Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 3 by Lindsay Dong and Version 2 by Catherine Yang.

The use of stainless steel components, particularly in new constructions, has experienced a huge increase in recent times. Stainless steel is now widely used for both non-structural applications and as ribbed reinforcement bars for concrete, members (beams, columns, ties, etc.) in trusses, bridges and buildings. Similar to structural carbon steel, stainless steel elements can be hot rolled and fabricated or cold rolled formed.

- stainless steel alloys

- reinforcement

- repair

1. Stainless Typologies for Structural Applications

The major chemical constituent of Stainless steels is Fe (Iron) alloys with some Cr (Chromium) addition. Chromium acts as the main alloying element (typically between 10–20%) and results in high corrosion resistance due to surface oxidation and protection. Stainless steel corrosion resistance is about 200 times that of normal carbon steel.

Other chemical elements, such as Ni (Nichel), Mo (Molybdenum) and Ti (Titanium) are usually added for special purposes. These added chemical elements have significant effects on the microstructure evolution, mechanical behavior and the corrosion resistance of the resulting stainless steel. Corrosion resistance of stainless steel can be further improved by reducing C (Carbon) content and increasing the content of other elements of the alloy. Generally, stainless steels can be can be categorized according to their chemical compositions as shown in Table 1.

| Stainless Steel Grade | 1.4016 | 1.4301 | 1.4462 |

|---|---|---|---|

| Type | Ferritic | Austenitic | Duplex |

| Molybdenum (%) | - | - | 2.5 |

| Nickel (%) | - | 8 | 4.5 |

| Chromium (%) | 17 | 17 | 21 |

Austenitic steel is the most common type of stainless steel and is mainly used for food processing equipment, utensils for kitchens and medical equipment. This easily weldable, non-magnetic and not heat-treatable material [3][4][5] can be divided into three families: Cr-Ni (300 series), Mn-Cr-Ni-N (200 series) and specialty alloys. This family of material is non-magnetic and not heat-treatable. Ferritic steels which usually contain low Ni content, 12–17% Cr and a very low amount of C (<0.1%) could also contain other alloying elements (e.g., Mo, Al, Ti). Although Ferritic steels are known for their good ductility and formability, their behavior at high temperatures is relatively poor when compared to austenitic materials and they are also not heat treatable. For some stainless steel grades (409 and 405), ferritic stainless steels are usually cheaper than many other stainless steels [6][7][8][9].

Another type of stainless steels are the martensitic alloys characterized by 11–17% Cr, < 0.4% Ni and relatively high C content (1.2%). Martensitic stainless steels are hardenable and their formability and weldability characteristics are affected by their carbon content. This alloy often requires preheating and post-welding heat treatment to achieve desired properties. They have wide applications in knives, cutting tools, dental and surgical equipment.

Finally, duplex alloys are mainly adopted in chemical plants and piping applications and are characterized by 22–25% Cr and 5% Ni and some Mo and N addition. They have high yield strength and stress corrosion resistance in chloride when compared with austenitic stainless steels. The last type of stainless steel is from precipitation hardening. This type of stainless steel contains Cr-Ni stainless and Al, Cu and Ti as alloying elements. These alloying elements allow the material to harden in a solution and show both austenitic or martensitic microstructure in an aged condition.

2. Repair Methods

Damaged timber elements are usually repaired by local interventions [10][11]. Degradation near masonry supports or near the timber-to-timber joints are typical reasons for repair. The use of metal fasteners or profiles is not new, it is also found in repair interventions dated back to the 19th century. Steel and iron have frequently been used in the repair/reinforcement of timber members which may have decayed due to rot and insect infestation or fractured/deformed because of over-loading. Because of the risk of condensation on metals, iron and steel reinforcement should always be visible and open to inspection [12]. This problem could be overcome when stainless steel is used. Although the use of stainless steel often follows the traditional steel repair methods, new technical solutions and methods have been proposed in this area. Table 2 shows the repair methods described in this section, with some information about usability and appropriateness for different repair interventions. It should be remarked that the application of stainless steel elements is often combined with re-construction/repair of pre-existing timber-to-timber lock-joints. The correct use of lock-joints is extremely important in timber connections, following the multi-century-old carpentry tradition of joining timber elements.

