Overall equipment effectiveness (OEE) is a key performance indicator used to measure equipment productivity. The purpose of this study is to review and analyze the evolution of OEE, present modifications made over the original model and identify future development areas.

- Overall Equipment Effectiveness

- OEE

- KPI

- Literature review

- model-based

1. Introduction

Overall equipment effectiveness (OEE) is a KPI introduced by Nakajima (1988) [5][1]; this metric was developed as part of the total productive maintenance (TPM) to measure the equipment productivity in a manufacturing system. OEE is a productivity ratio between real manufacturing and what could be ideally manufactured [6][2]. This indicator is widely accepted as a tool by some companies, e.g., when implementing lean manufacturing[3] [7] or maintenance programs[1] [5] to monitor the actual performance of an equipment. OEE identifies six big losses comprising aspects of availability, performance and quality that reduce the equipment effectiveness. Dunn (2015) [8][4] defined those three aspects as follows: (i) availability—‘Is the machine running or not?’; (ii) performance—‘How fast is the machine running?’; and (iii) quality—‘How many products satisfied the requirements?’.

Availability measures downtime losses due to breakdowns or setup/adjustments; performance measures speed losses due to minor stoppages and reduced speed; and quality measures defect losses due to process defects or reduced yield [9][5]. Over time, OEE applications have been modified depending on industry needs; some authors have slightly modified the original formula, whereas others have proposed new formulas.

The insufficiency of OEE as an indicator has resulted in its modification [10][6]. Many industries have customized it to fit to their particular requirements [11][7]. Based on the OEE structure, models have been developed for domains such as sustainability [12][8], line manufacturing [13[9][10],14], assets [10][6], resources [15][11], transport[12][13] [16,17] and ports [18][14].

2. The Focus of the Current Research Effort in the OEE Domain

The bibliometrix R-package was used to analyze the 186 articles from the two electronic databases. This packaged, which is written in the R language, provides a set of tools for quantitative studies in bibliometrics and scientometrics [24][15]. Using this program, the data extracted from WoS and Scopus were consolidated to perform a comprehensive bibliometrics analysis of the current research effort pertaining to OEE. Table 1 shows a general data summary from the 186 articles.

Table 1. General data summary.

|

Timespan |

1996–2020 |

|

Sources (journals) |

102 |

|

Documents |

186 |

|

Average citations per document |

16.57 |

|

Author keywords |

554 |

|

Keywords plus |

434 |

|

Authors |

450 |

|

Authors of single-author documents |

25 |

|

Authors of multi-author documents |

425 |

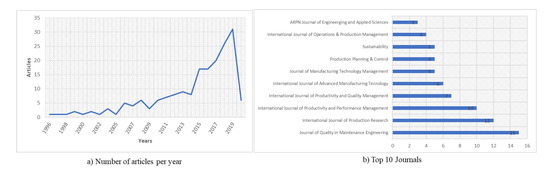

Despite a 24 years timespan, scientific productivity increased only in the later years. The results show that more than 50% of the publications regarding OEE were published in the last five years, indicating that interest in the OEE indicator has increased, i.e., by 9.1% in 2015, 9.1% in 2016, 10.8% in 2017, 14.0% in 2018 and 16.7% in 2019. Thus, far, an increase of 3.2% has been reported for 2020. Figure 2 presents (a) the number of articles per year since 1996 until 9 April 2020, revealing an increasing interest in the subject and (b) the top 10 journals with increasing publications over time.

Figure 1. Basic data analysis of (a) number of articles per year and (b) Top 10 journals.

The total number of journals published regarding OEE was 102. Journals pertaining primarily to manufacturing or maintenance issues were not the only ones that focused on the OEE indicator. Evidence shows that an increasing number of journals are focusing on sustainability, business, logistics, mining, etc.

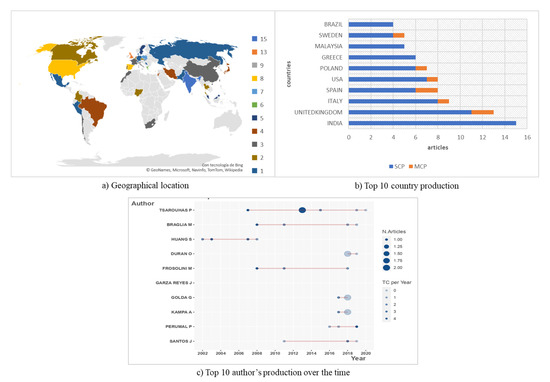

The current effort to spread the topic based on contributor and geographical location is shown in Figure 2. Europe is the continent with the most publications (45%) followed by Asia (26%), America (7%) and Africa (5%), as shown in Figure 2a. Figure 2b presents the top 10 countries in terms of single country publication (SCP) and multiple country publication (MCP). More than 80% of the publications were written by authors belonging to the same country; all the scientific productions in India were based entirely on SCPs, unlike the UK and Spain, who collaborative with other countries. Figure 2c indicate the top 10 most productive authors, including the number of articles (N articles) and total citations per year (TC per year). Greek author Panagiotis Tsarouhas was the first in the top 10, with 83.33% of his publications reporting cases in which OEE was applied to different production industries, e.g., croissant production lines [25][16], ice cream production lines[17] [26] and production plants of Italian cheese[18] [27] to identify potential opportunities for improving production systems. Braglia and Huang published four articles, whereas the other authors from the top 10 published three articles each. Some of them have developed new models based on OEE, whereas others have applied the indicator in different industries to measure equipment, process or resource effectiveness.

Figure 2. The effort in terms of (a) geographical location (b) top 10 country production and (c) authors contribution over the time.

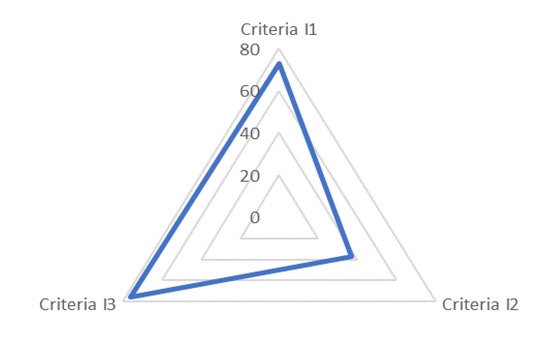

Three inclusion criteria were used for the analysis in this study. (a) Criteria I1—include papers that are literature reviews and/or are related specifically to OEE and its application; (b) Criteria I2—studies that mention OEE-based models; (c) Criteria I3—papers that only use the OEE to verify an improvement or change in any process (Table 2). Approximately 20% of the articles contributed scientifically to the modification or new development of models based on the original OEE (Figure 3). Instead of for use in production, the new models were built to measure the effectiveness in areas such as transportation, sustainability, mining, electricity and resources (human and monetary).

Table 2. Overall equipment effectiveness (OEE) application contribution by area.

Application Area | Inclusion Criteria | 1996–2000 | 2001–2005 | 2006–2010 | 2011–2015 | 2016–2020 | ||||||||||||||

Productivity in manufacturing processes | I1 |

|

[28–30] |

[31,32] |

[33–39] |

[26,40–60] |

[17][31][32][33][34][35][36][37][38][39][40][41][42][43][44][45][46][47][48][49][50][51] |

|||||||||||||

I3 |

|

|

[61] |

[52] |

[62–75] |

[53][54][55][56][57][58][59][60][61][62][63][64][65][66] |

[76–93] |

[67][68][69][70][71][72][73][74][75][76][77][78][79][80][81][82][83][84] |

||||||||||||

Productivity in maintenance | I1 |

[94,95] |

|

|

[27,96–98] |

[25,99–110] |

[16][90][91][92][93][94][95][96][97][98][99][100][101] |

|||||||||||||

I3 |

[111,112] |

[113] |

[104][113] |

[114–121] |

[105][106][107][108][109][110][111][112] |

[122–129] |

[113][114][115][116][117][118][119][120] |

[130–141] |

[121][122][123][124][125][126][127][128][129][130][131][132] |

|||||||||||

Oriented to resources productivity | I1 |

|

|

[142] |

[133] |

[143] |

[134] |

[144–149] |

[135][136][137][138][139][140] |

|||||||||||

I3 |

|

|

|

|

[150–152] | |||||||||||||||

Supply chain productivity | I1 |

|

|

|

[153] |

[144] |

| |||||||||||||

I3 |

|

|

|

[154,155] |

[156] |

[147] |

||||||||||||||

Other | I1 |

[9] |

[5] |

[157] |

[148] |

[158,159] |

[160–163] |

[164–166] | ||||||||||||

I3 |

|

[167] |

[158] |

[168] |

[159] |

[169] |

[160] |

[170–172] |

Figure 3. Distribution of inclusion criteria of analysis.

