1. Introduction

Rutin is a flavonoid plant metabolite. Tartary buckwheat is one of the most important nutritional sources of rutin in grain crops

[1]. Both common buckwheat (

Fagopyrum esculentum Moench) and Tartary buckwheat (

F. tataricum (L.) Gilib.) are used in human nutrition. Among their wild relatives, the wild species

Fagopyrum cymosum (Trevir.) Meisn. is used in traditional Chinese human and veterinary medicines (

Figure 1)

[2]. Besides appearing in the western parts of China,

Fagopyrum Fagopyrum cymosumcymosum is native to India, Nepal, Bhutan, Vietnam and Burma. The area of origin of cultivated buckwheat is the eastern Himalaya region

[2]. Tartary buckwheat was included in the interspecific crosses, and several new hybrid species were obtained by crossing them. The best known is

Fagopyrum giganteum Krotov., from the Ustymivska Experimental Station in Ukraine

[3][4]. Among the other important wild buckwheat species is

Fagopyrum Fagopyrum homotropicumhomotropicum Ohnishi, which has been a genetic source in the buckwheat breeding process for obtaining self-pollination in cultivated buckwheat species

[5].

Figure 1.

From left to right: plants and grain of common buckwheat, Tartary buckwheat and cymosum buckwheat. Height of plants is normally up to 1.2 m, and grain size is 4 to 6 mm.

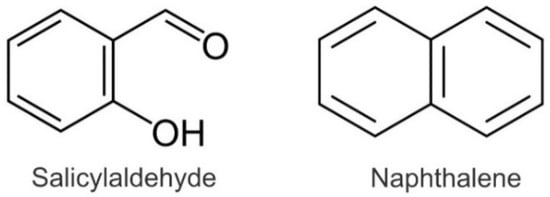

The strong aroma of Tartary buckwheat grain is characteristic and differs from that of common buckwheat. In the investigations of its phytochemical background, it was established that the most important difference of the Tartary buckwheat aroma in comparison to that of common buckwheat is the presence of naphthalene and the absence of salicylaldehyde in Tartary buckwheat (

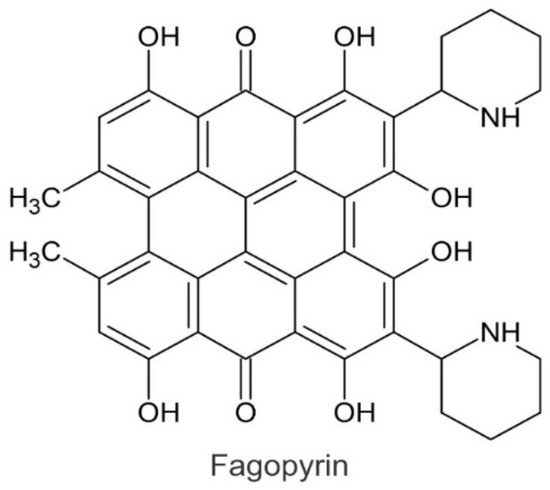

Figure 2) . Common buckwheat, Tartary buckwheat and cymosum buckwheat grain contain the phototoxic metabolite fagopyrin (

Figure 3)

[5]. Tartary buckwheat is known as an excellent source of high-quality proteins, starch, non-starch polysaccharides, flavonoids and other phenolic substances

[6].

Figure 2.

Molecules of salicylaldehyde and naphthalene.

Figure 3. Molecule of fagopyrin.

Molecule of fagopyrin.

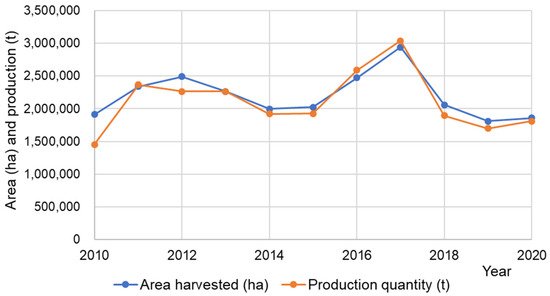

Buckwheat is grown in Asia, Europe, America and Africa. From the official statistical data (Table 1, Figure 4) , it is not possible to distinguish if the data are on common buckwheat or Tartary buckwheat. Authors have observed that, in many countries, it is cultivated common buckwheat with some admixture of Tartary buckwheat. In Bosnia and Herzegovina, the present researcheuthors observed the cultivation of a mixture of both buckwheat species in the same field. It is harvested as a mixture, and the seed mixture is then sown again in order to perpetuate the growing of a mixed crop.