Table 2. Repair methods using stainless steel elements.

| Method | Appropriate for Historic Structures | Appropriate for Repair of Beam Ends | Appropriate for Repair/Reinforcement of Truss Joints |

|---|---|---|---|

| Fasteners | Yes | No | Yes |

| Press-bended sheets | Yes | Yes | No |

| H-, T-, L-, I-shaped Profiles | Yes | Yes | Yes |

| Rods and prostheses | Yes/No 1 | Yes | Yes |

| Nail-plates | No | No | Yes |

1 This often depends on the used approach of a local conservation body.

2.1. Stainless Fasteners

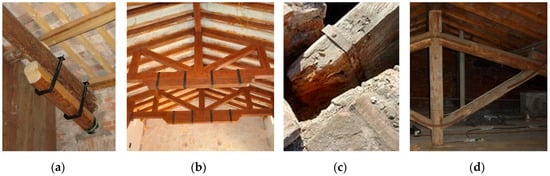

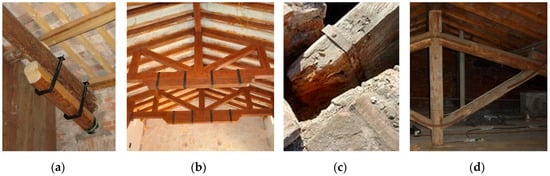

The use of metal fasteners to reinforce local timber beams and trusses is a traditional technique (Figure 1). This was very common in the 19th and 20th centuries and it is still applied today [13][14]. The method simply consists in the application of one or more metal fasteners, made of metal strips, to prevent the slippage between two timber elements and increase the resisting section in critical areas. It is typically applied at the beam-to-template connection points and in the timber-to-timber joints of the traditional king post roof trusses (Figure 2).

Figure 1. Salone dei Cinquecento, Palazzo Vecchio, Florence, Italy: Detail of timber roof structure and iron fasteners (the iron reinforcement is part of the original structure from 17th century).

Figure 2. The traditional use of metal fasteners in critical sections of the timber beam floor and the king post roof truss: (a) timber template-beam (beam-floor); (b) joint king post-tie beam (truss); (c) joint strut-king post and principal rafter-king post (truss); (d) joint principal rafter-tie beam (truss).

A major cause of failures in metal fasteners in timber structures is electrochemical corrosion (rust), caused by the galvanic action. Considering that timber seasoning is not an irreversible process, timber members can absorb moisture. It is well known that air circulation is essential for adequate maintenance of timber structures, but areas under the metal strips typically have higher humidity than the rest of the timber structure and this has deleterious consequences for both the timber and metal materials. Furthermore, the direct contact of damp timber and the fasteners facilitate biotic attacks in the timber and corrosion in the metal. The use of stainless steel strips can partially solve the problem of corrosion. Stainless steel should be carefully selected: high-resilience, high-modulus and high PRE values are sought after characteristics for these applications. Stainless fasteners for repair interventions of historic structures are typically applied on-site by experienced mason. To prevent stainless steel cracking during on-site applications due to high bend angles (for example during wrapping of timber beams with rectangular cross sections), the stainless steel should have high ductile behavior and high resilience strength.

2.2. Re-construction of Beam Ends

2.2.1. Use of Stainless Steel Sections

This one-way beam-floor is common in the UK, where it is still in use for new construction. To repair the joist ends from rotting at the point where the joists rest in brick or stone walls, pairs of stainless or galvanized steel plates, pre-drilled, are typically used with standard coach screws, which are secured at the end of degraded timber joists (Figure 3). The plates rest in or on the wall and allow for the rotted end to be cut off. To give additional stiffness, for use in rows of continuous end repairs, with no sound joist ends between. A bolted connection through the plates into the parent joist can be adopted [15][16][17].

Figure 3. Re-construction of joist ends with stainless steel L-shaped profiles (press-bended stainless steel sheets) [16].