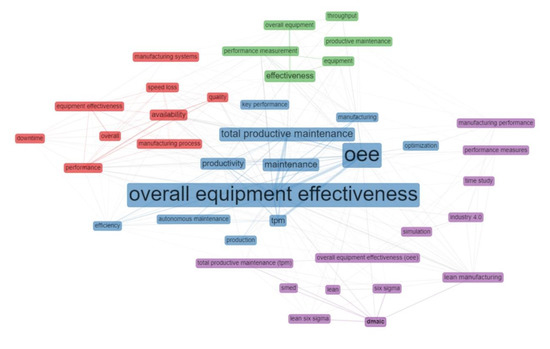

Two types of keywords are shown in Table 2: the author’s keywords and keywords plus. The former is provided by the original authors, whereas the latter is extracted from titles of cited references by Clarivate Analytics (WoS). Figure 4 shows the co-occurrence network of the author’s keywords; the number of nodes in the network was 40 and was related through association; the clustering algorithm used was Louvain. The network comprised four clusters. The first one comprised nine keywords related to the OEE formulation, availability, performance, quality, downtime, speed loss, etc. The second cluster comprised 12 keywords related to total productive maintenance, optimization, production, maintenance and autonomous maintenance. The third cluster comprised terms such as effectiveness, throughput and performance measurement. The last cluster comprised 13 keywords pertaining to current issues, such as Industry 4.0, simulation, lean manufacturing, six sigma, SMED and DMAIC.

Figure 54. Co-occurrence network.

Initially, studies regarding OEE are associated with total productive maintenance; subsequently, they are associated with the industry, availability and manufacturing process. Currently, they are related with terms such as lean manufacturing, improvement, implementation, reliability, design and optimization. The most cited document obtained from the systematic review considers quality assessments, such as lean tools and six sigma, to improve productivity and financial savings, e.g., in the die-casting unit of a company [115][96].

3. The Developed Models based on OEE

Over time, industries have adapted OEE to their needs. Hence, several authors have developed slight modifications to Nakajima’s model whereas others have developed new indicators based on the originally formulated OEE.

A list of models based on OEE, listed by the author and model name, is shown in Table 3. A brief description of each model is provided as well.

Table 3. List of models based on OEE.

Author | Year | Model Name | Brief Description |

|

[173] |

[[174] | 164] [165] |

2002 | 2007 | Overall throughput effectiveness | Calculates the productivity of a manufacturing system; | measures the factory level performance; identifies the bottleneck and hidden capacity. | |||||||||

|

[175] |

[166] |

2005 | Equipment effectiveness | Measures the equipment-dependent states, such as productive state, scheduled downstate and unscheduled downstate. | ||||||||||||

|

[13] |

[9] |

2006 | Overall line effectiveness | Measures the productivity of a line manufacturing system. | ||||||||||||

|

[176] |

[167] |

2006 | Total equipment efficiency | To achieve total equipment efficiency, it must include the resource usage efficiency of a machine. This input factor (resource requirements) is known as the overall input efficiency. | ||||||||||||

|

[10] |

[6] |

2008 | Overall asset effectiveness | Overall production effectiveness | Measures losses due to external and internal factors contributing to overall production/asset effectiveness. | |||||||||||

|

[177] |

[168] |

2008 | Modified OEE | Includes new factor usability; it classifies unplanned downtime events into equipment-related downtime. | ||||||||||||

|

[6] |

[2] |

2008 | Overall equipment effectiveness of a manufacturing line | Measures the performances of an automated line in the system. | ||||||||||||

|

[16] |

[12] |

2010 | OEE for shovel/oee for trucks | OEE is calculated for mining equipment. | ||||||||||||

|

[14] |

[10] |

2010 | Overall line effectiveness | The performance of the production line in the manufacturing system is measured. | ||||||||||||

|

[178] |

[169] |

2010 | Overall equipment effectiveness market-based | Monitors production in the steel market; measures equipment effectiveness for a full process cycle. | ||||||||||||

|

[179] |

[170] |

2011 | Integrated equipment effectiveness | This integration is based on three elements: loading-based, capital-based and market-based elements. | ||||||||||||

|

[180] |

[171] |

2012 | Overall equipment and quality cost loss | Calculates the losses of equipment, specifically production and quality cost losses, in monetary units. | ||||||||||||

|

[181] |

[172] |

2013 | Overall resource effectiveness | Includes losses related to resources, e.g., people, machines, materials and methods. | ||||||||||||

|

[182] |

[173] |

2015 | Machining equipment effectiveness | Calculates the OEE of a high-mix-low-volume manufacturing environment. | ||||||||||||

|

[15] |

[11] |

2015 | Overall resource effectiveness | Provides information regarding the process performance based on factor material efficiencies, process cost and material cost. | ||||||||||||

|

[12] |

[8] |

2015 | Overall environmental equipment effectiveness | Identifies losses due to sustainability, based on the calculated environmental impact of the workstation. | ||||||||||||

|

[183] |

[174] |

2015 | Fuzzy overall equipment effectiveness | Identifies performance fluctuations through LR Fuzzy numbers. | ||||||||||||

|

[184] |

[175] |

2016 | Stochastic shovel effectiveness | Quantifies performance effectiveness of electric and hydraulic shovels. | ||||||||||||

|

[185] |

[176] |

2017 | OEE of BELT equipment | Bucket-based excavating, loading and transport (BELT) including all equipment comprising a bucket, e.g., draglines, shovels, load-haul-dumps and trucks. | ||||||||||||

|

[186] |

[177] |

2017 | Strategic equipment effectiveness | Operational equipment effectiveness | A global measure of the effectiveness of an integrated electrical system. | |||||||||||

|

[187] |

[178] |

2017 | Overall machinery effectiveness | Identifies and ranks decision-making-units in terms of efficiency. | ||||||||||||

|

[18] |

[14] |

2017 | OEE of port terminal | Identifies the most efficient terminal, addressing either manageable or unmanageable factors. | ||||||||||||

|

[188] |

[179] |

2017 | Modified OEE | Includes losses associated with human factors and usability (the frequency of setup and changeover process) | ||||||||||||

|

[189] |

[180] |

2018 | Extended overall equipment effectiveness | Evaluates the entire process considering human resources and equipment Performance. It is applied in medicals activities of operating rooms. | ||||||||||||

|

[17] |

[13] |

2018 | OEE to transport management | Improves efficiency in road transport by adapting OEE to transport management. | ||||||||||||

|

[11] |

[7] |

2018 | Modified OEE | Optimizes the effectiveness of urban freight transportation. | ||||||||||||

|

[190] |

[181] |

2018 | Overall material usage effectiveness | Measures material usage effectiveness and identifies material loss in the manufacturing process. | ||||||||||||

|

[191] |

[182] |

2018 | Sustainable overall throughputability effectiveness | Includes sustainability criteria and can be used in the system lifecycle. | ||||||||||||

|

[7] |

[3] |

2019 | Overall task effectiveness | Analyses and evaluates losses related to manual assembly tasks. | ||||||||||||

|

[192] |

[183] |

2019 | Modified OEE | Improves the effectiveness of scheduling jobs with earliness/tardiness. | ||||||||||||

|

[193] |

[184] |

2019 | OEE–TCQ | Improves the process approach in maintenance in terms of time, cost and quality. | ||||||||||||

|

[194] |

[185] |

2019 | Overall effectiveness indicator | Adapted for mining production to examine the effectiveness of the mining machine. | ||||||||||||

|

[195] |

[186] |

2019 | Standalone OEE | Identifies system bottleneck and excludes effects from upstream and downstream. | ||||||||||||

|

[196] |

[187] |

2019 | Modified OEE | Calculates the OEE in serial, parallel and combined machine systems in the production line. | ||||||||||||

|

[197] |

[188] |

2019 | Modified OEE | Includes a term that considers material utilization. | ||||||||||||

|

[198] |

[189] |

2019 | Overall substation effectiveness | Measures substation performances and indicates the overall maintenance performances. |

