. The results showed that the proposed sensor can measure a low concentration of ethanol solution below 5 v/v%, whose sensitivity was about three times as that without the tapered structure. Besides, the sensor was temperature independent, and did not receive any influence from water, which was suitable for a real application. Yang et al. [71][7] optimized the tapered POF for the sensing of ethanol concentration. The ray-tracing method was used for theoretical investigation of different parameters of sensor, i.e., V-number matching, and evanescent wave penetration depth. The theoretical analysis and experimental results were used to optimize the taper ratio and taper length for the achievement of high evanescent wave penetration depth and high sensitivity. The analysis indicated that the sensitivity of tapered fiber sensor can be improved by decreasing the taper ratio with simultaneous increase in the taper length. The highest sensitivity of 1.527 mV/% was achieved from the tapered fiber with a taper ratio of 0.27 and taper length of 8 cm. The proposed parametric optimized tapered fiber sensor can detect the change in concentration of C2H5OH as small as 6.55 × 10−3.

Rahman et al. [79][16] proposed and demonstrated a simple tapered POF sensor for continuous monitoring of salinity based on different concentration of sodium chloride (NaCl) in deionized water. The results showed that as the solution concentration varied from 0% to 12%, and the output voltage of the sensor increased linearly from 0.109 mV to 1.142 mV, with a sensitivity of 0.0024 mV/% and a linearity of more than 98%. Similar to this work, Feng et al. [73][9] proposed a RI sensor based on a taper POF. Three wavelengths (532, 633, and 780 nm) were used to evaluate the sensitivity of the sensor, and results indicated that 633 nm was the best sensing wavelength due to the increased levels of sensitivity achieved at this wavelength. Besides, a double-tapered fiber structure was designed to enhance the sensitivity of sensor as shown in Figure 3, and a sensitivity of 950 μW/RIU at 633 nm was obtained when the launched power was 1 mW.

Some nanomaterials, such as carbon nanotubes [80][17], graphene [81][18], and ZnO nanostructures [82][19], were coated on the tapered POF to enhance the RI sensing performance. Batumalay et al. [80][17] proposed a simple tapered POF coated with a single-wall, carbon nanotube, polyethylene oxide composite for the measurement of the uric acid concentration. The results showed that an improved sensitivity can be obtained from this sensor, as the solution concentration of the uric acid varied from 0 to 500 ppm, and the output voltage of the sensor had a linear response with a sensitivity of 0.0023 mV/% when the waist diameter was 0.45 mm and tapering length was 10 mm. Later, a graphene-coated tapered POF was proposed for uric acid detection by the same group [81][18]. The results showed that as the solution concentration of the uric acid varied from 0 ppm to 500 ppm, the output voltage of the sensor increased linearly with a sensitivity of 0.0021 mV/% and a linearity of more than 98.88%. Similar to these works, they employed a tapered POF coated with ZnO nanostructures for the measurement of different concentrations of uric acid in deionized water and the changes in relative humidity (RH) [82][19]. The results showed that as the concentration of the uric acid varied from 0 ppm to 500 ppm, and the output voltage of the sensor using tapered POF with seeded ZnO nanostructures increased linearly with a higher sensitivity of 0.0025 mV/ppm compared to 0.0009 mV/ppm for unseeded tapered POF coated with ZnO.

Some nanomaterials, such as carbon nanotubes [80][17], graphene [81][18], and ZnO nanostructures [82][19], were coated on the tapered POF to enhance the RI sensing performance. Batumalay et al. [80][17] proposed a simple tapered POF coated with a single-wall, carbon nanotube, polyethylene oxide composite for the measurement of the uric acid concentration. The results showed that an improved sensitivity can be obtained from this sensor, as the solution concentration of the uric acid varied from 0 to 500 ppm, and the output voltage of the sensor had a linear response with a sensitivity of 0.0023 mV/% when the waist diameter was 0.45 mm and tapering length was 10 mm. Later, a graphene-coated tapered POF was proposed for uric acid detection by the same group [81][18]. The results showed that as the solution concentration of the uric acid varied from 0 ppm to 500 ppm, the output voltage of the sensor increased linearly with a sensitivity of 0.0021 mV/% and a linearity of more than 98.88%. Similar to these works, they employed a tapered POF coated with ZnO nanostructures for the measurement of different concentrations of uric acid in deionized water and the changes in relative humidity (RH) [82][19]. The results showed that as the concentration of the uric acid varied from 0 ppm to 500 ppm, and the output voltage of the sensor using tapered POF with seeded ZnO nanostructures increased linearly with a higher sensitivity of 0.0025 mV/ppm compared to 0.0009 mV/ppm for unseeded tapered POF coated with ZnO.

Thomas et al. [85][22] proposed a permanently micro-bent bare POF for detecting chemical species as shown in Figure 5. The results showed that the output intensity is linearly dependent on the logarithm of concentration of the absorbing species surrounding the bent portion of the fiber, and the sensor can even detect very low concentrations in the order of nanomoles per liter with a dynamic range of greater than six orders of magnitude. George et al. [86][23] employed the similar fiber structure to detect the continuously varying RI of chlorinated water. The results showed that the evaporation of chlorine from water and the change in RI followed a first-order exponential decay function of time.

Thomas et al. [85][22] proposed a permanently micro-bent bare POF for detecting chemical species as shown in Figure 5. The results showed that the output intensity is linearly dependent on the logarithm of concentration of the absorbing species surrounding the bent portion of the fiber, and the sensor can even detect very low concentrations in the order of nanomoles per liter with a dynamic range of greater than six orders of magnitude. George et al. [86][23] employed the similar fiber structure to detect the continuously varying RI of chlorinated water. The results showed that the evaporation of chlorine from water and the change in RI followed a first-order exponential decay function of time.

