The primary goal of edge computing (EC) is to reduce the time required to transfer large amounts of data. With the ability to analyze data at the edge, it is possible to obtain immediate feedback and use it in the decision-making process. However, the implementation of EC requires investments not only in infrastructure, but also in the development of employee knowledge related to modern computing methods based on artificial intelligence. Future research in EC should particularly cover areas where actions require immediate decision making and the processing of big data, such as autonomous control of robots, vehicles, or entire factories. The second area of research should be technologies related to mobile edge computing, for example, telecommunications and all issues related to 5G technology.

1. Introduction

Introducing new and improved tools, machines, devices, or techniques into production processes that increase work efficiency or save raw materials or energy leads to technical progress. In the history of industry so far, researchers can distinguish four breakthrough concepts that have had a huge impact on production systems: Industry 1.0—water and steam mechanization; Industry 2.0—mass production based on electricity; Industry 3.0—increasing production automation based on digitization; and Industry 4.0—digitalization of manufacturing systems.

Today’s industry is shifting towards a green and digital transformation. There is much emphasis on the implementation of sustainable development. Three aspects of sustainable development have been discussed in the literature: economic, environmental, and social. Industry 4.0 technology can support all of these

[1]. Sustainable development is associated with all technologies applied to develop the economy with simultaneous care for the preservation of the natural environment and respect for people

[2]. Consequently, there is a constant search for approaches and technologies that can support these activities. For example, the concept of zero defect manufacturing, widely explored in

[3], can support all aspects of sustainability. This is because researchers prevent the waste of materials and energy, and, thus, excessive costs and additional work that would have to be completed to eliminate defects or to produce a new product without defects. Therefore, the goal is to prevent defects and achieve correct production the first time. Some technologies are based on the analysis of previously collected data to predict problems, such as virtual metrology, which estimates the results of a process based on previous metrological measurements rather than performing them in real time

[4]. In the case of semiconductor manufacturing, a machine learning system is used for the purpose

[5]. For this to be possible, it is necessary to collect data for analysis.

It is indispensable to monitor the processes and ensure that the required parameters of the processes will be maintained throughout the entire production process. For the purpose, it becomes necessary to implement technologies that will enable data collection and analysis in real time, so that, if necessary, parameters can be adjusted immediately. This means that the entire procedure must be carried out at the point of process realization, that is, at the edge. Therefore, to ensure the quality of the process and products (that is, zero defect manufacturing), edge computing (EC) must be implemented

[6]. Therefore, it can be said that EC can also support sustainable development. However, for this to be possible, a digital transformation is necessary.

When analyzing the concepts of Industry 4.0, the literature distinguishes the following categories of technologies on which the concept is based: cyber-physical systems (e.g.,

[7]), Internet of Things, big data analytics, cloud computing, fog and edge computing (EC), Augmented Reality (AR) and Virtual Reality, robotics, cyber security, Semantic Web technologies, and additive manufacturing

[8][9].

2. Topic Definitions

The most common terms identified through text mining are defined as follows.

Edge computing (EC) is the so-called marginal calculations where data are generated and immediately processed at the edge of the network. This technology is necessary to cope with the growing number of communicating devices connected to the network. The goal is to avoid high latency and bottlenecks in cloud computing traffic in networks where several devices both access and generate large amounts of data.

Edge computing also improves network support for mobility, security, and privacy

[10].

Cyber-physical systems (CPS) are intelligent computer systems that are highly connected, and their physical and computational elements work together

[11].

Internet of Things is a system that is connected by a network of things, e.g., machines or devices. Due to this, they are able to communicate with each other by processing, collecting, or exchanging data

[8].

Industrial Internet of Things (IIoT) is the integration of different IoT technologies into industrial manufacturing processes to ensure a high level of efficiency and automation which leads to economic growth. In IIoT, communication technologies are present within the whole manufacturing lifecycle. IIoT is a key element of CPS, supporting the ability to collect data, compute, transfer information, and control processes

[12].

Cloud computing is a technology for storing and processing data using scalable services on the Internet

[8].

Fog computing is an extension of the concept of cloud computing that shifts computing to the edge of the network. It is closely related to edge computing and the Internet of Things and has all their advantages. It is the link between edge devices and data centers

[13].