Table 1. Crops of buckwheat (Fagopyrum spp.) by countries and in the world [7].

| Country |

Year of Data |

Area Harvested (ha) |

Yield

(t/ha) |

Production Quantity (t) |

| Belarus |

2020 |

27,354 |

1.03 |

28,300 |

| Bhutan |

2020 |

2004 |

1.35 |

2701 |

| Bosnia and Herzegovina |

2020 |

833 |

1.56 |

1301 |

| Brazil |

2020 |

46,416 |

1.40 |

65,117 |

| Canada |

2020 |

9800 |

0.91 |

8900 |

| China, mainland |

2020 |

624,780 |

0.81 |

503,988 |

| Croatia |

2017 |

695 |

0.90 |

624 |

| Czech Republic |

2017 |

887 |

2.55 |

2262 |

| Estonia |

2017 |

5278 |

0.64 |

3385 |

| France |

2017 |

74,883 |

3.52 |

263,485 |

| Georgia |

2020 |

106 |

1.11 |

118 |

| Hungary |

2017 |

969 |

0.94 |

909 |

| Japan |

2020 |

66,600 |

0.67 |

44,800 |

| Kazakhstan |

2020 |

55,076 |

0.73 |

40,094 |

| Kyrgyzstan |

2020 |

10 |

1.70 |

17 |

| Latvia |

2017 |

18,300 |

0.93 |

17,100 |

| Lithuania |

2017 |

48,499 |

1.10 |

53,221 |

| Nepal |

2020 |

10,369 |

1.13 |

11,724 |

| Poland |

2027 |

78,027 |

1.45 |

113,113 |

| Korea |

2020 |

1600 |

0.97 |

1549 |

| Republic of Moldova |

2020 |

5 |

0.80 |

4 |

| Russian |

2020 |

821,366 |

1.09 |

892,160 |

| Slovakia |

2017 |

429 |

0.86 |

367 |

| Slovenia |

2017 |

3647 |

0.80 |

2909 |

| South Africa |

2020 |

579 |

0.40 |

234 |

| Ukraine |

2020 |

84,100 |

1.16 |

97,640 |

| United Republic of Tanzania |

2020 |

24,295 |

1.06 |

25,772 |

| USA |

2020 |

81,620 |

1.06 |

86,397 |

| World |

|

2,088,527 |

1.16 |

2,268,191 |

Figure 4. Area harvested (ha) and buckwheat (Fagopyrum spp.) production quantity (t) in the world from 2010 to 2020.

Area harvested (ha) and buckwheat (Fagopyrum spp.) production quantity (t) in the world in the last ten years .

2. Interaction of Rutin and Its Degradation Products with Proteins

Recently, much attention has been paid to plant proteins in regard to sustainable development and the nutritional importance of plant proteins as they have low carbon footprints. Buckwheat is a low-input plant, adapted to environments that are not suitable for more demanding crops. Buckwheat protein is one of the alternative sources of high-quality plant-based proteins . However, the need to improve the buckwheat protein digestibility is suggested. Improving the buckwheat protein nutritional quality includes the deactivation of allergenic epitopes . Cereal proteins are known to have a reduced digestibility in the presence of phenolic substances . In buckwheat, diverse technologies have an impact on the structural properties and digestibility of proteins .

Storage proteins represent about 40% of the total grain proteins in buckwheat . The remaining are functional proteins. In the nutritional studies of diploid common buckwheat cultivar ‘Siva dolenjska’ and the tetraploid common buckwheat variety ‘Bednja 4n’, it was established that the studied buckwheat samples had an excellent amino acid composition, including lysine at the levels 5.0 and 5.2 g/16 g N. The biological value results of the studied buckwheat samples, obtained in the experiments with Wistar rats, were higher than in the high-lysine mutants of true cereals. However, the digestibility of buckwheat proteins was lower than that of wheat. The authors connected the low buckwheat protein digestibility with a high content of phenolic substances

[87].

The interaction between the proteins and phenolic substances of common buckwheat was confirmed in another experiment with laboratory rats. This interaction appeared during the hydrothermal treatment. As a result of the treatment, the digestion of proteins through the small and large intestine was reduced when animals were treated with antibiotics to prevent the activities of microbes in the large intestine. In the animals not treated with antibiotics, the large intestine microorganisms digested the proteins that would otherwise be blocked by phenolic substances due to the hydrothermal treatment of common buckwheat .