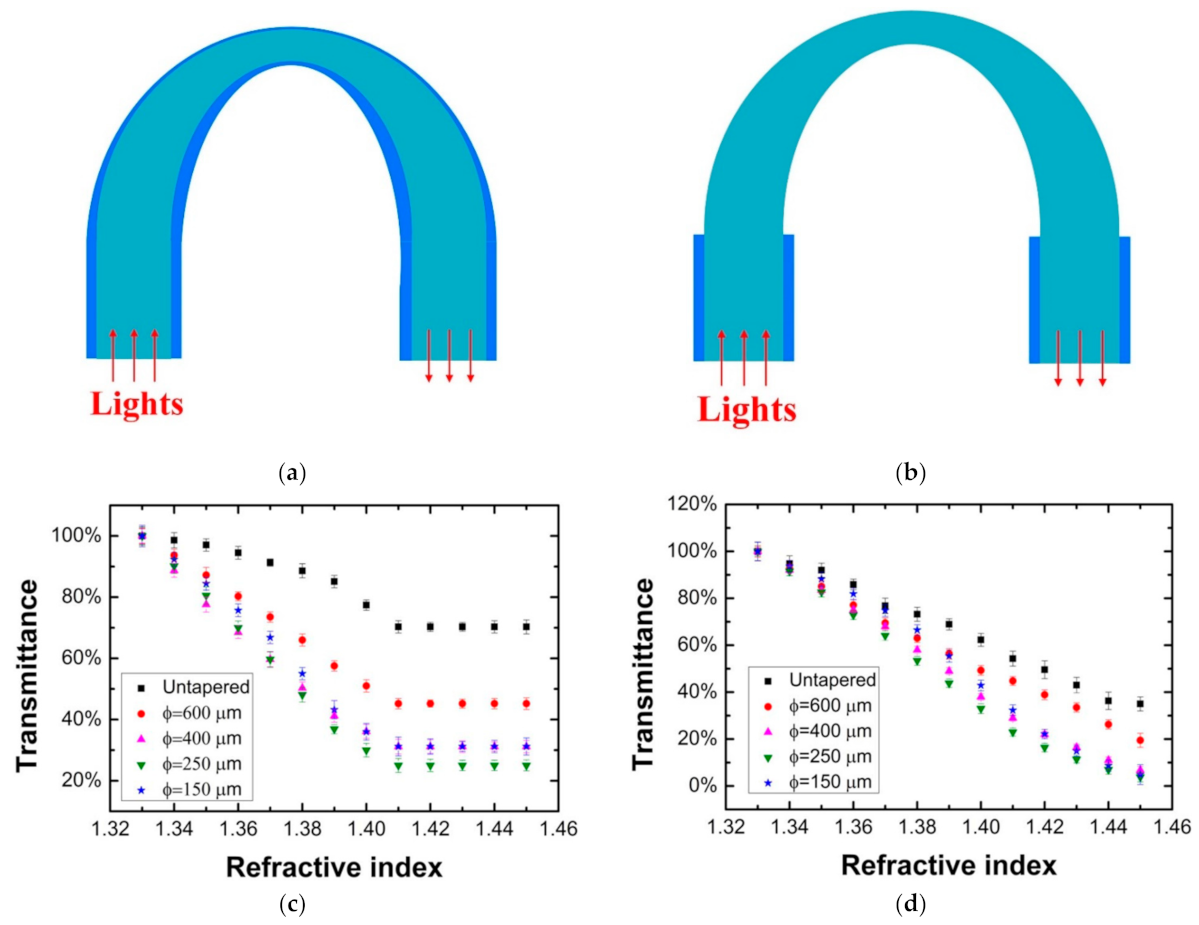

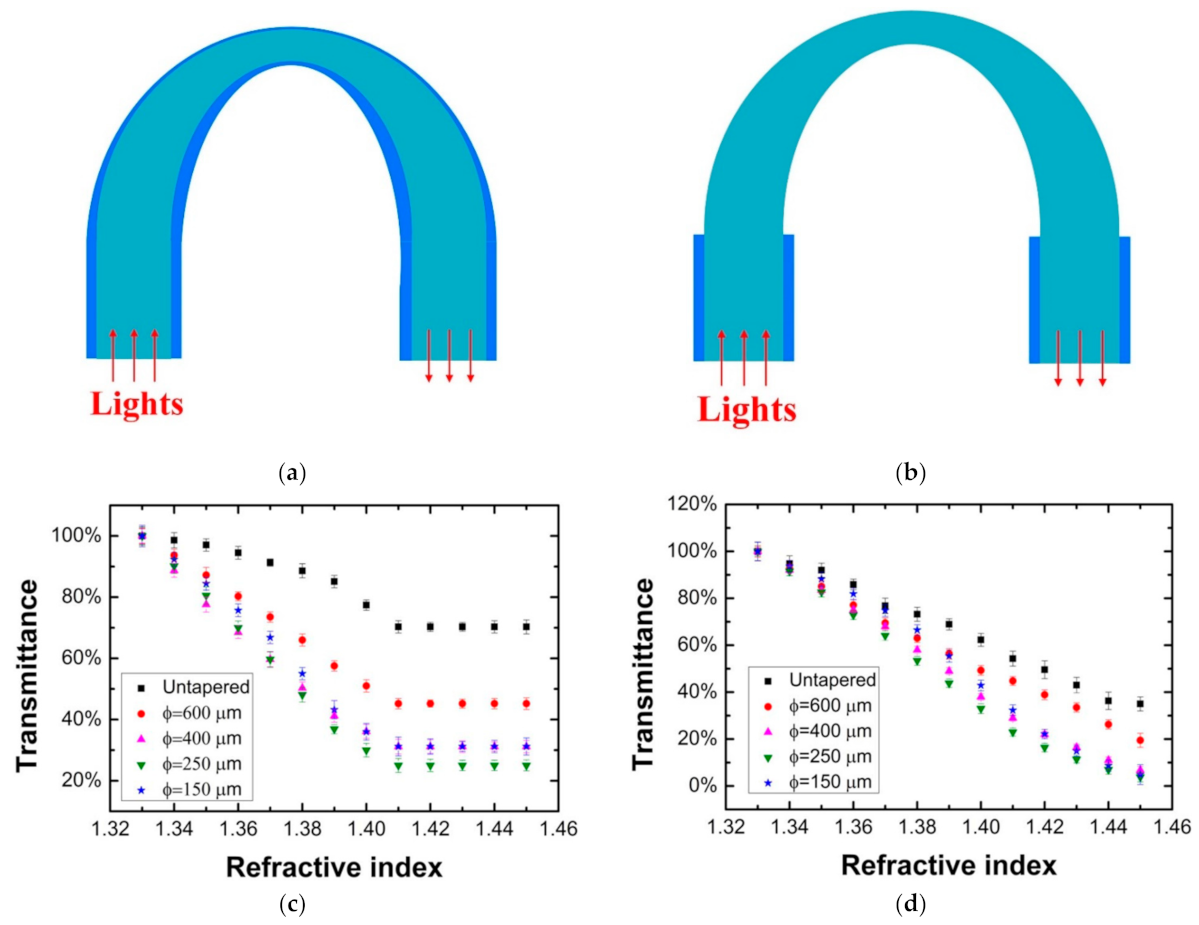

The macro-bending structure was often combined with the taper or side-polished structure to increase the RI sensitivity of sensor. For example, Teng et al. [87][24] proposed a macro-bending tapered POF for the RI sensing as shown in Figure 6. The RI sensing performance for the probes with and without cladding was investigated. By changing the taper waist and curvature radius, the sensing performance of the probe was optimized. The highest sensitivity of the probe with cladding reached 937%/RIU in the RI range of 1.33–1.41, for the probe without cladding, the RI sensing range expanded to 1.33–1.45, and the sensitivity was about 800%/RIU. The temperature dependence of the probe with cladding was also investigated by the same group [88][25]. Wandermur et al. [89][26] manufactured a U-shaped probe with a specially developed device. The RI sensing performances for the probes with different structure parameters were compared. After functionalizing with antibody anti-E. coli serotype O55, the probe was tested with bacterial concentrations of 104, 106, and 108 colony-forming units/mL (CFU/mL), and the decaying parameters of 3.0 × 10−3, 3.6 × 10−3, and 8.0 × 10−3 were obtained, respectively.

The macro-bending structure was often combined with the taper or side-polished structure to increase the RI sensitivity of sensor. For example, Teng et al. [87][24] proposed a macro-bending tapered POF for the RI sensing as shown in Figure 6. The RI sensing performance for the probes with and without cladding was investigated. By changing the taper waist and curvature radius, the sensing performance of the probe was optimized. The highest sensitivity of the probe with cladding reached 937%/RIU in the RI range of 1.33–1.41, for the probe without cladding, the RI sensing range expanded to 1.33–1.45, and the sensitivity was about 800%/RIU. The temperature dependence of the probe with cladding was also investigated by the same group [88][25]. Wandermur et al. [89][26] manufactured a U-shaped probe with a specially developed device. The RI sensing performances for the probes with different structure parameters were compared. After functionalizing with antibody anti-E. coli serotype O55, the probe was tested with bacterial concentrations of 104, 106, and 108 colony-forming units/mL (CFU/mL), and the decaying parameters of 3.0 × 10−3, 3.6 × 10−3, and 8.0 × 10−3 were obtained, respectively.

Figure 6. The schematic illustration of the macro-bending tapered POF probes with (a) and without (b) cladding, and the RI sensing performance for the probes with (c) and without (d) cladding [87][24].

