Cement concrete is currently the most widely used civil engineering construction material worldwide and has been applied in various civil infrastructures, such as roads, bridges, ports and tunnels. Under the external loads and environmental impacts, concrete structures are prone to be damaged, such as cracking and even spalling. In addition, inappropriate selection of raw materials, incorrect mixture design and irregular construction process may also cause damages to concrete, particularly regarding the cover protecting the reinforcement bars.

1. Introduction

Cement concrete is currently the most widely used civil engineering construction material worldwide and has been applied in various civil infrastructures, such as roads, bridges, ports and tunnels. Under the external loads and environmental impacts, concrete structures are prone to be damaged, such as cracking and even spalling. In addition, inappropriate selection of raw materials, incorrect mixture design and irregular construction process may also cause damages to concrete, particularly regarding the cover protecting the reinforcement bars. These damages not only reduce the durability of structures, but also lead to structural unserviceability during service

[1]. To solve these problems, it is necessary to repair the concrete in time to restore the structures safety and function and to extend their service life.

At present, there is a huge demand for concrete structure repair worldwide. The investments on the repair and reinforcement of old constructions in the USA were estimated at 90 billion dollars in 2016

[2]. In the Middle East Persian Gulf, the expenditure for repair and maintenance in the construction field accounted for 2.6% of the total expenditure in 2011

[3]. In Europe, the budget for maintenance and repair has been close to half of the European construction budget in recent years

[4]. In China, the repair and retrofit costs for infrastructure were estimated at 67 billion dollars in 2016

[5]. With the rapid development of civil engineering in the early 21st century, many existing concrete structures worldwide are facing the problem of “aging”. Therefore, demand for building restoration is continually surging.

The effectiveness of surface repair is greatly dependent on the properties of the repair materials and the interface between the repair and concrete substrate

[6]. However, the interface between repair materials and concrete substrate is usually a weak zone. There have been various repair materials for concrete structures and plenty of researchers are focusing on the factors that influence the interface and their mechanisms. However, the categories and respective mechanisms are ambiguous, so that high quality concrete structures repair is difficult to achieve.

2. Concrete Repair Materials

The effectiveness of repair systems mainly depends on the performances of the repair materials. Usually, repair materials should have good mechanical performances, especially high early mechanical strength, strong bonding with substrates and appropriate workability. The China building materials industry standard (JC/T2381-2016) for repair formulates the fundamental properties (see

Table 1)

[7]. The European standard (EN1504-3) for repair specifies the relevant requirements for the properties of surface repair materials (see

Table 2)

[8]. The compressive strength and bond strength are required to be at least 10 MPa and 0.8 MPa, respectively. The American standard (ASTM) for repair also stipulates the relevant requirements for the properties of surface repair materials (see

Table 3)

[9]. A suitable repair material can effectively prolong the service life of deteriorated concrete structures. At present, the materials for repairing concrete structures have been classified into cement-based materials, polymer materials and polymer-modified mortar

[10].

Table 1.

China Building Materials Industry Standard (JC/T-2016) for the basic performance requirements for repair mortar

.

| Concrete Type |

Compressive Strength

(MPa) |

Flexural Strength

(MPa) |

Compressive Flexure Ratio |

Stretching Bond Strength (MPa) |

Rate of Drying Shrinkage (%) |

| 28 Days |

28 Days |

28 Days |

14 Days |

28 Days |

| Class R4 |

|---|

| Class R3 |

Class R2 |

Class R1 |

| NF |

≥20.0 |

≥5.0 |

≤4.0 |

≥0.8 |

≤0.1 |

Table 3.

American standard (ASTM) for performance requirements for repair products

.

| Time |

3 h |

1 Day |

7 Days |

28 Days |

Table 2.