As presented above, the OEE was modified to solve gaps in various issues, such as sustainability, human factor, transport, manufacturing system, mining, cost, port and resources.

4. The Principal Contributions in OEE and Its Future Trends

Initially, OEE was used in production, in particular for TPM, which assists in identifying the overall equipment performance in a manufacturing process [199][190]. To accommodate industry needs, some researchers began to analyze the productivity of manufacturing line systems[2][9] [6,13] or factories [174][165]. Currently, OEE is used with continuous improvement methodologies, such as lean manufacturing to increase productivity by eliminating waste [200][191]. It is also used as a KPI and data collection tool to measure the effectivity and process capability of new six sigma implementations [61][52]. Following the methodology of continuous improvement, Braglia et al. (2019) [7][3] developed a new metric based on OEE, known as overall task effectiveness. This new indicator supports lean and six sigma methodologies to identify, analyze and evaluate losses that occur during manual assembly activities.

Sustainability is an aspect that has been investigated by several companies in recent years [201][192], which shows that concerns regarding the environment have been growing. Hence, it has become increasingly important to include this variable as a criterion in business decision-making. Ghafoorpoor Yazdi et al. (2018)[141] [150] created a design in a study based on OEE and its relationship with sustainability in Industry 4.0. Meanwhile, other authors incorporated the concept of sustainability in OEE, e.g., Domingo et al. (2015) [12][8] developed the overall environmental equipment effectiveness to identify and measure losses due to sustainability. Likewise, Durán et al. (2018)[182] [191] designed the Sustainable Overall throughput effectiveness indicator to measure the operating performance and factory level sustainability.

The OEE has been adapted for the transport sector. To the best of our knowledge, it first occurred in the mining industry [16][12] and was used to identify possible losses in the availability, performance and quality of equipment such as shovels and trucks. In recent years, the efficiency framework in the port terminal[14] [18] that considers manageable and unmanageable variables has been studied to create indicators based on OEE. Additionally, the OEE has been adapted to road transportation[13] [17] based on distance, load capacity, route time, stops and services. Furthermore, it has been used to evaluate the effectiveness of urban freight transportation[7] [11] as well as optimize availability, performance and quality metrics.

Accordingly, some authors have established interesting frameworks that can be developed in future studies. Some of them proposed future studies based on the frameworks that they have developed thus far, whereas others developed innovations in new areas. Abdelbar et al. (2019)[184] [193] used a new OEE formula to identify and implement process improvements. Braglia et al. (2018)[181] [190] extended the proposed methodology, including the analysis of material losses based on the finished product. Ghafoorpoor Yazdi et al. (2018)[141] [150] proposed re-performing experiments for long time periods and as a case study in the manufacturing industry. Dadashnejad and Valmohammadi, (2019) [76][67] applied the same value stream mapping technique that is used to identify improvements in other factories.

By contrast, other authors proposed different areas in which OEE is applicable. In the study by García-Arca et al. (2018)[13] [17] where OEE was adapted to transport management, they assume that the same methodology is applicable to the service sector and other logistics processes, such as goods reception or performing selection in a warehouse. Sharma et al. (2018) [137][128] and Supriyanto and Mokh (2018) [59][50] reported that their studies can be replicated in the service sector as well as in other industries, such as pharmaceutical, electrical/electronic, textile and transportation (rail and air travel).

References

- Nakajima, S. Introduction to TMP; Productivity Press: Portaland, OR, USA, 1988.

- Marcello Braglia; Marco Frosolini; Francesco Zammori; Overall equipment effectiveness of a manufacturing line (OEEML). Journal of Manufacturing Technology Management 2008, 20, 8-29, 10.1108/17410380910925389.

- Marcello Braglia; Roberto Gabbrielli; Leonardo Marrazzini; Overall Task Effectiveness: a new Lean performance indicator in engineer-to-order environment. International Journal of Productivity and Performance Management 2019, 68, 407-422, 10.1108/ijppm-05-2018-0192.

- Dunn, T. OEE Effectiveness. In Manufacturing Flexible Packaging; Elsevier: Amsterdam, The Netherlands, 2015; pp. 77–85.

- Patrik Jonsson; Magnus Lesshammar; Evaluation and improvement of manufacturing performance measurement systems ‐ the role of OEE. International Journal of Operations & Production Management 1999, 19, 55-78, 10.1108/01443579910244223.

- Peter Muchiri; L. Pintelon; Performance measurement using overall equipment effectiveness (OEE): literature review and practical application discussion. International Journal of Production Research 2008, 46, 3517-3535, 10.1080/00207540601142645.

- Andres Muñoz-Villamizar; Javier Santos; Jairo R. Montoya-Torres; Carmen Jaca; Using OEE to evaluate the effectiveness of urban freight transportation systems: A case study. International Journal of Production Economics 2018, 197, 232-242, 10.1016/j.ijpe.2018.01.011.

- Rosario Domingo; Sergio Aguado; Overall Environmental Equipment Effectiveness as a Metric of a Lean and Green Manufacturing System. Sustainability 2015, 7, 9031-9047, 10.3390/su7079031.

- Nachiappan, R.M.; Anantharaman, N. Evaluation of overall line effectiveness (OLE) in a continuous product line manufacturing system. J. Manuf. Technol. Manag. 2006, 17, 987–1008.

- Raja, P.N.; Kannan, S.M.; Jeyabalan, V. Overall line effectiveness—A performance evaluation index of a manufacturing system. Int. J. Product. Qual. Manag. 2010, 5, 38.

- Jose Arturo Garza-Reyes; From measuring overall equipment effectiveness (OEE) to overall resource effectiveness (ORE). Journal of Quality in Maintenance Engineering 2015, 21, 506-527, 10.1108/jqme-03-2014-0014.

- Elevli, S.; Elevli, B. Performance Measurement of Mining Equipments by Utilizing OEE. Acta Montan. Slovaca Ročník 2010, 15, 95–101.

- García-Arca, J.; Prado-Prado, J.C.; Fernández-González, A.J. Integrating KPIs for improving efficiency in road transport. Int. J. Phys. Distrib. Logist. Manag. 2018, 48, 931–951.

- Marcos M O Pinto; David J K Goldberg; João S L Cardoso; Benchmarking operational efficiency of port terminals using the OEE indicator. Maritime Economics & Logistics 2017, 19, 504-517, 10.1057/mel.2016.6.

- Massimo Aria; Corrado Cuccurullo; bibliometrix : An R-tool for comprehensive science mapping analysis. Journal of Informetrics 2017, 11, 959-975, 10.1016/j.joi.2017.08.007.