Computation offloading is the offloading of calculations by moving the location of execution from the cloud to the edge of the network in order to accelerate them and reduce delays

[14].

Blockchain technology is based on the use of blockchains, which are shared distributer registers. It is used in smart and digitally connected factories to store information about resources and processes. Blockchain technology ensures that the processes are more autonomous, efficient, faster, and secure by providing safe communication mechanisms (a public and private key) to ensure authentication

[15].

Smart factory enables high personalization of production with little participation from employees. Cyber-physical production systems are constructed in such a way that they can react to almost any change in the market in a short time

[16].

Smart manufacturing is a new form of production that integrates current and future production assets with sensors, computing platforms, communication technology, control, simulation, modeling, and data-intensive computing with manufacturing engineering

[17].

Artificial Intelligence (AI) is, according to Andreas Kaplan and Michael Haenlein, “the ability of a system to correctly interpret data from external sources, learn from them and use this knowledge to perform specific tasks and achieve goals through flexible adaptation”

[18].

Machine learning (ML) is the process of constructing computer programs that are capable of learning from data. Appropriate algorithms allow the software to automate the process of data acquisition and analysis for the purpose of improving and developing its own system

[19]. ML can have a positive impact on products and processes by enabling effective prediction of their behavior based on past experience, data, and information

[20].

Deep learning is an ML category where algorithms (usually artificial neural networks) are composed to form communicating layers. Each layer is taught to transform input into a more meaningful concept (e.g., pixels—edges—a shape—a flower)

[21].

Deep reinforcement learning is when techniques of deep learning are combined with reinforcement learning methods and used to represent problems related to the introduction of raw multidimensional data

[22].

Mobile edge computing is a concept that combines elements of information technology and a telecommunications network, in which computing, memory, and network resources are integrated with a cellular base station

[23].

5G is the fifth generation cellular network standard that is expected to transmit data faster, increase the connectivity spectrum of devices, increase throughput, lower costs, increase consistency, increase quality, and reduce data transmission delays

[24].

Big data is, according to Jarosław Woźniczka, “diverse and variable data sets created thanks to modern telecommunications devices that are stored, processed and analyzed using advanced information technology”

[25].

Resource allocation is the allocation of the required resources to the nodes in the network according to the possibility of their use

[26].

Resource management is the efficient and effective development of an organization’s resources when they are needed

[27].

Game theory is a mathematical theory of socio-economic phenomena that shows interactions between decision-making units. This theory is based on structural procedures of mathematics and addresses problems from various fields of application

[28].

Digital twin is a virtual model that is fully compatible and consistent with a physical object. It simulates object behavior and performance in a real-time environment

[29]. Digital twins support sustainable development by saving resources, preventing waste, and, thus, optimizing the effort involved

[30].

SDN (software-defined networking) is a programmable network building technology that enables central management and control. It consolidates all control into one node—a network controller (no distributed control architecture). Network relay devices no longer participate in network control and only forward data packets

[31].

Anomaly detection uses data mining techniques to detect surprising behaviors hidden in data. When applied to cybersecurity, anomaly detection increases the probability of detecting an attempted break-in or attack

[32]. Machine failure can be predicted in machine monitoring with anomaly detection.