Jing et al. [90][27] proposed a side-polished, macro-bending POF for RI sensing as shown in Figure 7. By changing the curvature radius, the polished depth, and the polished position (angle), the RI sensing performance of the probe was optimized. They obtained the maximum RI sensitivity of 154 dB/RIU in the RI range of 1.33–1.44 when the curvature radius, the polished depth, and the polished position were 5 mm, 500 µm, and 60°, respectively. The influence of the temperature was also tested by the same group [91][28]. Wang et al. [92][29] demonstrated a U-shaped, double-sided, polished POF for RI sensing. They optimized the processing parameters experimentally, and a sensitivity of 1541%/RIU was obtained with a resolution of 5.35 × 10−4 in the scope of 1.33–1.39. Besides, Zhong et al. [93][30] explored the temperature-independent operation of a POF-based evanescent wave sensor immersed in distilled water. They observed that the light transmission modes and sensitivity of the sensor were affected by changes in the surface morphology, diameter, and RI of the sensing region caused by changes in temperature. The transmitted light intensity of the sensor was maintained at a constant level after five cycles of the heating–cooling treatment, after which the fibers exhibited a smooth surface, low RI, and large fiber diameter.

Figure 6. The schematic illustration of the macro-bending tapered POF probes with (a) and without (b) cladding, and the RI sensing performance for the probes with (c) and without (d) cladding [87][24].

Jing et al. [90][27] proposed a side-polished, macro-bending POF for RI sensing as shown in Figure 7. By changing the curvature radius, the polished depth, and the polished position (angle), the RI sensing performance of the probe was optimized. They obtained the maximum RI sensitivity of 154 dB/RIU in the RI range of 1.33–1.44 when the curvature radius, the polished depth, and the polished position were 5 mm, 500 µm, and 60°, respectively. The influence of the temperature was also tested by the same group [91][28]. Wang et al. [92][29] demonstrated a U-shaped, double-sided, polished POF for RI sensing. They optimized the processing parameters experimentally, and a sensitivity of 1541%/RIU was obtained with a resolution of 5.35 × 10−4 in the scope of 1.33–1.39. Besides, Zhong et al. [93][30] explored the temperature-independent operation of a POF-based evanescent wave sensor immersed in distilled water. They observed that the light transmission modes and sensitivity of the sensor were affected by changes in the surface morphology, diameter, and RI of the sensing region caused by changes in temperature. The transmitted light intensity of the sensor was maintained at a constant level after five cycles of the heating–cooling treatment, after which the fibers exhibited a smooth surface, low RI, and large fiber diameter.