- Panagiotis Tsarouhas; Improving operation of the croissant production line through overall equipment effectiveness (OEE). International Journal of Productivity and Performance Management 2019, 68, 88-108, 10.1108/ijppm-02-2018-0060.

- Tsarouhas, P.H.; Overall equipment effectiveness (OEE) evaluation for an automated ice cream production line: A case study. Int. J. Product. Perform. Manag. 2019, null, null.

- Panagiotis H. Tsarouhas; Equipment performance evaluation in a production plant of traditional Italian cheese. International Journal of Production Research 2013, 51, 5897-5907, 10.1080/00207543.2013.807373.

- Huang, S.H.; Dismukes, J.P.; Shi, J.; Su, Q.; Razzak, M.A.; Bodhale, R.; Robinson, D.E. Manufacturing productivity improvement using effectiveness metrics and simulation analysis. Int. J. Prod. Res. 2003, 41, 513–527.

- Dal, B.; Tugwell, P.; Greatbanks, R. Overall Equipment Effectiveness as a Measure of Operational Improvement a Practical Analysis. Int. J. Oper. Prod. Manag. 2000, 20, 1488–1502.

- Bamber, C.J.; Castka, P.; Sharp, J.M.; Motara, Y. Cross-functional team working for overall equipment effectiveness (OEE). J. Qual. Maint. Eng. 2003, 9, 223–238.

- Ilar, T.; Powell, J.; Kaplan, A. Modelling, simulation and analyses of systems with breakdown imposed scrapping. J. Simul. 2009, 3, 107–113.

- Ferko, R.; Znidarsic, A. Using OEE approach for improving manufacturing performance. Inf. Midem Ljubl. 2007, 37, 105

- Tsarouhas, P.H. Evaluation of overall equipment effectiveness in the beverage industry: A case study. Int. J. Prod. Res. 2013, 51, 515–523.

- Norden, C.; Ismail, J. Defining a representative overall equipment effectiveness (OEE) measurement for underground bord and pillar coal mining. J. S. Afr. Inst. Min. Metall. 2012, 112, 845–851.

- Shahin, A.; Isfahani, N.G. Estimating overall equipment effectiveness for continuous production lines: With a case study in Esfahan Steel Company. Int. J. Serv. Oper. Manag. 2015, 21, 466–478.

- De Carlo, F.; Arleo, M.A.; Tucci, M. OEE Evaluation of a Paced Assembly Line through Different Calculation and Simulation Methods: A Case Study in the Pharmaceutical Environment. Int. J. Eng. Bus. Manag. 2014, 6, 27.

- Anand, R. Cloud computing OEE (Overall Equipment Effectiveness) for reducing production downtime. SAE Int. J. Mater. Manuf. 2013, 6.

- Mansour, H.; Ahmad, M.M.; Dhafr, N.; Ahmed, H. Evaluation of operational performance of workover rigs activities in oilfields. Int. J. Product. Perform. Manag. 2013, 62, 204–218.

- Palanisamy, V. Implementing Overall Equipment Effectiveness in a Process Industry. Indian J. Sci. Technol. 2013, 6, 1–5.

- Trattner, A.; Hvam, L.; Haug, A. Why slow down? Factors affecting speed loss in process manufacturing. Int. J. Adv. Manuf. Technol. 2020, 106, 2021–2034.

- Foulloy, L.; Clivillé, V.; Berrah, L. A fuzzy temporal approach to the Overall Equipment Effectiveness measurement. Comput. Ind. Eng. 2019, 127, 103–115.

- Fekri Sari, M.; Avakh Darestani, S. Fuzzy overall equipment effectiveness and line performance measurement using artificial neural network. J. Qual. Maint. Eng. 2019, 25, 340–354.

- Yılmaz Eroğlu, D. Systematization, implementation and analyze of overall throughput effectiveness calculation in finishing process of weaving industry. Tekstil Konfeksiyon 2019.

- Roda, I.; Macchi, M. Factory-level performance evaluation of buffered multi-state production systems. J. Manuf. Syst. 2019, 50, 226–235.

- Sonmez, V.; Testik, M.C.; Testik, O.M. Overall equipment effectiveness when production speeds and stoppage durations are uncertain. Int. J. Adv. Manuf. Technol. 2018, 95, 121–130.

- Zennaro, I.; Battini, D.; Sgarbossa, F.; Persona, A.; De Marchi, R. Micro downtime: Data collection, analysis and impact on OEE in bottling lines the San Benedetto case study. Int. J. Qual. Reliab. Manag. 2018, 35, 965–995.

- He, F.; Shen, K.; Lu, L.; Tong, Y. Model for improvement of overall equipment effectiveness of beerfilling lines. Adv. Mech. Eng. 2018, 10, 168781401878924.

- Hwang, G.; Lee, J.; Park, J.; Chang, T.W. Developing performance measurement system for Internet of Things and smart factory environment. Int. J. Prod. Res. 2017, 55, 2590–2602.

- Kardas, E.; Brožova, S.; Pustějovská, P.; Jursová, S. The Evaluation of Efficiency of the Use of Machine Working Time in the Industrial Company—Case Study. Manag. Syst. Prod. Eng. 2017, 25, 241–245.

- Mousavi, A.; Siervo, H.R.A. Automatic translation of plant data into management performance metrics: A case for real-time and predictive production control. Int. J. Prod. Res. 2017, 55, 4862–4877.

- Fourie, H. Improvement in the overall efficiency of mining equipment: A case study. J. S. Afr. Inst. Min. Metall. 2016, 116, 275–281.

- Green, C.; Taylor, D. Consolidating a Distributed Compound Management Capability into a Single Installation: The Application of Overall Equipment Effectiveness to Determine Capacity Utilization. J. Lab. Autom. 2016, 21, 811–816.

- Samatemba, B.; Zhang, L.; Besa, B. Evaluating and optimizing the effectiveness of mining equipment; the case of Chibuluma South underground mine. J. Clean. Prod. 2020, 252, 119697.

- Cheah, C.K.; Prakash, J.; Ong, K.S. An integrated OEE framework for structured productivity improvement in a semiconductor manufacturing facility. Int. J. Product. Perform. Manag. 2020.

- Putz, M.; Koriath, H.J.; Kuznetsov, A.P. Resource consumption classes of machine tools. MM Sci. J. 2019, 2019, 3301–3309.

- Bhattacharjee, A.; Roy, S.; Kundu, S.; Tiwary, M.; Chakraborty, R. An analytical approach to measure OEE for blast furnaces. Ironmak. Steelmak. 2019.

- Pemural, P.A.; Yoong, S.S.; Tay, C.C. Classification of Losses in Overall Equipment Effectiveness Calculation. Int. J. Recent Technol. Eng. 2019, 7–11.

- Sharma, R. Overall equipment effectiveness measurement of TPM manager model machines in flexible manufacturing environment: A case study of automobile sector. Int. J. Product. Qual. Manag. 2019, 26, 206–222.

- Supriyanto, H.; Mokh, S. Performance evaluation using lean six sigma and overall equipment effectiveness: An analyzing tool. Int. J. Mech. Eng. Technol. 2018, 9, 487–495.

- Stryczek, R.; Szczepka, W. Process Factors of Impact on OEE for Lathes for Machining of Wheelset. J. Mach. Eng. 2016, 16, 126–140.

- Paul Martin Gibbons; Improving overall equipment efficiency using a Lean Six Sigma approach. International Journal of Six Sigma and Competitive Advantage 2006, 2, 207, 10.1504/ijssca.2006.010110.

- Benjamin, S.J.; Marathamuthu, M.S.; Murugaiah, U. The use of 5-WHYs technique to eliminate OEE’s speed loss in a manufacturing firm. J. Qual. Maint. Eng. 2015, 21, 419–435.

