Electric microgrids based mainly on renewable energies have seen a big expansion in recent years due to the great advantages they present against fossil fuels. Nowadays different governments are becoming aware of the use of environmentally friendly energies, so progressive investment has been granted to the consumers in Spain. It should be noted that in applications using renewable energies, the use of energy storage systems (ESS) has Many microgrids have been implemented with the aim of improving the reliability of the system to avoid the intermittent nature of energy generation. Most of these ESS use lithium-ion batteries and sodium–sulfur batteries having high power and energy densities and high efficiency. Many industrial activities are gradually giving an opportunity to this type of MG system of renewable energy (RE) with EESnstalled in both connected and isolated circumstances, and this fact brings new challenges regarding the technical and economic points of view.

- microgrids

- distributed generation

- photovoltaic

- wind

- energy storage system

- renewable energy

1. Introduction

2. Definitions of Distributed Generation and Microgrid

Ackermann et al. [49] presented a discussion of the relevant aspect of distributed generation (DG) and provide a definition that understands the DG as an electric power source connected directly to the distribution network or on the customer side of the meter. Robert et al. [50] reported the benefits of introducing distributed energy resources (DERs) within an industrial site, detailing the factory design, its electrical system, the loads, and the micro-turbines used. Viral et al. [51] describe the concept as an electric source connected directly to the network or to the customer site and indicates that a hybrid of two or more optimization techniques would yield a more efficient and reliable optimal solution. Table 1 shows the different ratings of DG according to the authors:-

Advantages

- -

-

No distribution requirements.

- -

-

Reduced interruptions.

- -

-

Short lead times for procurement and installation.

- -

-

Available in modular units.

-

Disadvantages

- -

-

Higher energy costs.

- -

-

Less load diversity requires increased peak capacity.

- -

-

Requires redundancy for equivalent reliability.

- -

-

May require a utility connection for backup power.

- -

-

May require a utility connection for load following.

| Categories | Ratings |

|---|---|

| Micro-distributed generation | ~1 W < 5 kW |

| Small distributed generation | 5 kW < 5 MW |

| Medium distributed generation | 5 MW < 50 MW |

| Large distributed generation |

- -

-

Planning and sizing.

- -

-

Grid Synchronization.

- -

-

Frequency and voltage regulation.

- -

-

Stability and protection.

- -

-

Power quality.

Microgrid Topologies and Configurations

There are several studies that address the different topologies, sizes, and configurations of microgrids. An MG can operate both connected and disconnected from the main grid. MGs can be classified based on the characteristics of the distribution line (AC or DC). Several authors, such as Alsaidan et al. [56], discuss that there are two main types of microgrids in terms of grid connection: grid-tied and isolated microgrids. The first one is connected through the PCC meanwhile the second one is used to supply remote areas’ demand for electricity. Different MGs models are proliferating based on some parameters such as voltage, geography, consumer preferences, and economic viability. Nevertheless, based on the different components that a microgrid can have, three main different configurations exist according to Soshinskaya et al. [57]: radial, ring, or mesh.A radial grid configuration uses a mainline to which power consumers and generation are connected, so the current goes in one direction. Ring configuration is usually used while the current flows in more than one direction. Mesh grid configuration is used when some nodes are established, getting more benefits regarding the reachability of power for the consumers, but making some more other technical aspects such as protection, control, and operation more difficult.3. Reviews of Microgrids

