High-speed motorized spindles tend to develop in the direction of high precision, high speed, low energy consumption, high efficiency, and high reliability.

- high-speed motorized spindle

- precision bearing

- dynamic balancing

- thermal error measurement and compensation

- development trend

1. Introduction

As modern machine tools are developing towards high speed and high precision, the technical requirements for the spindles of machine tools are increasing. The motorized spindle is one of the core functional components of high-speed machine tools; the motor of a motorized spindle is placed inside the spindle unit of the machine tool to drive the spindle. Therefore, the machine drive structure is simplified, and “zero drive” is achieved [1][2]. Because the motorized spindle has the advantages of its compact structure, is lightweight, has small inertia and good dynamic performance, the dynamic balance of the machine tool is improved and the vibration and noise are avoided. The structure of traditional rolling bearings makes it difficult to meet the requirements of high speed and high precision for high-speed machine tools, so the research of bearings is one of the key research objects in the field of high-speed machine tools [3]. As the key support technology for high-speed motorized spindles, bearings must meet the requirements of high-speed operation, and have high rotary accuracy and low-temperature rise, in addition to long service life, especially with regard to maintaining the accuracy. The current high-speed motorized spindle applied bearings are mainly angular contact ball bearings, liquid floating bearings, air bearings, and magnetic bearings. But the speed and precision of the spindle-bearing improvement is based on the premise of high-precision dynamic balance. For motorized spindles, the unbalance phenomenon is inevitable due to the influence of factors such as manufacturing, installation error, and material unevenness.