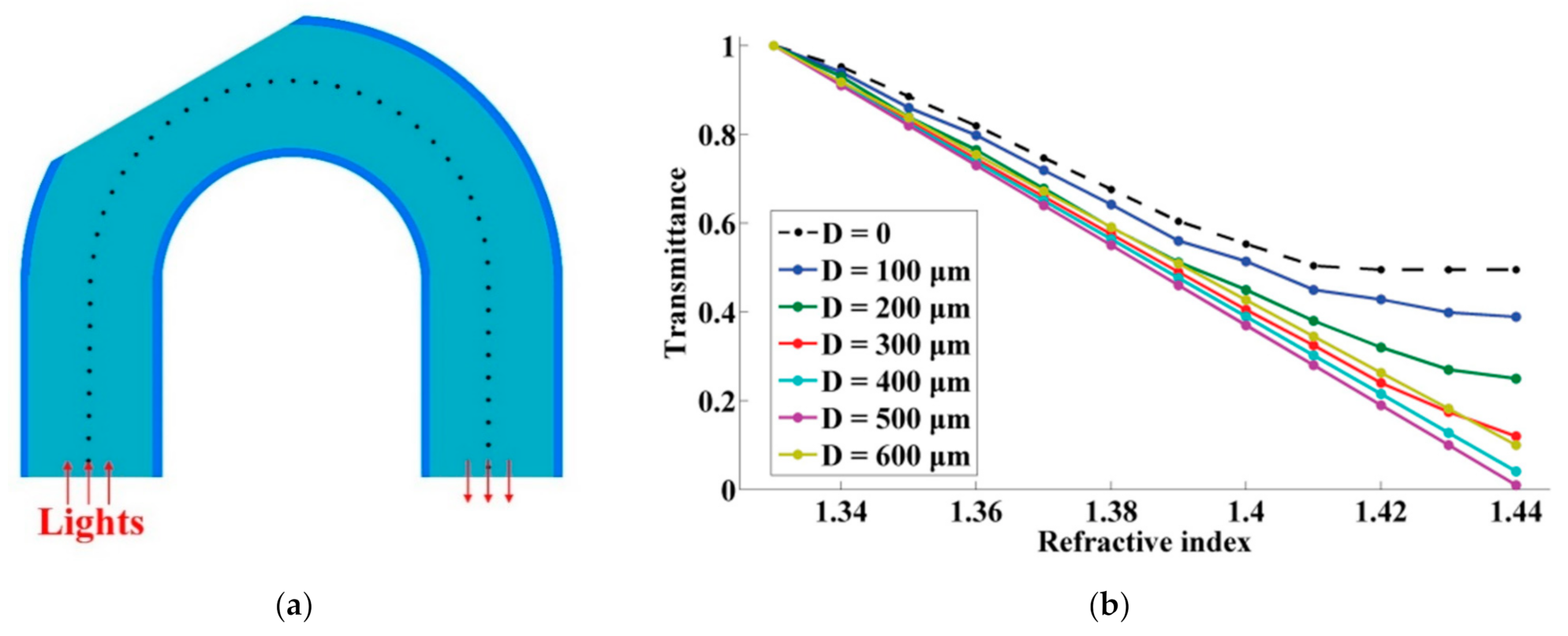

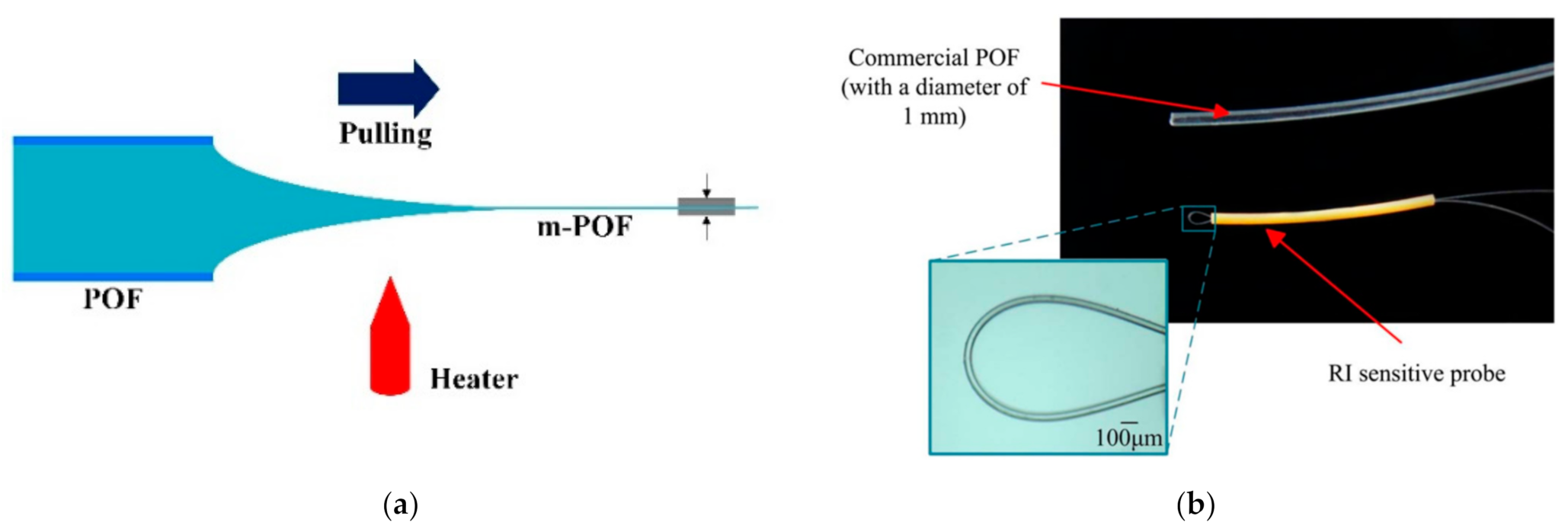

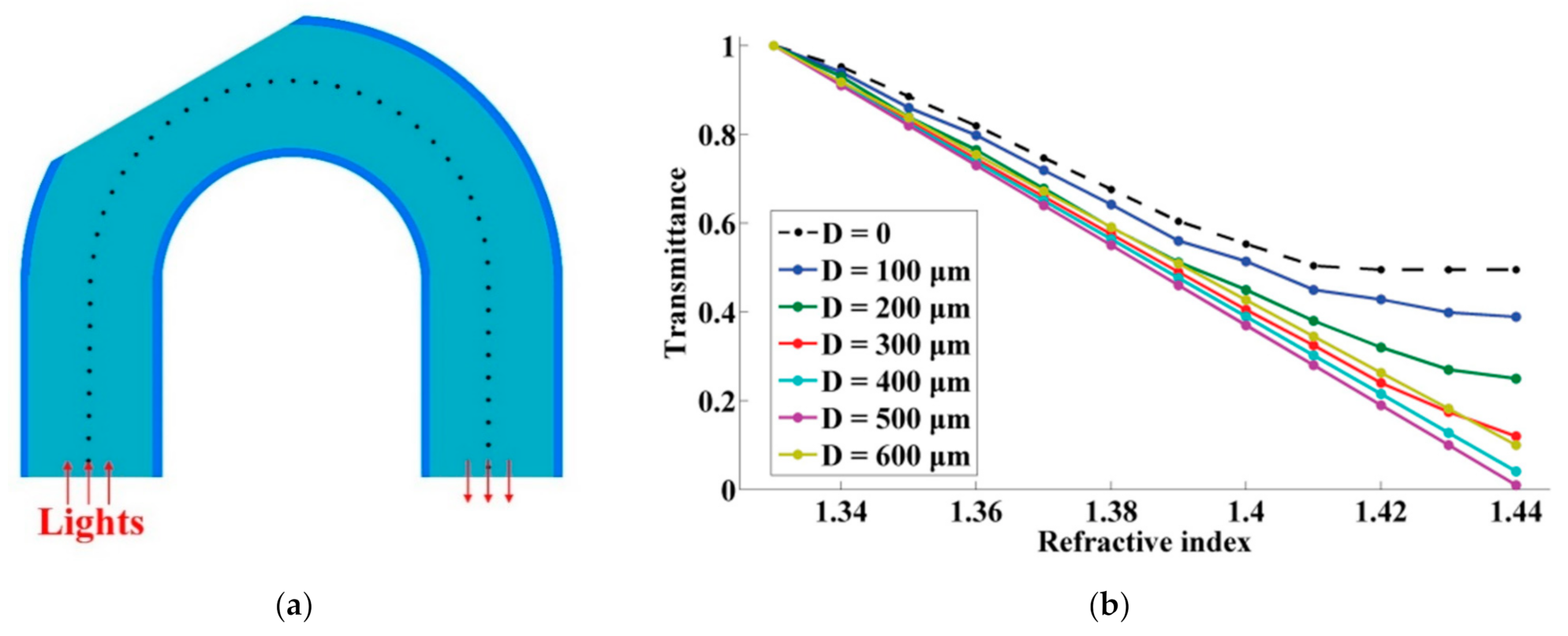

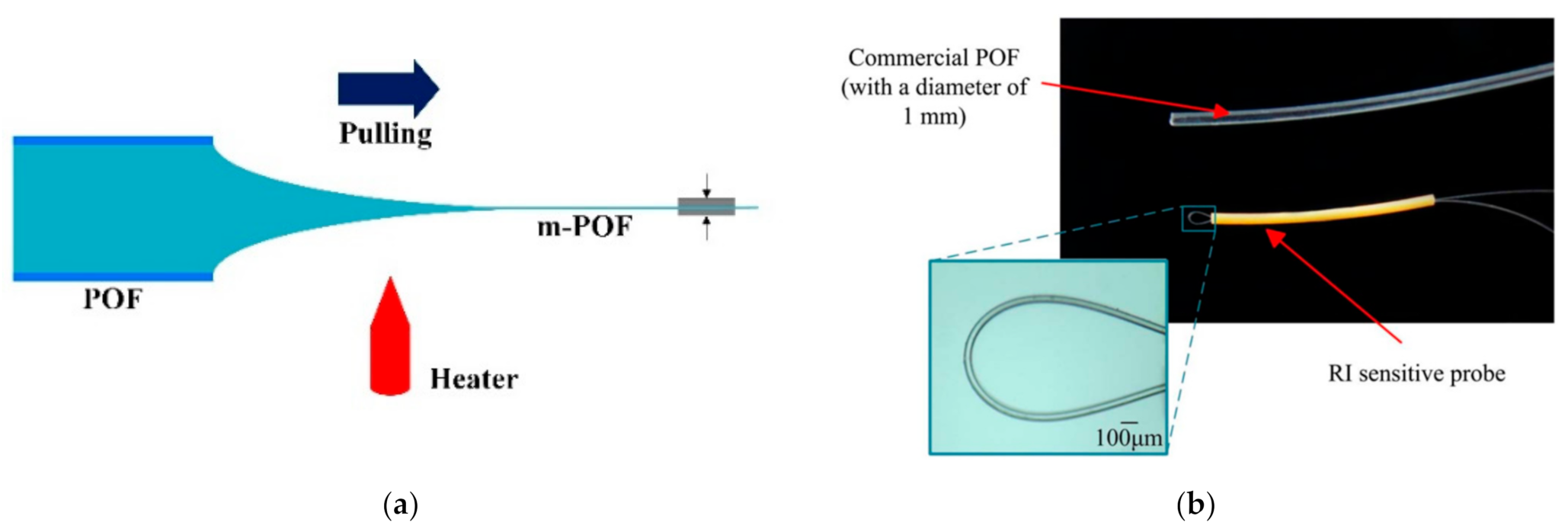

In addition, due to the large evanescent field of micro-fiber, the macro-bending micro-POFs were proposed for RI sensing [94,95,96,97][31][32][33][34]. Jing et al. [94,95][31][32] fabricated a micro-POF directly from the commercial POF and proposed a RI sensor based on a macro-bending micro-POF as shown in Figure 8. The macro-bending structure of the m-POFs was simulated and optimized by using the ray-tracing method. A linear RI sensing response was obtained with the sensitivity of 500%/RIU when the ratio of the radius of curvature of the macro-bending fiber to the radius of the fiber was 20. Irawati et al. [96,97][33][34] drew the micro-POF from melting PMMA and fabricated a micro-fiber loop resonator; after coating a layer of ZnO nanostructure, it was used for measuring the changes of relative humidity, with a variation from 20% to 80%. The experiment results showed that the output power of the sensor decreased linearly from −9.57 dBm to −20.19 dBm with a maximum sensitivity, linearity, and resolution of 0.1746 dBm/%, 94%, and 6.17%, respectively.

In addition, due to the large evanescent field of micro-fiber, the macro-bending micro-POFs were proposed for RI sensing [94,95,96,97][31][32][33][34]. Jing et al. [94,95][31][32] fabricated a micro-POF directly from the commercial POF and proposed a RI sensor based on a macro-bending micro-POF as shown in Figure 8. The macro-bending structure of the m-POFs was simulated and optimized by using the ray-tracing method. A linear RI sensing response was obtained with the sensitivity of 500%/RIU when the ratio of the radius of curvature of the macro-bending fiber to the radius of the fiber was 20. Irawati et al. [96,97][33][34] drew the micro-POF from melting PMMA and fabricated a micro-fiber loop resonator; after coating a layer of ZnO nanostructure, it was used for measuring the changes of relative humidity, with a variation from 20% to 80%. The experiment results showed that the output power of the sensor decreased linearly from −9.57 dBm to −20.19 dBm with a maximum sensitivity, linearity, and resolution of 0.1746 dBm/%, 94%, and 6.17%, respectively.

