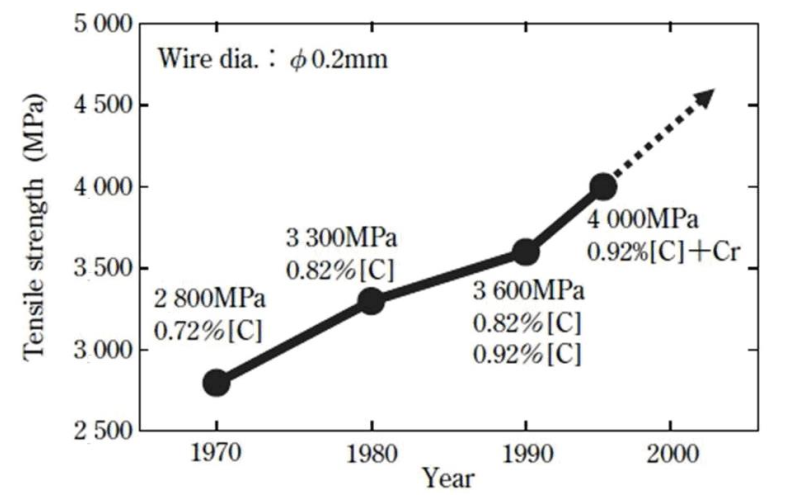

It is a well-known fact that to manufacture an automobile tire more than 200 different materials are used, including high-carbon steel wire. In order to withstand the affecting forces, the tire tread is reinforced with steel wire or other products such as ropes or strands. These ropes are called steel cord. Steel cord can be of different constructions. To ensure a good adhesive bond between the rubber of the tire and the steel cord, the cord is either brass-plated or bronzed. The reason brass or bronze is used is because copper, which is a part of these alloys, makes a high-strength chemical composition with sulfur in rubber. For steel cord, the high carbon steel is usually used at 0.70–0.95% C. This amount of carbon ensures the high strength of the steel cord. This kind of high-quality, unalloyed steel has a pearlitic structure which is designed for multi-pass drawing. To ensure the specified technical characteristics, modern metal reinforcing materials for automobile tires, metal cord and bead wire, must withstand, first of all, a high breaking load with a minimum running meter weight. At present, reinforcing materials of the strength range 2800–3200 MPa are increasingly used, the manufacture of which requires high-strength wire. The production of such wire requires the use of a workpiece with high carbon content, changing the drawing regimes, patenting, and other operations. At the same time, it is necessary to achieve a reduction in the cost of wire manufacturing. In this context, the development and implementation of competitive processes for the manufacture of high-quality, high-strength wire as a reinforcing material for automobile tires is an urgent task.

- high carbon steel wire

- reinforcing material

- automobile tire

- steel cord

- bead wire

- drawing

- patenting

- brass-plated wire

- laying

1. Introduction

References

- Smithers Rapra. Available online: https://www.smithersrapra.com/resources/2017/april/tire-industry-in-boom-cycle (accessed on 30 June 2021).

- Fleming, R.A.; Livinsto, D.I. Tire Reinforcement and Tire Performance; American Society for Testing and Materials: Philadelphia, PA, USA, 1979; pp. 112–134.

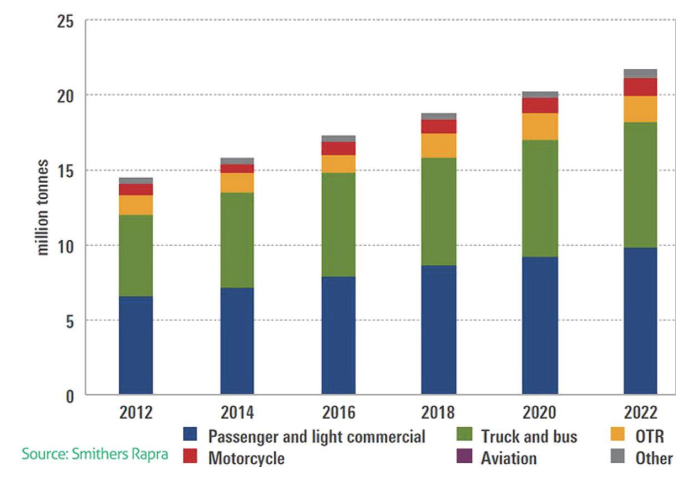

- Vedeneev, A.V.; Bobarikin, Y.A.; Zalewski, V.P. Analysis of the development of consumption and production of steel cord. Foundry Prod. Metall. 2019, 48–59.

- AZoM Materials. Available online: https://www.azom.com/ (accessed on 1 August 2021).

- Tarui, T.; Takahashi, T.; Tashiro, H.; Nishida, S. Metallurgical design of ultra high strength steel wires for bridge cable and tire cord. In Metallurgy Processing and Applications of Metal Wires; Paris, H.G., Kim, D.K., Eds.; TMS: Warrendale, PA, USA, 1996; pp. 87–96.

- Minamida, T.; Hiraga, N.; Shibata, T. R&D Kobe Steel Engineering Reports. 2000, p. 32. Available online: https://www.kobelco.co.jp/technology-review/pdf/50_3/031-035.pdf (accessed on 20 August 2021).

- Tashiro, H.; Tarui, T. Nippon Steel Technical Report. 2003, p. 87. Available online: https://www.nipponsteel.com/en/tech/report/nsc/pdf/n8818.pdf (accessed on 20 August 2021).

- Kirihara, K. Production technology of wire rod for high tensile strength steel cord. Kobelco Technol. Rev. 2011, 30, 62–65.