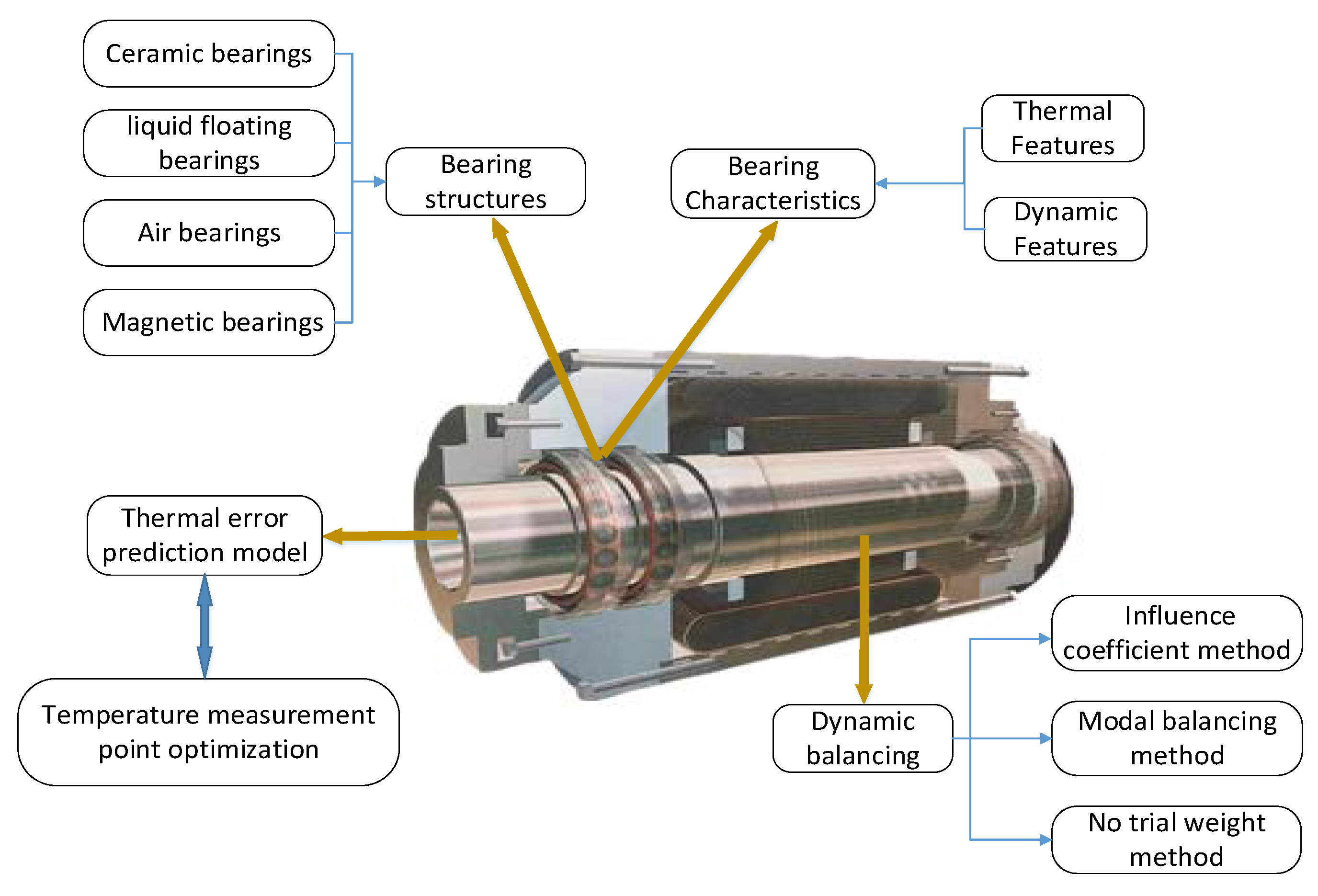

Figure 1.

Analysis diagram of high-speed electric spindle technology.