- Arima, S.; Kobayashi, A.; Wang, Y.F.; Sakurai, K.; Monma, Y. Optimization of Re-Entrant Hybrid Flows with Multiple Queue Time Constraints in Batch Processes of Semiconductor Manufacturing. IEEE Trans. Semicond. Manuf. 2015, 28, 528–544.

- Olivella, J.; Gregorio, R. A case study of an integrated manufacturing performance measurement and meeting system. J. Manuf. Technol. Manag. 2015, 26, 515–535.

- Wang, T.Y.; Pan, H.C. Improving the OEE and UPH data quality by Automated Data Collection for the semiconductor assembly industry. Expert Syst. Appl. 2011, 38, 5764–5773.

- Bevilacqua, M.; Ciarapica, F.E.; De Sanctis, I.; Mazzuto, G.; Paciarotti, C. A Changeover Time Reduction through an integration of lean practices: A case study from pharmaceutical sector. Assem. Autom. 2015, 35, 22–34.

- Kuiper, A.; Van Raalte, M.; Does, R.J.M.M. Quality quandaries: Improving the overall equipment effectiveness at a pharmaceutical company. Qual. Eng. 2014, 26, 478–483.

- Uddin, M.K.; Puttonen, J.; Martinez Lastra, J.L. Context-sensitive optimisation of the key performance indicators for FMS. Int. J. Comput. Integr. Manuf. 2015, 28, 958–971.

- Chiarini, A. Improvement of OEE performance using a Lean Six Sigma approach: An Italian manufacturing case study. Int. J. Product. Qual. Manag. 2015, 16, 416–433.

- Singh, K.; Ahuja, I.P.S. Assessing the business performance measurements for transfusion of TQM and TPM initiatives in the Indian manufacturing industry. Int. J. Technol. Policy Manag. 2014, 14, 44.

- Benedetti, M.; Cesarotti, V.; Giuiusa, A.; Introna, V. Buffer Size Design in Pharmaceutical Packaging Lines: An Analytical Methodology Proposal and Case Study. Int. J. Eng. Bus. Manag. 2014, 6, 26.

- Singh, J.; Singh, H. Performance enhancement of a manufacturing industry by using continuous improvement strategies—A case study. Int. J. Product. Qual. Manag. 2014, 14, 36.

- Svrzic, U.; Danon, G. Solving problems in wood parquet production by using “7 steps” of world class manufacturing (WCM) methodology. J. Appl. Eng. Sci. 2014, 12, 113–120.

- Jebaraj Benjamin, S.; Murugaiah, U.; Srikamaladevi Marathamuthu, M. The use of SMED to eliminate small stops in a manufacturing firm. J. Manuf. Technol. Manag. 2013, 24, 792–807.

- Mandahawi, N.; Fouad, R.H.; Obeidat, S. An Application of Customized Lean Six Sigma to Enhance Productivity at a Paper Manufacturing Company. Jordan J. Mech. Ind. Eng. 2012, 6, 103–109.

- Dadashnejad, A.-A.; Valmohammadi, C. Investigating the effect of value stream mapping on overall equipment effectiveness: A case study. Total Qual. Manag. Bus. Excell. 2019, 30, 466–482.

- Baghbani, M.; Iranzadeh, S.; Bagherzadeh khajeh, M. Investigating the relationship between RPN parameters in fuzzy PFMEA and OEE in a sugar factory. J. Loss Prev. Process Ind. 2019, 60, 221–232.

- Ghafoorpoor Yazdi, P.; Azizi, A.; Hashemipour, M. A Hybrid Methodology for Validation of Optimization Solutions Effects on Manufacturing Sustainability with Time Study and Simulation Approach for SMEs. Sustainability 2019, 11, 1454.

- Dresch, A.; Veit, D.R.; de Lima, P.N.; Lacerda, D.P.; Collatto, D.C. Inducing Brazilian manufacturing SMEs productivity with Lean tools. Int. J. Product. Perform. Manag. 2019, 68, 69–87.

- Daneshjo, N.; Malega, P.; Pajerská, E.D. Production Efficiency in Company with Small Series Production. TEM J. 2019, 8, 1118–1126.

- Al-Refaie, A.; Abbasi, G.; Al-shalaldeh, H. Lean and agile practices to improve the performance of filling process via simulation and data envelopment analysis. SN Appl. Sci. 2019, 1.

- Pereira, A.M.H.; Silva, M.R.; Domingues, M.A.G.; Sá, J.C. Lean six sigma approach to improve the production process in the mould industry: A case study. Qual. Innov. Prosper. 2019, 23, 103–121.

- Tortorella, G.; Fettermann, D. Help chain in companies undergoing a lean implementation: The impact of critical success factors on quality and efficiency performance. Int. J. Lean Six Sigma 2018, 9, 113–132.

- Fera, M.; Fruggiero, F.; Costabile, G.; Lambiase, A.; Pham, D.T. A new mixed production cost allocation model for additive manufacturing (MiProCAMAM). Int. J. Adv. Manuf. Technol. 2017, 92, 4275–4291.

- Lozano, J.; Saenz-Díez, J.C.; Martínez, E.; Jiménez, E.; Blanco, J. Methodology to improve machine changeover performance on food industry based on SMED. Int. J. Adv. Manuf. Technol. 2017, 90, 3607–3618.

- Morales Méndez, J.D.; Silva Rodríguez, R. Set-up reduction in an interconnection axle manufacturing cell using SMED. Int. J. Adv. Manuf. Technol. 2016, 84, 1907–1916.

- Gendre, Y.; Waridel, G.; Guyon, M.; Demuth, J.F.; Guelpa, H.; Humbert, T. Manufacturing execution systems: Examples of performance indicator and operational robustness tools. Chimia 2016, 70, 616–620.

- Chen, B.; Wan, J.; Shu, L.; Li, P.; Mukherjee, M.; Yin, B. Smart Factory of Industry 4.0: Key Technologies, Application Case, and Challenges. IEEE Access 2017, 6, 6505–6519.

- Canizo, M.; Conde, A.; Charramendieta, S.; Minon, R.; Cid-Fuentes, R.G.; Onieva, E. Implementation of a large-scale platform for cyber-physical system real-time monitoring. IEEE Access 2019, 7, 52455–52466.

- Kasashima, Y. Easy-to-use detection method for micro-arc discharge in plasma etching equipment by measuring current flowing to ground. Jpn. J. Appl. Phys. 2018, 57.

- Chang, T.W.; Cho, E.; Jun, J.H.; Ahn, H. Implementation of smart factory for sme: Focusing on data acquisition and monitoring. ICIC Express Lett. Part B Appl. 2019, 10, 551–558.

- Alvarado, L.; Grimaldo Quispe, C.R. Method for optimizing the production process of domestic water tank manufacturing companies. Int. J. Eng. Res. Technol. 2018, 11, 1735–1757.

- Perumal, P.A.; Teruaki, I.; Siang, T.Y.; Sieng, Y.S. Examination of Overall Equipment Effectiveness (OEE) in term of Maynard’s Operation Sequence Technique (MOST). Am. J. Appl. Sci. 2016, 13, 1214–1220.

- Ljungberg, Õ. Measurement of overall equipment effectiveness as a basis for TPM activities. Int. J. Oper. Prod. Manag. 1998, 18, 495–507.

- Al-Najjar, B. Total quality maintenance: An approach for continuous reduction in costs of quality products. J. Qual. Maint. Eng. 1996, 2, 4–20.

- Abdul Samat, H.; Kamaruddin, S.; Abdul Azid, I. Integration of overall equipment effectiveness (OEE) and reliability method for measuring machine effectiveness. S. Afr. J. Ind. Eng. 2012, 23, 92–113.

- Tsarouhas, P.H. Evaluation of maintenance management through the overall equipment effectiveness of a yogurt production line in a medium-sized Italian company. Int. J. Product. Qual. Manag. 2015, 16, 298–311.