To reinforce the decayed timber beam ends, stainless steel flitch plates can be inserted along the beam length (Figure 4). This method involves cutting a slot into the timber and making the beam a composite of stainless steel and timber. The plate may also take a T-shape either the right way up (top of the beam) or upside down (underside of the beam). The steel flitch plate is best used at the underside of the beam and fixed upside down, so the wide part of the T is positioned to carry the highest tensile stresses. However, the functionality of the composite beam depends on the type of connection between steel and timber members. When reinforcement is carried out at the ends of simply-supported beams, connection should be able to transfer only the shearing forces (zero bending moment at the supports). In this situation, bolts in the stainless steel web are sufficient. From a practical viewpoint, these are difficult repairs to carry out on site, requiring overhead cutting of the slot by multiple drillings or chain-morticer/chain-saw cutting.

2.2.2. Use of Stainless Steel Rods

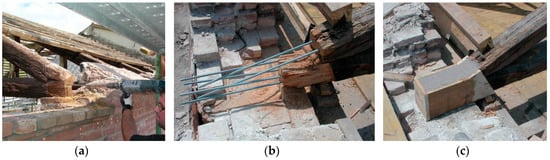

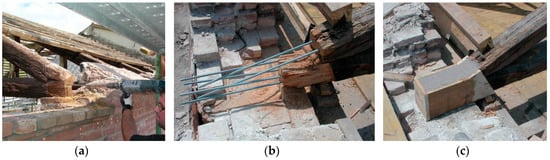

For repairing old solid timber beams, lintels or rafters, it is also common to use timber prostheses to connect with the damaged beam using smooth or ribbed stainless steel rods, connectors or bars. Holes are drilled, or a groove cut, in the undamaged pre-existing timber to accommodate the rod reinforcement. The prosthesis is usually made of a new, laminated structural timber (Figure 5), made in kiln dried wood or epoxy paste (using construction shutters). The rods are typically made of fiberglass, carbon FRP or stainless steel (Figure 6 and Figure 7). Pouring or injection resins are used to fix the rods into the prostheses and the pre-existing beam [18][19][20][21].

Figure 5. Re-construction of the beam ends: (a) stainless steel reinforced wooden prosthesis; (b) detail of the stainless steel reinforced epoxy prosthesis [21].

Figure 6. Re-construction of joist or beam ends with stainless steel rods [16].

Figure 7. Re-construction of tie or rafter ends with stainless steel rods [18]: (a) drilling the holes for rod installation; (b) insertion of the stainless steel rods; (c) resin casting.

2.2.3. Use of Nail Plates

Nail plates, made of stainless steel, can be used in various applications, mainly for new low-value timber constructions. Nail plates are typically used for repairing or joining timber elements or to increase the flexural stiffness of timber beams and joists. However, these plates are often used to connect wood elements in the same plain. Low carpentry skills are needed in order to construct a timber structure using nail-plated connections.

Although the use of nail plates can be considered a versatile and cost-effective method to improve the connection between wood elements (Figure 8), their use for historic or listed timber structures is rare and not often authorized by conservation bodies. This is mainly due to the fact that a nail-plate connecting system can cause damage to the timber structure, and facilitate biotic attack by saprophytic insects and fungi. For historic structures, it is always preferable to repair/restore the pre-existing historic connecting devices (post-and-beam, tie-and-rafter and other construction techniques). Furthermore, nail-plate connections are rarely able to transfer to maximum allowable internal force from one element to another [22][23].

3. Reinforcement Methods

Historic timber structures have to transfer external loads to the walls, dealing with the corresponding internal axial load, shearing force and bending moment. The stresses and deformations in the timber structures should not exceed the strength and deformation limits given by modern standards and building codes. Furthermore, the resisting sections of the structure and the mechanical properties of the timber has to be reduced due to mechanical and biological damage. In many situations, except for dismantling and reconstruction of the timber structure, the only option available for structural engineers is to apply a reinforcement. In this section, some traditional and innovative retrofitting solutions will be described and discussed. It should be recommended here that the on-site application of a bending reinforcement should always be preceded by a total or partial removal of the external loads, with the aim of facilitating the stress transfer to the reinforcement during future loading. When this is difficult to carry out, bending moment could be reduced by applying opposite external forces, using hydraulic loading cylinders.