3. Network and Its Visualization

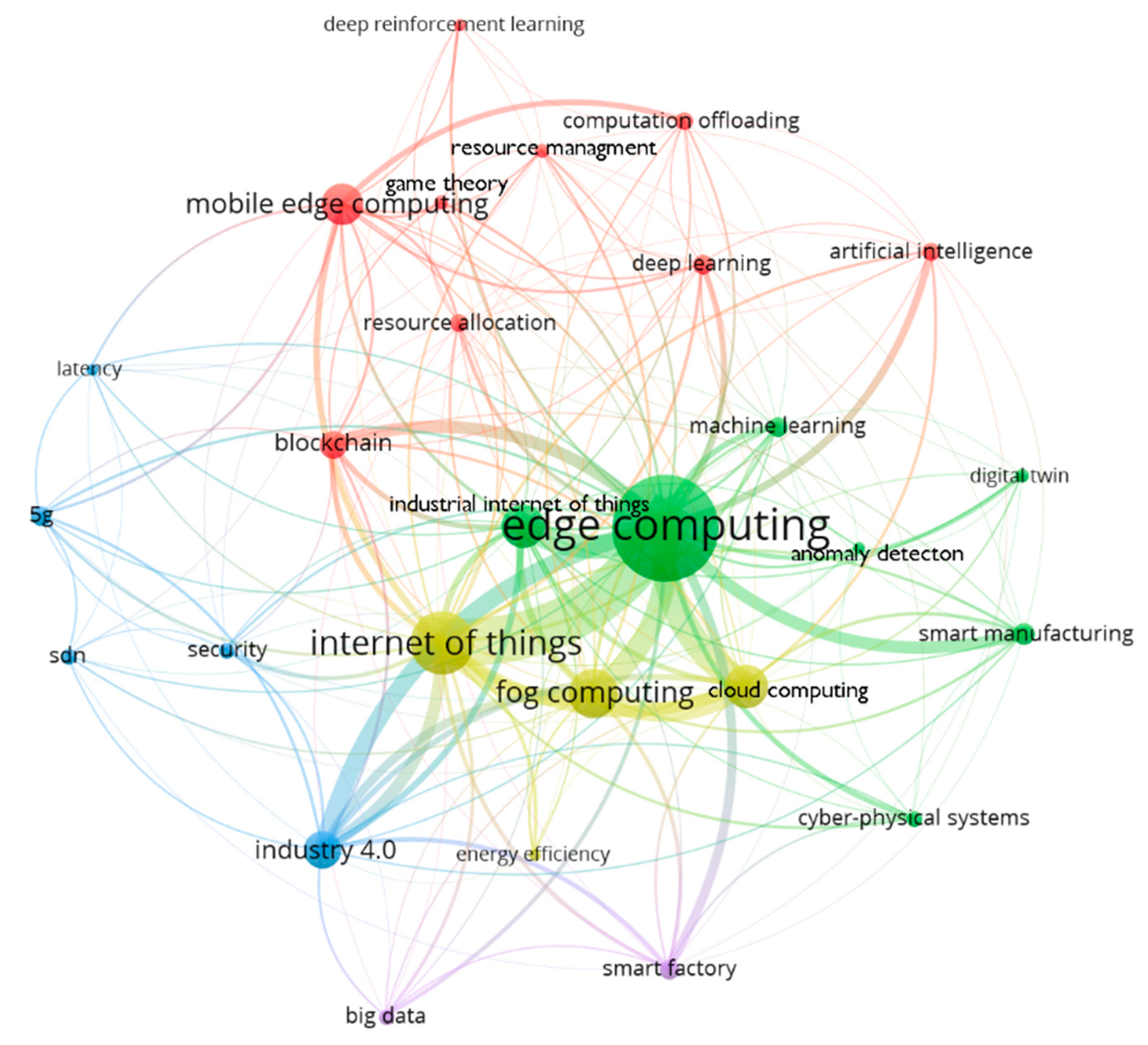

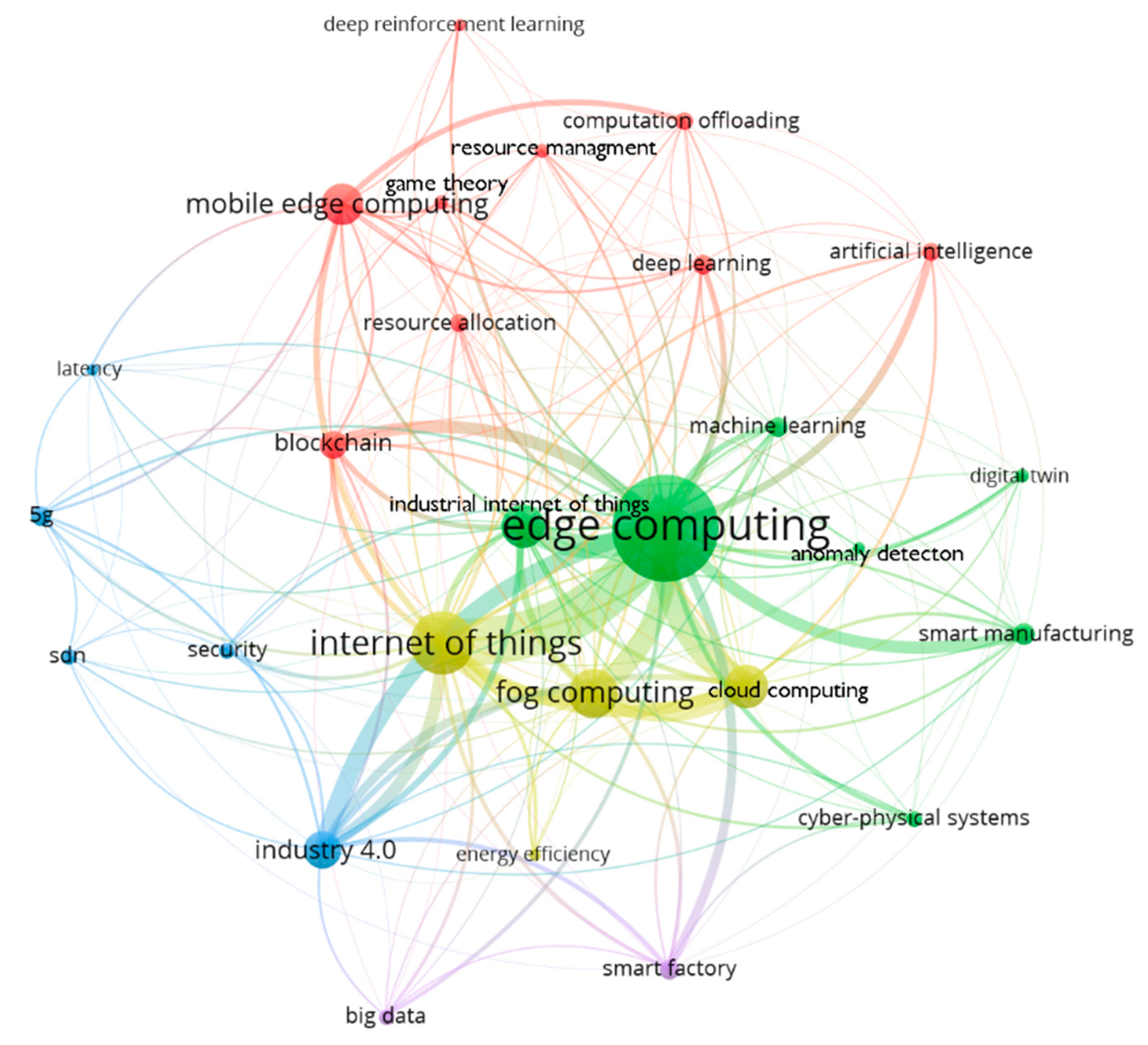

Based on the mapping of keywords that appeared at least 10 times, the network visualization

[33] was obtained after the use of thesaurus grouping (

Figure 1). In the visualization, each circle represents a specific term. The area of the circle indicates the number of publications with the appropriate term. The thickness of the line joining the terms indicates the total strength of the term co-occurrences in different works

[34].

Figure 1. Terms network visualization In VOSviewer version 1.6.16.

Terms that often coexisted with each other are placed close to each other in the visualization. The terms were grouped into five clusters. The blue cluster in the left area of the visualization consists of terms related to the decrease in data transfer time. The red cluster in the top area covers AI-related terms. In the right and central visualization areas, the green cluster consists of manufacturing-system-related terms. In the central part of the yellow cluster are terms related to locations where data are computed. At the bottom of the map, the purple cluster contains terms related to data volume. The conducted mapping gives a general view of issues related to EC.

The numerical values of term weights and link strengths are presented in

Table 1 and

Table 2, respectively. The weights inform about the importance of the terms. Here, it refers to the number of occurrences of a term in publications. The link strength provides information about the degree of association between the term

Edge Computing and a term shown in the first column of

Table 2. The absolute value is the number of publications in which both terms occurred in the keywords section. Relative values were calculated as a percent of the maximum value from the given category.