2. Developments in Precision Bearing Technology

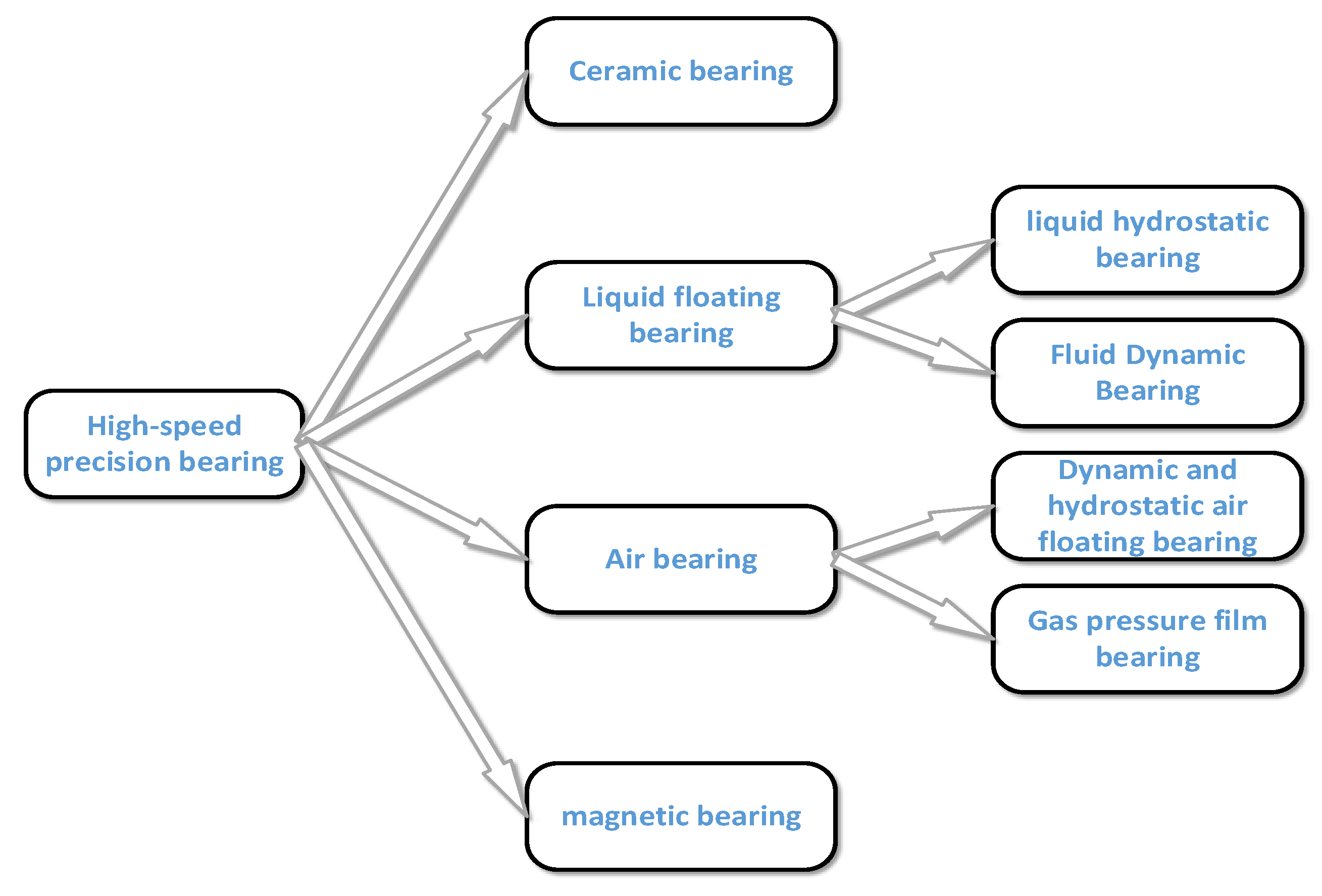

The high-speed precision bearing is one of the core supporting components of a high-speed motorized spindle. Bearings are often in high-speed or ultra-high-speed operation, so the bearings must have a series of characteristics such as good high-speed performance, high dynamic load-carrying capacity, superior lubrication performance, and low heat generation. At present, high-speed precision bearings have become the key research and development technology in the world. There are four main types of bearings for high-speed spindles, including angular contact ceramic ball bearings, liquid floating bearings, air bearings, and magnetic bearings. The specific classification is shown in Figure 2 [4]. In addition, after extensive literature research, surveys are presented in this section and summarized in Table 1.

Figure 2.

High-speed precision bearings classification.

Table 1.

Research work on bearing structures.

To achieve an accurate dynamic balancing of the post-installation motor rotor, the factors of force and self-excited vibration ability that cause dynamic balancing of the problems are considered. The designed components of a spindle are considered in terms of the effects of two different vibrations to ensure good running accuracy at high speed. The dynamic balancing method is the necessary condition and method for online dynamic balancing of high-speed motorized spindles. The primary method of dynamic balancing for rigid spindles is the influence coefficient method. The main methods of dynamic balancing for flexible spindles are the modal balancing method and no trial weight balancing method. Recent research works have been summarized in| Reference | Brief Summary | Method | Objective | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Zhang et al. | [16] | |||||||||

| 36] | Influence coefficient method for maximum total phase difference |

Influence coefficient method | Provide the theoretical basis for the | Partial least squares regression method two-sided impact factor method |

||||||

| Multiple linear regression method | Average | Chen et al. | [17] | Online dynamic balancing method for low pressure rotors with least squares influence factor |

||||||

| Miao et al. | [37 | The vibration amplitude of the rotor is reduced |

||||||||

| ] | Unbiased estimation splitting method | Multiple linear regression method | Good | Wang et al. | [18] | |||||

| Zhou et al. | [38] | Single plane influence coefficient method | The problems of misalignment and long equilibrium time during mass movement are solved | |||||||

| Classical multiple linear regression method | Multiple linear regression method | Fair | Zhang et al. | [19] | Single plane influence coefficient method | |||||

| Jiang et al. | [39] | The choice of counterweight position is proposed |

Standard grey system model | Multiple linear regression method | Average | Zhao et al. | [20] | Dual-plane influence coefficient method | Verified that the dual-plane influence coefficient method is more effective in optimizing vibration measurement points |

|

| Zhang et al. | [40] | Serial grey neural network and parallel grey neural network | Grey theory | Good | Zhang et al. | [21] | Dual-plane influence coefficient method | The effect law of counterweight size with counterweight plane shift was found | ||

| Wang et al. | [41] | Comparison of grey prediction model and BP neural network prediction model | - | - | Zhu et al. | [22] | Single and dual-plane influence coefficient method | The multifaceted influence coefficient method applied to flexible rotors is derived | ||

| Particle swarm optimization optimized BP model | Neural network | Good | Khulief et al. | [23] | Combined influence coefficient method and modal equilibrium method | |||||

| Xie et al. | [43] | Low-speed balancing problem of | Thinking evolutionary algorithm optimized BP model high-speed rotors is solved |

|||||||

| Neural network | Good | Qu et al. | [24] | |||||||

| Wu et al. | Holographic spectrum theory | [ | Modal equilibrium method | 44] | A new technique of holographic spectrum is introduced on the basis of the modal | Simulated annealing algorithm coupled with particle swarm algorithm to optimize BP model balance method |

||||

| Neural network | Good | Liu et al. | [25] | |||||||

| Sun et al. | [ | On-site holographic dynamic balancing method | 45] | Multiple sensor information is fused with flexible rotor balancing technology to improve rotor balancing accuracy |

||||||

| Bat algorithm optimized BP model | Neural network | Excellent | Chen et al. | [26] | Modal dynamic balance method for | |||||

| Lv et al. | [46] | flexible rotors |

The reliability of the flexible rotor modal dynamic balancing method was verified | |||||||

| Generalized radial basis function neural | Neural network | Good | Liu et al. | [27] | Dual-plane spindle balancing method based on the modalities of the spindle | The validity of dual-plane dynamic balancing method is proved |

||||

| Zhong et al. | [28] | Modal equilibrium theory | Avoid the blindness of choosing the frontal and balance speed | |||||||

| Sun et al. | [29] | The dynamic balancing method without trial weight based on multi-factor coupled finite element dynamics model |