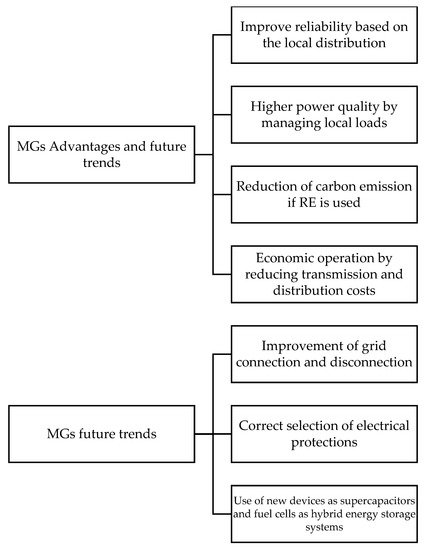

The paper presented in [58] by Feng et al. reviews through some U.S. projects, the trends in the technology development of MG systems and control methods, and establishes a reference for research from the lessons learned during the expansion of this kind of power source. Work presented in [59] by Planas et al. provides a detailed study of AC and DC MGs and the main features of the components of both. Moreover, technical, economic, and regulatory issues are discussed here. A review of issues concerning MGs is presented in [37] by Parhizi et al., getting a general view of the MG integration in power systems. A state of the art review is presented by Kumar et al. [28] with different control strategies and key integration issues of REs within MGs. Work described by Delfino [60] focuses extendedly on MGs that can be representative for DER in a district grouped on a geographical basis over America, Europe, Asia, Africa, and Oceania. Mehta et al. [61] discuss the research in MGs based on small-signal, transient, and voltage stability. Soshinskaya et al. [57] identify the main problems of MGs grouped in main categories: technical, regulatory, financial, and stakeholder-based in thirteen cases of study. Figure 1 represents some main advantages of the use of MGs, as well as future trends to be researched. Figure 1.Main advantages of the use of MGs and future trends (source: own elaboration).Sultana et al. [62] performed a review of the optimal allocation of DG regarding the power and energy loss minimization, voltage stability, and voltage profile improvement. However, the study does comment slightly on the allocation techniques in industrial environments using RE. An overview of aspects such as MG development, control and operation strategies and protection schemes are presented by Hassan et al. in [63]. Alam et al. [10] present a review of the state of the art for networked MGs. The main architecture, control, and EMS of networked MGs is pointed. The main potential benefits such as operational cost reduction and the improvement of the resiliency and the reliability of the system are discussed. Major challenges such as protection schemes, operation during emergency situations, and threats of cyber-attack are discussed and will need to be researched according to the authors. Olivares et al. in [35] presented a review of the state of the art related to the control in the MG. The authors define a three-level hierarchical structure, primary, secondary, and tertiary, and introduce main control systems for each one. Moreover, the ESS is identified as a key technology for the use of renewable sources, which introduces, at the same time, more challenges for the control systems regarding the effectiveness and reliability in MGs.Others such as Boqtob et al. [64] reviewed the state of the art regarding the EMS for MGs. The paper discusses the integration of EMS into different MGs based on load type, optimization constraints, combined heat power, and electrical vehicles and reviews some optimization algorithms that can improve the overall EMS. A review of MGs through layer structures was presented by Carpintero-Rentería et al. in [65]. The authors classified the manuscript based on six different layers: policies and standards, business, climate conditions, infrastructure, communications, and operation and control. The latter is considered a key factor in the success of the electrical system, and it has been extendedly studied by authors based on IEEE 2030.7 Standards. Colmenar et al. [66] presented and evaluated a novel charging strategy aiming to increase penetration of RES by electric vehicles. According to the authors, in the 2050 context, electric power will be the main technology used in road transport, so the use of electric vehicles will increase the demand for electricity, and it will be needed new strategies for charging and avoiding problems in the main power grid supply.Some other authors [28][35][38][61][67][28,35,38,61,67] addressed the different MGs control techniques in their research. Reliability and economical operation of the microgrid must be ensured. From a general point of view, MGs control techniques can be divided into two main groups: centralized and decentralized control techniques. Kumar et al. [28] separate the hierarchical control into three main groups: primary, secondary, and tertiary. The primary level controls power-sharing, local dynamics, voltage control, and current control. The secondary level controls power quality and grid synchronization. Finally, the tertiary level controls power flow and energy management.