European standard (EN1504-3) for performance requirements for cement-based structural and non-structural repair products

.

| Item |

Requirement |

| Structural |

Non-Structural |

| Compressive Strength at 7 days |

≥45 MPa |

≥25 MPa |

≥15 MPa |

≥10 MPa |

Compressive strength

min, MPa |

| Chloride Ion Content |

≤0.05% |

≤0.05% |

| R1 concrete or mortar |

3.5 |

14 |

28 |

≥28 |

Adhesive Bond at 7days |

≥2.0 MPa |

| R2 concrete or mortar | ≥1.5 MPa |

≥0.8 MPa |

| 7.0 |

21 |

28 |

≥28 |

Restrained shrinkage

Expansion |

Max average crack width < 0.05 mm

No crack width > 0.1 mm

No delamination |

No requirement |

| R3 concrete or mortar |

21 |

35 |

35 |

≥35 |

≥2.0 MPa |

≥1.5 MPa |

≥0.8 MPa |

Bond strength

min, MPa |

Durability Carbonation Resistance (not required if coated) |

| R1, R2 and R3 concrete or mortar | d | k | ≤ Control concrete C (0.45) |

Not required |

| - |

7 |

10 |

- |

Length change, based on length at 3 h

max |

| R1, R2 and R3 concrete or mortar |

allowable increase after 28 days in water |

−0.15% |

| allowable increase after 28 days in air |

+0.15% |

2.1. Cement-Based Repair Materials

Cement-based materials are the most widely used materials for repairing concrete structures. These materials not only have a good compatibility with the substrate, but also have advantages of good bonding with the substrate, high economic benefit and easy operations for repair. The most used binders in cement-based repair materials are Portland cement (PC), sulphoaluminate cement (SAC) and magnesium phosphate cement (MPC). In addition, blending materials, such as fly ash, blast furnace slag and silica fume, are usually used to modify the repair materials for better performance.

Qian et al.

[11] studied the fundamental properties of cementitious repair mortar and found that the compressive strength of ordinary Portland cement mortar after 1 day curing was 22 MPa and the setting time was over 180 min (see

Table 4). In order to shorten the curing time of the repair materials and rehabilitate the performances of concrete structures as soon as possible, the cements used should have a fast hardening property. Compared with ordinary Portland cement, fast-hardening cement has higher early strength because of higher C3S and C3A content

[12]. Cifuentes et al.

[13] found that the compressive strength of fast-hardening Portland cement concrete at 1 day could reach 42.8 MPa. Compared with ordinary Portland cement, the setting time further decreases from 180 min to 28 min (see

Table 4). Therefore, the

resea

uthorchers of this

studentry believe that fast-hardening Portland cement is more suitable for emergent repair work

[11].

Table 4.

Properties of Ordinary Portland cement mortar and Rapid-Hardening cement mortar.

| Reference |

Mix Proportion |

Performance |

| Cement:Sand:Water:Reducer |

Setting Time/Min |

Compressive Strength at 1 Days/MPa |

Flexural Bond Strength at 7 Days/MPa |

| [11] |

1:1.5:0.25:0.01 |

>180 |

22 |

4.8 |

| [13] |

1:0.09:-:- |

28 |

42.8 |

- |

| Elastic Modulus |

| ≥20 GPa |

| ≥15 GPa |

Sulphoaluminate cement is also a fast-hardening binder, of which the main mineral components are C

2S and 3CaO∙3Al

2O

3∙3CaSO

4. Hydration products with a large amount of crystalline water can not only provide a strong bonding capacity and shorten the setting time for emergent repairs, but also effectively reduce the shrinkage

[14]. Yu et al.

[15] studied the effect of ettringite on the performance of SAC repair mortar. They found that ettringite seeds can remarkably accelerate the hydration of SAC and increase the compressive strength. When the water-to-cement ratio was 0.28, the SAC mortar strength reached 63 MPa at 1 day, higher than PC mortar, and the final setting time was about 12 min (see

Table 5). Qian et al.

[11] also reported that SAC mortar exhibited a better early mechanical property than OPC mortar and MPC mortar. However, if the fine needle-like and expansive ettringite was too concentrated and distributed unevenly, the strength of SAC mortar at the later hydration period could decline, which may reduce the quality of repair

[16]. Meanwhile, the rapid hardening property of SAC leads to more shrinkage, which may cause the development of cracks. Hajir et al.

[17] found that the use of fiber reinforced SAC mortar for the repair of concrete structures can mitigate the influence of shrinkage. They reported that the crack widths in fiber reinforced SAC mortar are 60% lower than the normal SAC mortar.

Table 5.