- Shahin, A.; Attarpour, M.R. Developing decision making grid for maintenance policy making based on estimated range of overall equipment effectiveness. Mod. Appl. Sci. 2011, 5, 86–97.

- Durán, O.; Durán, P.A. Prioritization of Physical Assets for Maintenance and Production Sustainability. Sustainability 2019, 11, 4296.

- Khisamova, E.D.; Kodolova, I.A.; Kucherbaeva, A.A. Impact of Lean Technology on Overall Equipment Effectiveness. HELIX 2019, 9, 5159–5164.

- Daniewski, K.; Kosicka, E.; Mazurkiewicz, D. Analysis of the correctness of determination of the effectiveness of maintenance service actions. Manag. Prod. Eng. Rev. 2018, 9, 20–25.

- Ylipää, T.; Skoogh, A.; Bokrantz, J.; Gopalakrishnan, M. Identification of maintenance improvement potential using OEE assessment. Int. J. Product. Perform. Manag. 2017, 66, 126–143.

- Saleem, F.; Nisar, S.; Khan, M.A.; Khan, S.Z.; Sheikh, M.A. Overall equipment effectiveness of tyre curing press: A case study. J. Qual. Maint. Eng. 2017, 23, 39–56.

- Fattah, J.; Ezzine, L.; Lachhab, A. Evaluating the performance of a production line by the overall equipment effectiveness: An approach based on best maintenance practices. Int. J. Eng. Res. Afr. 2017, 30, 181–189.

- Binti Aminuddin, N.A.; Garza-Reyes, J.A.; Kumar, V.; Antony, J.; Rocha-Lona, L. An analysis of managerial factors affecting the implementation and use of overall equipment effectiveness. Int. J. Prod. Res. 2016, 54, 4430–4447.

- Gupta, P.; Vardhan, S. Optimizing OEE, productivity and production cost for improving sales volume in an automobile industry through TPM: A case study. Int. J. Prod. Res. 2016, 54, 2976–2988.

- Wudhikarn, R. Implementation of the overall equipment cost loss (OECL) methodology for comparison with overall equipment effectiveness (OEE). J. Qual. Maint. Eng. 2016, 22, 81–93.

- Duran, O.; Rojas, S.; Duran, P. Measuring the impact of maintenance postponement on overall performance in a chilean crushing plant. IEEE Lat. Am. Trans. 2018, 16, 1951–1958.

- Acharya, A.; Garg, D.; Singh, N.; Gahlaut, U. Plant effectiveness improvement of overall equipment effectiveness using autonomous maintenance training:—A case study. Int. J. Mech. Prod. Eng. Res. Dev. 2018, 9, 103–112.

- Saidi, R.; Soulhi, A.; El Alami, J. The role of the overall equipment effectiveness as a decision support tool for structuring the roadmap of a tfs transformation (Constraint theory, safety of operation, and six sigma). J. Theor. Appl. Inf. Technol. 2017, 3441–3449.

- Prickett, P.W. An integrated approach to autonomous maintenance management. Integr. Manuf. Syst. 1999, 10, 233–243.

- Blanchard, B.S. An enhanced approach for implementing total productive maintenance in the manufacturing environment. J. Qual. Maint. Eng. 1997, 3, 69–80.

- F. K. Wang; W. Lee; Learning curve analysis in total productive maintenance. Omega 2001, 29, 491-499, 10.1016/s0305-0483(01)00039-1.

- Rashid, M.M.; Ismail, H. Generic approach for the customisation of the TPM programme: Using the process transformation model and reliability assessment tool. Eur. J. Ind. Eng. 2008, 2, 401–427.

- Kumar, M.; Antony, J.; Singh, R.K.; Tiwari, M.K.; Perry, D. Implementing the lean sigma framework in an Indian SME: A case study. Prod. Plan. Control 2006, 17, 407–423.

- Fore, S.; Zuze, L. Improvement of overall equipment effectiveness through total productive maintenance. World Acad. Sci. Eng. Technol. 2010, 61, 2010.

- Shetty, D.; Ali, A.; Chapdelaine, J.J. A model for the total productive manufacturing assessment and implementation. J. Adv. Manuf. Syst. 2009, 8, 117–136.

- Azar, A.T. The influence of maintenance quality of hemodialysis machines on hemodialysis efficiency. Saudi J. Kidney Dis. Transplant. 2009, 20, 49.

- Da Silva, C.M.I.; Cabrita, C.M.P.; De Oliveira Matias, J.C. Proactive reliability maintenance: A case study concerning maintenance service costs. J. Qual. Maint. Eng. 2008, 14, 343–355.

- Sarkar, B.N. Capability enhancement of a metal casting processes in a small steel foundry through Six Sigma: A case study. Int. J. Six Sigma Compet. Advant. 2007, 3, 56–71.

- Tsarouhas, P. Implementation of total productive maintenance in food industry: A case study. J. Qual. Maint. Eng. 2007, 13, 5–18

- Jain, A.; Bhatti, R.S.; Singh, H. OEE enhancement in SMEs through mobile maintenance: A TPM concept. Int. J. Qual. Reliab. Manag. 2015, 32, 503–516.

- Rødseth, H.; Skarlo, T.; Schjølberg, P. Profit loss indicator: A novel maintenance indicator applied for integrated planning. Adv. Manuf. 2015, 3, 139–150.

- Arango Serna, M.D.; Alzate Lopez, J.F.; Zapata Cortes, J.A. Tpm implementation impact on companies’ competitivity in the medellin metropolitan and Antioquia’s eastern region, Colombia. Dyna 2012, 79, 164–170.

- Santos, J.; Garcia, M.P.; Arcelus, M.; Viles, E.; Uranga, J. Development of a wireless PlugandLean system for improving manufacturing equipment diagnosis. Int. J. Comput. Integr. Manuf. 2011, 24, 338–351.

- Ananth, G.; Vinayagam, B.K. Effectiveness improvement through total productive maintenance using particle swarm optimisation model for small and micro manufacturing enterprises. Int. J. Product. Qual. Manag. 2015, 16, 473–503.

- Kumar, J.; Soni, V.K.; Agnihotri, G. Impact of TPM implementation on Indian manufacturing industry. Int. J. Product. Perform. Manag. 2014, 63, 44–56.

- Ohunakin, O.S.; Leramo, R.O. Total productive maintenance implementation in a beverage industry: A case study. J. Eng. Appl. Sci. 2012, 7, 128–133.

- Dogra, M.; Sharma, V.S.; Sachdeva, A.; Dureja, J.S. TPM—A key strategy for productivity improvement in process industry. J. Eng. Sci. Technol. 2011, 6, 1–16.

- Wakiru, J.M.; Pintelon, L.; Muchiri, P.; Chemweno, P. Integrated maintenance policies for performance improvement of a multi-unit repairable, one product manufacturing system. Prod. Plan. Control 2020, 1–21.

- Singh, J.; Singh, H.; Sharma, V. Success of TPM concept in a manufacturing unit—A case study. Int. J. Product. Perform. Manag. 2018, 67, 536–549.

- Nwanya, S.C.; Udofia, J.I.; Ajayi, O.O. Optimization of machine downtime in the plastic manufacturing. Cogent Eng. 2017, 4.

- Nallusamy, S. Enhancement of productivity and efficiency of CNC machines in a small scale industry using total productive maintenance. Int. J. Eng. Res. Afr. 2016, 25, 119–126.

- Bataineh, O.; Al-Hawari, T.; Alshraideh, H.; Dalalah, D. A sequential TPM-based scheme for improving production effectiveness presented with a case study. J. Qual. Maint. Eng. 2019, 25, 144–161.

- Nallusamy, S.; Kumar, V.; Yadav, V.; Prasad, U.K.; Suman, S.K. Implementation of total productive maintenance to enhance the overall equipment effectiveness in medium scale industries. Int. J. Mech. Prod. Eng. Res. Dev. 2018, 8, 1027–1038.