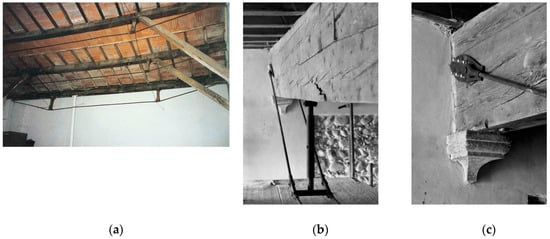

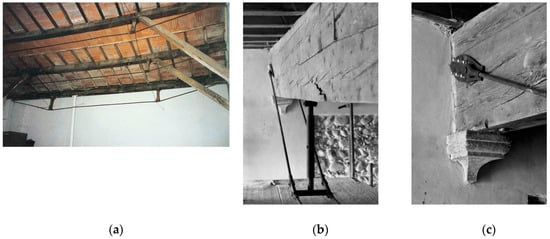

3.1. Reinforcement by Converting a Beam Element into a Trussed Girder

The conversion of a beam-floor into a trussed system is a traditional method, introduced in the 19th century to reinforce deficient timber-beam floors [26][27][28][29][30][31]. Figure 9a shows a retrofitting intervention carried out in the 1920s on a timber-beam floor in Italy. A more recent application is shown in Figure 9b,c. Nowadays, it is possible to use stainless steel bars, thus highly reducing corrosion problems. A critical aspect of this intervention is the creep deformation of both the timber and the stainless steel materials. Mechanical devices (turnbuckles) are often needed for the stainless ties and low-creep, high-modulus stainless steel alloys should be preferred.

Figure 9. Examples of bending reinforcement by conversion of a timber-beam floor into a trussed girder by adding steel struts and tension rods underneath ([26] for (b) and (c)).

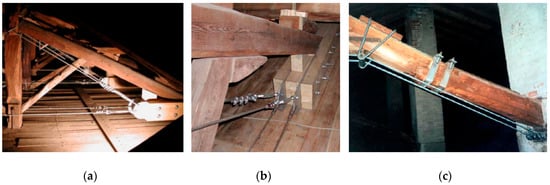

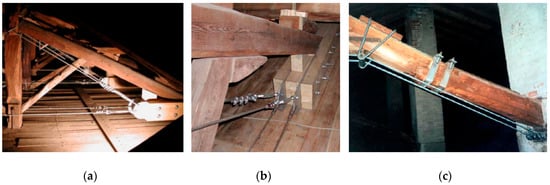

Figure 10 shows different retrofitting interventions, designed by professor L. Jurina [27]. The use of stainless steel wire ropes may represent an interesting solution when the reinforcement is exposed and unprotected. The installation of the ropes is relatively easy, the intervention is reversible, and the damage to the timber structure is very limited. However, particular attention should be given to stress concentration problems at the rope-timber joints and it is recommended to take periodic measurements of the creep deformation of the stainless steel ropes. The joint between the wire rope (tie) and the timber rafter is made using two steel plates (Figure 10b). These are inserted into a glulam element connected to the diagonal timber rafter with a bolted connection. The wall-to-wire connection can be effectively realized using anchor bolts (Figure 10c).

Figure 10. Reinforcement interventions using stainless steel wire ropes (design, Prof. L. Jurina): (a) and (b) Residence Masciadri in Arcene, Italy; (c) Residence Masciadri in Arcene, Italy [28].