Properties of Sulphoaluminate cement mortar as repair materials.

| Reference |

Mix Proportion |

Performance |

| Cement:Sand:Water:Reducer |

Setting Time/Min |

Compressive Strength at 1 Days/MPa |

Flexural Bond Strength at 7 Days/MPa |

[19], lower shrinkage and better environmental tolerance

[20][21]. Qian et al.

[11] found that the flexural bonding strength between MPC mortar and concrete substrates was about 9 MPa, higher than OPC and SAC mortar, and the setting time of MPC mortar was only 22 min at most, which can significantly shorten the repair period (see

Table 6).

Table 6.

Properties of Magnesium Phosphate mortar as repair materials.

| Reference |

Mix Proportion |

Performance |

| Cement:Sand:Water |

Setting Time/Min |

Compressive Strength at 7 Days/MPa |

Flexural Bond Strength at 7 Days/MPa |

| ] |

1:1.5:0.25:0.01 |

| [22] | 15 |

50 |

1:1.5:0.2 (M/P = 6) |

11.25 |

61.87.8 |

| 9.1 |

[15] |

1:-:0.3:- |

27 |

40.2 |

- |

| 1:-:0.28:- |

12 |

63 |

- |

Magnesium phosphate cement made by mixing the magnesia and phosphate with some inert fillers in certain proportions is a new eco-friendly material because it consumes less resources and energy during production than other traditional cements. Compared to Portland cement mortar, MPC mortar features advantages of higher early strength, shorter setting time, better bonding performance

[18]

| [ |

| 11 |

| ] |

| 1:1.5:0.12 |

22 |

33 |

4.3 |

Qiao et al.

[22] studied MPC with different Mg/P ratio and found that the flexural bonding strength between MPC and concrete substrates reached maximum with Mg/P ratio of 6, and the concrete substrate was 9.1 MPa at 7 days (see

Table 6), also much higher than OPC and SAC. Recently, Monica et al.

[23] developed an innovative repair material by adding halloysite nanotubes (HNTs) into MPC mortar. It was illustrated that the introduction of HNTs into MPC mortar can improve the consistency and the handling properties of the mortar without affecting the setting time, which is significant, as the fast hardening of MPC is one of the main advantages for concrete repair. Moreover, HNTs can disperse in the MPC mortar and improve the compressive strength. The hydration reaction of MPC is extremely exothermic, making it suitable for applications in cold weather conditions

[20][22]. However, when the MPC mortar is exposed to additional water, hydration product MgKPO

4·6H

2O dissolves and the porosity of the mortar increases, causing a decrease in the mechanical strength. Therefore, MPC-based repair materials should not be applied in moist or underwater environments

[20].

In summary, cement-based materials with the properties of rapid hardening and high early mechanical strength are more suitable for the concrete repair materials. However, the effect of shrinkage of rapid hardening materials should be valued. Among the above cement-based materials, MPC shows better early mechanical properties, shorter setting time and lower shrinkage than PC and SAC.

2.2. Alkali-Activated Materials

Alkali-activated material (AAM) is an environmentally friendly repair material because it causes little pollution during production and it presents desirable characteristics, such as high mechanical strength and resistance to chemical agents, better temperature stability, improved abrasion resistance and good adhesion to concrete substrates

[24]. Therefore, it has good potential to be used for concrete repair

[25]. AAMs are obtained from the alkaline activation of silica (SiO

2) and alumina (Al

2O

3)-rich materials, such as fly ash (FA), blast furnace slag (BFS) and metakaolin (MK)

[26]. When AAM is applied to repair concrete substrates, the Ca (OH)

2 in the substrate will react with the SiO

2 and Al

2O

3 in AAM to form calcium (natrium) silicoaluminate hydrate (C(N)ASH), thereby enhancing the interfacial adhesion

[27]. Nunes et al.

[28] found that when 20% of MK was partially substituted by BFS, the repair performance was best; the compressive strength was higher than 50 MPa, and the tensile bond strength with concrete substrate exceeded 1.7 MPa (see

Table 7). Gomaa et al.

[27] found the vertical bond strength between AAM and concrete decreased with the increase in water content. The MK-based AAM featured good workability. The fly ash concrete required the addition of a little expansion agent and plasticizer to reduce the shrinkage of the fresh AAM and enhance its workability

[29]. However, the main problem of AAM mortar is the high shrinkage and cracking, which are many times higher than in PC repair mortar. Mariana et al.