- Udomraksasakul, C.; Udomraksasakul, C. Increase improvement of overall equipment effectiveness of plastic molding machine. Int. J. Mech. Eng. Technol. 2018, 9, 1107–1113.

- Sharma, R.; Singh, J.; Rastogi, V. The impact of total productive maintenance on key performance indicators (PQCDSM): A case study of automobile manufacturing sector. Int. J. Product. Qual. Manag. 2018, 24, 267.

- Fam, S.F.; Prastyo, D.D.; Loh, S.L.; Utami, S.; Yong, D.H.Y. Total productive maintenance practices in manufacture of electronic components & boards industry in Malaysia. J. Telecommun. Electron. Comput. Eng. 2018, 10, 97–101.

- Pires, S.P.; Sénéchal, O.; Loures, E.F.R.; Jimenez, J.F. An approach to the prioritization of sustainable maintenance drivers in the TBL framework. IFAC Pap. OnLine 2016, 49, 150–155.

- En-Nhaili, A.; Meddaoui, A.; Bouami, D. Effectiveness improvement approach basing on oee and lean maintenance tools. Int. J. Process Manag. Benchmarking 2016, 6, 147–169.

- Kar, M.K. Implementation of planned maintenance using tpm methodology for a bi-cycle manufacturing industry. Int. J. Mech. Eng. Technol. 2016, 7, 253–270.

- Paul M. Gibbons; Stuart C. Burgess; Introducing OEE as a measure of lean Six Sigma capability. International Journal of Lean Six Sigma 2010, 1, 134-156, 10.1108/20401461011049511.

- Francesco Zammori; M. Braglia; Marco Frosolini; Stochastic overall equipment effectiveness. International Journal of Production Research 2011, 49, 6469-6490, 10.1080/00207543.2010.519358.

- Gołda, G.; Kampa, A.; Paprocka, I. Analysis of human operators and industrial robots performance and reliability. Manag. Prod. Eng. Rev. 2018, 9, 24–33.

- Tham, K.D.; Madni, A.M. Sox Compliance with OEE, Enterprise Modeling and Temporal-ABC. Intell. Autom. Soft Comput. 2017, 1–9.

- Kampa, A.; Gołda, G. Modelling and simulation method for production process automation in steel casting foundry. Arch. Foundry Eng. 2018, 18, 47–52.

- Kampa, A.; Gołda, G.; Paprocka, I. Discrete Event Simulation Method as a Tool for Improvement of Manufacturing Systems. Computers 2017, 6, 10.

- Rylková, Ž.; Stelmach, K.; Vlcek, P. Overall equipment effectiveness within counterfactual impact evaluation concept. Sci. Ann. Econ. Bus. 2017, 64, 29–40.

- Esa, F.; Yusof, Y. Implementing overall equipment effectiveness (OEE) and sustainable competitive advantage: A case study of hicom diecastings SDN. BHD.(HDSB). ARPN J. Eng. Appl. Sci. 2016, 11, 199–203.

- Ghafoorpoor Yazdi, P.; Azizi, A.; Hashemipour, M. An Empirical Investigation of the Relationship between Overall Equipment Efficiency (OEE) and Manufacturing Sustainability in Industry 4.0 with Time Study Approach. Sustainability 2018, 10, 3031.

- Teoh, Y.S.; Ito, T.; Perumal, P. Invisibility of impact from customer demand and relations between processes in Overall Equipment Effectiveness (OEE). J. Adv. Mech. Des. Syst. Manuf. 2017, 11, JAMDSM0065.]

- Kukla, S. Modelling and Optimization of Organization of Workplaces in a Foundry. Arch. Foundry Eng. 2016, 16, 55–58

- Borut Buchmeister; D. Friscic; Iztok Palcic; Impact of demand changes and supply chain’s level constraints on bullwhip effect. Advances in Production Engineering & Management 2013, null, 199-208, 10.14743/apem2013.4.167.

- Jaegler, A.; Burlat, P. What is the impact of sustainable development on the re-localisation of manufacturing enterprises? Prod. Plan. Control 2014, 25, 902–911.

- Buchmeister, B.; Friscic, D.; Lalic, B.; Palcic, I. Analysis of a three-stage supply chain with level constraints. Int. J. Simul. Model. 2012, 11, 196–210.

- Rodolfo Eleazar Perez Loaiza; Elias Olivares-Benitez; Pablo A. Miranda Gonzalez; Aaron Guerrero Campanur; Jose Luis Martinez Flores; Supply chain network design with efficiency, location, and inventory policy using a multiobjective evolutionary algorithm. International Transactions in Operational Research 2016, 24, 251-275, 10.1111/itor.12287.

- Ki-Young Jeong; Don T. Phillips; Operational efficiency and effectiveness measurement. International Journal of Operations & Production Management 2001, 21, 1404-1416, 10.1108/eum0000000006223.

- De Ron, A.J.; Rooda, J.E. OEE and equipment effectiveness: An evaluation. Int. J. Prod. Res. 2006, 44, 4987–5003.

- Garza-Reyes, J.A.; Eldridge, S.; Barber, K.D.; Soriano-Meier, H. Overall equipment effectiveness (OEE) and process capability (PC) measures: A relationship analysis. Int. J. Qual. Reliab. Manag. 2010, 27, 48–62.

- Yuniawan, D.; Ito, T.; Bin, M.E. Calculation of overall equipment effectiveness weight by Taguchi method with simulation. Concurr. Eng. 2013, 21, 296–306.

- Kumar, J.; Soni, V.K. An Exploratory Study of OEE Implementation in Indian Manufacturing Companies. J. Inst. Eng. Ser. C 2015, 96, 205–214.

- Maran, M.; Manikandan, G.; Thiagarajan, K. Fuzzy expert system for plant overall equipment effectiveness. Eur. J. Sci. Res. 2012, 83, 430–438.

- Zuashkiani, A.; Rahmandad, H.; Jardine, A.K.S. Mapping the dynamics of overall equipment effectiveness to enhance asset management practices. J. Qual. Maint. Eng. 2011, 17, 74–92.

- Bengtsson, M. Using a game-based learning approach in teaching overall equipment effectiveness. J. Qual. Maint. Eng. 2019.

- Ng, K.C.; Chong, K.E. A framework for improving manufacturing overall equipment effectiveness. J. Adv. Manuf. Technol. 2018, 12, 383–400.

- Hidayat, A.; Irdas, I. Evaluation of micro hydro power plant (MHPP) using overall equipment effectiveness (OEE) method. ARPN J. Eng. Appl. Sci. 2017, 12, 5271–5275.

- H.-J. Krokoszinski; Efficiency and effectiveness of wind farms—keys to cost optimized operation and maintenance. Renewable Energy 2003, 28, 2165-2178, 10.1016/s0960-1481(03)00100-9.

- Kanthi M. N. Muthiah; Samuel H. Huang; Sangeetha Mahadevan; Automating factory performance diagnostics using overall throughput effectiveness (OTE) metric. The International Journal of Advanced Manufacturing Technology 2007, 36, 811-824, 10.1007/s00170-006-0891-x.

- Ruisheng Ng; Jonathan Sze Choong Low; Bin Song; Integrating and implementing Lean and Green practices based on proposition of Carbon-Value Efficiency metric. Journal of Cleaner Production 2015, 95, 242-255, 10.1016/j.jclepro.2015.02.043.

- Alzubi, E.; Atieh, A.M.; Abu Shgair, K.; Damiani, J.; Sunna, S.; Madi, A. Hybrid Integrations of Value Stream Mapping, Theory of Constraints and Simulation: Application to Wooden Furniture Industry. Processes 2019, 7, 816.