Figure 1.Main advantages of the use of MGs and future trends (source: own elaboration).Sultana et al. [62] performed a review of the optimal allocation of DG regarding the power and energy loss minimization, voltage stability, and voltage profile improvement. However, the study does comment slightly on the allocation techniques in industrial environments using RE. An overview of aspects such as MG development, control and operation strategies and protection schemes are presented by Hassan et al. in [63]. Alam et al. [10] present a review of the state of the art for networked MGs. The main architecture, control, and EMS of networked MGs is pointed. The main potential benefits such as operational cost reduction and the improvement of the resiliency and the reliability of the system are discussed. Major challenges such as protection schemes, operation during emergency situations, and threats of cyber-attack are discussed and will need to be researched according to the authors. Olivares et al. in [35] presented a review of the state of the art related to the control in the MG. The authors define a three-level hierarchical structure, primary, secondary, and tertiary, and introduce main control systems for each one. Moreover, the ESS is identified as a key technology for the use of renewable sources, which introduces, at the same time, more challenges for the control systems regarding the effectiveness and reliability in MGs.Others such as Boqtob et al. [64] reviewed the state of the art regarding the EMS for MGs. The paper discusses the integration of EMS into different MGs based on load type, optimization constraints, combined heat power, and electrical vehicles and reviews some optimization algorithms that can improve the overall EMS. A review of MGs through layer structures was presented by Carpintero-Rentería et al. in [65]. The authors classified the manuscript based on six different layers: policies and standards, business, climate conditions, infrastructure, communications, and operation and control. The latter is considered a key factor in the success of the electrical system, and it has been extendedly studied by authors based on IEEE 2030.7 Standards. Colmenar et al. [66] presented and evaluated a novel charging strategy aiming to increase penetration of RES by electric vehicles. According to the authors, in the 2050 context, electric power will be the main technology used in road transport, so the use of electric vehicles will increase the demand for electricity, and it will be needed new strategies for charging and avoiding problems in the main power grid supply.Some other authors [28][35][38][61][67][28,35,38,61,67] addressed the different MGs control techniques in their research. Reliability and economical operation of the microgrid must be ensured. From a general point of view, MGs control techniques can be divided into two main groups: centralized and decentralized control techniques. Kumar et al. [28] separate the hierarchical control into three main groups: primary, secondary, and tertiary. The primary level controls power-sharing, local dynamics, voltage control, and current control. The secondary level controls power quality and grid synchronization. Finally, the tertiary level controls power flow and energy management.4. Microgrids in the Industrial Environment