[24] found that higher aggregate/binder ratio (2.5/1.5), fiber reinforcement and better curing control (prevention of moist evaporation) can significantly reduce shrinkage and cracking.

Table 7.

Properties of Alkali-Active Materials mortar as repair materials.

| Reference |

Mix Proportion |

Performance |

| MK (%):BFS (%) |

W/B | a |

Compressive Strength at 7 Days/MPa |

Bond Strength at 7 Days/MPa |

| Flexural Bond Strength |

Vertical Bond Stress |

| [28] |

100:0 |

- |

49.3 |

1.78 |

- |

| 1:1.5:0.2 (M/P = 8) |

8 |

28 |

4 |

| 80:20 |

- |

50 |

1.74 |

- |

1:1.5:0.2 (M/P = 10) |

7.25 |

37 |

4.6 |

| 60:40 |

- |

56.7 |

1.3 |

- |

| [27] |

- |

0.36 |

37 |

- |

26 |

| - |

0.39 |

33 |

- |

23 |

| - |

0.54 |

34 |

- |

24.5 |

2.3. Polymer-Modified Mortar Repair Materials

Cement-based repair materials usually have problems of high shrinkage and low flexibility. Therefore, modification of cement-based repair materials by using organic materials has attracted lots of attention.

The epoxy-modified cement mortar (EC) has been widely studied for concrete repair

[30][31][32] due to its good compatibility with cement-based materials

[33][34]. Saccani et al.

[35] studied the adhesion and durability of water-based epoxy resin–modified cement mortar used to repair deteriorated concrete structures under high temperatures. The experimental results showed that the EC had good adhesion to the concrete substrate under heating conditions and the mechanical stress caused by differential thermal expansion coefficients. An aqueous epoxy resin was used to modify ordinary Portland cement with four different dosages

[36]. It was found that the flexural strength of Portland cement mortar could be improved with epoxy resin reinforcement. It was found that when the epoxy resin was 5% by weight of cement, the mortar has the highest mechanical strength and interfacial bonding strength. (see

Table 8). Ariffin et al.