Common buckwheat milling fractions may have diverse concentrations of proteins and phenolic substances . In the fraction with the highest concentration of proteins (31%), it was 475 ppm rutin and 6% of tannins. In one of the starch-rich fractions (about 90% starch), it was only 19 ppm rutin, 0.1% tannins and 4.4% proteins. The milling of buckwheat grain to milling fractions with diverse concentrations of nutrients could become a novel processing technology for delivering materials for preparing functional healthy foods.

In buckwheat grain, the protein content and total polyphenols content in both free and bound polyphenols gradually decreased from the outer to the inner fractions . This result was obtained by gradual surface abrasion. The protein-rich fraction was, via this method, enriched with a polyphenol concentration of up to 55 mg/g and a protein concentration of up to 36%. After treatment with hot steam at 130 °C and being cooled down, the high temperature of the hydrothermal process may cause the denaturation of proteins, with decreased availability of proteins for enzymatic actions. The decrease in protein digestibility could be connected with the restricted accessibility of proteins to enzymes in the more rigid protein network .

Phenolic compounds have low absorption after food intake, so, after ingestion, they remain for some time in the gastrointestinal tract. They can act in an inhibitory manner on enzymes degrading proteins . This inhibition of protein digestion is not advantageous from the point of view of the availability of amino acids for the needs of the body. However, slowly digestible proteins have several desirable effects

[98]. The quality of buckwheat products and their nutritional functionality depend on the presence of proteins and peptides . Buckwheat proteins ameliorate constipation problems in rats and reduce the hepatic triglyceride concentration . Interesting results were obtained in experiments with rats that were fed extracted buckwheat protein. The results showed that buckwheat proteins counteract mammary carcinogenesis . The anticancer activities of rutin, quercetin and other buckwheat metabolites have been studied by in vitro experiments in regard to the inhibition capacity on the growth of cancer cells, or by effects in experimental animals with chemically induced cancers (

Figure 56) . Promising results were obtained in rats fed a buckwheat protein extract as the source of protein. Compared to the rats fed casein, the buckwheat protein diet reduced the body fat and caused muscle hypertrophy .

Figure 56.

Pathways of alleged suppression of appearance of cancer, according to the references (Refs. ).

In buckwheat grain, there are different levels of phenolics, which could react with proteins . Ikeda et al. studied buckwheat plant antinutrients and their impact on the digestibility of buckwheat proteins. Among the trypsin inhibitors are known buckwheat plant defence peptides .

Hydrolysed buckwheat proteins contained di-, tri-, and tetrameric peptides. Based on the content of tryptophan, proline, valine, leucine and phenylalanine, the proteins show a strong radical scavenging activity. Buckwheat albumin is very rich in antioxidant amino acids; they demonstrate antioxidant activity as well when the proteins are digested to peptides . Buckwheat products may contain important blood-pressure-lowering peptides, obtained from fermented buckwheat sprouts .

Many other bioactivities of buckwheat proteins are known. Phenolic-protein complexes act as radical sinks . They are involved in angiotensin-I-converting enzyme inhibitors and in diverse anti-tumour activities (Figure 56) and antimicrobial potential . Buckwheat protein suppresses the plasma cholesterol concentration in hamsters and prevents the formation of gallstones more intensively than soybean protein .

Another important function of proteins is that they are able to include selenium amino acids as the selenium storage. However, proteins with selenium amino acids in place of non-selenium variants may have different activities or functions

[109]. Common and Tartary buckwheat treated with selenium could be a rich source of this essential element

[1110].

3. Interaction of Flavonoids with Starch

The digestibility of gelatinized starch depends on the starch structure . The Tartary buckwheat starch digestibility is reduced by rutin and quercetin as they alter the starch structure and inhibit the activity of digestive enzymes. Quercetin has better enzyme inhibition than rutin . The interactions between Tartary buckwheat starch and quercetin probably result from hydrogen bonding with a weak hydrophobic force . In abrasive milling fractions, the starch digestibility and bioaccessibility of the buckwheat protein were increased with hydrothermal treatment . After the hydrothermal treatment, the structure disruption of the buckwheat protein flour enhanced the digestibility of the starch and biological accessibility of phenolic substances with the time of impact. This route of the dry surface abrasion process in combination with hydrothermal treatment demonstrates promising ways to obtain attractive buckwheat products. It was established that the starch digestibility is higher after the hydrothermal treatment of buckwheat than in untreated flour. Generally, when the flour is treated by steam at an elevated pressure and is suddenly exposed to atmospheric pressure, the steam in the flour particles quickly expands and the steam disrupts the structures, producing holes in the material . Some nutrients, such as starch and protein, can bind to phenols in complexes, which can slow the digestion .