No trial weight method | The unbalanced vibration of each stage of the spindle is suppressed | ||||||

| Bin et al. | [30] | The least squares method solves the system of equilibrium vector equations to obtain the equilibrium counterweight |

Complete dynamic balancing of the flexible spindle without trial weight is achieved | |||||||

| Jia et al. | [31] | The dynamic balancing method without trial weight for high-speed flexible rotors | Zhang et al. | [32] | ||||||

| Ma et al. | [42] | The problem of low balancing efficiency due to multiple test weights required for traditional dynamic balancing is solved |

Based on a multivariant finite element analysis model, the dynamic balancing method without trial weight is performed |

The model can accurately describe the dynamic characteristics of the spindle |

||||||

| Xu et al. | [33] | Dynamic balancing method without trial weight | The method is proven to reduce the unbalance of rotating shafts | |||||||

| Zhang et al. | [34] | Genetic algorithm and particle swarm optimization are combined to identify multi-point unbalance of rotor | The reliability of neural network algorithms for online prediction of rotor's unevenness is proposed | |||||||

| Zhang et al. | [35] | The dynamic balancing method without trial for modalities | Suppression of vibration caused by rotor unbalance |

| 参考 | 小结 | 轴承类型 | 目的 | |

|---|---|---|---|---|

| Wu et al. | [5] | Grease lubricated ceramic bearing | Ceramic bearing | Avoid the noise caused by fracture or slipping of the inner ring of the bearing |

| Liu et al. | [6] | New Dynamic pressure gas radial ceramic bearing | Ceramic bearing | High stability of high-speed rotating spindle |

| Jiang et al. | [7] | Liquid Hydrostatic bearing of the slotted water cavity type with varying opposing areas | Liquid floating bearing | Provide large hydrostatic load capacity and overcome the defect of low rotation accuracy of spindle at high speed |

4. Research Progress of Thermal Error Measurement and Compensation Technology

The thermal error prediction model of the high-speed motorized spindle is the core of the thermal error compensation system. Using temperature data to predict the change of thermal displacement, the establishment of the thermal error compensation system. In the study of thermal error modeling of high-speed motorized spindles, researchers have widely used the multiple regression method, gray theory and neural network method. In this section, the research results related to thermal error modeling are presented and summarized in Table 4.

| 参考 | Brief Summary | Method | Effect of Prediction Accuracy |

|---|---|---|---|

| Xue et al. | [ |

| Zhang et al. | ||||

| [ | ||||

| 8 | ||||

| ] | Hydrostatic floating bearing of through-hole type | Liquid floating bearing | Simple structure,easy to achieve the purpose of spindle at high speed | |

| Ko et al. | [9] | Hydrostatic bearing monitoring system and monitoring method | Liquid floating bearing | Real-time monitoring of hydrostatic bearing performance and fault warning |

| Yu et al. | [10] | Ultra-precise air bearing with active compound throttling type | Air bearing | Suppress micro-amplitude vibration of air-bearing, improve dynamic stiffness |

| Yin et al. | [11] | Air bearing with replaceable throttle plug | Air bearing | Effectively avoid the phenomenon of "air hammer" in bearing |

| Keun et al. | [12] | Improved structure of the new air bearing | Air bearing | Avoid thermal deformation of bearing or spindle caused by dynamic instability of the rotor and high speeds |

| Chen et al. | [13] | Hybrid magnetic bearing structure | Magnetic bearing | Effective simplification of magnetic floating bearing structure,saving cost |

| Zhang et al. | [14] | Protective structures for magnetic bearings and magnetic assemblies |

Magnetic bearing | Solve the problem of spindle and bearing wear due to easy failure of the magnetic bearing protection structure |

| Chen et al. | [15] | Coil type axial permanent magnet electric magnetic bearing |

Magnetic bearing | Realize axial bidirectional self- stabilization, less resistance and lower energy consumption |

3. Research on Dynamic Balance Technology

5. Development Trend of High-Speed Motorized Spindle Technology

With the rapid development of high-speed cutting, CNC technology and the needs of practical applications, the performance of the high-speed motorized spindle of CNC machine tools has put forward higher and higher requirements. Based on the analysis of the key technologies of the high-speed motorized spindle, the research direction of high-speed motorized spindle unit technology is summarized. The main aspects are as follows.