3.2. Reinforcement by Addition of Stainless Steel H-shaped Profiles

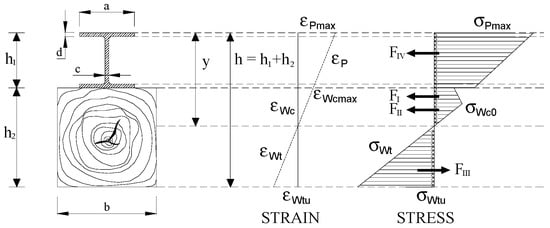

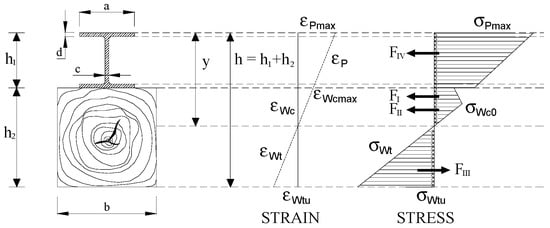

When conservation bodies or local authorities do not authorize retrofitting interventions, on listed buildings, at beam intrados (under the timber beams), for example, for the presence of decorations, it is possible to effectively reinforce timber-beam floors by operating on the beam extrados (over the beams) [31] (Figure 11 and Figure 12). In fact, to increase both the bending capacity and stiffness characteristics of existing wood beams, the use of stainless steel profiles placed in the compression side is an interesting solution. Stainless steel elements do not function as a substitute for the timber beams but rather effect an increase in their capacity and flexural stiffness through the creation of a mixed timber–stainless steel structure [32]. The application of stainless steel profiles can be done using epoxy resins, fasteners and/or metal screws or bolts. The use of mechanically attached connectors (screws or bolts) is usually preferred, given the high stress level, under loading, at interface between the timber beam and stainless steel beam. Stainless steel profiles can be also notched to better accommodate the floor joists, without highly affecting the effectiveness of the steel reinforcement. Furthermore, it should be noted that the reinforcement can be completely invisible behind the timber beams, it does not cause significant damage to the timber beams, and it can be easily removed, if needed, providing the method with reversibility characteristics. The reinforcement with H-type elements is characterized by this property and by high machinability of stainless steel elements to be carried out on-site. The reinforcement of timber beams using stainless steel beams is capable of resulting in a significant increase in strength, stiffness, and ductility and the application of the reinforcement is extremely fast and effective.

Figure 11. Reinforcement of a timber beam using a stainless steel H-shaped beam applied on the compressed area.

Figure 12. Reinforced timber beam cross section: stress and strain distribution, after timber yielding in compression. Reproduced from [31], with permission from Elsevier, 2007.

3.3. Reinforcement with Side Tension Rods or Plates

Stainless steel rods or plates can also be used as side tension reinforcement. This method simply consists of the application of a reinforcement at the bottom or either side of a timber beam under bending. This can be externally attached or bonded-in. When conversion into a trussed girder is not possible due to space constraints, a possible variation is to use side rods or plates. This method should be used with more caution as the smaller height of the timber-steel cross section produces higher stresses in both materials and problems related to stress concentration are likely to occur near the bolted joints.

References

- EN10088 Part 1 Stainless Steels Part 1—List of Stainless Steels; BSI: London, UK, 1995.

- EN10088 Part 2 Stainless Steels. Technical Delivery Conditions for Sheet/Plate and Strip of Corrosion Resisting Steels for General Purposes; BSI: London, UK, 2005.

- Sanstrom, R.; Bergqvist, H. Temperature dependence of tensile properties and strengthening of nitorgen alloyed austenitic stainless steels. Scand. J. Metall. 1977, 6, 156–169.

- Di Schino, A.; Longobardo, M.; Turconi, G.L.; Porcu, G.; Scoppio, L. Metallurgical design and development of C125 grade for mild sour service application. In Proceedings of the NACE—International Corrosion Conference, San Diego, CA, USA, 12–16 March 2006; pp. 061251–0612514.

- Di Schino, A.; Kenny, J.M.; Salvatori, I.; Abbruzzese, G. Modelling primary recrystallization and grain growth in a low nickel austenitic stainless steel. J. Mater. Sci. 2001, 36, 593–601.

- International Molybdenum Association. Practical Guidelines for the Fabrication of Duplex Stainless Steels; IMOA: London, UK, 2014.

- Outokumpu. Available online: http://www.outokumpu.com/SiteCollectionDocuments/Outokumpu -Product-Range-Wallchart.pdf (accessed on 14 November 2018).

- European Standard EN ISO 15156-1:2015, NACE MR0175 Petroleum and Natural Gas Industries—Materials for Use in H2S-Containing Environments in Oil and Gas Production—Part 1: General Principles for Selection of Cracking-Resistant Materials; ISO: Geneva, Switzerland, 2015.

- National Association of Corrosion Engineers (NACE). TM-01-69:1995 (R2000)—Laboratory Corrosion Testing of Metals; NACE: Houston, TX, USA, 2000.