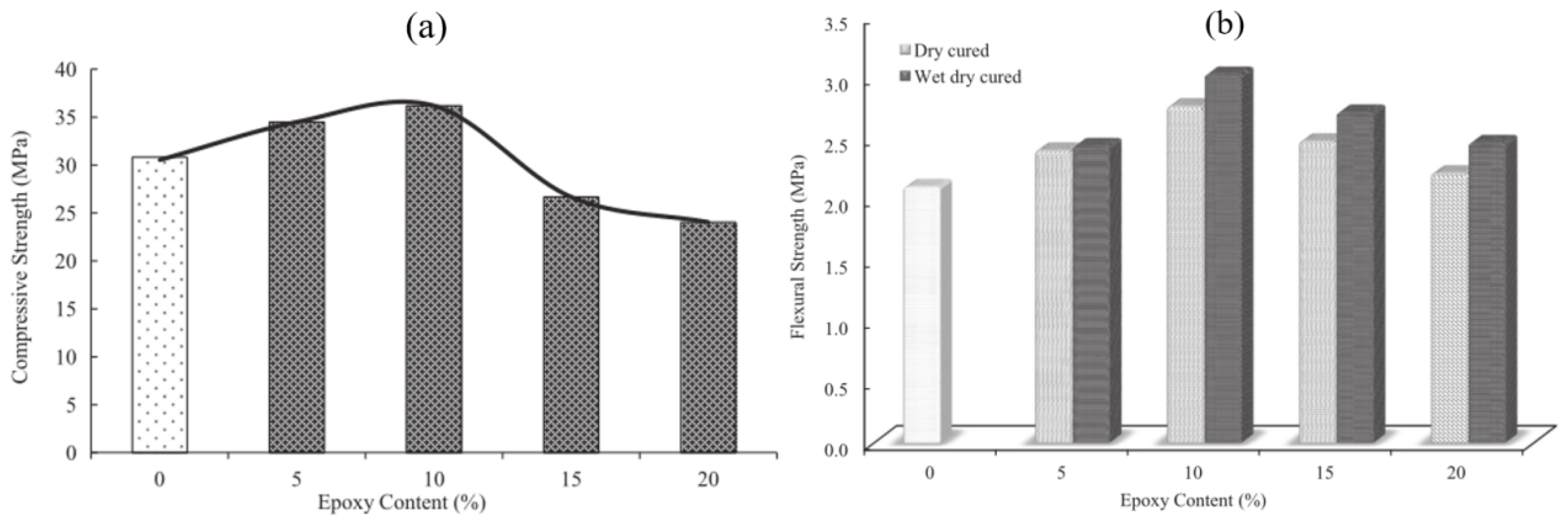

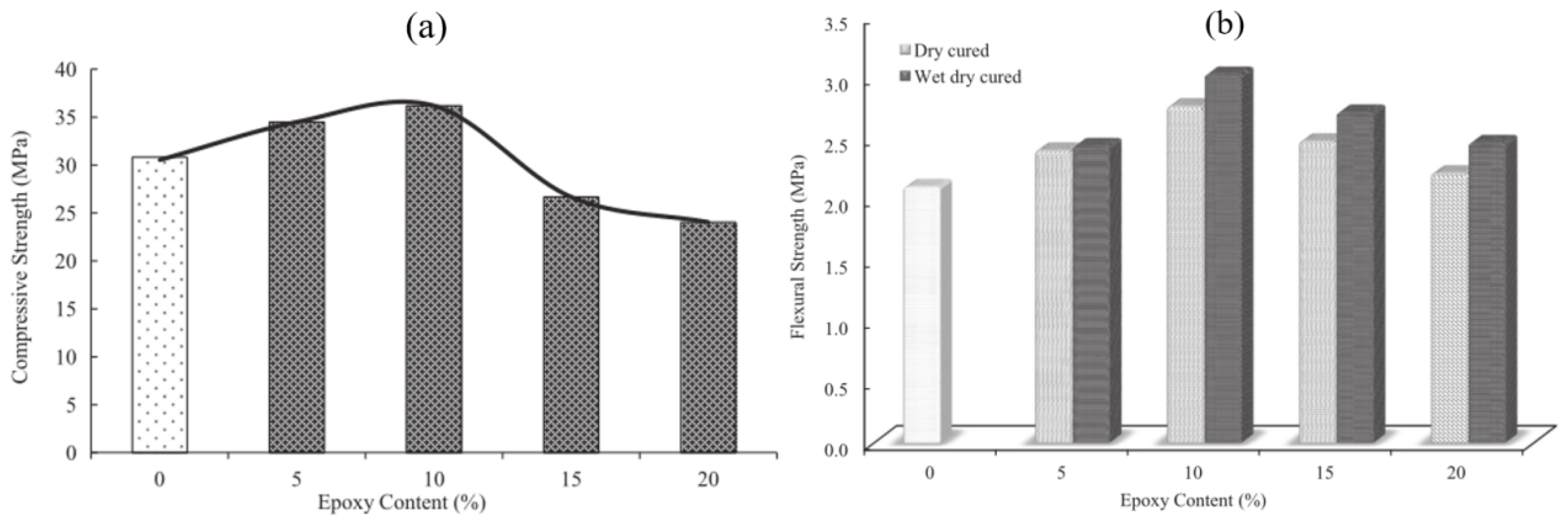

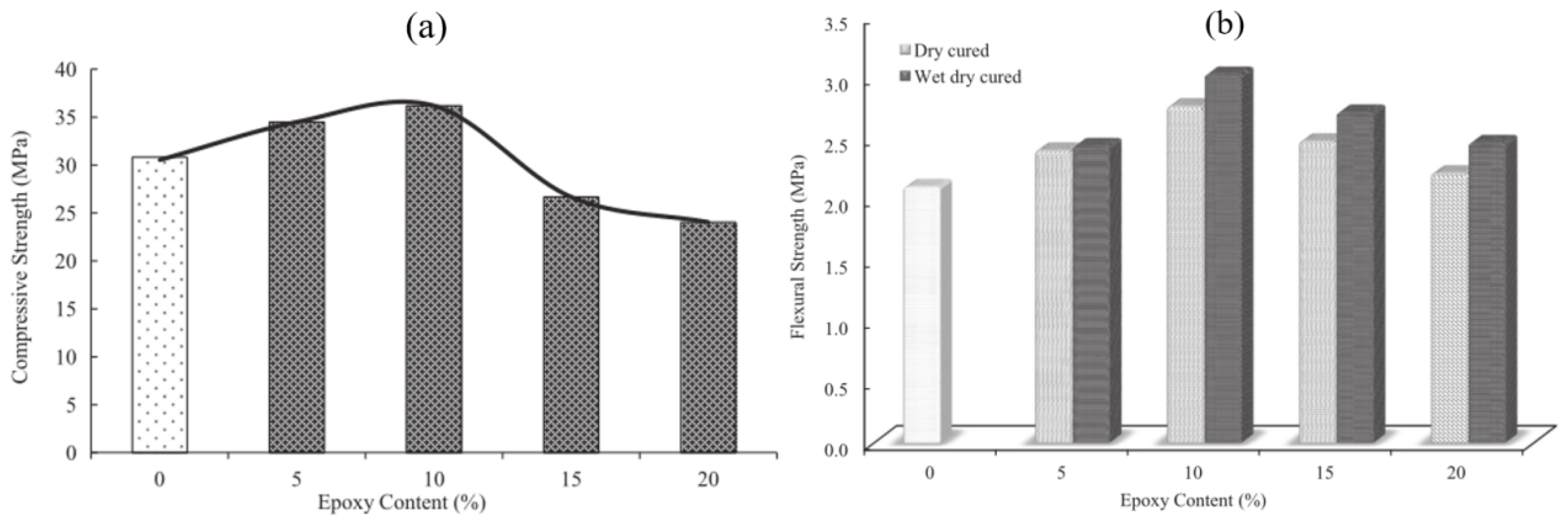

[37][38][39] studied the mechanical property of epoxy resin–modified cement mortar with different resin contents and found that that the modified mortars with a resin content of 5% and 10% had compressive strengths of 33 MPa and 36 MPa, respectively, at 28 days. However, when the epoxy resin content exceeded 10%, the mechanical properties of the modified mortar decreased with an increase in the resin content (

Figure 1). This can be attribute to the unhardened epoxy resin left in polymer-modified mortars. The excessive epoxy resin inside the mortar probably hinder the hydration and polymerization process. Wang et al.

[40] found that the epoxy resin can repair the damaged concrete structure by filling cracks. Due to the good mechanical properties and adhesion of epoxy resin, it can restore the integrity of repaired concrete.

Figure 1.

Figure 1. The mechanical strength of epoxy mortar: (

a) Relationship between compressive strength and epoxy content for wet–dry curing; (

b) Relationship between flexural strength and epoxy content for wet curing and wet–dry curing

[37]. (Adapted and reprinted with permission from ref.