Table 1. Term weights in the analyzed databases.

| Term |

All Databases |

WoS |

IEEE Explorer |

SCOPUS |

| Weight |

Relative Weight |

Table 2. Link strength between a term and the Edge Computing term.

| Term |

All Databases |

WoS |

IEEE Explorer |

SCOPUS |

| Weight |

Relative Weight |

Weight |

Relative Weight |

Weight |

Relative Weight |

|---|

| Link Strength |

Relative Link Strength |

Link Strength |

Relative Link Strength |

Link Strength |

Relative Link Strength |

Link Strength |

Relative Link Strength |

|---|

| latency |

10 |

energy efficiency2.9 |

0 |

0.0 |

0 |

20.0 |

2.5 |

0 |

0.0 |

00 |

0.0 |

| 0.0 |

0 |

0.0 |

anomaly detection |

11 |

3.2 |

6 |

4.3 |

0 |

0.0 |

0 |

0.0 |

| deep reinforcement learning |

11 |

3.2 |

0 |

0.0 |

7 |

3.9 |

0 |

0.0 |

| energy efficiency |

11 |

3.2 |

0 |

0.0 |

8 |

4.4 |

0 |

0.0 |

| digital twin |

12 |

3.5 |

7 |

5.1 |

0 |

0.0 |

9 |

4.1 |

| computation offloading |

4 |

5.0 |

0 |

0.0 |

3 |

7.9 |

3 |

5.4 |

game theory |

12 |

3.5 |

0 |

0.0 |

9 |

5.0 |

0 |

0.0 |

| resource management |

12 |

3.5 |

0 |

0.0 |

9 |

5.0 |

0 |

0.0 |

| big data |

14 |

4.0 |

4 |

2.9 |

10 |

5.6 |

7 |

3.2 |

| SDN |

14 |

4.0 |

0 |

0.0 |

8 |

4.4 |

6 |

2.8 |

| security |

14 |

4.0 |

0 |

0.0 |

11 |

6.1 |

0 |

0.0 |

| cyber-physical systems |

15 |

4.3 |

5 |

3.6 |

7 |

3.9 |

10 |

4.6 |

| computation offloading |

18 |

5.2 |

0 |

0.0 |

15 |

8.3 |

6 |

2.8 |

| resource allocation |

18 |

5.2 |

0 |

0.0 |

14 |

7.8 |

6 |

2.8 |

| artificial intelligence |

20 |

5.8 |

5 |

| 6.6 |

| 11 |

| 8.0 |

13 |

7.2 |

13 |

6.0 |

| smart manufacturing |

24 |

6.9 |

13 |

9.4 |

13 |

7.2 |

19 |

8.7 |

| blockchain |

36 |

10.4 |

10 |

7.2 |

23 |

12.8 |

15 |

6.9 |

| Industry 4.0 |

60 |

17.3 |

17 |

12.3 |

38 |

21.1 |

33 |

15.1 |

| smart manufacturing |

21 |

26.3 |

mobile edge computing |

73 |

21.1 |

12 |

8.7 |

50 |

27.8 |

31 |

14.2 |

| cloud computing |

76 |

22.0 |

20 |

| 41.6 |

| 47 |

34.1 |

79 |

43.9 |

91 |

41.7 |

| edge computing |

346 |

100.0 |

138 |

| mobile edge computing |

2 |

2.5 |

1 |

2.6 |

1 |

2.6 |

1 |

1.8 |

| latency |

3 |

3.8 |

0 |

0.0 |

0 |

0.0 |

0 |

0.0 |

| SDN |

3 |

3.8 |

0 |

0.0 |

3 |

7.9 |

1 |

1.8 |

14.5 |

45 |

25.0 |

38 |

17.4 |

| Industrial Internet of Things |

78 |

22.5 |

26 |

18.8 |

57 |

31.7 |

34 |

15.6 |

| fog computing |

97 |

28.0 |

25 |

18.1 |

70 |

38.9 |

37 |

17.0 |

| Internet of Things |

144 |

| resource management |

4 |

5.0 |

0 |

0.0 |

2 |

5.3 |

0 |

0.0 |

| security |

4 |

5.0 |

0 |

0.0 |

3 |

7.9 |

0 |

0.0 |

| 5G |

5 |

6.3 |

3 |

7.9 |

2 |

5.3 |

3 |

5.4 |

| anomaly detection |

5 |

6.3 |

1 |

2.6 |

0 |

0.0 |

0 |

0.0 |

| deep reinforcement learning |

5 |

6.3 |

0 |

0.0 |

2 |

5.3 |

0 |

0.0 |

| game theory |

5 |

6.3 |

0 |

0.0 |

4 |

10.5 |

0 |

0.0 |

| big data |

7 |

8.8 |

3 |

7.9 |

5 |

13.2 |

5 |

8.9 |

| resource allocation |

7 |