- Tampone, G.; Mannucci, N.; Macchioni, N. Strutture di Legno. Cultura Conservazione Restauro; De Lettera: Rome, Italy, 2002.

- Mariani, M. Consolidamento Delle Strutture Lignee con L’acciaio; DEI: Rome, Italy, 2004.

- Charles, F.W.B. Dismantling, Repairing and Rebuilding as a Means of Conservation. In Proceedings of the ICOMOS UK: Timber Engineering Conference, London, UK, 8 April 1992.

- Bulleit, W.M. Reinforcement of wood materials: A review. Wood Fiber Sci. 2007, 16, 391–397.

- Giordano, G. Tecnica Delle Costruzioni in Legno; Hoepli: Milan, Italy, 1999.

- Franke, S.; Franke, B.; Harte, A.M. Failure modes and reinforcement techniques for timber beams–State of the art. Constr. Build. Mater. 2015, 97, 2–13.

- Buildingconservation. Available online: http://www.buildingconservation.com/articles/structural-timber- repairs/structural-timber-repairs.htm (accessed on 21 October 2018).

- Joist-repair. Available online: https://www.joist-repair.co.uk/joistendrepair_diydoc.htm (accessed on 3 December 2018).

- Fiorentecnica. Available online: http://www.fiorentecnica.it/paginaintx02.html (accessed on 25 November 2018).

- Alessandri, C.; Mallardo, V.; Pizzo, B.; Ruocco, E. The roof of the Church of the Nativity in Bethlehem: Structural problems and intervention techniques. J. Cult. Herit. 2012, 13, 70–81.

- Pizzo, B.; Gavioli, M.; Lauriola, M.P. Evaluation of a design approach to the on-site structural repair of decayed old timber end beams. Eng. Struct. 2013, 48, 611–622.

- Resine-epossidiche. Available online: https://resine-epossidiche.it/edilizia-conservativa/ (accessed on 25 November 2018).

- Blass, H.J.; Schmid, M.; Litze, H.; Wagner, B. Nail plate reinforced joints with dowel-type fasteners. In Proceedings of the 6th World Conference on Timber Engineering, British Columbia, Canada, 31 July–3 August 2000.

- Karadelis, J.N.; Brown, P. Punched metal plate timber fasteners under fatigue loading. Constr. Build. Mater. 2000, 14, 99–108.

- Fordevr. Available online: https://www.fordevr.com/nail-plate-construction.html (accessed on 10 January 2019).

- Beauty. Available online: http://beauty.fzl99.com/gang-nail-truss-plates/ (accessed on 10 January 2019).

- Studiofornale. Available online: http://www.studiofornale.it/intervento-di-consolidamento-trave-in-legno-lesionata-con-.contraffisso-metallico/ (accessed on 15 December 2018).

- Larsen, K.E.; Marstein, N. Conservation of historic timber structures: An ecological approach. In Butterworth-Heinemann Series in Conservation and Museology; Butterworth Heinemann: Oxford, UK, 2000.

- Jurina, L. L’uso Dell’acciaio nel Consolidamento delle Capriate e dei Solai in Legno. 2004. Available online: http://www.jurina.it/10/2012/02/2011_L%E2%80%99uso-dell%E2%80%99acciaio-nel-consolidamento-delle- capriate-e-dei-solai-in-legno.pdf (accessed on 21 January 2019).

- New South Wales State Heritage Office. The Maintenance Series, Timber Repairs, Information Sheet 5.2; New South Wales State Heritage Office: Sidney, Australia, 1998.

- Song, J.K.; Kim, S.Y.; Yang, K.H.; Han, S.A. Flexural behavior of post-tensioned glued-laminated timber with wire rope. In Proceedings of the International Conference on Sustainable Building Asia, Seoul, Korea, 27–29 June 2007.

- Corradi, M.; Borri, A. Fir and chestnut timber beams reinforced with GFRP pultruded Elements. J. Compos. Part B 2007, 38, 172–181.

- Borgin, K.B.; Loedolff, G.F.; Saunders, G.R. Laminated wood beams reinforced with steel strips. J. Struct. Div. 1968, 94, 1681–1706.

More