[37], © 2015,

Construction and Building Materials).

Table 8.

Properties of the epoxy-modified cement mortar as repair materials.

| Reference |

Mix Proportion |

Performance |

| Cement:Sand:Water:Epoxy Resin |

Properties of cement asphalt mortar as repair material.

| Reference |

Mix Proportion |

| Compressive Strength at 7 Days/MPa |

Flexural Bond Strength at 28 Days/MPa |

| Performance |

|---|

| Cement:Sand:Water:Asphalt Emulsion |

Unconfined Compressive Strength at 28 Days/MPa | Flexural Strength at 7 Days/MPa |

Setting Time/Min |

Flexural Bond Strength at 4 h/MPa |

| [36] |

1:2:0.36:0.03 |

49 |

9.5 |

3.8 |

| [42] |

1:0.5:0.4:0.75 |

4.1 |

17 |

-- |

| 1:2:0.36:0.05 |

50 |

9.8 |

| 1:0.5:0.4:1 |

3.4 | 4.9 |

| 21 |

-- |

1:2:0.36:0.07 |

49.8 |

9.6 |

4.7 |

| 1:2:0.36:0.09 |

49.5 |

9.4 |

4.6 |

Asphalt mortar (AM) has been applied widely in repairing high-speed railways

[41]. Minh et al.

[42] studied the factors which influence rheology and hardening properties of AM, such as asphalt–cement ratio, sand–cement ratio and the type and dosage of additive. They developed an AM with high fluidity, rapid setting time and high strength which can improve the stability and regularity of railway roads (see

Table 9). Fang et al.