- (1) The The development of high precision, high reliability and long life of CNC machine tools is the goal. At present, the precision and reliability of the use of CNC machine tools need to meet higher requirements. As one of the core functional components of CNC machine tools, the high-speed motorized spindle requires higher precision and reliability.

- development of high precision, high reliability and long life of CNC machine tools is the goal. At present, the precision and reliability of the use of CNC machine tools need to meet higher requirements. As one of the core functional components of CNC machine tools, the high-speed motorized spindle requires higher precision and reliability.

- (2) With the improvement of the bearing technology as the goal, the problems of high cost, large structures and difficult to control of magnetic bearings need to be solved. Research and development of high speed and high power shaftless high-speed motorized spindles with magnetic bearings as support must be undertaken.

(3) To improve the running accuracy of the motorized spindle, the research on the generalization of dynamic balancing technology, using a dynamic balancing method that capable to balance the rigid spindle and flexible spindle at the same time, which would help to reduce the impact of vibration on the high-speed motorized spindle, must be accelerated.

(4) To reduce the influence of heat generation and thermal error of the spindle, and improve the accuracy of the spindle, research on the application of computer simulation technology in the design of high-speed motorized spindles must be strengthened, and the development of highly reliable modeling methods to realize the compensation of errors must be achieved.

-

References

- Zhang, L.X.; Li, C.Q.; Li, J.P.; Zhang, K.; Wu, Y.H. The temperature prediction mode of high speed and high precision motorized spindle. J. Mech. Eng. 2017, 53, 129–136.

- Jiang, S.Y.; Zhang, S.W. Progress in the key technologies of high speed motorized spindle supported by water-lubricated bearings. Mach. Des. Manuf. Eng. 2016, 45, 11–17.

- Xiong, W.L.; Sun, W.B.; Liu, K.; Xu, M.H.; Pei, T. Active magnetic bearing technology development in high-speed motorized spindles. J. Mech. Eng. 2021, 57, 1–17.

- Peng, X.L.; Li, Z. Review of spindle motor technology. Electron. Meas. Technol. 2020, 43, 1–7.

- Wu, Y.H.; Xia, Z.X.; Li, S.H.; Chen, S.Z.; Sun, J.; Wang, H.; Tain, J.X.; Wang, Y.H. A Kind of Grease Lubricated Ceramic Bearing with a Piezoelectric Ceramic Inner Ring. China Patent 2019. under review.

- Liu, X.L.; Xia, Z.X. A Kind of Dynamic Pressure Gas Radial Ceramic Bearing. China Patent 2018. in press.

- Jiang, S.Y.; Xu, W.Z. A Kind of Hydrostatic Water Bearing with Slotted Water Chamber Against Unequal Area Water Chamber. China Patent, 2019, under review.

- Zhang, F.Q. A Kind of Hydrostatic Liquid Floating Bearing. China Patent 2018. in press.

- KO, P.H.; Chan, C.M.; Chan, S.T.; Xu, W.Z. Hydrostatic Bearing Monitoring System and Method. U.S. Patent 2017. under review.

- Yu, P.L.; Kong, J.Y.; Yang, J.T. An Active Air Float Bearing With Variable Air Film Shape. China Patent 2020. under review.

- Yin, Z.Q.; Zhuang, Z.W. A Kind of Air Floating Bearing. China Patent 2021. in press.

- Ryu, K.H. Air Bearing and Rotor System. U.S. Patent 2020. in press.

- Chen, H.X.; Mao, K.; Han, S.C.; Wu, Z.X.; Zhou, D.S.; Lv, M.D.; Zhang, Z.H.; Gong, J.; Hu, D.Y.; Li, P.; et al. A Hybrid Magnetic Levitation Bearing System. China Patent 2020. in press.

- Zhang, F.H.; Hu, Y.S.; Zhang, X.B.; Xu, W.Z. Protective Structure for Magnetic Bearing and Magnetic Bearing Assembly. U.S. Patent 2020. in press.

- Chen, Y.; Deng, Y.C.; Tang, W.; Li, L.W.; Miu, X.Y.; Li, Q.; Wang, M. A Coil Type Axial Permanent Magnet Electric Magnetic Floating Bearing. China Patent 2017. in press.

- Zhang, S.H.; Zhang, Z.M. A method to select correcting faces of a double-face dynamic balancing rotor. Adv. Mech. Eng. 2016, 8, 1687814016682892.