An industrial MG is a set of DERs where a common industrial process is located (manufacturing, refinery, transformation process, and desalinization) in addition to RE generation processes such as RE plants (CSP, PV, and wind) and which needs electric power to complete the industrial process. The industrial plants use large step changes in loads and sensitive loads, which could result in outages due to lack of power supply if the DERs are not properly sized and there is no adequate protection system nor an optimization and reliability program that provides the system with the necessary robustness.A first approach to the benefits of introducing distributed resources within an industrial site can be found in the work presented by Robert et al. [50]. The work describes a fictional industry with multiple sensitive loads and analyses both steady and transient states, establishing the main micro-sources power setpoints (connected to the grid and in an islanded mode) and the load dispatch strategy. In [18], Derakhshandeh et al. propose a dynamic optimal power flow formulation for industrial MGs that includes security and factories constraints related to photovoltaic (PV) constraints based on DERs using combined heat power and PV generation systems with energy storage. The study concludes that introducing PV generation systems coupled with battery storage in industrial MGs has a positive effect on the scheduling solution and minimizes the overall cost of it. Moreover, the possibilities for the storage of electric energy to cover the power quality needs of industrial operations are also discussed by Kueck et al. [68].The work addressed by Kaushal et al. [26] presents a framework for an AC MG combination, PV energy and wind energy as main DERs, testing an automatic generation control method for controlling the frequency and the voltage changes while loads shedding occurs. In [15], Cetinkaya et al. analyzed three aspects of a power system of a real refinery (TUPRAS-RAF/RUP) through SINCALTM software. The paper examines the decoupling from the grid and the voltage and frequency recoveries and continues with a study of the load shedding stages depending on the number of generators simulated. In [29] Lainfiesta et al. compare two simulated industrial MGs with the aim of studying the CO2 emissions and total annual cost for both connected and non-connected facilities. The results show that the cost could rise while reducing the CO2 emissions.According to Zhe et al. [48], natural gas power generation and internal combustion engine technology are mostly used as DG main technologies, and wind energy and PV are widely used. Thangam et al. [69] reviewed and analyzed the diverse techniques associated with PV-based MGs (controllers, PV capacity, and inverter topologies) and focused on PV-based MG systems for better regulation of the maximum power point tracking (MPPT). In [23], Heo et al. described an MG design using PV and ESS in both grid-connected and islanded mode operation. AC and DC connections in the MG were simulated for an active load and ESS, considering the phase synchronization and the power conditioning system that regulates the overall system. Rosales-Asensio et al. [70] propose a configuration for a desalination plant aimed at reducing the cost of water. The configuration is based on wind energy and battery systems. Colmenar-Santos et al. [71] review the possible repowering of the Spanish wind energy systems concerning their economical and profitable aspects. It shows a comparison study between the opportunities of installing new wind farms against the repowering of old ones maintaining the same energy conditions. Results obtained show the feasibility of repowering wind farms from a profitability point of view in Spain.Choudhary et al. presented a review of the main solar PV trends and growth opportunities in [72]. The authors review goes from the background of solar PV, through some methods for reaching environmental sustainability, to some related future sustainable solutions. In [13], Bracco et al. presented a performance analysis of a PV plant connected to a low voltage MG. The authors obtained real data key parameters (net electricity production, solar radiation on the PV modules, final PV system yield, reference yield, performance ratio, and overall PV system global efficiency) from the plant for one year and later compared it with the performance obtained from a new one. Javid et al. [73] proposed a methodology for optimal sizing of a hybrid system for an industrial load located in Pakistan. They studied five simulated cases using HOMER software to achieve the best result regarding reliability and sustainability, analyzing whether such a hybrid option is a cost-effective solution or not. Gust et al. [74] established both proactive and reactive strategies under real-world conditions for an MG located in California. Using DER-CAM software, the authors conclude that proactive strategies perform better regarding the total costs, while reactive strategies perform better regarding one cost component. Blake et al. [75] introduced a model of an industrial MG and studied the costs and emissions associated with the use of different DERs (wind, combined heat power, and ESS) using, like many others, MATLAB software. The results presented confirm the reduction of costs and carbon emissions while using RE sources in the industrial environment. In [76] Horhoianu et al. presented an MG simulation of the oil industry using HOMER software. The paper shows an MG formed by a RE system (PV and wind) with an ESS and a cogeneration energy system. Results show that several factors and parameters need to be considered due to the number of design options available. In the work presented by Naderi et al. [77], industrial MG research is presented. The authors made a five scenarios simulation using HOMER software. CNC machines were considered as sensitive loads, and different components were used to set up the distribution resources generation such as fuel cell, electrolyzer, PV, wind turbines, a battery storage system (BESS), and a diesel power generator.In Spain, some MGs facilities have been developed for several years since the government eased the administrative processing and fees related to implementing this kind of project. As a real example, it has been developing in La Graciosa Island (Canary Islands, Spain) an MG with BEES and ultracapacitors aimed at optimizing the distribution grid based on the implication of different stakeholders such as distribution companies, marketers, and final consumers, as well as to reduce investment and operational costs. In relation to the aforementioned, Sanz et al. in [78] analyzed the European policies and incentives and described the constraints to which Spain was subject. Colmenar et al. [79] discuss the implementation of installing a theoretical multi-effect distillation plant of 9000 m3. It opens a new path for distillation plants regarding the use of MGs based on RE to feed the power equipment that can be used according to the configuration (use of EMS, Double Effect Absorption, Heat Pump technique, etc.) Polleux et al. [80] provide a review of the scientific literature from fossil engine thermodynamics to control system theory applied to industrial systems as new challenges of solar PV integration in industrial installations. Table 2 shows the category of industrial MGs, as well as the advantages, disadvantages, and applied techniques. Applied techniques can be applied for every kind of industrial MGs.Table 2.Industrial microgrids types, advantages, disadvantages, and applied techniques (source: own elaboration).Industrial MG Advantages Disadvantages Applied Techniques Oil and Gas Reduction of CO2 emissions

Possibility of use of Hybrid Energy Storage SystemsUse of sensitive loads in instrumentation

Use of big loads

High costsImprovement of reliability

Voltage and frequency control

Reduction of costs

HVDC protections techniques

Control optimization

Control of HESS

MGs size and location methodsMining MG can be fully islanded

Possibility of use of Hybrid Energy Storage Systems (HESS)Use of big sensitive loads

Location of MGChemical Reduction of CO2 emissions

Possibility of use of Hybrid Energy Storage SystemsUse of sensitive loads in instrumentation

Use of big loads

High costsManufacturing MG can be fully islanded

Possibility of use of Hybrid Energy Storage Systems (HESS)Use of sensitive loads

Discontinuity in power consumption if grid-connected

High costsEnergy Production No use of big loads

Easy connection and disconnection of the main gridUse of DC voltage for distribution

Use of sensitive loads