[43] found that the interaction between asphalt and cement can be attributed to both physical and chemical actions. Normally, the physical actions of adsorption of asphalt on cement surface and destabilization of asphalt emulsion hold a dominant position. However, when there are more carboxylic acids components in the emulsion, the chemical action, such as interaction with Ca

2+ and chemical bonding, should be taken in consideration. Liu et al.

[44] investigated the bonding mechanism between asphalt-modified SAC repair mortar and concrete substrates. They found that the bond strength between the mortar and substrate decreased with the increase in asphalt content when the asphalt–cement mass ratio exceeded 0.5 (see

Table 9), indicating that excessive asphalt had a negative effect on the modified mortar. This can be attributed to the reduction in free water with the increase in asphalt–cement mass ratio, which decreased the amount of Aft, and it is AFt that mainly provides interfacial strength.

Table 9.

| 1:0.5:0.4:1.25 |

| 1.8 |

24 |

- |

| 1:-:0.4:0.75 |

2.2 |

20 |

- |

| 1:-:0.4:1 |

2.1 |

25 |

- |

| 1:-:0.4:1.25 |

1.7 |

37.5 |

- |

| |

Sulphoaluminate cement:sand:water:asphalt emulsion |

Unconfined compressive strength at 28 days/MPa |

Setting time/min |

Flexural bond strength at 4 h/MPa |

| [44] |

1:2.2:0.52:0 |

- |

- |

2.65 |

| 1:2.2:0.52:0.1 |

- |

- |

2.33 |

| 1:2.2:0.52:0.3 |

- |

- |

2.12 |

| 1:2.2:0.52:0.5 |

- |

- |

1.87 |

| 1:2.2:0.52:0.7 |

- |

- |

0.99 |

Wang et al.

[45] studied the flow properties and mechanical properties of cement mortars modified with styrene–butadiene emulsion. It was found that styrene–butadiene emulsion had significant influence on the flexural strength of the cement repair mortar, while it had little influence on the compressive strength. Kharazian et al.

[46] found that there is a decreasing trend in the air voids for samples with higher dosage of the copolymer (optimizing at a dosage of 15%). It is further strengthened by the results of mechanical analyses. Bureau et al.

[47] found that the strain at rupture and ductility of the mortar increased with the increase in polymer content. Li et al.

[48] also utilized styrene–butadiene emulsion-modified cement mortar as a repair material and found that the styrene–butadiene emulsion not only boosted the cement mortar compactness by filling the pores, but also prolonged the mortar setting time because of the retardation effect of polymers on cement hydration. There are two aspects of this retardation effect: (1) The carboxyl groups on the polymer complex calcium ions and (2) polymers are adsorbed on the cement surface and delay the hydration.

In summary, polymer-modified mortar generally has high mechanical strength, excellent durability and high bond strength with the substrates, but its setting time is usually longer than that of the non-modified ones.

Figure 1. The mechanical strength of epoxy mortar: (a) Relationship between compressive strength and epoxy content for wet–dry curing; (b) Relationship between flexural strength and epoxy content for wet curing and wet–dry curing [37]. (Adapted and reprinted with permission from ref. [37], © 2015, Construction and Building Materials).

Figure 1. The mechanical strength of epoxy mortar: (a) Relationship between compressive strength and epoxy content for wet–dry curing; (b) Relationship between flexural strength and epoxy content for wet curing and wet–dry curing [37]. (Adapted and reprinted with permission from ref. [37], © 2015, Construction and Building Materials).

Figure 1. The mechanical strength of epoxy mortar: (a) Relationship between compressive strength and epoxy content for wet–dry curing; (b) Relationship between flexural strength and epoxy content for wet curing and wet–dry curing [37]. (Adapted and reprinted with permission from ref. [37], © 2015, Construction and Building Materials).

Figure 1. The mechanical strength of epoxy mortar: (a) Relationship between compressive strength and epoxy content for wet–dry curing; (b) Relationship between flexural strength and epoxy content for wet curing and wet–dry curing [37]. (Adapted and reprinted with permission from ref. [37], © 2015, Construction and Building Materials).