Banerjee et al. [98][35] described the experimental results on RI sensing by a low-cost plastic-cladded POF and a silica fiber with a plastic coating that forms a protective layer on the silica cladding. The cladding of these two fibers were stripped to different thickness to make the fibers sensitive to RI of the environment. The results showed that the sensitivity of the sensor to RI change was nonlinear and was dependent on cladding thickness, and the sensitivity would reach a maximum at an intermediate thickness value. L. Bilro et al. [99][36] presented a cure monitoring system based on a side-polished interface on POF, and they also presented the modeling of a side-polished POF as a sensor for RI and curvature measurement by using a geometric optic approach [100][37]. The model considered different details such as the geometric description of the sensor, the intensity profile of the emitter, and the possibility of a multireflection for a light ray at the sensitive area. Teng et al. [101][38] investigated the RI sensing performances of the straight and macro-bending side-polished POFs. Results showed that the macro-bending probe had an enhanced RI sensing performance, and when the polished depth was 400 μm, the polished length was 10 mm and the curvature radius was 2 mm, and a sensitivity of 864%/RIU and a resolution of 3.3 × 10−4/RIU with a standard deviation of 0.16 were obtained.

Feng et al. [102][39] made a RI sensor based on a D-shaped POF, and different depths of the D-shaped groove and a different curvature radius of the fiber probe were used to research the influence for the sensor sensitivity. Experiment results showed that the proposed sensor had a good linear response for the measured RI ranging from 1.333 to 1.455, and the highest sensitivity of the sensor was obtained when the depth of the D-shaped fiber was 500 μm. They also simulated the energy distribution of the D-type structure by using the Finite Element Method [103][40], and the experiment results showed that the normalized transmittance intensity decreased 13.4% with the RI increasing from 1.333 to 1.455 when the depth and length were 500 µm and 2 cm, respectively, with an excurvature radius of 5 cm and optical source wavelength of 652 nm.

In addition, Sequeira et al. [104][41] reported the optimization of the length for a D-shaped POF sensor for RI sensing from a numerical and experimental point of view. Results showed that, in the RI range of 1.33–1.39, the sensitivity and the resolution of the sensor were strongly dependent on the sensing region length, and the highest sensitivity resolution of 6.48 × 10−3 RIU was obtained with a 6 cm sensing length. While in the RI range of 1.41–1.47, the length of the sensing region was not a critical aspect to obtain the best resolution. Besides, Zhong et al. [105][42] investigated the mechanism of the effect of heat treatments on physical and optical properties of D-shape POF-based EW sensors.

Banerjee et al. [98][35] described the experimental results on RI sensing by a low-cost plastic-cladded POF and a silica fiber with a plastic coating that forms a protective layer on the silica cladding. The cladding of these two fibers were stripped to different thickness to make the fibers sensitive to RI of the environment. The results showed that the sensitivity of the sensor to RI change was nonlinear and was dependent on cladding thickness, and the sensitivity would reach a maximum at an intermediate thickness value. L. Bilro et al. [99][36] presented a cure monitoring system based on a side-polished interface on POF, and they also presented the modeling of a side-polished POF as a sensor for RI and curvature measurement by using a geometric optic approach [100][37]. The model considered different details such as the geometric description of the sensor, the intensity profile of the emitter, and the possibility of a multireflection for a light ray at the sensitive area. Teng et al. [101][38] investigated the RI sensing performances of the straight and macro-bending side-polished POFs. Results showed that the macro-bending probe had an enhanced RI sensing performance, and when the polished depth was 400 μm, the polished length was 10 mm and the curvature radius was 2 mm, and a sensitivity of 864%/RIU and a resolution of 3.3 × 10−4/RIU with a standard deviation of 0.16 were obtained.

Feng et al. [102][39] made a RI sensor based on a D-shaped POF, and different depths of the D-shaped groove and a different curvature radius of the fiber probe were used to research the influence for the sensor sensitivity. Experiment results showed that the proposed sensor had a good linear response for the measured RI ranging from 1.333 to 1.455, and the highest sensitivity of the sensor was obtained when the depth of the D-shaped fiber was 500 μm. They also simulated the energy distribution of the D-type structure by using the Finite Element Method [103][40], and the experiment results showed that the normalized transmittance intensity decreased 13.4% with the RI increasing from 1.333 to 1.455 when the depth and length were 500 µm and 2 cm, respectively, with an excurvature radius of 5 cm and optical source wavelength of 652 nm.

In addition, Sequeira et al. [104][41] reported the optimization of the length for a D-shaped POF sensor for RI sensing from a numerical and experimental point of view. Results showed that, in the RI range of 1.33–1.39, the sensitivity and the resolution of the sensor were strongly dependent on the sensing region length, and the highest sensitivity resolution of 6.48 × 10−3 RIU was obtained with a 6 cm sensing length. While in the RI range of 1.41–1.47, the length of the sensing region was not a critical aspect to obtain the best resolution. Besides, Zhong et al. [105][42] investigated the mechanism of the effect of heat treatments on physical and optical properties of D-shape POF-based EW sensors.