- Bokrantz, J.; Skoogh, A.; Ylipää, T.; Stahre, J. Handling of production disturbances in the manufacturing industry. J. Manuf. Technol. Manag. 2016, 27, 1054–1075.

- Abd Rahman, M.S.; Mohamad, E.; Abdul Rahman, A.A. Enhancement of overall equipment effectiveness (OEE) data by using simulation as decision making tools for line balancing. Indones. J. Electr. Eng. Comput. Sci. 2020, 18, 1040–1047

- Samuel H. Huang; John P. Dismukes; J. Shi; Qi Su; Ge Wang; Mousalam A. Razzak; D.Eugene Robinson; Manufacturing system modeling for productivity improvement. Journal of Manufacturing Systems 2002, 21, 249-259, 10.1016/s0278-6125(02)80165-0.

- K. M. N. Muthiah; Samuel H. Huang; Overall throughput effectiveness (OTE) metric for factory-level performance monitoring and bottleneck detection. International Journal of Production Research 2007, 45, 4753-4769, 10.1080/00207540600786731.

- A.J. Deron; J.E. Rooda; Equipment Effectiveness: OEE Revisited. IEEE Transactions on Semiconductor Manufacturing 2005, 18, 190-196, 10.1109/tsm.2004.836657.

- D. Daniel Sheu; Overall Input Efficiency and Total Equipment Efficiency. IEEE Transactions on Semiconductor Manufacturing 2006, 19, 496-501, 10.1109/tsm.2006.884718.

- Anil S. Badiger; R. Gandhinathan; Vinayak Neelakanth Gaitonde; A methodology to enhance equipment performance using the OEE measure. European J. of Industrial Engineering 2008, 2, 356, 10.1504/ejie.2008.017690.

- Farhad Anvari; Rodger Edwards; Andrew Starr; Evaluation of overall equipment effectiveness based on market. Journal of Quality in Maintenance Engineering 2010, 16, 256-270, 10.1108/13552511011072907.

- Farhad Anvari; Rodger Edwards; Performance measurement based on a total quality approach. International Journal of Productivity and Performance Management 2011, 60, 512-528, 10.1108/17410401111140419.

- R. Wudhikarn; Improving overall equipment cost loss adding cost of quality. International Journal of Production Research 2011, 50, 3434-3449, 10.1080/00207543.2011.587841.

- Eswaramurthi; Pidugun Venkatachalam Mohanram; IMPROVEMENT OF MANUFACTURING PERFORMANCE MEASUREMENT SYSTEM AND EVALUATION OF OVERALL RESOURCE EFFECTIVENESS. American Journal of Applied Sciences 2013, 10, 131-138, 10.3844/ajassp.2013.131.138.

- Juan M. Jauregui Becker; Jesper Borst; Abele Van Der Veen; Improving the overall equipment effectiveness in high-mix-low-volume manufacturing environments. CIRP Annals 2015, 64, 419-422, 10.1016/j.cirp.2015.04.126.

- Francesco Zammori; Fuzzy Overall Equipment Effectiveness (FOEE): capturing performance fluctuations through LR Fuzzy numbers. Production Planning & Control 2014, 26, 451-466, 10.1080/09537287.2014.920545.

- S.R. Dindarloo; E. Siami-Irdemoosa; S. Frimpong; Measuring the effectiveness of mining shovels. Mining Engineering 2016, 68, 45-50, 10.19150/me.6501.

- Mousa Mohammadi; Piyush Rai; Suprakash Gupta; Performance Evaluation of Bucket based Excavating, Loading and Transport (BELT) Equipment – An OEE Approach. Archives of Mining Sciences 2017, 62, 105-120, 10.1515/amsc-2017-0008.

- Jesus Maria Larrañaga Lesaca; Ekaitz Zulueta Guerrero; Jose Manuel Lopez-Guede; Josean Ramos-Hernanz; Ana Larrañaga Juaristi; Ortzi Akizu; Measuring global effectiveness of integrated electric energy systems. International Journal of Hydrogen Energy 2017, 42, 18121-18133, 10.1016/j.ijhydene.2017.04.057.

- Aneirson Francisco Da Silva; Fernando Augusto Silva Marins; Patricia Miyuki Tamura; Erica Ximenes Dias; Bi-Objective Multiple Criteria Data Envelopment Analysis combined with the Overall Equipment Effectiveness: An application in an automotive company. Journal of Cleaner Production 2017, 157, 278-288, 10.1016/j.jclepro.2017.04.147.

- Puvanasvaran, A.P.; Yoong, S.S.; Tay, C.C.; Effect of hidden wastes in overall equipment effectiveness calculation. ARPN J. Eng. Appl. Sci. 2017, 12, 6443–6448.

- Michel Nakhla; Designing extended overall equipment effectiveness: application in healthcare operations. International Journal of Management Science and Engineering Management 2018, null, 1-10, 10.1080/17509653.2017.1373377.

- M. Braglia; D. Castellano; M. Frosolini; M. Gallo; Overall material usage effectiveness (OME): a structured indicator to measure the effective material usage within manufacturing processes. Production Planning & Control 2017, 29, 143-157, 10.1080/09537287.2017.1395920.

- Orlando Duran; Andrea Capaldo; Paulo Andrés Duran Acevedo; Sustainable Overall Throughputability Effectiveness (S.O.T.E.) as a Metric for Production Systems. Sustainability 2018, 10, 362, 10.3390/su10020362.

- Andres Muñoz-Villamizar; Javier Santos; Jairo Montoya-Torres; Maria Jesus Alvaréz; Improving effectiveness of parallel machine scheduling with earliness and tardiness costs: A case study. International Journal of Industrial Engineering Computations 2019, null, 375-392, 10.5267/j.ijiec.2019.2.001.

- Abdelbar, K.M.; Bouami, D.; Elfezazi, S.; New approach towards formulation of the overall equipment effectiveness. J. Qual. Maint. Eng. 2019, null, null, 10.1108/JQME-07-2017-0046.

- Jarosław Brodny; Magdalena Tutak; Analysing the Utilisation Effectiveness of Mining Machines Using Independent Data Acquisition Systems: A Case Study. Energies 2019, 12, 2505, 10.3390/en12132505.

- He Tang; A new method of bottleneck analysis for manufacturing systems. Manufacturing Letters 2019, 19, 21-24, 10.1016/j.mfglet.2019.01.003.

- Zdeněk Aleš; Jindřich Pavlů; Václav Legát; František Mošna; Vladimír Jurča; Methodology of overall equipment effectiveness calculation in the context of Industry 4.0 environment. Ekspolatacja i Niezawodnosc - Maintenance and Reliability 2019, 21, 411-418, 10.17531/ein.2019.3.7.

- Annamalai, S.; Suresh, D.; Implementation of Total Productive Maintenance for Overall Equipment Effectiveness Improvement in Machine Shop. Regular 2019, 8, 7686-7691, 10.35940/ijrte.c6212.098319.

- Durga Prasad, N.V.P.R.; Radhakrishna, C; Key Performance Index for Overall Substation Performance. Regular 2019, 8, 6067-6071, 10.35940/ijrte.b3797.078219.

- P. De Groote; Maintenance performance analysis: a practical approach. Journal of Quality in Maintenance Engineering 1995, 1, 4-24, 10.1108/13552519510089556.

- Pamela Danese; Valeria Manfè; Pietro Romano; A Systematic Literature Review on Recent Lean Research: State-of-the-art and Future Directions. International Journal of Management Reviews 2017, 20, 579-605, 10.1111/ijmr.12156.

- Sachin S. Kamble; Angappa Gunasekaran; Shradha Ashok Gawankar; Sustainable Industry 4.0 framework: A systematic literature review identifying the current trends and future perspectives. Process Safety and Environmental Protection 2018, 117, 408-425, 10.1016/j.psep.2018.05.009.