The rutin and quercetin in Tartary buckwheat grain have an impact upon the physicochemical properties of the starch after cooking. The aging enthalpy of retrograde starch is lowered, and the viscosity of the Tartary buckwheat starch and paste is increased. Starch-phenolic binding is stronger than that of the complex of starch and iodine. Starch is gelatinised and retrograde, and the morphology is affected by quercetin and rutin .

The slow digestion properties of starch were studied by Luo et al. following the ethanol extract of Tartary buckwheat. The slow digestibility of this starch appeared to be due to the impact of the phenolic substances on the starch. In their in vivo experiments, mice demonstrated reduced postprandial glycaemic responses. These data of Luo et al. for Tartary buckwheat grain and glycaemic responses were similar to those obtained earlier in common buckwheat .

As mentioned, common buckwheat milling fractions may have diverse concentrations of constituents, including starch. In starch-rich fractions, it could be over 90% of the starch . Such products are of lesser importance from the nutritional point of view. However, small buckwheat starch granules are hydrophobic, and they are, in contrast to large wheat or other true cereal starch granules, rarely damaged during milling. Buckwheat starch granules are hydrophobic, and they are potentially a suitable material for producing fat replacers . In the traditional processing of Japanese buckwheat “soba” noodles, the milling fraction with a high starch content is known as “sarashina” buckwheat flour, and it is used to prevent the buckwheat dough layers from sticking after rolling out, or to prepare “sarashina-soba”, white buckwheat noodles

[1211]. The amount of resistant starch is affected by the composition of the starch in terms of its high amylose content and depending on ecological and genetic factors .

In Tartary buckwheat, the quercetin complexation with starch molecules has an impact on the in vitro digestibility of the starch and the appearance of resistant starch, thus altering the physicochemical properties of the Tartary buckwheat starch . The effects of this quercetin–polyphenol complexation indicate that food products based on Tartary buckwheat will show lower digestibility. Indeed, the quercetin in Tartary buckwheat can reduce body weight, serum triacylglycerols and low-density lipoprotein. In rats, a diet with 0.1% quercetin was shown to significantly lower the low-density lipoprotein concentrations in the serum, with no such effects on the high-density lipoprotein concentrations. Tartary buckwheat has also been shown to prevent increases in body weight and fat deposition during high fat intake in rats, although, on the other hand, this was reported to protect against hepatic stenosis . A buckwheat diet can also reduce insulin and ameliorate glucose intolerance in humans .

Rat experiments with common buckwheat have further suggested the complexity of the impact regarding the gut microbiota . Indeed, Peng et al. suggested that the link between weight gain and the gut microbiota is very complex, with the need for further studies to be conducted in the future.

Interestingly, it has been shown that rutin-enriched Tartary buckwheat flour extracts provide better flavonoid oral absorption, with the phenolic substances in the blood detectable for longer than with standard rutin, and even longer than for a native Tartary buckwheat grain flour extract . Rutin is, for the most part, bound to other grain substances and structures. Indeed, the extraction of rutin from untreated Tartary buckwheat grain flour showed 0.57 g rutin/100 g flour, while autoclaving resulted in 3.03 g/100 g flour, boiling resulted in 2.97 g rutin/100 g flour and steaming resulted in 2.50 g/100 g flour . Dzah et al. also studied solid–liquid extraction conditions for Tartary buckwheat, where they indicated that the extraction of the phenolic compounds from Tartary buckwheat flour can be performed at <65 °C

[1312].

During the process of hydrothermal preparation, which is a traditional way of preparing buckwheat groats, phenolic substances migrate with hot water from the grain pericarp into the inner parts. Therefore, in dehusked groats, there are more phenolic substances than originally in the inner part of the grain or in the groats that are dehusked without water and temperature treatment . In processing buckwheat grain for different food products, various interactions are possible among the constituents, especially during hydrothermal treatments. Tartary buckwheat noodles, prepared by using extrusion technology, showed lower estimated glycaemic index values and reduced the level of total cholesterol, triacylglycerols and low-density lipoprotein cholesterol but increased the concentration of high-density lipoprotein cholesterol .