- Chen, X.; Liao, M.F.; Zhang, X.M.; Wang, S.J. Field balancing technology for low pressure rotors of high bypass ratio turbofan engines. J. Nanjing Univ. Aeronaut. Astronaut. 2017, 32, 808–819.

- Wang, Z.; Tu, W.; Li, J.; Liu, M.H.; Zhu, F.L. High Speed Spindle Online Dynamic Balancing Control Strategy and Experimental Research. Mach. Tool Hydraul. 2019, 47, 61–66.

- Zhang, K.; Zhang, C.Y.; Zhang, L.X.; Wu, Y.H. Performance Analysis and experiment of electromagnetic ring balancer during operation. J. Vib. Meas. Diagn. 2018, 38, 34–38.

- Zhao, W.Z.; Chen, J.; Zhou, R.M.; Gu, W.F.; Hua, M. Application of double-side dynamic balance method in a two-stage adjustable vane axial flow fan. Power Equip. 2018, 32, 434–436.

- Zhang, Z.C.; He, L.D.; Wan, F.T.; Li, Z.W.; Chen, Z. Law of weights transfer based on double-sided dynamic balance. J. Mech. Electr. Eng. 2019, 36, 712–716.

- Zhu, Y.T.; Yao, Y.G.; Huang, K.; Li, D.Y.; Zhang, H.T.; Zhai, D.Y. The study of influence coefficient method and its application in the dynamic balancing for high-speed spindle. Mech. Electr. Eng. Technol. 2021, 50, 228–235.

- Khulief, Y.A.; Oke, W.; Mohiuddin, M.A. Modally Tuned Influence Coefficients for Low-Speed Balancing of Flexible Rotors. J. Vib. Acoustics. 2014, 136, 024501: 1–024501: 5.

- Qu, L.S.; Zhang, X.N.; Wu, S.T.; Qiu, H.; Xu, B.G. Flexible rotor holographic field dynamic balancing technology and application. J. Manuf. Sci. Eng. 2005, 12, 75.

- Liu, S.; Qu, L.S. A study of methods for an on-site shafting dynamic balance based on a holographic spectrum technology. J. Eng. Therm. Energy Power 2009, 24, 24–30.

- Chen, X.; Liao, M.F.; Liu, Z.C.; Li, Y. Model balancing method for flexible rotors with elastic supports. J. Nanjing Univ. Aeronaut. Astronaut. 2016, 48, 402–409.

- Liu, C.; Liu, G. Field dynamic balancing for rigid rotor-AMB System in a magnetically suspended flywheel. IEEE/ASME Trans. Mechatron. 2016, 21, 1140–1150.

- Luo, Z.; Wei, Y.H.; Hou, X.J.; Wang, F. Dynamical Balance and Verification of a Rotor System Based on Sensitivity Analysis. J. Vib. Test. Syst. Dyn. 2018, 3, 271–280.

- Sun, H. Analysis of Imbalance Vibration Behavior of High Speed Spindle and Research of its Suppression Method. Master’s Thesis, Xidian University, Xi’an, China, 2015.

- Bin, G.F.; He, L.D.; Gao, J.J.; Li, L.B. High-speed dynamic balancing method for low pressure rotor of a large steam turbine based on modal shape analysis. J. Vib. Shock 2013, 32, 87–92.

- Jia, S.X.; Zheng, L.X.; Deng, W.Q.; Mei, Q. Development of modal balancing system without trail weights for high speed flexible rotors. J. Vib. Shock 2018, 38, 1108–1113.

- Zhang, Y.; Sun, H.; Hu, Z.B. Behavior analysis and suppression strategy for unbalanced vibration in high-speed spindle. J. Xi’an Jiaotong Univ. 2019, 53, 24–29.

- Xu, Y.; Yi, J.; Deng, H.; Zhou, F.; Han, Z.J.; Zeng, M.H. Dynamic balance method without trial weights for a folding shaft based on the reverse structural designing. J. Vib. Shock 2019, 38, 263–270.

- Zhang, R.X.; Wen, G.R.; Zhang, Z.F.; Xu, B. Multi-unbalances identification of rotor system integrated with GA-PSO method. J. Vib. Meas. Diagn. 2019, 39, 801–809.

- Zhang, Y.; Li, M.; Yao, H.Z.; Gou, Y.J.; Wang, X.Y. A modal-based balancing method for a high-speed rotor without trial weights. Mech. Sci. 2021, 12, 85–96.