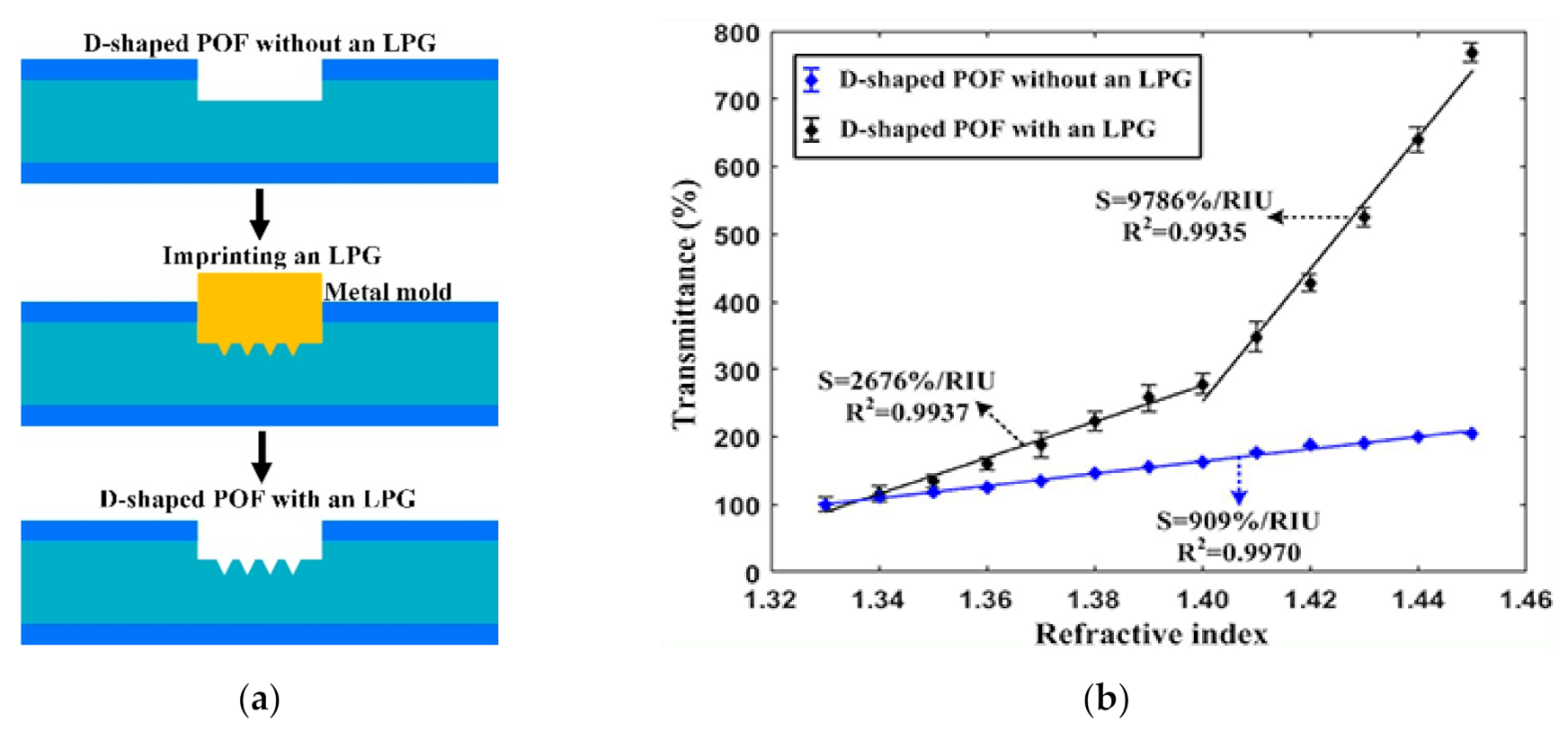

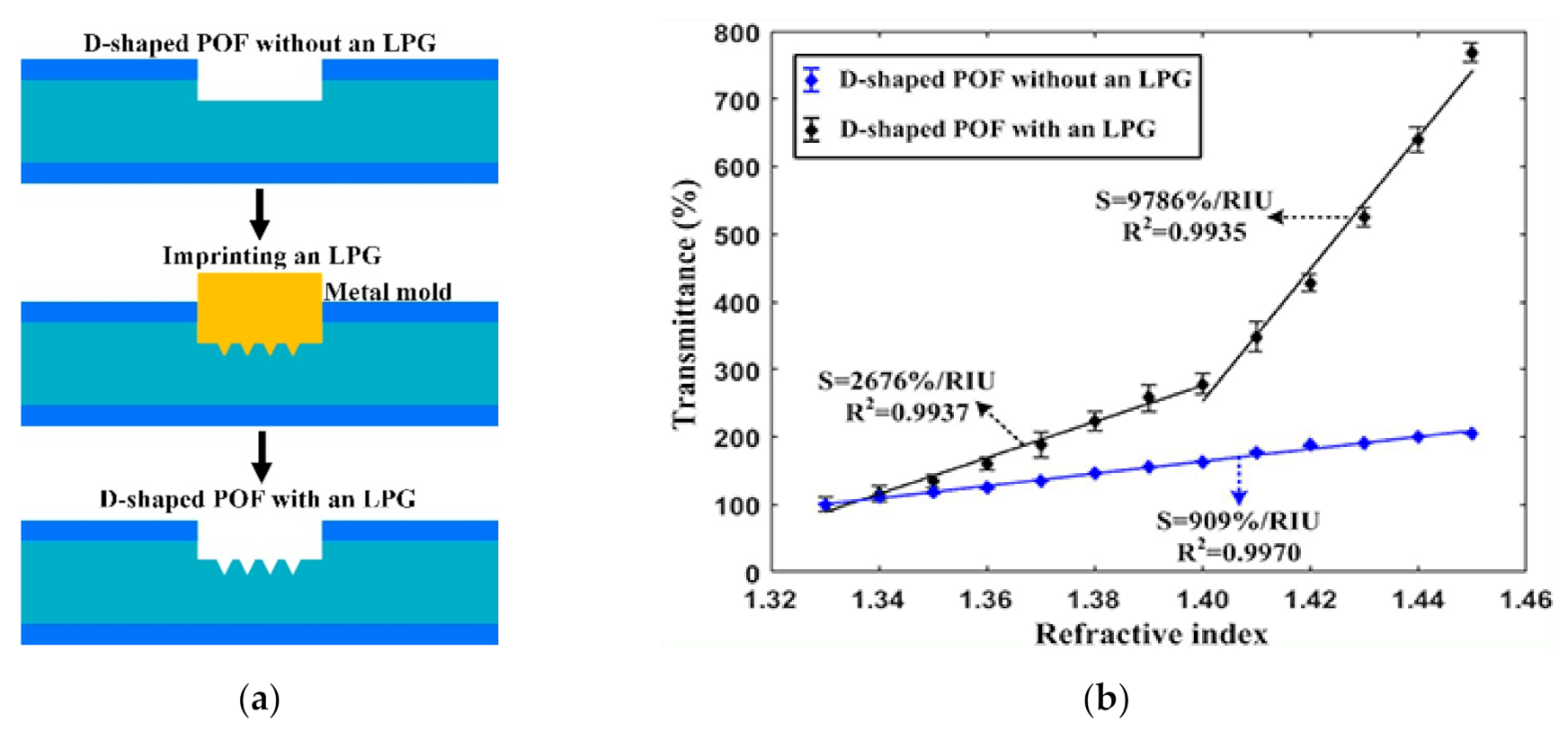

In 2019, Xue et al. [108][46] fabricated the LPGs on the POFs with different diameters and investigated their RI sensing performances. The results showed that a higher RI sensitivity can be obtained when the LPG structure was imprinted on a thin POF (with a diameter of 0.25 mm), and the optimum sensitivity of 2815%/RIU with a resolution of 1.39 × 10−4 RIU was achieved in the RI range of 1.33–1.45 when the grating period, the groove depth, and the tilted angle were 100 µm, 65 µm, and 20 °, respectively. Later, the same group proposed a D-shaped POF assisted by an LPG structure for RI sensing [109][47], as shown in Figure 11. The results showed that the LPG structure could achieve an enhanced RI sensitivity. When this structure was fabricated on POF with a thin diameter of 0.25 mm, the high sensitivities of 2676 %/RIU and 9786 %/RIU could be obtained in the RI ranges of 1.33–1.40 and 1.40–1.45, respectively.

In 2019, Xue et al. [108][46] fabricated the LPGs on the POFs with different diameters and investigated their RI sensing performances. The results showed that a higher RI sensitivity can be obtained when the LPG structure was imprinted on a thin POF (with a diameter of 0.25 mm), and the optimum sensitivity of 2815%/RIU with a resolution of 1.39 × 10−4 RIU was achieved in the RI range of 1.33–1.45 when the grating period, the groove depth, and the tilted angle were 100 µm, 65 µm, and 20 °, respectively. Later, the same group proposed a D-shaped POF assisted by an LPG structure for RI sensing [109][47], as shown in Figure 11. The results showed that the LPG structure could achieve an enhanced RI sensitivity. When this structure was fabricated on POF with a thin diameter of 0.25 mm, the high sensitivities of 2676 %/RIU and 9786 %/RIU could be obtained in the RI ranges of 1.33–1.40 and 1.40–1.45, respectively.

Figure 3. The schematic diagram of the double-tapered POF.