8.8 |

0 |

0.0 |

4 |

10.5 |

4 |

7.1 |

3.6 |

9 |

5.0 |

14 |

| digital twin | 6.4 |

| 8 |

10.0 |

4 |

10.5 |

0 |

0.0 |

7 |

12.5 |

machine learning |

21 |

6.1 |

11 |

8.0 |

14 |

7.8 |

18 |

| cyber-physical systems | 8.3 |

| 9 |

11.3 |

3 |

7.9 |

4 |

10.5 |

5 |

8.9 |

5G |

23 |

6.6 |

7 |

5.1 |

10 |

5.6 |

14 |

| deep learning | 6.4 |

| 10 |

12.5 |

3 |

7.9 |

6 |

15.8 |

5 |

8.9 |

deep learning |

23 |

6.6 |

8 |

5.8 |

14 |

7.8 |

12 |

| machine learning | 5.5 |

| 10 |

12.5 |

5 |

13.2 |

6 |

15.8 |

9 |

16.1 |

smart factory |

23 |

| artificial intelligence |

13 |

16.3 |

3 |

7.9 |

6 |

15.8 |

9 |

16.1 |

| smart factory |

16 |

20.0 |

9 |

23.7 |

8 |

21.1 |

9 |

16.1 |

| blockchain |

21 |

26.3 |

8 |

21.1 |

12 |

31.6 |

12 |

21.4 |

12 |

31.6 |

11 |

28.9 |

18 |

32.1 |

| Industry 4.0 |

30 |

37.5 |

10 |

26.3 |

16 |

42.1 |

18 |

32.1 |

| cloud computing |

46 |

57.5 |

17 |

44.7 |

19 |

50.0 |

31 |

55.4 |

In

Table 1, the absolute values of the weights do not sum up in a table row. For example, the number of occurrences of the term

Edge Computing in all three databases was 346 and 346 ≠ 138 + 180 + 218. The reasons for this phenomenon are as follows:

-

The same publication could have been indexed in multiple databases;

-

The number of occurrence of a term in a database was less than 10 (in such cases, the term was not included in the results).

| fog computing |

| 37 |

| 46.3 |

| 17 |

| 44.7 |

| 18 |

| 100.0 |

| 180 |

| 100.0 |

| 218 |

| 100.0 |

| 47.4 |

| 23 |

| 41.1 |

| Industrial Internet of Things |

| 40 |

| 50.0 |

| 19 |

| 50.0 |

| 25 |

| 65.8 |

| 22 |

| 39.3 |

| Internet of Things |

80 |

100.0 |

38 |

100.0 |

38 |

100.0 |

56 |

100.0 |

In

Table 2, the sum of the absolute values in the column

link strength for all databases was 397, which was the total link strength for the term

Edge Computing. However, as in

Table 1, the absolute value of

link strength for a selected term does not sum up. The reasons are identical to those mentioned earlier.

4. Identified Challenges and Technologies Related to EC in Production Systems

An analysis of the full articles retrieved from the WoS database allowed for the identification of EC industrial applications and technologies related to the EC.

Apart from edge computing, the following technologies were indicated in the analyzed works: 5G, blockchain, AR, Mixed Reality, HoloLens, discrete-event simulation, big data, CPS, data analytics, data mining, cloud computing, fog computing, fog-edge computing, AI, ML, deep learning, reinforcement learning, deep reinforcement learning, inverse reinforcement learning, neural networks, deep neural network, convolutional neural networks, distributed ensemble learning, dynamic knowledge bases, emotion interaction, facial recognition, image mining, mobile cloud computing, mobile edge computing, mobile edge-cloud computing, particle swarm optimization, evolutionary algorithm, programmable computer network (SDN), and programmable gate arrays.