2.2. Bending POF-Based RI Sensors

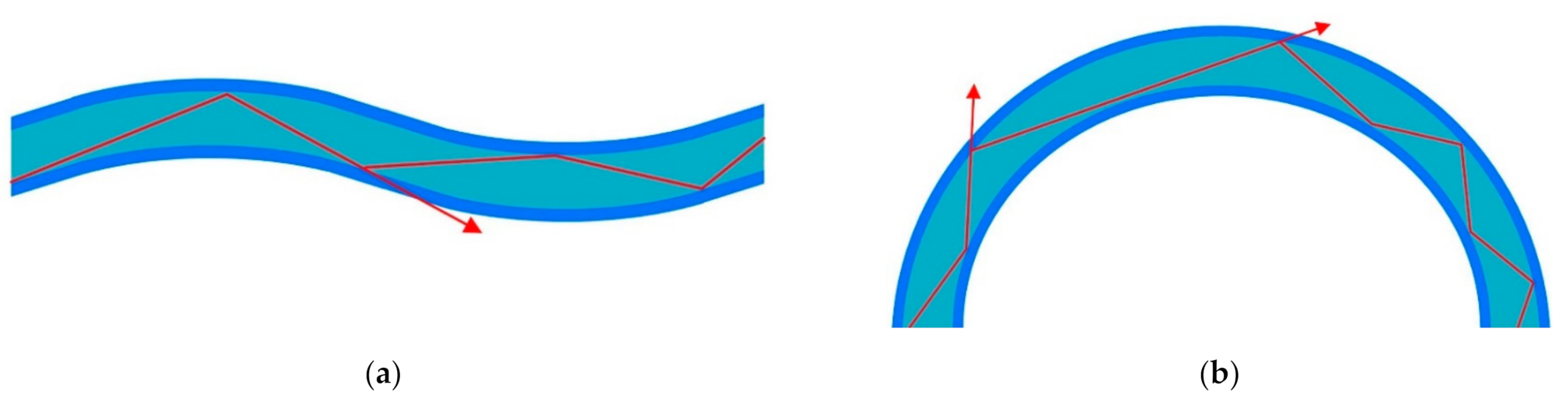

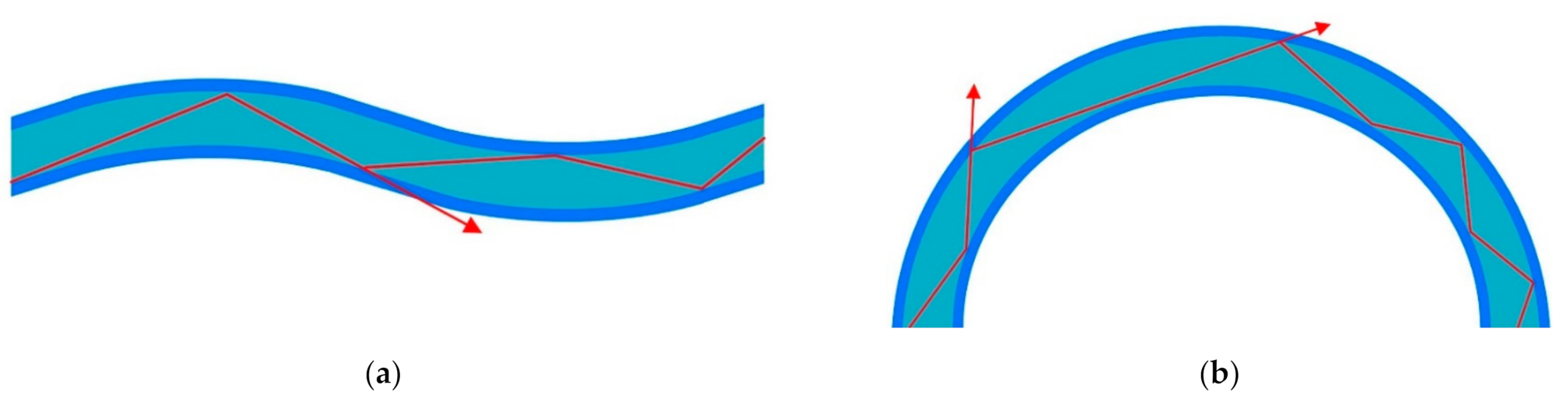

Similar with the tapering structure, bending the fiber can also increase the evanescent field power, which is mainly caused by the changes of RI profile and mode field distribution [83][20]. The bending can be classified into micro-bending and macro-bending. Micro-bending fiber usually means that the curvature radius of the fiber is comparable with the diameter of the fiber, as shown in Figure 4a. While for the macro-bending fiber, the curvature radius is usually much larger than the fiber diameter as shown in Figure 4b [84][21].

Figure 4. The schematic illustration of the micro-bending (a) and macro-bending POFs (b).

Figure 5. The schematic diagram of the permanent micro-bending POF.

Figure 6. The schematic illustration of the macro-bending tapered POF probes with (a) and without (b) cladding, and the RI sensing performance for the probes with (c) and without (d) cladding [87][24].

Figure 6. The schematic illustration of the macro-bending tapered POF probes with (a) and without (b) cladding, and the RI sensing performance for the probes with (c) and without (d) cladding [87][24].

2.3. Polished POF-Based RI Sensors

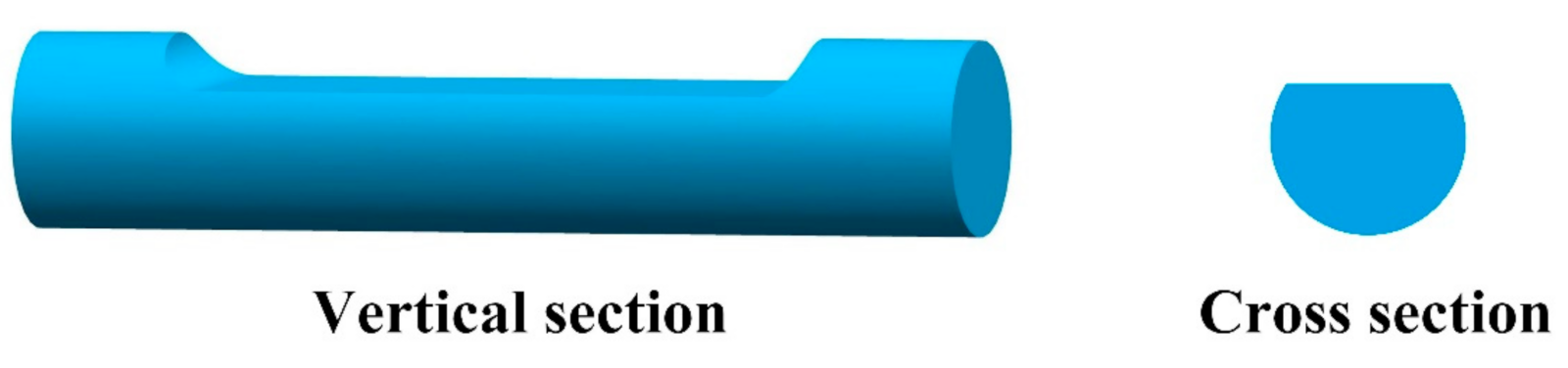

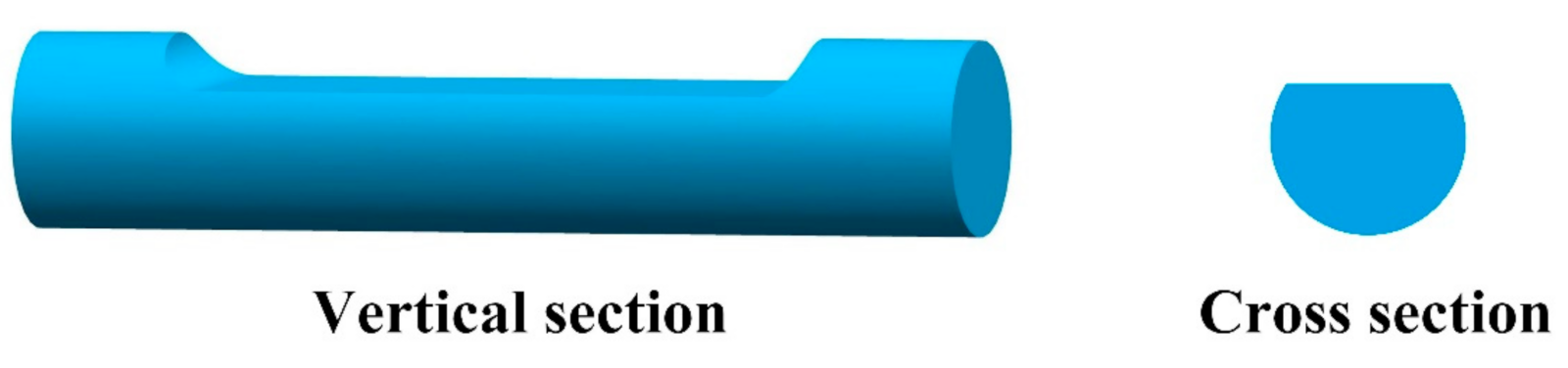

The side-polished fiber removes parts of the fiber cladding or the core to increase the evanescent field power to interact with the surrounding medium. Because the shape of its cross section is similar to the English capital letter ”D”, it is also called the D-shaped optical fiber, as shown in Figure 9.

Figure 9. The schematic diagram of the side-polished POF.

2.4. Grating Structure-Based RI Sensors

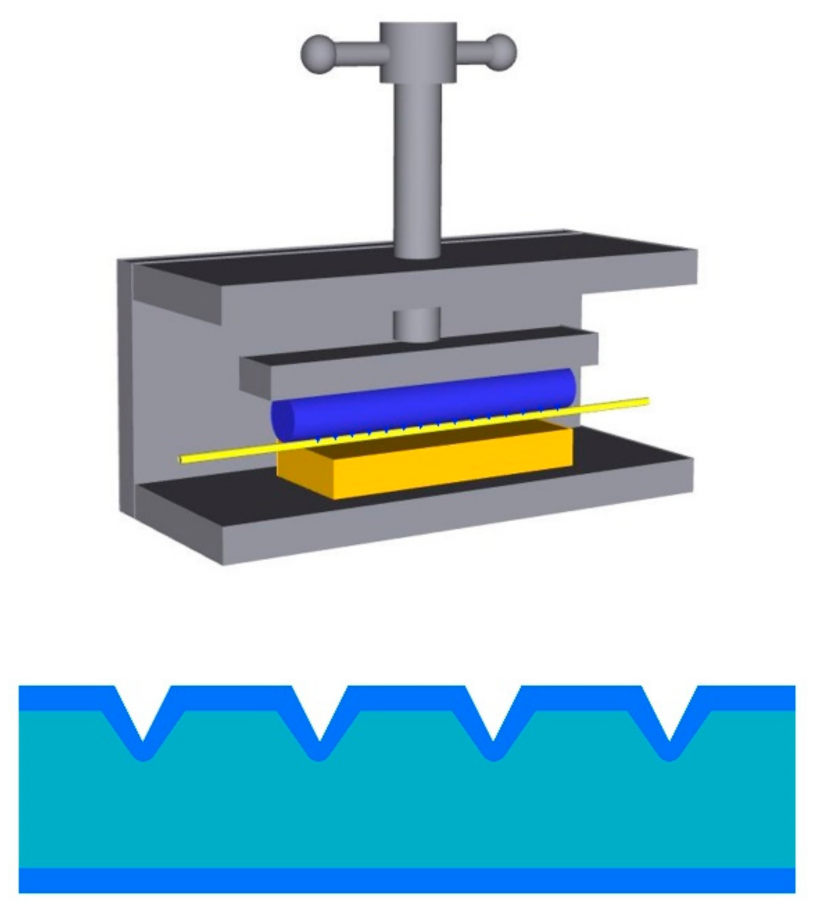

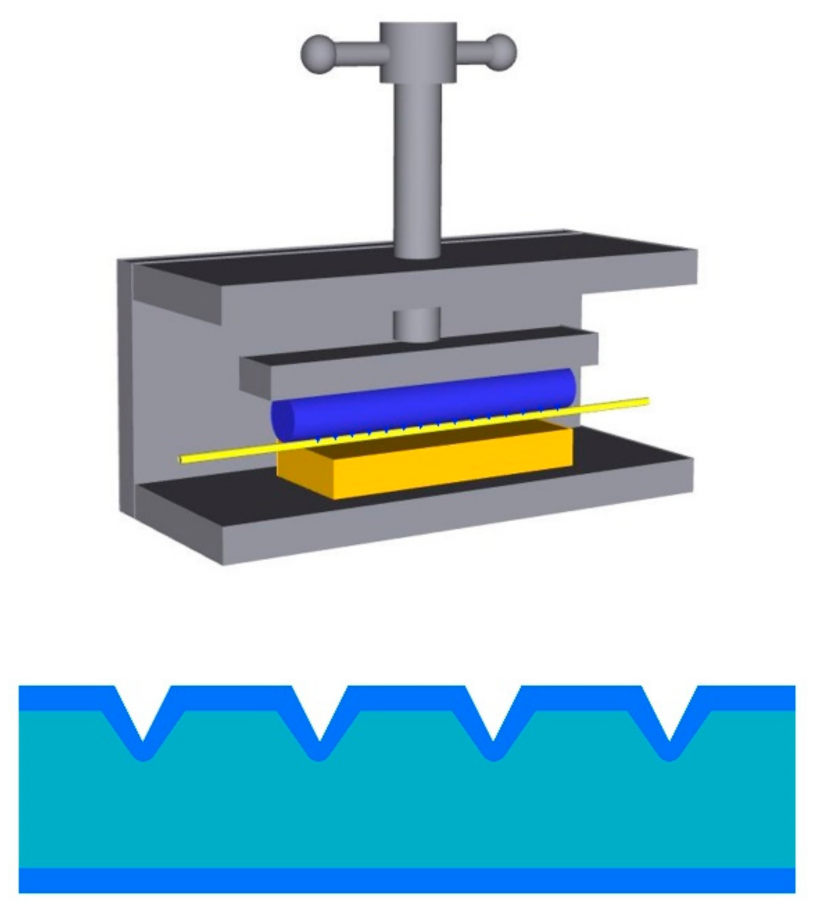

The fiber gratings usually refer to the fiber Bragg gratings (FBG), the long-period gratings (LPG), and the titled Bragg gratings, which are fabricated on the single-mode silica fibers [106][43] or the single-mode polymer fibers [48][44]. They often work on the wavelength modulation method. The grating structures introduced were fabricated on the multimode POF by a simple mechanical die press print method; due to the coupling of the core modes and cladding modes that occurs at all wavelengths, this type of fiber sensors work on the intensity modulation mode. In 2017, Teng et al. [107][45] proposed a POF with a multi-notched structure as a long-period grating for RI sensing. The structure was simply made on the surface of the fiber by pressing a thread rod against the POF as shown in Figure 10. The RI sensing performances for straight and macro-bending POFs with this structure were studied. Results showed that the POF probes with straight multi-notched structures were not sensitive enough for RI measurement. After bending the multi-notched structure into U-shaped probes, the RI sensing performance was improved markedly. The highest sensitivity of 1130%/RIU with a resolution of 8.44 × 10−4 RIU in the RI range of 1.333–1.410 was obtained.

Figure 11. The schemes diagram of fabrication pross of LPG structure on POF (a), and (b) is the comparison of the experiment data for the D-shape POF probe with and without LPG structure [108][46].

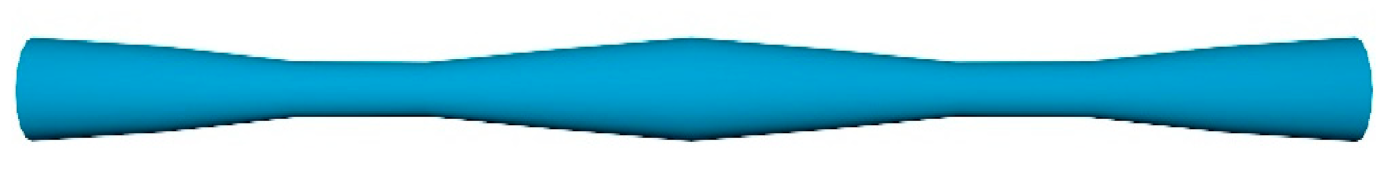

In addition, a screw-shaped POF was fabricated through a heat pressing and twisting method and proposed for RI sensing by this group, as shown in Figure 12 [110][48]. This structure can lead to periodic coupling between core modes and cladding modes, which is similar to the working principle of LPG.